DOI: 10.11817/j.issn.1672-7207.2020.10.005

TBM滚刀刀圈材料合金成分对组织和耐磨性能的影响

贾连辉1,尚勇1,龙伟民2,夏毅敏3,薛广记1

(1. 中铁工程装备集团有限公司,河南 郑州,450016;

2. 郑州机械研究所有限公司,河南 郑州,450001;

3. 中南大学 机电工程学院,湖南 长沙,410083)

摘要:为提高TBM滚刀刀圈在高磨蚀地层的使用寿命,研究刀圈合金成分和组织中耐磨相种类及状态对耐磨性的影响规律,调配新型TBM刀圈材料进行微观组织观察,并通过磨粒磨损试验、缩尺滚刀破岩试验及掘进破岩试验进行磨损性能对比。研究结果表明:C,Cr和Mo等合金元素的增多有助于共晶碳化物耐磨相的形成,对材料的耐磨性有一定的提升作用,而对材料的抗冲击性却是不利的;耐磨相的尺寸和形貌对材料耐磨性能及硬度的影响各不相同,大块的共晶碳化物对耐磨性的贡献比粒状的共晶碳化物的高,大块的共晶碳化物对硬度的贡献比粒状的共晶碳化物的略小。在掘进高磨蚀、完整性较好的弱冲击岩层时,相比于常规的高韧性C-1材料,C-2新材料的刀圈寿命可提升30%以上,C-3新材料的刀圈寿命可提升70%以上。3种材料的综合性能能够满足不同岩层的掘进要求,可为刀圈地质适应性选型提供参考。

关键词:滚刀刀圈;合金成分;共晶碳化物;耐磨性能

中图分类号:U455.31 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)10-2730-09

Effect of alloy composition of materials for TBM cutter rings on microstructure and wear resistance

JIA Lianhui1, SHANG Yong1, LONG Weimin2, XIA Yimin3, XUE Guangji1

(1. China Railway Engineering Equipment Group Co. Ltd., Zhengzhou 450016, China;

2. Zhengzhou Research Institute of Machinery Mechanical Engineering Co. Ltd., Zhengzhou 450001, China;

3. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: In order to improve the service life of disc cutter rings in TBM in high erosion lithology, the effects of alloy composition ingredient and type of wear-resistant phase in microstructure on wear resistance were studied. New TBM cutter ring material was blended for microstructure observation. The wear performance was compared through abrasive wear test, scale-reduction rock-breaking test and tunneling rock-breaking test. The results show that the increases of C, Cr, Mo and other alloying elements enhance the formation of wear-resistant phases of eutectic carbides, and have a certain effect on improving the wear resistance of the material, but reduce the impact resistance of the material. The effect of the size and morphology of the wear-resistant phase on the wear resistance and hardness of the material is also different. Large eutectic carbides contribute more to wear resistance than the granular eutectic carbides, and large eutectic carbides contribute slightly less to the hardness than the granular eutectic carbides. In driving high abrasion and weak integrity rock formations, compared with the conventional high toughness C-1 material, the life of the cutter ring of the new C-2 material can be increased by more than 30%, and C-3 new material ring life can be increased by more than 70%. The comprehensive performance of the three materials can meet the requirements of different rock formations, which provides reference for the geological adaptability selection of cutter ring.

Key words: disc cutter ring; alloy composition; eutectic carbide; wear-resisting performance

