DOI: 10.11817/j.issn.1672-7207.2017.03.009

淬火速度对高强度弹簧钢组织与力学性能的影响

姜云1, 2, 3,梁益龙3, 4,徐军3, 4,雷磊3, 4,欧梅桂3, 4

(1. 贵州大学 机械工程学院,贵州 贵阳,550025;

2. 贵州大学 现代制造技术教育部重点实验室,贵州 贵阳,550025;

3. 贵州大学 贵州省材料结构与强度重点实验室,贵州 贵阳,550025;

4. 贵州大学 高性能金属结构材料与制造技术国家地方联合工程实验室,贵州 贵阳,550025)

摘要:采用DIL805A相变仪结合光学显微镜(OM)、扫描电镜(SEM)和透射电镜(TEM)研究不同淬火速度对60Si2CrVAT弹簧钢显微组织、力学性能和马氏体转变点的影响。研究结果表明:在淬火速度从10 ℃/s增加800 ℃/s的过程中,随淬火速率的增加,马氏体块的宽度从666.0 nm减小至573.9 nm,马氏体板条的宽度从189.0 nm减少到147.3 nm。60Si2CrVAT弹簧钢的强度、塑性和硬度总体呈现先增加后降低的趋势,马氏体转变温度则呈先下降后增加的趋势,当冷速为200 ℃/s时,马氏体转变开始点温度最低而强度和塑性均达到最大,分别为1 924 MPa和26.4%,综合力学性能最好。淬火过程中产生的微纳米孪晶马氏体对提高材料的强塑性起到了促进作用。

关键词:淬火速度;弹簧钢;组织;力学性能;微纳米孪晶

中图分类号:TG142;TG156 文献标志码:A 文章编号:1672-7207(2017)03-0617-08

Effect of quenching rate on microstructure and mechanical properties of high strength spring steel

JIANG Yun1, 2, 3, LIANG Yilong3, 4, XU Jun3, 4, LEI Lei3, 4, OU Meigui3, 4

(1. School of Mechanical Engineering, Guizhou University, Guiyang 550025, China;

2. Key Laboratory of Advanced Manufacturing Technology, Ministry of Education, Guizhou University,

Guiyang 550025, China;

3. Guizhou Key Laboratory for Mechanical Behavior and Microstructure of Materials, Guizhou University,

Guiyang 550025, China;

4. National & Local Joint Engineering Laboratory for High-performance Metal Structural Materials and Advanced Manufacturing Technology, Guizhou University, Guiyang 550025, China)

Abstract: The influences of different quenching rates on microstructure, mechanical properties and martensite start transformation temperature (Ms) of 60Si2CrVAT spring steel were performed by DIL805A transformation instrument with optical microscope (OM), scanning electron microscope (SEM) and transmission electron microscope (TEM). The results show that the width of martensite blocks decreases from 666.0 nm to 573.9 nm and that of lathes decreases from 189.0 nm to 147.3 nm with the increase of quenching rate from 10 ℃/s to 800 ℃/s. With the increase of quenching rate, the strength, plasticity and hardness of the tested 60Si2CrVAT steel increase to a peak at around 200 ℃/s. The martenitic transformation point shows the opposite characteristics. At the quenching rate of 200 ℃/s, the martensitic transformation point is the lowest and the tested steel has the best comprehensive properties in which the tensile strength reaches 1 924 MPa and the reduction of area comes to 26.4%. Micro-nano-scale twin martensite appears during quenching process which plays a significant role in improving mechanical properties.

Key words: quenching rate; spring steel; microstructure; mechanical properties; micro-nano-scale twins

近年来,中国高铁行业取得了突飞猛进的发展[1]。高铁列车速度高达200~300 km/h,弹簧作为其中起制动、缓冲、减震作用的关键零部件对列车的平稳安全运行起到至关重要的作用。在常用的弹簧钢材料中,60Si2CrVAT钢是在60Si2Mn钢的基础上加入Cr和V元素得到的弹簧钢品种,其强度高达1 900 MPa,同时具有优良的综合性能,因此在高铁弹簧钢材料中得到了越来越广泛的应用。针对这种材料,目前的研究多集中在不同热处理温度对组织和性能的影响[2-3],冷却速度对性能的影响的研究鲜有报道。这是因为对于钢的马氏体转变来说,冷却速度影响马氏体转变的起始点和终止点,最终影响马氏体的形态和碳化物的析出。由于马氏体相变过程发生在较高的温度,实际检测相变存在一定的困难。在此,本文作者采用热模拟的方法分析相变过程,通过测定不同冷速下该弹簧钢的热膨胀曲线,利用试样在加热冷却循环中相对线膨胀量变化的信息获取相关相转变过程的动力学信息,同时结合显微组织,分析冷速变化对于马氏体转变的影响,进一步了解不同条件下60Si2CrVAT弹簧钢的组织和性能转变规律,从而为获得性能更优异的弹簧钢提供指导。

