文章编号:1004-0609(2016)01-0223-10

低品位铂钯精矿的富氧压浸出

刘志强1, 2, 3,王 伍2,曹洪杨1, 3,周向前1,张魁芳1, 3,邱显扬1, 3

(1. 广州有色金属研究院 稀有金属研究所,广州 510650;

2. 中南大学 冶金与环境学院,长沙 410083;

3. 广东省稀土开发及应用重点实验室,广州 510650)

摘 要:对高镁低品位复杂铂钯精矿进行工艺矿物学分析,提出采用硫酸氧压浸出工艺对该精矿中的贱金属铜、镍、铁选择性浸出分离并富集铂钯的处理工艺。考察磨矿粒度、反应温度、时间、初始硫酸浓度、氧压、搅拌速度、木质素磺酸钙用量、液固比对铜、镍、铁浸出率及渣率的影响,确定最佳工艺参数。实验结果表明:当精矿粒度小于43 μm占有率为93%、时间3 h、浸出温度150 ℃、初始硫酸浓度2 mol/L、氧分压0.7 MPa、搅拌速度400 r/min、添加剂木质素磺酸钙用量0.6 g、液固比5:1的最佳工艺条件下,铜浸出率达99.27%、镍浸出率达98.04%、渣率为37%左右,铂钯几乎不被浸出,铂和钯在浸出渣中富集近3倍。

关键词:铂;钯;浮选精矿;氧压浸出

中图分类号:TF83 文献标志码:A

铂族金属是一类具有战略地位的工业金属,由于其特殊的物理化学性质,铂族金属在现代工业、国防和科技发展中具有关键的作用,被誉为现代工业维他命[1]。目前,国内外针对铂钯精矿的常用处理方法可分为湿法和火法工艺两种,主要方法有常压无机酸浸出、微波加热或硫酸熟化浸出[2-7]、氯化浸出、火法造锍熔炼工艺[7-14]、加压氧化酸浸-加压氰化的全湿法新工艺[14-25]等。

云南金宝山铂钯矿是我国目前发现的第一个具有工业开采价值的原生铂钯矿,该矿中铂钯品位低,矿物种类繁多,嵌布粒度极细。从20世纪90年代开始,国家多次把“金宝山铂钯矿的开发利用”列入国家科技攻关项目计划,先后通过选矿得到了铂钯品位50g/t的铂钯精矿,并进行了冶金提取铂钯研究,取得了较大进展,但该矿一直未能开发利用,处于呆滞状态。其主要原因为:铂钯品位为50g/t的铂钯精矿中含有少量铜、镍、铁的硫化物,硫含量低(质量分数约14%),同时镁含量较高。对于该类低品位铂钯精矿,若采用铂钯精矿常用的处理方法进行处理主要存在以下技术缺陷:1) 湿法直接浸出铂钯工艺。需要消耗大量氧化剂,并且浸出液中的铂钯浓度低,其他元素浓度高,回收难度大,成本高;2) 火法造锍熔炼工艺。由于精矿中含有大量镁矿物,硫化物含量低,熔炼时炉渣黏度高,同时回收工序繁多,导致铂钯综合回收率低[25]。因此,开发出高镁低品位复杂铂钯精矿的高效处理工艺对资源有效利用具有重要意义。

本文作者在高镁低品位复杂铂钯精矿工艺矿物学分析的基础上结合物相特点,提出适合该类低品位铂钯精矿的资源化利用方法:拟通过富氧浸出实验,将铜、镍、铁选择性浸出,而铂、钯贵金属保留在浸出渣中;不仅可以回收铜、镍资源,同时将铜镍铁与铂钯贵金属的分离并进一步富集铂钯贵金属,为后续提取铂钯创造了有利条件。

1 实验

1.1 实验原料及试剂

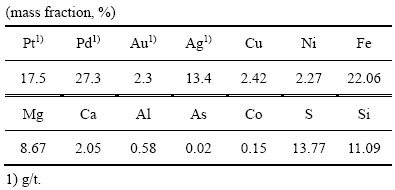

试验原料为某铂钯硫化矿经浮选富集获得的低品位铂钯浮选精矿。其主成分分析结果列于表1。经水筛测得该精矿的粒度小于43 μm的占57.55%(质量分数)。

实验所用硫酸为分析纯,纯度为96%~98%(质量分数)。氧气、木质素磺酸钙为工业级。

表1 铂钯精矿化学成分

Table 1 Chemical composition of Pt-Pd flotation concentrates

1.2 试验设备

实验所用加压设备为钛质TZPCF2-10型高压反应釜(烟台市招远松岭仪器设备有限公司生产),容积为2 L,GSH-215/2.0磁力驱动反应釜(山东威海化工机械有限公司生产),容积215 L。

1.3 实验方法

称取一定量的铂钯浮选精矿放入高压反应釜内,按设定的液固比加入设定浓度的硫酸溶液,并加入木质素磺酸钙、装釜密封、程序升温至设定温度。到达设定温度时,通过快速开启针状截止阀通入氧气至预定氧分压并持续通氧,开始计时。反应至设定时间后,关闭进气阀,接通盘管冷却水降温后,泄压开釜。矿浆用真空抽滤过滤,固液分离。浸出渣用一定量自来水洗涤数次,然后放入干燥箱干燥。

1.4 分析检测

矿石的晶型采用X射线衍射仪(日本理学D/MAX1200)分析。工艺矿物学采用工艺矿物学参数自动定量分析检测系统(澳大利亚昆士兰大学MLA)表征;贵金属含量采用火试金法测定,其他金属铜、镍、铁等含量采用化学法及ICP法测定。