岩石隧道掘进机(tunnel boring machine, TBM)掘进过程中伴随刀盘转动,刀盘上安装的盘形滚刀刀圈直接与岩体相互作用,滚刀贯入岩体滚动挤压,岩石表面产生局部变形并出现微观裂纹,随着挤压力增大,微观裂纹发展成为主裂纹并贯通,形成岩片破碎[1-2]。而在此过程中,大载荷、强冲击的工作环境极易引起刀圈的磨损,特别是在掘进高磨蚀性岩层时,滚刀磨损更为严重[3]。滚刀刀圈的耐磨性能成为制约刀具使用寿命的主要因素[4]。目前,国内外大多采用类H13材料制作滚刀刀圈,综合性能较好,可承受一定的冲击,但通过热处理难以实现将该材料硬度提高到洛氏硬度60以上的同时又保持较高的耐磨性,特别是在掘进磨蚀性物质(比如石英)含量高的地层时,磨粒磨损速率较高,主要失效特征是磨损快,寿命低[5]。为减少更换刀具次数、缩短停机时间,开发适用于高磨蚀性岩层掘进的刀圈材料,实现滚刀长寿命掘进具有重要意义。为此,本文作者探究不同合金成分的刀圈材料组织形态和碳化物分布状态对材料力学性能和耐磨性的影响规律,并以提高耐磨性为目的,开发适应于高磨蚀性岩层掘进的刀圈材料。

1 试验材料及方法

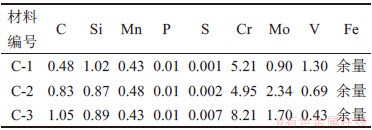

本文以刀圈常用材料H13钢为研究对象(编号为C-1),考虑合金元素Cr的增韧,C和Mo的增强等作用[6-7],调配出C-2和C-3试验材料,化学成分如表1所示。

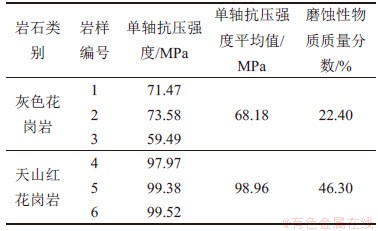

表1 3种试验材料化学成分(质量分数)

Table 1 Chemical composition of three types of test materials %

将3种试验材料采用真空感应炉冶炼、浇筑电极棒,再经气保电渣炉进行电渣重熔,各获得200 kg左右的电渣钢锭;去除钢锭头尾,取中间150 kg,进行锻造,锻造比为8;经球化退火处理后,根据材料成分计算3种材料的奥氏体化临界温度(AC3)。采用Nabertherm-LH11型电阻炉完成调质热处理:C-1材料淬火温度为1 040 ℃,保温时间为90 min,分别在520和510 ℃温度下完成2次保温4 h回火处理;C-2和C-3材料调质热处理工艺一致,淬火温度为1 020 ℃,保温时间为90 min,经520和515 ℃ 2次回火处理,回火时间均为4 h。

回火后取样进行理化性能和金相分析,试样经苦味酸+盐酸+酒精水浴腐蚀,利用Leica-2700M金相显微镜观察淬火组织,采用PTM300J金属摆锤冲击试验机进行KU2缺口冲击试验。选用洛氏硬度仪测试硬度;选用ZEISS-EVOMA-15型电子扫描显微镜完成微观组织观察和碳化物能谱分析;采用MLS-225橡胶轮式磨损试验台完成耐磨试验,选用直径为280 μm的石英砂作为磨粒,转速为200 r/min,试验周期为6 000 r,磨损压力为225 N,磨损前试样的质量为M1,试验完成后对试样进行清洗、烘干称质量,记为M2,然后计算磨损质量损失率P:

(1)

(1)