1 实验

1.1 实验材料

实验材料为商用热轧态棒状材料,直径为24 mm。通过TASMAN全谱直读电火花光谱仪分析测得试样化学成分(质量分数,%)为:C 0.59,Si 1.61,Cr 1.15,Mn 0.66,V 0.16,Cu 0.014,P 0.009,S 0.015,Fe余量。

1.2 实验方法

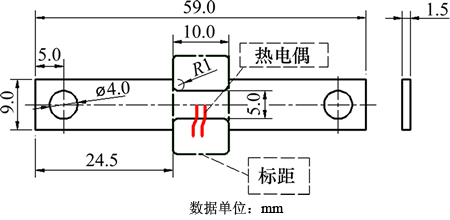

将试样加工成标准板状拉伸试样,如图1所示。采用DIL805A/D热模拟试验机进行淬火试验,其中,真空度为10-4,冷却气体为氦气。试验工艺流程如下:将试样以5 ℃/s的升温速率加热至900 ℃进行奥氏体化,保温20 min后分别以10,50,120,200,400和800 ℃/s的淬火速度冷却至300 ℃,再以5 ℃/s冷却至室温,停留30 s后,再进行回火处理,回火温度为440 ℃,回火时间为1 h。实验过程中,每个状态下用2根板条拉伸样进行实验,一根用于力学性能的测定,另一根用于组织的观察。

在Instron8501电液伺服数字控制式材料试验机上测试强塑性指标。采用显微硬度仪HV-1000进行硬度测量,每个数据均测试5个点,并取平均值;采用4%(体积分数)硝酸酒精制备金相试样。使用LeiCa光学显微镜、SUPPA40高分辨率热场发射扫描电镜和Tecnai G2F20 S-TWIN透射电镜观察样品的金相及微观组织形貌。

图1 板状试样

Fig. 1 Plate sample

2 结果与讨论

2.1 显微组织

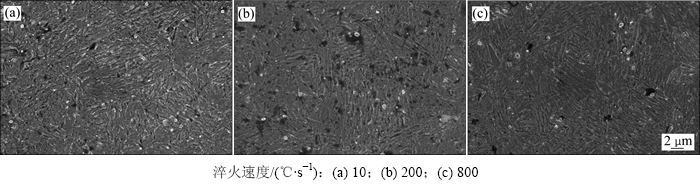

图2所示为实验用弹簧钢经不同淬火速度淬火后再进行440 ℃回火后的显微组织。从图2可以看出:所有状态下的显微组织均为典型的回火屈氏体组织,且随着淬火速度的增加,组织呈细化趋势。

选取淬火速度为10,200和800 ℃/s的试样进行SEM和TEM观察,进一步研究不同淬火速度对该弹簧钢显微组织的影响。

图3所示为不同淬火速度下试样经腐蚀后在扫描电镜下观察到的微观显微组织。从图3可知:所有状态显微组织均为板条状马氏体混合组织,随淬火速度的增大,马氏体板条逐渐细化。