2 结果与讨论

2.1 铂钯精矿的工艺矿物学

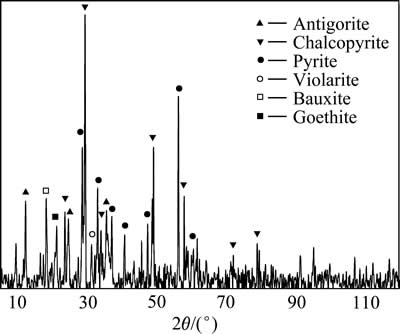

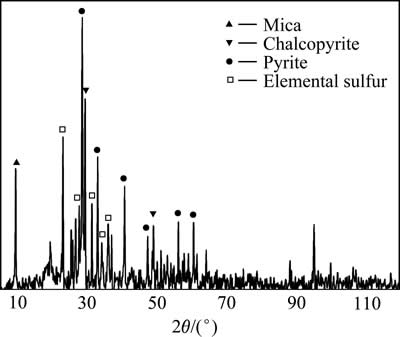

铂钯精矿的XRD谱如图1所示。由XRD谱可知,

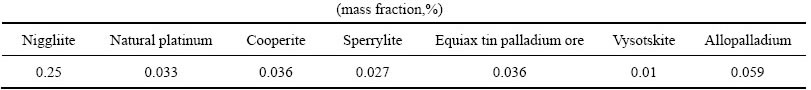

该铂钯精矿中主要金属矿物为叶蛇纹石(含镁硅酸类)、黄铜矿、黄铁矿、紫硫镍矿、铝土矿、针铁矿及脉石矿物等。由于精矿中铂钯含量较低(约50 g/t),很难发现独立铂钯矿物相。通过工艺矿物学参数自动定量分析检测系统(澳大利亚昆士兰大学MLA)对铂钯精矿进行分析,分析结果如表 2和3所示。从表 2和3可以看出,该铂钯精矿中主要有价矿物为黄铜矿、黄铁矿、紫硫镍矿;铂钯主要分布在碲铂矿、硫铂矿、砷铂矿、硫钯矿等矿物相中,以金属硫化物及类硫化物为主要存在形式,与金属硫化物共生。

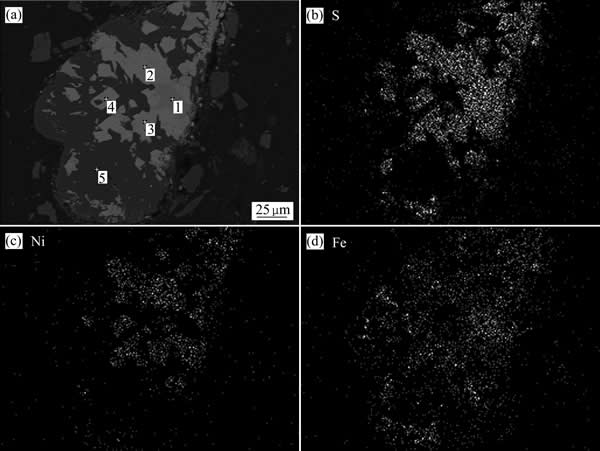

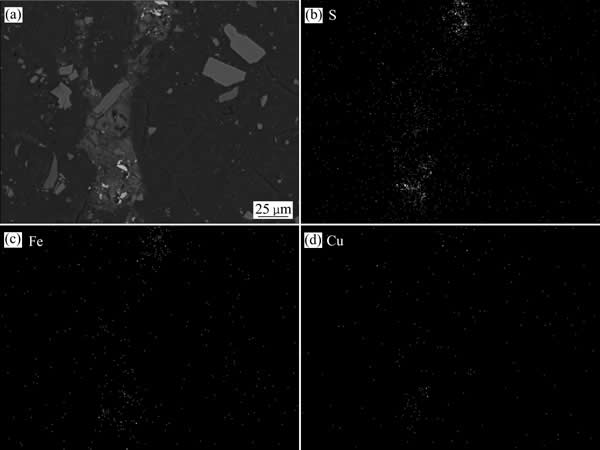

图2所示为精矿不同区域的背散射电子形貌像,由图2可知,该区域矿相组成复杂,主要存在灰黑色区域1,灰色区域2、3、4及黑色区域5。可以看出:矿物分布不均匀,不同矿相间相互嵌布,且粒度分布范围较宽。由元素面扫描分布图可直观地看出:镍的分布与硫的分布相似,说明镍主要以硫化物形式存在,主要集中分布在灰色区域部分;铁存在于硫化物及硅酸盐相中,分布不均匀,说明铁以硫化物和氧化态形式存在。

为了更好地认识铂钯精矿的物相组成及贵/贱金属在矿物中赋存状态,对铂钯精矿进行了电子探针及能谱分析。各区域的能谱微区成分分析结果如表4所列。由表4可知,灰黑色区域1主要由铁与硫组成,为硫化铁矿物相,是矿物中铁的主要赋存形式;区域2、3、4的组成均为镍、铁、硫,为镍锍矿物相,是镍的主要赋存形式;区域5成分较为复杂,主要由镁、铁、硅、氧组成,是矿物中主要的硅酸盐相,可能为叶蛇纹石。

图1 铂钯精矿的XRD谱

Fig. 1 XRD spectrum of Pt-Pd flotation concentrates

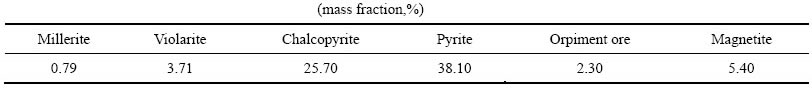

表2 铂钯精矿中主要金属矿物类别及相对含量

Table 2 Main metal mineral types and relative contents of Pt-Pd flotation concentrates