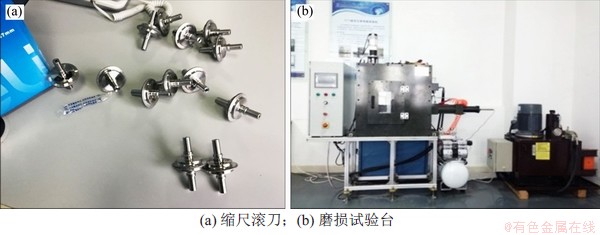

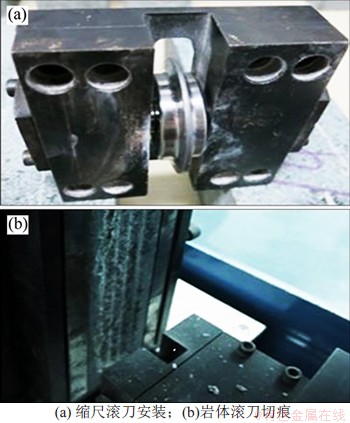

将3种材料按缩尺比例1:10制作成6.3 cm滚刀,通过滚刀复合磨损试验台进行切削磨损模拟试验,如图1所示。第1个100 m作为岩石表面处理,统计第2个和第3个100 m刀圈磨损量,作为刀圈的耐磨性能参考值。同时,在新疆额河引水硬岩隧道项目进行工业性试验,考察刀圈材料的耐磨性能,在3个刀位(51号、52号、53号,安装半径依次增大,为了避免干扰,50号和54号更换材质C-1新刀圈)更换这3种材料的刀圈共9个,记录磨损量和总掘进距离,计算单位磨损量的掘进距离平均值。

图1 缩尺滚刀及磨损试验台

Fig. 1 Downscaled disc cutter and wear test bench

2 试验结果与分析

2.1 合金元素对碳化物的影响

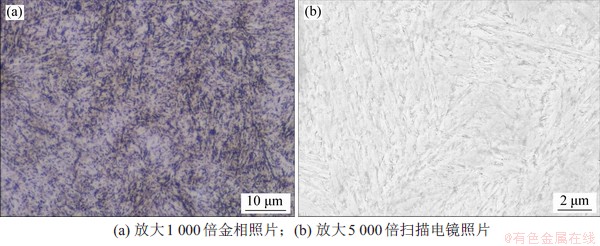

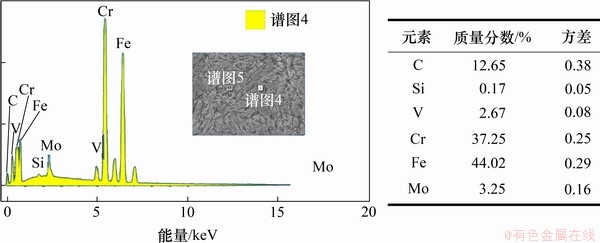

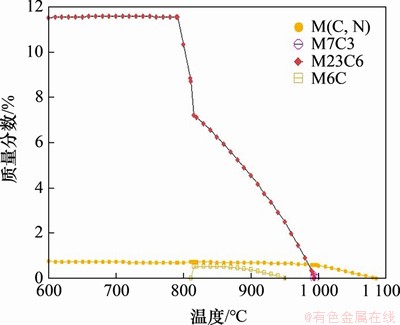

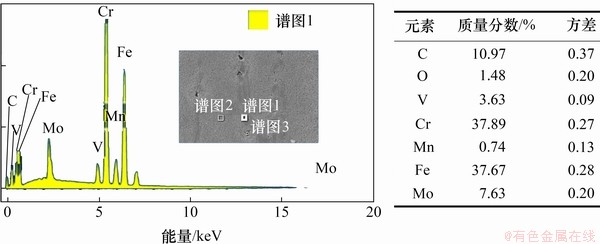

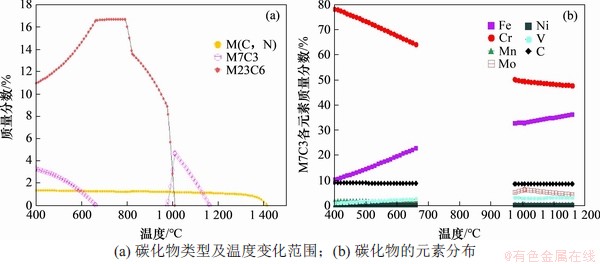

锻造球化退火后再经过调质热处理的C-1材料金相组织如图2所示。由图2(a)可见:材料组织为回火索氏体组织,可见马氏体板条,二次碳化物充分析出。由图2(b)可见:二次碳化物以小点状弥散分布。C-2材料调质处理后的微观组织如图3所示。由图3(a)可见:材料C-2的金相组织图与图2(a)中的相似,但可见更多小微弥散分布的白点。由图3(b)可以看到:材料中的小白点直径范围为1.0~1.5 μm,从图4所示的能谱分析结果可判定,该白亮的小球为共晶碳化物,并结合JMatPro材料分析软件分析,判定为M7C3型共晶碳化物,如图5所示。由于Fe和Cr可以互相置换,因而其成分并不固定,同时也能溶解少量的Mo等元素。