图2 不同淬火速度对显微组织的影响

Fig. 2 Effect of different quenching rates on OM microstructure

图3 不同淬火速度对微观组织SEM形貌的影响

Fig. 3 Effect of different quenching rates on SEM morphology

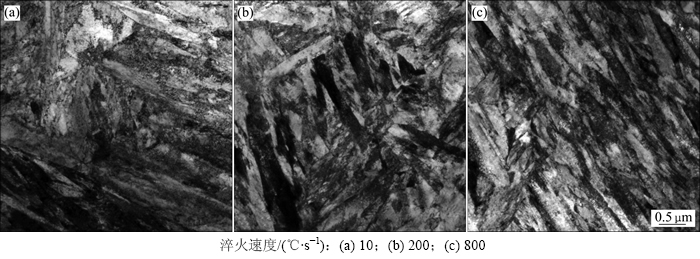

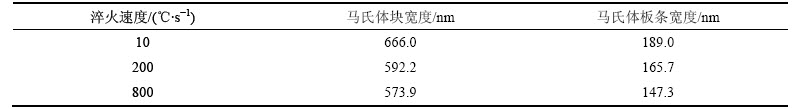

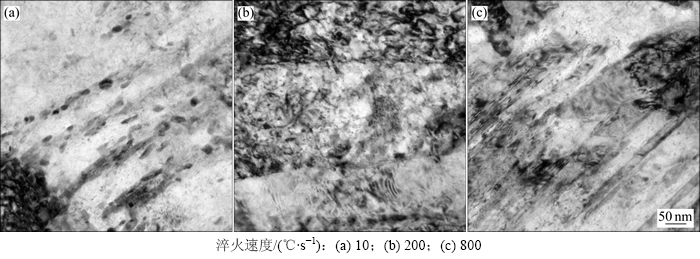

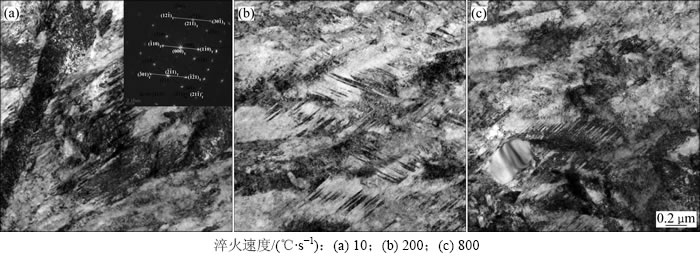

图4所示为实验用弹簧钢经10,200和800 ℃/s淬火回火后的TEM照片。由图4可知:不同淬火速度处理的弹簧钢均为板条马氏体组织,且在马氏体块内的板条接近平行排列。由于板条马氏体的亚结构主要为位错,因此所有影响位错滑移的因素都会对材料的性能起着重要的作用。研究表明:马氏体块界和板条界对位错的运动都有较大的阻碍作用,可以提高材料的屈服强度,因此通常认为它们是控制材料强度的主要因素[4-6]。为了研究淬火速度对马氏体束条尺寸的影响,本试验采用截线法,选取不同透射图片中共约200个马氏体块和约150个马氏体板条的宽度进行测量和统计,得到了不同淬火速率下马氏体块和板条宽度,如表1所示。由表1可见:马氏体块宽度和马氏体板条宽度在淬火速度最低(10 ℃/s)时最大,分别为666 nm和189 nm;而当淬火速度增加到800 ℃/s时,其马氏体块和板条宽度分别减小至573.9 nm和147.3 nm。

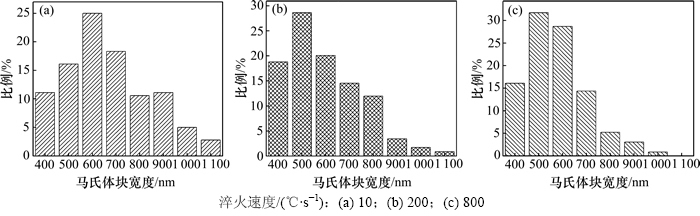

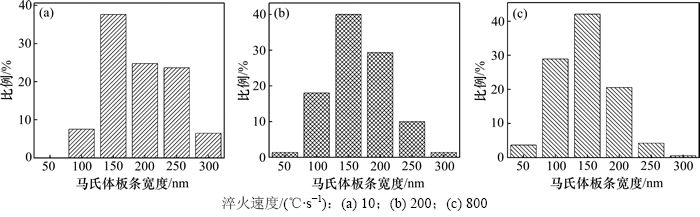

图5和图6所示分别为10,200和800 ℃/s淬火速率下试样的马氏体块和马氏体板条宽度的比例分布图。从表1、图4和图5可以看出:马氏体板条块宽度变化范围较大,且分布比较分散、主要集中在400~ 1 110 nm范围内;而马氏体板条宽度变化范围较小,且分布相对较集中,主要集中在50~300 nm。无论是平均数据还是统计数据均说明马氏体块和马氏体板条宽度均随淬火速度的增加而减小。