表3 精矿中铂钯矿物相组成及相对含量

Table 3 Pt-Pd phase composition and relative content of flotation concentrates

图2 铂钯精矿的背散射电子形貌像及元素面扫描分布曲线

Fig. 2 BS image(a) of Pt/Pd concentrates and scanning distribution of elements S(b), Ni(c) and Fe(d)

表4 图2(a)中精矿能谱微区成分分析结果

Table 4 Energy spectroscopic analysis results of concentrate in Fig. 2(a)

通过工艺矿物学分析可知,精矿中主要矿物为铜、镍、铁的硫化物。因此,考虑采用控制氧化还原反应电位,选择性浸出铜、镍、铁等金属,铂、钯贵金属保留在浸出渣中,从而达到铜、镍、铁与铂钯贵金属的分离,富集铂钯贵金属。

2.2 磨矿粒度对铜、镍、铁浸出率及渣率的影响

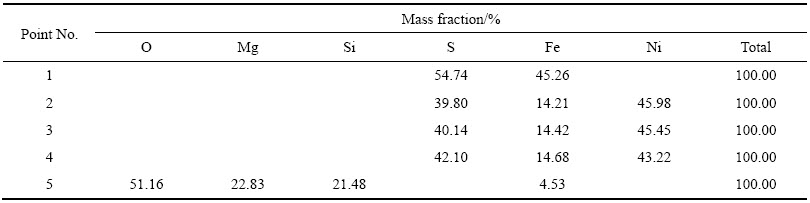

选取添加剂木质素磺酸钙量为浮选精矿加入量的0.6 g,固定液固比5:1,反应时间3 h,反应温度150 ℃,氧分压0.7 MPa,初始硫酸浓度2 mol/L,搅拌速度400 r/min,控制精矿磨矿粒度小于43 μm的占有率分别为70%、80%、88%、93%、97%、99%,研究不同浮选精矿粒度对铜镍铁浸出率及渣率影响,实验结果如图3所示。

由图3可见,随着浮选精矿粒度减小,铜、镍、铁的浸出率呈上升趋势,铜浸出率由72.66%提高至94.62%,铁浸出率由85%提高到92%,镍浸出率由76%提高到82%,同时,渣率呈下降趋势,由50.23%降低至39%。由于机械球磨实际上也是一个机械活化过程,磨矿中5%~10%的能量转化为化学能储存在晶格中,晶体内部出现缺陷,化学反应活性增加[26]。随着物料粒度减小,液固反应接触比表面积增大,越有利于物料中有价组分铜铁镍的浸出。虽然矿物粒度细有利于浸出的进行,但磨矿时间的延长,导致磨矿成本增加;同时,浸出渣粒度也变小,导致过滤困难,生产效率降低。根据试验结果可以看出,当精矿粒度小于43 μm的占有率为93%以上时,粒度变化对浸出率变化不大。因此,综合考虑,精矿粒度小于43 μm的占有率为93%时的粒度比较合适。

图3 粒度对金属浸出率、渣率的影响

Fig. 3 Effect of granularity on Cu, Ni, Fe leaching rate and slag rate

2.3 浸出温度对铜镍铁浸出率及渣率的影响

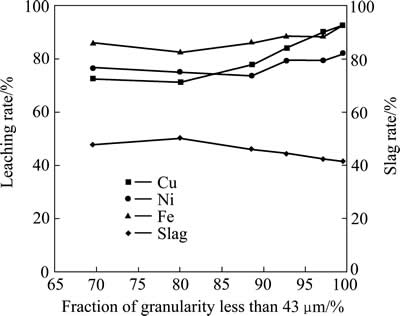

选取添加精矿150 g(粒径小于43 μm的占有率为93%),液固比8:1,反应时间3 h,添加剂木质素磺酸钙0.6 g(0.4%),氧分压0.7 MPa,初始硫酸浓度2 mol/L,搅拌速度300 r/min。控制浸出温度分别为110、120、130、140和150 ℃,研究浸出温度对铜镍铁氧化浸出率及渣率的影响,其结果如图4所示。

由图4可见,随着浸出温度的升高,铜、镍和铁的浸出率逐渐增加,铜浸出率由37.16%提高至72.86%,铁浸出率由43.68%提高到64.65%,镍浸出率由30.34%提高到46.31%,同时,渣率呈下降趋势,由62.47%降低至56.67%。温度对硫化矿加压浸出过程的影响显著,通常随着浸出温度升高,金属浸出率增大。这是由于升高温度不仅可以加快反应速率,而且可以促进氧键断裂,溶解的氧分子裂解成氧原子。但对于硫化物的氧压浸出反应,不同温度硫化物发生的化学反应不同。

图4 浸出温度对金属浸出率及渣率的影响

Fig. 4 Effect of temperature on Cu, Ni and Fe leaching rate and slag rate

高温氧压浸出化学反应:

2FeS2+7.5O2+H2O=Fe2(SO4)3+H2SO4 (1)

MeS+2O2=MeSO4 (Me代表Cu,Ni) (2)

在氧化浸出过程中,氧化还原反应电位高,可将硫化物中的硫全部转化为硫酸根,可能会导致贵金属也部分溶出。同时,在高温溶液中硫酸铁可以发生如下反应:

低酸度时,

Fe2(SO4)3+3H2O=Fe2O3+3H2SO4 (3)

中高温氧压浸出反应如下,

CuS+Fe2(SO4)3=CuSO4+2FeSO4+S0 (4)

Ni2S3+3Fe2(SO4)3=Ni2(SO4)3+6FeSO4+3S0 (5)

2FeSO4+H2SO4+1/2O2=Fe2(SO4)3+H2O (6)