图2 C-1材料金相照片及扫描电镜照片

Fig. 2 Metallographic and scanning electron microscopic photographs of C-1 material

图3 C-2材料经调质处理后的微观组织

Fig. 3 Metallographic and scanning electron microscopic photographs of C-2 material after tempering

图4 C-2材料球状碳化物能谱分析

Fig. 4 Energy spectrum analysis of eutectic carbides in C-2 material

图5 JMatPro分析C-2材料碳化物类型及温度变化范围

Fig. 5 JMatPro analysis of carbide type and temperature range of C-2 material

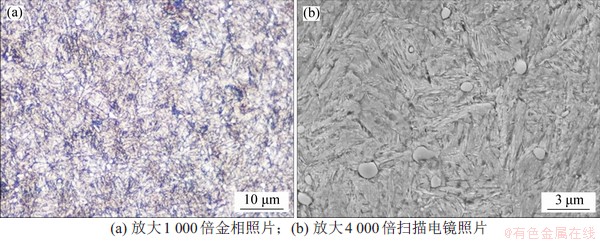

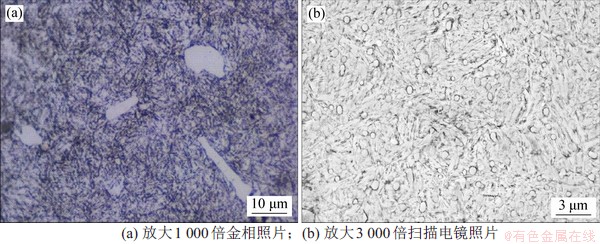

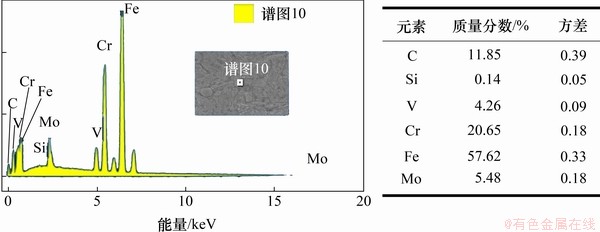

C-3材料金相组织如图6所示。由图6(a)可见较大块状或棒状的白色共晶碳化物。由图6(b)可见:除了较大块状或棒状白色的共晶碳化物外,同时基体中弥散分布着1.0~1.5 μm的粒状碳化物,形状和分布状态与C-2材料中的M7C3碳化物类似。C-3材料小尺寸共晶碳化物的能谱分析图谱及成分如图7所示,由图7可见小颗粒的碳化物与C-2中的小颗粒碳化物的元素成分比较相似。C-3材料中大尺寸共晶碳化物能的谱分析图谱及成分如图8所示。由图8可见大颗粒的共晶碳化物与图4中C-2材料的稍有不同,Fe与Cr这2种元素质量分数更接近,其他合金元素质量分数变化不大,合金元素总质量分数与C元素质量分数的比值较一致。通过模拟得到元素在碳化物中分布规律,如图9(b)所示;在高温下形成的共晶碳化物,Fe与Cr元素质量分数接近。随着温度降低,Fe元素质量分数减少,Cr元素质量分数增加,可认为是同一类碳化物,其凝固和析出状态不同,即M7C3在C-3材料基体中的分布有2种情况:一是在晶界处形成共晶组织,二是在晶粒内以小颗粒形态均匀分布。

图6 C-3材料中金相照片及扫描电镜照片

Fig. 6 Metallographic and scanning electron microscopic photographs of C-3 materials

图7 C-3材料小尺寸共晶碳化物的能谱分析图谱及成分

Fig. 7 Energy spectrum analysis atlas and composition of small-size crystalline carbides in C-3 material

图8 C-3材料中大尺寸共晶碳化物的能谱分析图谱及成分

Fig. 8 Energy spectrum analysis atlas and composition of large-size crystalline carbides in C-3 material