图7所示为不同冷速淬火回火后的TEM像。从图7可见:碳化物大多数呈球状或短杆状,其中冷速为10℃/s的试样其组织中碳化物粒径较粗大,随冷速增大,碳化物粒径减小,呈细小弥散状分布于基体组织中。产生这一现象的原因可能是当淬火过程中冷却速度降低后,碳原子容易从母相奥氏体中析出,并与晶界处未溶入奥氏体的合金元素形成合金碳化物,且该碳化物随淬火介质冷却速度的降低而增多、变大[7]。随碳化物沿晶界析出,残余奥氏体因碳含量减少而使马氏体转变开始点(Ms点)温度升高,稳定性降低,在回火过程中,残留奥氏体更容易分解,且以淬火过程形成的碳化物为形核处,进而沿界面处形成粗大碳化物。这些沿晶界和马氏条界面分布的粗大碳化物不再起到弥散强化作用,割裂了基体之间的联系,从而降低材料的力学性能。

图4 不同淬火速度弹簧钢TEM形貌

Fig. 4 TEM images of spring steel at different quenching rates

表1 不同淬火速度下马氏体块和马氏体板条的平均宽度

Table 1 Average width of martensite blocks and laths under different quenching rates

图5 不同淬火速度下马氏体块宽度统计分布图

Fig. 5 Statistical distribution diagram of martensite block width at different quenching rates

图6 不同淬火速度下马氏体板条宽度统计分布图

Fig. 6 Statistical distribution diagram of martensite lath width at different quenching rates

图7 实验钢中的碳化物TEM照片

Fig. 7 TEM images of carbide in tested steel

2.2 力学性能

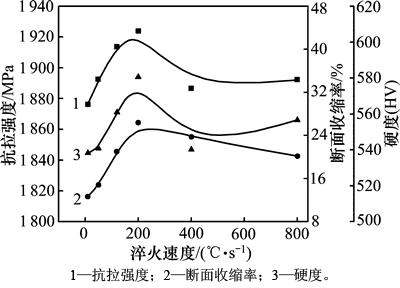

利用Instron8501测定的力学性能试验结果如图8所示。从图8可以看出:随着淬火冷却速度的增大,该弹簧钢的抗拉强度、硬度和断面收缩率总体变化趋势一致,都呈现先增加后降低的趋势。其中,当淬火速度为200 ℃/s时,材料的综合力学性能最佳,其抗拉强度、硬度和断面收缩率均达到最大值,分别为1924 MPa,581(HV)和26.4%。

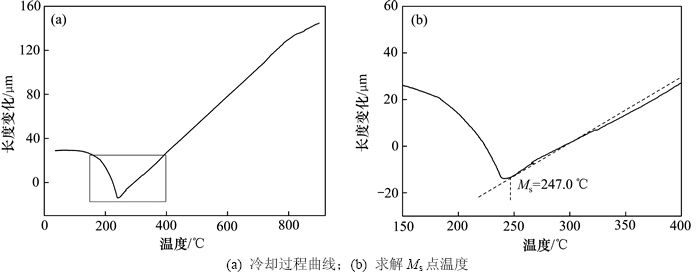

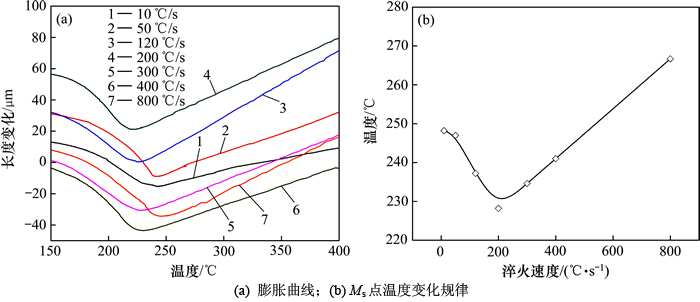

图9所示为淬火速度为50 ℃/s的马氏体转变开始点温度求解过程曲线。将图9(a)中方框区域放大得到图9(b),采用切线法测得弹簧钢的马氏体转变开始点温度为247.0 ℃。使用此方法求得其他淬火速度对应的Ms点温度(图10(a)所示)。由图10可知:随淬火冷却速度的增加,马氏体转变开始点温度呈先下降后升高的趋势。当冷速为200 ℃/s时,马氏体的开始转变温度最低,为227 ℃。