在氧化浸出过程中,Fe3+主要起到传输氧的作用。在中高温氧压浸出时,氧化还原反应电位低,可将铜、镍、铁的硫化物浸出分解,使贵金属从矿物中解离出来,并保证贵金属不溶出,且目前锌氧压浸出温度一般都不超过150 ℃,因此,选择最佳浸出温度为150 ℃比较合适。

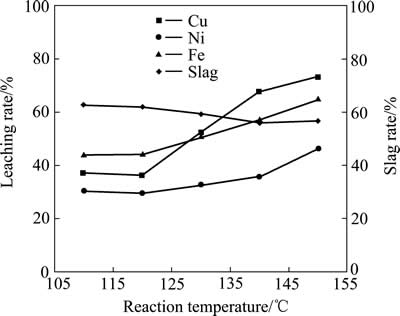

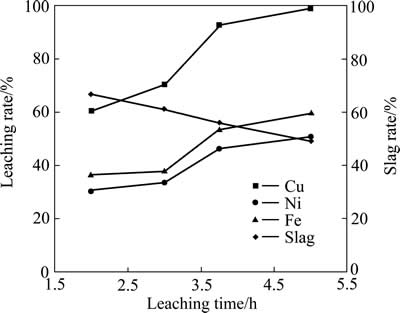

2.4 浸出时间对铜镍铁浸出率及渣率的影响

选取添加精矿150 g(粒径小于43 μm的占有率为93%),液固比8:1,初始硫酸浓度4 mol/L,添加剂木质素磺酸钙0.6 g,反应温度150 ℃,氧分压0.7 MPa,搅拌速度300 r/min,控制浸出时间分别为2.0、3.0、3.75和5.0 h。研究浸出时间对铜、镍、铁浸出率及渣率的影响,实验结果如图5所示。

由图5可见,随着浸出时间延长,铜浸出率由60.42%提高至98.82%,铁浸出率由36.32%提高到59.56%,镍浸出率由30.34%提高到50.57%,同时,渣率呈下降趋势,由66.67%降低至49.33%。当浸出时间为3.75 h后,铜镍铁浸出率增加趋于平缓。考虑到生产能耗和设备产能,最佳浸出时间为3.75 h为宜。

图5 浸出时间对贱金属浸出率、渣率的影响

Fig. 5 Effect of leaching time on Cu, Ni, Fe leaching rate and slag rate

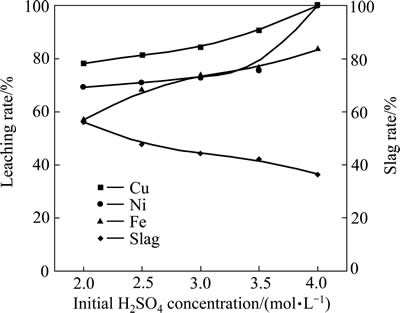

2.5 初始硫酸浓度对铜、镍、铁浸出率及渣率的影响

选取添加精矿150 g(粒径小于43 μm的占有率为93%),液固比8:1,反应时间3 h,添加剂木质素磺酸钙0.6 g,反应温度150 ℃,氧分压0.7 MPa,搅拌速度300 r/min,控制始酸酸浓度分别为1.0、1.25、1.5、1.75、2.0 mol/L。研究始酸酸浓度对铜、镍、铁浸出率及渣率的影响,实验结果如图6所示。

由图6可知,随着始酸酸浓度提高,铜浸出率由78.05%提高至100%,铁浸出率由56.74%提高到83.51%,镍浸出率由69.3%提高到100%;而渣率呈下降趋势,由56.27%降低至36.53%。从浸出过程原理(见式(4))也可以看出,随着初始硫酸浓度的增加,反应过程向右移动,并且根据式(3)初始硫酸浓度增加也可以防止铁水解,使浸出渣减少。虽然初始硫酸浓度较高时,铜、镍和铁均接近完全浸出,但是硫酸成本和浸出液中铜、镍和铁的分离成本增加,同时对设备耐腐蚀性能要求更高。

图6 初始硫酸浓度对贱金属浸出率和渣率的影响

Fig. 6 Effect of initial H2SO4 concentration on Cu, Ni, Fe leaching rate and slag rate

因此,最佳始酸浓度4 mol/L为宜。

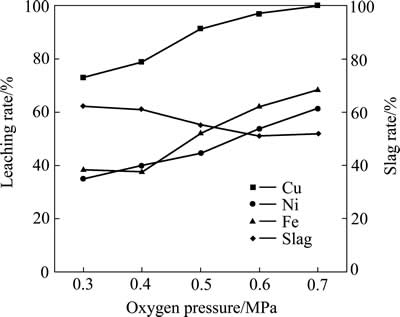

2.6 氧分压对铜、镍、铁浸出率及渣率的影响

选取添加精矿150 g(粒径小于43 μm的占有率为93%),液固比8:1,反应时间3 h,添加剂木质素磺酸钙0.6 g(0.4%),反应温度150 ℃,初始硫酸浓度4 mol/L搅拌速度300 r/min,控制氧分压分别为0.3、0.4、0.5、0.6和0.7 MPa。研究氧分压对铜、镍、铁浸出率及渣率的影响,实验结果如图7所示。

由图7可见,随着氧分压由0.3 MPa提高到0.7 MPa,铜、镍、铁的浸出率逐渐增加,铜浸出率由72%提高至99%以上,镍的浸出率由35.12%提高到61.32%,铁的浸出率由38.37%提高到68.41%。同时,渣率呈下降趋势,由62%降至52%。氧压浸出是一个气液固三相化学反应过程,在一定范围内,氧分压越大就越有利于反应的进行;氧分压的升高增加溶液中氧的溶解度,使反应式(7)二价铁氧化速度加快。当氧分压继续增加时,铜、镍的浸出变化不大;但由于氧分压的增加,浸出体系氧化气氛更高,单质硫氧化成硫酸的量增加,不利于硫的集中回收,还可能会导致贵金属的浸出。因此,最佳氧分压0.7 MPa为宜。