由图7还可见:在共晶碳化物的能谱分析中合金元素与碳元素质量分数明显比基体组织中的高,主要合金元素为Cr和Fe,且根据元素质量分数之比,可推算该共晶碳化物为(Fe,Cr)7C3型。由大尺寸的碳化物的能谱分析可知:与小尺寸碳化物相比,其Cr元素质量分数增大,与Fe质量分数相近,其主要原因为C-3材料中Cr元素质量分数高,Cr元素的增加对基体组织的影响不大,但对不同类型碳化物的质量分数变化影响较大[7]。材料发生共晶反应时,析出了更多块状的共晶碳化物,其化学成分的分布与JMatPro材料模拟软件在淬火条件下计算结果一致,见图9。此外,在奥氏体温度下,M23C6型碳化物溶解,主要共晶碳化物类别为M7C3型,为复杂的六方晶格结构。而碳化物中的M(C和N)在高温下形成,该碳化物的析出起到提高材料强度和细化晶粒度的作用[8],其质量分数为1%~2%,判断为面心立方晶格结构的VC碳化物,且其质量分数与C-2材料中该类碳化物质量分数相当,因此,忽略该类碳化物对耐磨性差异带来的影响。

图9 JMatPro模拟计算C-3材料共晶碳化物及该碳化物的元素分布

Fig. 9 JMatPro simulation calculation of eutectic carbides and element distribution for C-3

2.2 组织形态和碳化物分布状态对力学性能及耐磨性能的影响

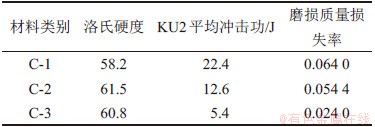

3类材料的力学性能和磨损质量损失率结果如表2所示。从表2可见:C-1,C-2和C-3这3种材料中随着碳元素与合金元素质量分数的增加,由于基体中固溶的C等合金元素及回火时析出的二次碳化物等强化作用,3种材料耐磨性依次升高、抗冲击性依次降低;而其洛氏硬度表现出先升高后降低的趋势,这是因为C-3材料中存在较大体积的碳化物,富集了碳及Cr,Mo和V等合金元素,与C-2材料相比其洛氏硬度稍有降低。

表2 3种刀圈材料热处理后的力学性能和磨损质量损失率

Table 2 Mechanical properties and wear mass loss ratio of three kinds of ring materials after heat treatment

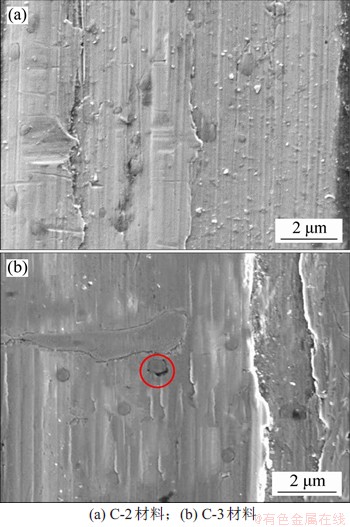

扫描电镜下观察在皮带式磨损试验台磨损后的试样外貌,如图10所示,其中磨损方向为自下而上。由图10可知:C-2材料磨损试样明显可见与金相中类似的小颗粒碳化物“浮凸”于基体(图10(a)),阻挡了磨粒“犁沟”的延伸,在碳化物颗粒后有些“犁沟”发生偏移,有些犁沟仍然能够在碳化物后继续延伸。如图10(b)所示,在C-3材料中大尺寸的碳化物对“犁沟”的阻挡作用较为明显,经过大尺寸碳化物后“犁沟”的深度和宽度明显减弱,甚至经过碳化物1 μm左右的距离“犁沟”才重新出现,体现了高硬度碳化物在磨料磨损过程中的“阴影效应”。这是由于材料基体硬度相对石英磨粒较低,产生磨粒“犁沟”,而共晶碳化物(Fe,Cr)7C3的维氏硬度为1 700~1 800[6],碳化物的维氏硬度远高于石英颗粒的维氏硬度(为900~1 280)。石英磨粒划过共晶碳化物的表面,磨粒楔入受阻,不产生“犁沟”[9]。此外,在图10(b)中框圈位置,小颗粒碳化物有明显的松动现象,而小颗粒的碳化物脱落后也有可能成为新的磨粒参与到磨损中;但由于大块状的共晶碳化物,基体结合程度较好,周围没有明显的裂纹和基体颗粒脱落的现象。这种大块状共晶碳化物和基体之间可以形成相互依存、相互保护的作用,可以承受更强的磨粒冲击磨损[10-12],这正是C-3材料耐磨性提升的主要因素。但大块、有尖锐棱角的共晶碳化物的存在,应力集中点在强冲击的作用下,容易开裂,因此,不利于整体材料冲击韧性的提升。