图8 淬火速度对力学性能的影响

Fig. 8 Effect of quenching rates on mechanical properties

2.3 讨论

力学性能的差异是由于显微组织结构的不同造成的,不同的淬火冷却速度将影响弹簧钢显微组织的形态,进而造成材料力学性能的不同。实验结果显示:虽然组织中马氏体板条块宽度、马氏体板条宽度和碳化物粒径均随淬火速度的增加而减小,但强度和塑性并未随淬火速度的增大而提升。由此说明强塑性的实际变化不仅仅受板条马氏体块宽度、板条宽度和碳化物粒径的控制,还会受到其他因素的影响。

图11所示为冷却速度为10,200和800 ℃/s的TEM照片。从图11可知:在不同淬火速度试样中均观察到在部分马氏体板条中存在微纳米级孪晶结构[8-10]。对图11(a)中该区域进行电子衍射,衍射斑点呈现出明显的孪晶花样。经标定可知,该结构为{211}孪晶面的马氏体孪晶。对3种冷却速率下不同TEM图像中的孪晶进行统计发现:当冷却速度为200 ℃/s时,试样组织中孪晶数量最多。马氏体亚结构是孪晶还是位错主要取决于马氏体转变过程是孪生机制还是滑移机制[11],而相变时是以孪生还是滑移的方式切变又主要取决于钢的Ms点温度和淬火过程形成的碳原子气团。当淬火冷却速度低时,高温区停留的时间较长,碳原子的活动能力较强,碳原子在缺陷处偏聚后又容易挣脱缺陷,因此很难形成“碳原子气团”,不能提高奥氏体屈服强度[12]。另外,冷速的降低使得碳化物沿奥氏体晶界析出的倾向增大,冷速越小碳化物析出越多,奥氏体中含碳量越少,奥氏体屈服强度也就越低,从而使得Ms点温度升高[13]。当淬火速度较大时,容易形成淬火空位,在高温区停留时间短,使得碳原子在缺陷处偏聚且不易挣脱。由于淬火空位和“碳原子气团”对位错的钉扎作用,增加了母相奥氏体的屈服强度。当冷却速度增加到一定程度时,碳原子的活动能力急剧下降,扩散受阻,碳原子很难扩散到缺陷处,不能形成“碳原子气团”,淬火速度越高,“碳原子气团”越不容易形成,对母相奥氏体的强化能力越低,Ms点温度又开始上升[14]。此外,在极高淬火速度下,形成较大的淬火内应力也会影响Ms点温度,淬火内应力提供了一部分马氏体转变驱动力,从而提高Ms点温度,故在200~800 ℃/s阶段,Ms点温度随淬火速度的增加而显著增加[13, 15]。可见:在适当的淬火速度下,容易形成“碳原子气团”,提高了母相奥氏体屈服强度,使得奥氏体向马氏体转变的过程中,位错滑移困难,切变就会以孪生的方式进行,从而可能会在马氏体基体中产生大量细小的微纳米孪晶结构;另外奥氏体屈服强度提高后,Ms点温度降低,畸变能增大,也会促使微纳米孪晶结构的形成。由于这些微纳米孪晶的存在,有助于实验钢的强化[16-18],因此冷却速率为200 ℃/s时,弹簧钢的综合力学性能最好。其他淬火速度下由于母相奥氏体屈服强度较低,Ms点温度升高,影响了纳米孪晶的形成,数量较少,使得该弹簧钢力学性能指标降低。

图9 淬火速度为50 ℃/s时的Ms点温度求解过程

Fig. 9 Determination of Ms points at quenching rate of 50 ℃/s

图10 不同淬火速度下冷却段膨胀曲线及Ms点温度的变化规律

Fig. 10 Dilatometric curves of cooling stage at different quenching rates and its change rule of Ms

图11 马氏体中微纳米孪晶形貌及衍射花样标定

Fig. 11 Morphology of micro-nano-scale twin martensite and calibration of diffraction pattern

3 结论

1) 不同淬火速度下得到的金相组织均为回火屈氏体组织。微观组织中,马氏体块和马氏体板条的宽度随淬火速度的增加而减小,且淬火速度对马氏体块宽度的影响较大,对马氏体板条宽度的影响相对较小。

2) 淬火速度从10 ℃/s增加800 ℃/s的过程中,60Si2CrVAT弹簧钢的马氏体开始转变点温度呈先下降后增加的趋势,材料的强度、塑性和硬度总体呈先增加后降低的趋势。当冷速为200 ℃/s时,马氏体开始转变点温度最低。此时,其强度达1 904 MPa,断面收缩率达26.4%,综合力学性能最好。

3) 淬火过程中,形成了纳米孪晶马氏体。200 ℃/s时形成的微纳米孪晶马氏体的数量最多。

参考文献:

[1] 周菲, 夏亚明. 中国高铁产业的国际化起步及其影响[J]. 对外经贸实务, 2011(7): 21-24.