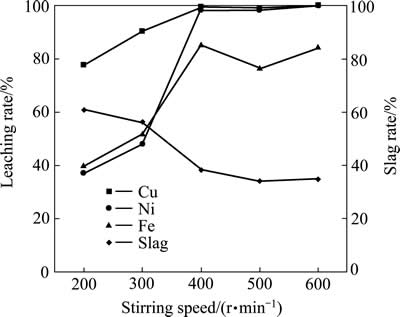

2.7 搅

图7 氧分压对贱金属浸出率和渣率的影响

Fig. 7 Effect of oxygen pressure on Cu, Ni, Fe leaching rate and slag rate

拌速度对铜、镍、铁浸出率及渣率的影响

选取添加精矿150 g(粒径小于43 μm的占有率为93%),液固比8:1,反应时间3 h,添加剂木质素磺酸钙0.6 g,反应温度150 ℃,氧分压0.7 MPa,初始硫酸浓度2 mol/L,控制搅拌速度分别为200、300、400、500和600 r/min。研究搅拌速度对铜、镍、铁浸出率及渣率的影响,实验结果如图8所示。

由图8可知,搅拌速度由200 r/min提高到600 r/min,铜、镍、铁的浸出率逐渐增加,铜浸出率由77.73%提高至100%以上,镍的浸出率由37.26%提高到100%,铁的浸出率由39.92%提高到84.18%。同时,渣率呈下降趋势,由60.87%降至34.18%。搅拌速度从200 r/min提高到400 r/min时,浸出率和渣率变化非常明显。当搅拌速度提高到为400 r/min时,铜、镍几乎全部浸出,铁浸出亦达80%以上;若继续增大搅拌速度,对铜、镍、铁浸出率的提高作用不大。由此可以看出,搅拌速度对浸出率的影响较大。主要原因为:搅拌转速反映了矿浆搅拌强度,其作用是使气-液固三相充分接触,减少反应物及生成物的扩散阻力;对于氧压浸出反应,较大的搅拌强度可以使矿物颗粒之间相互摩擦,破坏矿物颗粒表面包裹得单质硫,使浸出反应顺利进行;但搅拌速度过快,对设备要求更高,因此搅拌速度以400 r/min为宜。

图8 搅拌速度对金属浸出率和渣率的影响

Fig. 8 Effect of stirring speed on Cu, Ni, Fe leaching rate and slag rate

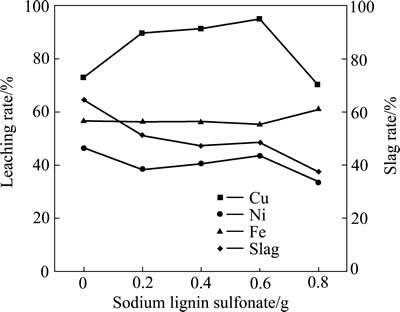

2.8 木质素磺酸钙用量对铜、镍、铁浸出率及渣率的影响

选取添加定精矿150 g(粒径小于43 μm的占有率为93%),液固比8:1,反应时间3 h,反应温度150 ℃,氧分压0.7 MPa,初始硫酸浓度2 mol/L,搅拌速度为300 r/min,控制木质素磺酸钙添加量分别为0、0.2、0.4、0.6和0.8 g。研究木质素磺酸钙用量对铜、镍、铁浸出率及渣率的影响,实验结果如图9所示。

由图9可见,添加剂用量由0提高至0.6 g,铜的浸出率显著提高,从78.82%提高到95.04%;镍和铁的浸出率、渣率变化不明显;当木质素磺酸钙用量从0.6 g继续增加,铜、镍、铁浸出率反而降低,渣率显著增加。由于单质硫的熔点为112 ℃、氧压浸出在150 ℃时,反应生成的单质硫处于熔融状态,包裹在未反应的铂钯矿精矿颗粒表面,从而阻碍铂钯精矿颗粒与浸出液的接触,使浸出率降低;因此,为了改变熔融单质硫在矿物颗粒表面的吸附状态,选择高温稳定性较好的分散剂木质素磺酸钙来分散单质硫,防止单质硫在矿物表面的包裹与聚集,改善矿物与浸出剂的接触与反应,从而保证浸出反应的顺利进行。但如果木质素磺酸钙用量添加过多,使多余的木质素磺酸钙也会吸附在矿物颗粒表面,有硫酸钙形成并包裹在矿物表面,阻碍了浸出液与矿物颗粒的接触,阻碍了浸出反应。因此,添加剂木质素磺酸钙用量以0.6 g为宜。

图9 木质素磺酸钙用量对浸出率和渣率的影响

Fig. 9 Effect of sodium lignin sulfonate on Cu, Ni, Fe leaching rate and slag rate

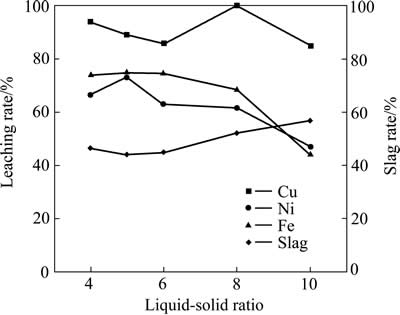

2.9 液固比对铜、镍、铁浸出率及渣率的影响

选取添加精矿150 g(粒径小于43 μm的占有率为93%),氧分压0.7 MPa,反应温度150 ℃,反应时间3 h,添加剂木质素磺酸钙0.6 g,初始硫酸浓度2 mol/L,搅拌速度300 r/min,控制液固比分别为4:1、5:1、6:1、8:1、10:1。研究液固比对铜、镍、铁浸出率及渣率的影响,实验结果如图10所示。