图10 试样磨损后表面对比

Fig. 10 Surface contrast of worn specimens

综上可知,相比于C-1材料,C-2和C-3耐磨性能的提高主要依靠碳化物的作用。因为碳化物的硬度远高于石英磨粒的硬度,碳化物阻断了“犁沟”的连续性,大量的粒状碳化物提高了耐磨性;大块状的碳化物对“犁沟”的阻断效果更为明显,并且不易脱落,产生明显“阴影效应”,可以有效保护其周围的基体,C-3材料的磨损质量损失率最低,耐磨性最好。因此,在满足冲击的条件下,针对高磨蚀地层,C-3材料加工的刀圈可以大幅提高刀圈寿命。

2.3 缩尺滚刀耐磨性对比

将成型的3种材料先加工成1:10的缩尺刀圈,利用图1所示试验台,分别测试3种刀圈材料在灰色花岗岩、天山红花岗岩2种岩石上磨损情况,2种岩石参数如表3所示。

表3 磨损试验用岩石参数

Table 3 Rock parameters for wear testing

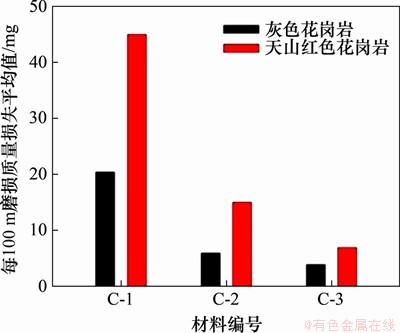

刀盘切削磨损试验如图11所示。统计3种刀圈材料的第2个和第3个100 m刀圈磨损量,如图12所示。针对灰色花岗岩、天山红花岗岩2种岩石,C-1材料(洛氏硬度为57.0)每100 m磨损质量损失平均值分别为20.5 mg和45 mg,C-2材料(洛氏硬度为61.2)每100 m磨损质量损失平均值分别为6 mg和15 mg,C-3材料(洛氏硬度为60.8)每100 m磨损质量损失平均值分别为4 mg和7 mg。

图11 刀盘切削磨损试验

Fig. 11 Cutterhead cutting wear test

图12 刀具切削磨损试验前后对比

Fig. 12 Comparison before and after cutting wear test of cutters

对比3种缩尺刀圈在2种岩石上的每100 m磨损质量损失(见图13)发现,相比C-1材料刀圈,C-2和C-3耐磨性能得到明显提升;另一方面,由于天山红花岗岩磨蚀性物质质量分数较高,且具有较高的单轴抗压强度,在双重因素作用下,滚刀磨损量比灰色花岗岩的更大。