由图10可见,液固比由10降至4,渣率由57%降至44%,铜几乎全部浸出,镍、铁浸出率由45%提高至75%;可以看出,液固比对浸出率的影响较大。主要原因是由于液固比过低,体系黏度增大,搅拌困难,氧气在渣、液之间的传输困难,矿物颗粒与浸出液之间不能充分接触,浸出液中金属离子浓度过高促使浸出逆向反应加大,浸出反应减慢;但液固比过高时,矿物颗粒之间的摩擦减弱,不能破坏吸附在矿物颗粒表面的单质硫层,影响了矿物颗粒的浸出反应顺利进行;同时随着液固比的增大,酸用量也增加,浸出液中铜、镍浓度降低,不利于后续处理。因此,液固比以4:1为宜。

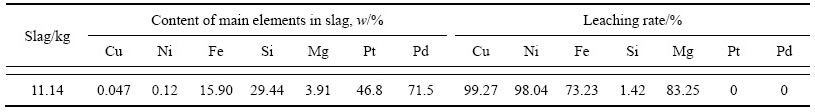

2.10 富氧浸出中试试验

在氧压浸出实验室小试最优工艺条件基础上,按最佳工艺条件:精矿粒度小于43 μm的占有率为93%,时间3.75 h,浸出温度150 ℃,初始硫酸浓度2 mol/L,氧分压0.7 MPa,搅拌速度400 r/min,添加剂木质素磺酸钙0.6 g,液固比4:1,进行了30 kg铂钯精矿氧压浸出扩大试验。试验结果如表5所示。通过扩大试验结果可以看出:扩大试验结果与小型试验结果比较吻合,铜浸出率可达99.27%、镍浸出率可达98.04%、渣率为37%左右,铂钯富集近3倍。氧压浸出液中铂钯含量也低于1.0×10-7(浓缩后采用ICP分析,折算所得),几乎不存在铂钯浸出。实验证明氧压酸浸工艺在浸出铜、镍、铁金属时,不会造成铂钯贵金属的溶出,实现了铂钯在浸出渣中的富集,铜、镍进入浸出液中将进一步回收铜、镍。

图10 液固比对金属浸出率和渣率的影响

Fig. 10 Effect of liquid-solid ratio on Cu, Ni, Fe leaching rate and slag rate

对氧压浸出渣性质进行了表征,精矿氧压浸出渣的XRD分析如图11所示。由图11可知,经氧压浸出后,浸出渣的物相组成变得简单,主要为黄铁矿、黄铜矿、单质硫及云母。初始精矿中硫主要以金属硫化物形式存在,而浸出后渣中的硫主要以单质硫形式存在。图12所示为氧压浸出渣不同区域的背散射电子形貌。从图12可直观地看出,氧压浸出渣中铜、铁含量已显著降低,硫富集的区域铜、铁含量很少。说明氧压浸出工艺可将铜、镍、铁硫化物转变为单质硫和金属硫酸溶液,实现了铂钯的二次富集。

图11 精矿氧压浸出渣XRD谱

Fig. 11 XRD pattern of slag in concentration

表5 富氧浸出中试部分试验数据

Table 5 Part of expanding experimental data in rich oxygen leaching experiment

图12 氧压浸出渣不同区域的背散射电子形貌

Fig. 12 Electron morphology(a) of back-scattered map and scanning distribution of elements S(b), Fe(c) and Cu(d)

3 结论

1) 采用氧压浸出工艺,可将低品位铂钯浮选精矿中铜、镍、铁的硫化物浸出分解,硫转化为单质硫,铂钯贵金属保留在浸出渣中,可实现铜、镍、铁与铂钯贵金属的分离及铂钯在浸出渣中的富集。

2) 在精矿粒度小于43 μm的占有率为93%,浸出温度为150 ℃,浸出时间为3.75 h,初始硫酸浓度为2 mol/L,氧分压为0.7 MPa,搅拌速度为400 r/min,添加剂木质素磺酸钙为0.4%、液固比以4:1时,铜浸出率可达99.27%、镍浸出率可达98.04%,铂钯几乎不浸出,渣率为37%左右,铂钯富集近3倍。

REFERENCES

[1] 刘时杰. 铂族金属矿冶学[M]. 北京: 冶金工业出版社, 2001: 1-5.

LIU Shi-jie. Mining and metallurgy for platinum group metals[M]. Beijing: Metallurgical Industry Press, 2001: 1-5.

[2] 黄绍勇. 浅析铂钯精矿的提取技术[J]. 铜业工程, 2003(2): 36-37.

HUANG Shao-yong. On technology of extraction of platinum and palladium concentrate[J]. Copper Engineering, 2003(2): 36-37.

[3] 马 宠, 寇建军. 含铂钯铜镍精矿湿法冶金处理新工艺[J]. 矿产综合利用, 1999(5): 47-48.

MA Chong, KOU Jian-jun. A new hydrometallurgical process for the treatment of Pt-Pd-Cu-Ni concentrates[J]. Multipurpose Utilization of Mineral Resources, 1999(5): 47-48.

[4] 吴 萍. 铂钯矿湿法预处理试验研究[J]. 有色金属(冶炼部分), 2002(3): 35-37.

WU Ping. Experimental study on hydrometallurgical pre-treating for Pt-Pd ore[J]. Nonferrous Metals (Extractive Metallurgy), 2002(3): 35-37.

[5] 廖秋玲, 姜 东, 龚卫星. 从铂钯精矿中回收铂、钯、金的工艺研究[J]. 中国资源综合利用, 2010, 28(8): 16-19.

LIAO Qiu-ling, JIANG Dong, GONG Wei-xing. Study on technology of recycling Pt, Pd, Gold from Pt Pd rich mines[J]. China Resources Comprehensive Utilization, 2010, 28(8): 16-19.

[6] 张钦发, 龚竹青, 陈白珍. 从铂钯精矿中提取金铂钯的研 究—铂钯精矿的预处理[J]. 矿冶工程, 2002, 22(2): 70-72, 76.

ZHANG Qin-fa, GONG Zhu-qin, CHEN Bai-zhen. Investigation on extraction of Au, Pt and Pd—Pretreatment of the concentrate[J]. Mining and Metallurgical Engineering, 2002, 22(2): 70-72, 76.

[7] 王爱荣, 陈志刚, 涂百乐. 卡尔多炉处理铜阳极泥的生产实践[J]. 有色金属(冶炼部分), 2014(8): 18-21.

WANG Ai-rong, CHEN Zhi-gang, TU Bai-le. Plant practice to treat copper anode slime in Kaldo furnace[J]. Nonferrous Metals (Extractive Metallurgy), 2014(8): 18-21.

[8] 王爱荣, 李春侠. 从铂钯精矿中回收贵金属工艺选择[J]. 安徽化工, 2002(5): 11-12.

WANG Ai-ling, LI Chun-xia. Process selection of extracting precious metal form Pt and Pd concentrate[J].Anhui Chemical, 2002(5): 11-12.

[9] 卢学纯, 刘 瑜. 钯精矿冶炼综合回收新工艺研究之我见[J]. 有色金属设计, 2004, 31(4): 1-6.

LU Xue-chun, LIU Yu. Opinions on new process study of comprehensive recovery in Pt-Pd concentrate smelting[J]. Nonferrous Metals Design, 2004, 31(4): 1-6.

[10] 张钦发. 从铜阳极泥分金钯后的铂精矿中提取分离铂钯金新工艺及萃取机理研究[D]. 长沙: 中南大学, 2007: 18-22.

ZHANG Qin-fa. Research on extraction and separation of platinum, palladium and aurum from platinum concentration and on mechanism of extraction[D]. Changsha: Central South University, 2007: 18-22.

[11] MCLNNES M F. Extraction of platinum, palladium and gold by cyanidation of coronation hill ore[J]. Hydrometallurgy, 1994, 35: 141-159.

[12] 马玉天, 陈大林, 郭晓辉, 潘从明, 张 燕, 王 立. 从低品位金铂钯物料中提取贵金属新工艺研究[J]. 黄金科学技术, 2014, 22(5): 100-104.

MA Yu-tian, CHEN Da-lin, GUO Xiao-hui, PAN Cong-ming, ZHANG Yan, WANG Li. Research on new technology for extracting precious metals from low grade gold platinum palladium material[J]. Gold Science and Technology, 2014, 22(5): 100-104.

[13] 李耀星. 从富铋的铂钯物料中提炼铂、钯的工艺研究[J]. 中国资源综合利用, 2011, 29(12): 14-17.

LI Yao-xing. Technology study on refined platinum-palladium from platinum and palladium materials contained rich bismush[J]. China Resources Comprehensive Utilization, 2011, 29(12): 14-17.

[14] 赵家春, 汪云华, 王靖坤, 吴晓峰, 昝林寒, 李博捷, 范兴祥. 从铂钯精矿中氯化浸出Au、Pt、Pd[J]. 贵金属, 2012, 22(1) : 45-48.

ZHAO Jia-chun, WANG Yun-hua, WANG Jing-kun, WU Xiao-feng, ZAN Lin-han, LI Bo-jie, FAN Xing-xiang. Chloridizing lenching of Au, Pt and Pd from platinum and palladium concentrate[J]. Precious Metals, 2012, 22(1): 45-48.

[15] 刘时杰, 杨茂才, 汪云华, 张关录, 陆跃华, 王永录, 吴晓峰. 云南金宝山铂钯矿资源综合利用工艺研究[J].贵金属, 2012, 33(4): 1-8.

LIU Shi-jie, YANG Mao-cai, WANG Yun-hua, ZHANG Guan-lu, LU Yue-hua, WANG Yong-lu, WU Xiao-feng. A new process engineering for comprehensive exploitation of the Jinbaoshan Pt-Pd ore resources[J]. Precious Metals, 2012, 33(4): 1-8.

[16] 张博亚, 王吉坤. 加压酸浸预处理铜阳极泥的工艺研究[J]. 矿冶工程, 2007, 27(5): 41-43.

ZHANG Bo-ya, WANG Ji-kun. The technological research on pre-treating copper anode slime with pressure acid leaching method[J]. Mining and Metallurgical Engineering, 2007, 27(5): 41-43.

[17] 黄 昆, 陈 景. 加压湿法冶金处理含铂族金属铜镍硫化矿的应用及研究进展[J]. 稀有金属, 2003, 27(6): 752-757.

HUANG Kun, CHEN Jing. Application and progress of pressure hydrometallurgy of Cu-Ni sulfide ores containing platinum group metals[J]. Chinese Journal of Rare Metals, 2003, 27(6): 752-757.

[18] 郭学益, 肖彩梅, 钟菊芽, 田庆华. 铜阳极泥处理过程中贵金属的行为[J]. 中国有色金属学报, 2010, 20(5): 990-998.

GUO Xue-yi, XIAO Cai-mei, ZHONG Ju-ya, TIAN Qing-hua. Behaviors of precious metals in process of copper anode slime treatment[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 990-998.