2.4 掘进寿命对比

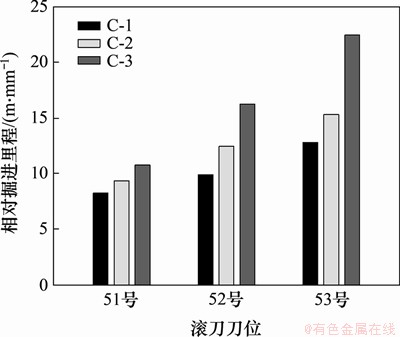

为进一步探索3种刀圈材料掘进性能,在新疆某引水硬岩隧道项目进行工业试验。项目地层以Ⅲ类围岩为主,分布有斜长花岗岩、花岗斑岩、闪长岩,岩石的饱和抗压强度为52.4~98.9 MPa,花岗岩中石英质量分数一般为20%~30%,最高可达35%,其他类岩石石英质量分数5%~10%。采用敞开式主梁TBM掘进,刀盘开挖直径为7.83 m、额定转速为4 r/min。试验选择TBM刀盘上3个邻近边滚刀51号、52号、53号刀位,切削半径分别为3.873,3.894和3.908 m,安装3种刀圈材料的共9把滚刀,进行循环试验,消除安装位置不同对试验数据的影响,测量相对掘进里程(即掘进里程与单位磨损量的比值)来考核刀圈材料的耐磨性,如图14所示。从图14可见:在刀盘的外侧区域3种材料的磨损量均随着切削半径的增大而减少,这是由于TBM在刀盘设计时,在边缘位置的刀间距越来越小,破岩相对容易[13-14],刀具磨损量越小。对比图14的任一个刀位的3种刀圈材料的耐磨性可以发现:相比刀盘初装C-1材料的滚刀,C-2和C-3材料刀圈耐磨性能均得到明显提升;相比C-1材料,C-2的耐磨性能平均值提升136%;相比C-1材料,C-3刀圈耐磨性能平均值提升178%。这说明在弱冲击高磨损地质条件下,C-3材料具有优异性能。

图13 3种缩尺刀圈在2种岩石上每100 m磨损质量失对比

Fig. 13 Comparison of wear mass loss per 100 m of three scale rings on two rocks

图14 不同安装位置3种刀圈的相对掘进里程对比

Fig. 14 Comparison of unit wear and relative driving mileage of three cutter rings in different installation positions

3 结论

1) 对提高合金元素含量后的新材料进行金相、扫描电子显微镜和能谱观测,分析确定了组织中的粒状碳化物和大块状碳化物均为(Fe,Cr)7C3类别的共晶碳化物,但2种碳化物中Fe与Cr元素质量分数比略有区别。

2) 通过磨粒磨损试验,发现大块状的共晶碳化物相比弥散状态的小颗粒碳化物对刀圈材料耐磨性的影响更大。在高磨蚀性岩层掘进中,刀圈材料耐磨相的形貌和其占总材料的面积比是影响磨粒磨损速度主要因素。

3) C-2和C-3这2种材料通过热处理可使洛氏硬度在59~62之间变化,冲击功达5~14 J。在高磨蚀低冲击的地质中掘进时,其寿命相比C-1材料的刀圈大幅提升。

参考文献:

[1] 谭青, 孙鑫健, 夏毅敏, 等. TBM盘形滚刀磨损预测模型[J]. 中南大学学报(自然科学版), 2017, 48(1): 54-60.

TAN Qing, SUN Xinjian, XIA Yimin, et al. A wear prediction model of disc cutter for TBM[J]. Journal of Central South University(Science and Technology), 2017, 48(1): 54-60.

[2] 韩美东, 蔡宗熙, 曲传咏. 基于动力稳定性的全断面岩石隧道掘进机刀盘临界推进速度研究[J]. 机械工程学报, 2014, 50(21): 10-16.

HAN Meidong, CAI Zongxi, QU Chuanyong. Study on the critical driving speed of the tunnel boring machine cutterhead based on the dynamic stability[J]. Journal of Mechanical Engineering, 2014, 50(21): 10-16.

[3] HUO Junzhou, SUN Xiaolong, LI Guangqing, et al. Multi-degree-of-freedom coupling dynamic characteristic of TBM disc cutter under shock excitation[J]. Journal of Central South University, 2015, 22(9): 3326-3337.

[4] 夏毅敏, 周明, 毛晴松, 等. 不同岩石特性下TBM滚刀刀圈磨损性能[J]. 哈尔滨工程大学学报, 2017, 38(9): 1456-1460.

XIA Yimin, ZHOU Ming, MAO Qingsong, et al. Wear characteristics of TBM disc-cutter ring under different rock characteristics[J]. Journal of Harbin Engineering University, 2017, 38(9): 1456-1460.

[5] 林赉贶, 夏毅敏, 贾连辉, 等. TBM边缘滚刀组合破岩特性及其影响因素敏感性评价[J]. 机械工程学报, 2018, 54(1): 18-26.

LIN Laikuang, XIA Yimin, JIA Lianhui, et al. Rock-breaking characteristics of TBM gage disc cutters and sensitivity analysis of their influencing factors[J]. Journal of Mechanical Engineering, 2018, 54(1): 18-26.

[6] 陈华辉. 耐磨材料应用手册[M]. 2版. 北京: 机械工业出版社, 2012: 34-35, 47-50.

CHEN Huahui. Wear resistant material application manual[M]. 2nd ed. Beijing: Machinery Industry Press, 2012: 34-35, 47-50.

[7] 杨勇维, 符寒光, 鞠江, 等. 铬对高钒耐磨合金凝固组织和耐磨性能的影响[J]. 材料工程, 2018, 46(9): 122-130.

YANG Yongwei, FU Hanguang, JU Jiang, et al. Effect of chromium on solidification microstructure and wear property of high vanadium wear-resistant alloy[J]. Journal of Materials Engineering, 2018, 46(9): 122-130.

[8] 龚建勋, 肖逸锋, 张清辉, 等. 高铬不锈钢堆焊合金的超细化显微组织及耐磨性[J]. 中南大学学报(自然科学版), 2009, 40(4): 950-955.

GONG Jianxun, XIAO Yifeng, ZHANG Qinghui, et al. Ultrafine microstructure and wear resistance of high-chromium stainless steel surfacing alloys[J]. Journal of Central South University(Science and Technology), 2009, 40(4): 950-955.

[9] 石骁, 吴建中, 郭汉杰, 等. DH36高强度船板钢中碳化物及碳氮化物析出行为[J]. 中南大学学报(自然科学版), 2018, 49(3): 518-528.

SHI Xiao, WU Jianzhong, GUO Hanjie, et al. Precipitation behaviors of carbides and carbonitrides in DH36 high-strength ship plate steel[J]. Journal of Central South University(Science and Technology), 2018, 49(3): 518-528.

[10] 刘芳, 周科朝, 李志友. 颗粒强化粉末冶金钢耐磨性能的影响因素[J]. 粉末冶金技术, 2011, 29(5): 357-361.

LIU Fang, ZHOU Kechao LI Zhiyou. The influence factors in wear-resisting property of PM particulate reinforced steel[J]. Powder Metallurgy Technology, 2011, 29(5): 357-361.

[11] WANG S Q, WANG F, CUI X H, et al. Effect of secondary carbides on oxidation wear of the Cr-Mo-V cast steels[J]. Materials Letters, 2008, 62(2): 279-281.

[12] CARDAKLI I S, KALKANLI A. Refinement of primary carbides in AISI DC 53 cold work tool steel by thin section copper permanent mould casting and water atomization[J]. International Journal of Cast Metals Research, 2019, 32(3): 145-153.

[13] SUN Hongyan, GUO Wei, LIU Jianqin, et al. Layout design for disc cutters based on analysis of TBM cutter-head structure[J]. Journal of Central South University, 2018, 25(4): 812-830.

[14] HUO Junzhou, SUN Wei, CHEN Jing, et al. Optimal disc cutters plane layout design of the full-face rock tunnel boring machine (tbm) based on a multi-objective genetic algorithm[J]. Journal of Mechanical Science and Technology, 2010, 24(2): 521-528.

(编辑 伍锦花)

收稿日期: 2020-01 -25; 修回日期: 2020 -04 -29

基金项目(Foundation item):国家重点研发计划项目(2017YFB1302601);河南省重大科技专项(181200210100) (Project(2017YFB1302601) supported by the National Research and Development Program of China; Project(181200210100) supported by the Significant Science and Technology Program of Henan Province)

通信作者:贾连辉,教授级高级工程师,从事隧道掘进机设计制造研究;E-mail: jialianhui2005@163.com