[19] BRUCKARD W J, MCDONALD K J. Platinum, palladium, and gold extraction from Coronation Hill ore by cyanidation at elevated temperatures[J]. Hydrometallurgy, 1992, 30: 211-227

[20] 黄 昆, 陈 景, 陈奕然, 赵家春, 李奇伟, 杨秋雪. 加压碱浸处理-氰化浸出法回收汽车废催化剂中的贵金属[J]. 中国有色金属学报, 2006, 16(2): 363-369.

HUANG Kun, CHEN Jing, CHEN Yi-ran, ZHAO Jia-chun, LI Qi-wei, YANG Qiu-xue. Recovery of precious metals from spent auto-catalysts by method of pressure alkaline treatment-cyanide leaching[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 363-369.

[21] 陈 景, 黄 昆, 陈奕然, 赵家春, 李奇伟, 杨秋雪. 加压氰化处理铂钯硫化浮选精矿全湿法新工艺[J]. 中国有色金属学报, 2004, 14(1): 41-46.

CHEN Jing, HUANG Kun, CHEN Yi-ran, ZHAO Jia-chun, LI Qi-wei, YANG Qiu-xue. Pressure cyanide hydrometallurgical process for treatment of Pt-Pd sulfide flotation concentrates[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 41-46.

[22] 王靖坤, 汪云华, 赵家春, 吴晓峰, 李博捷, 昝林寒, 范兴祥. 从铂钯精矿中回收Au、Pt、Pd[J]. 湿法冶金, 2012, 31(1): 13-15.

WANG Jing-kun, WANG Yun-hua, ZHAO Jia-chun, WU Xiao-feng, LI Bo-jie, ZAN Lin-han, FAN Xing-xiang. Recovery of gold, platinum and palladium from platinum-palladium concentrate[J]. Hydrometalluegy of China, 2012, 31(1): 13-15.

[23] 黄 昆, 陈 景, 陈奕然, 赵家春, 李奇伟, 杨秋雪. 加压氰化全湿法处理低品位铂钯浮选精矿工艺研究[J].稀有金属, 2006, 30(3): 369-375.

HUANG Kun, CHEN Jing, CHEN Yi-ran, ZHAO Jia-chung, LI Qi-wei, YANG Qiu-xue. Hydrometallurgical pressure cyanide leaching process for treating low-grade Pt-Pd flotation concentrates[J]. Chinese Journal of Nonferrous Metals, 2006, 30(3): 369-375.

[24] 黄 昆, 陈 景. 失效汽车催化剂中铂族金属的加压氰化浸出[J]. 中国有色金属学报, 2003, 13(6): 1559-1564.

HUANG Kun, CHEN Jing. Pressure cyanide leaching of platinum-group metalsfrom spent auto-catalysts[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1559-1564.

[25] 赵吉寿, 黄 昆, 陈 景. 金属铂加压氰化溶解动力学实验研究[J]. 稀有金属, 2008, 32(2): 211-215.

ZHAO Ji-shou, HUANG Kun, CHEN Jing. Kinetics dissolution of pressure-cyanide of platinum[J]. Chinese Journal of Rare Metals, 2008, 32(2): 211-215.

[26] 陈永强, 邱定蕃, 王成彦, 尹 飞. 常压装置富氧浸出闪锌矿[J]. 有色金属, 2009, 61(4): 61-64.

CHEN Yong-qiang, QIU Ding-fan, WANG Cheng-yan, YIN Fei. Oxygen-enriched leaching of zinc sulfide concentrate in atmospheric pressure equipment[J]. Nonferrous Metals, 2009, 61(4): 61-64.

Oxygen pressure leaching of low-grade Pt-Pd concentrate

LIU Zhi-qiang1, 2, 3, WANG Wu2, CAO Hong-yang1, 3, ZHOU Xiang-qian1, ZHANG Kui-fang1, 3, QIU Xian-yang1, 3

(1. Department of Rare Metal, Guangzhou Research Institute of Non-ferrous Metals, Guangzhou 510650, China;

2. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

3. Guangdong Province Key Laboratory of Rare Earth Development and Application, Guangzhou 510650, China)

Abstract: The process mineralogy investigation and the oxygen pressure leaching of low grade Pt-Pd concentrate with high content of magnesium were studied. Sulfuric acid pressure-oxidation leaching process was employed to achieve the selective leaching of copper, nickel, iron and enrichment of Pt-Pd. The effects of process parameters including the particle size, sulphuric acid concentration, the amount of calcium lignosulfonate, oxygen pressure, stirring speed, liquid-solid ratio, leaching temperature and time on the slag rate and leaching rates of copper, nickel and iron were investigated. The results show that leaching rates of copper and nickel are 99.27% and 98.04%, respectively, and slag rate is 37% under the leaching conditions of concentrate particle size d93<43 μm, leaching time of 3 h, leaching temperature of 150 ℃, sulphuric acid concentration initial 4 mol/L, oxygen pressure of 0.7 MPa, stirring speed of 400 r/min, calcium lignosulfonate of 0.4% and liquid-solid ratio of 5:1. Moreover, Pt and Pd are still not leached and the grade of Pt-Pd concentrate could be increased by 3 times after leaching process.

Key words: platinum; palladium; flotation concentrate; oxygen pressure leaching

Foundation item: Project(2012CB724200) supported by the National Basic Research Development Program of China

Received data: 2015-06-29; Accepted data: 2015-11-20

Corresponding author: LIU Zhi-qiang; E-mail: lzqgd168@126.com

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2012CB724200)

收稿日期:2015-06-29;修订日期:2015-11-20

通信作者:刘志强,教授级高工;E-mail: lzqgd168@126.com