ZHOU Fei, XIA Yaming. The Internationalizing start and its influence of China’s high speed railway[J]. Practice in Foreign Economic Relations and Trade, 2011(7): 21-24.

[2] 张博, 王福明, 吴华林, 等. Nb对60Si2CrVAT弹簧钢力学性能的影响[J]. 金属热处理, 2011(5): 29-33.

ZHANG Bo, WANG Fuming, WU Hualing, et al. Effect of Nb on mechanical properties of 60Si2CrVAT spring steel[J]. Heat Treatment of Metals, 2011(5): 29-33.

[3] 吴华林, 王福明, 李长荣, 等. 提速列车用弹簧钢60Si2CrVAT的热处理工艺优化[J]. 材料热处理学报, 2011(9): 35-41.

WU Hualin, WANG Fuming, LI Changrong, et al. Optimization of heat treatment process of 60Si2CrVAT spring steel for high-speed trains[J]. Transactions of Materials and Heat Treatment, 2011(9): 35-41.

[4] 王春芳. 低合金马氏体钢强韧性组织控制单元的研究[D]. 北京: 钢铁研究总院, 2008: 5-15.

WANG Chunfang. Research on the control unit of strength and toughness for low alloy martensitic steel[D]. Beijing: Centrel Iron & Steel Research Institute, 2008: 5-15.

[5] SHI Zengmin, LIU Kai, WANG Maoqiu. Effect of tensile deformation of austenite on the morphology and strength of lath martensite[J]. Metals and Materials International, 2012, 18(2): 317-320.

[6] MORITO S, TANAKA H, KONISHI R, et al. The morphology and crystallography of lath martensite in Fe-C alloys[J]. Acta Materialia, 2003, 51(6): 1789-1799.

[7] TOMITA Y, OKABAYASHI K. Effect of quench rate on microstructure and tensile properties of ALSL 4320 and 4340 steels[J]. Metallurgical & Materials Transactions A, 1987, 18(1): 115-121.

[8] STORMVINTER A, PETER HEDSTR M, BORGENSTAM A. A transmission electron microscopy study of plate martensite formation in high-carbon low alloy steels[J]. Journal of Materials Science & Technology, 2013, 29(4): 373-379.

[9] ZHANG Pan, CHEN Yulin, XIAO Wenlong, et al. Twin structure of the lath martensite in low carbon steel[J]. Progress in Natural Science: Materials International, 2016, 26(2): 169-172.

[10] LIU G Z, TAO N R, LU K. 316L austenite stainless steels strengthened by means of nano-scale twins[J]. Journal of Materials Science & Technology, 2010, 26(4): 289-292.

[11] 刘宗昌, 计云萍, 段宝玉, 等. 板条状马氏体的亚结构及形成机制[J]. 材料热处理学报, 2011, 32(3): 56-61.

LIU Zongchang, JI Yunping, DUAN Baoyu, et al. Structure and formation mechanism of lath marten site[J]. Transactions of Materials and Heat Treatment, 2011, 32(3): 56-61.

[12] 徐祖耀. 马氏体相变与马氏体[M]. 北京: 科学出版社, 1999: 58.

XU Zuyao. Martensite phase transformation and martensite[M]. Beijing: Science Press, 1999: 58.

[13] 李国庆. 淬火冷却速度对冷作模具钢Ms点的影响[J]. 国外金属热处理, 1997, 18(2): 18-21.

LI Guoqing. The effect of quenching rate on Ms for cold working die steel[J]. Foreign Heat Treatment of Metals, 1997, 18(2): 18-21.

[14] DONACHIE S J, ANSELL G S. The effect of quench rate on the properties and morphology of ferrous martensite[J]. Metallurgical Transactions A, 1975, 6(10): 1863-1875.

[15] 宁保群, 刘永长, 高志明, 等. 淬火速率对T91铁素体耐热钢马氏体转变开始温度的影响[J]. 材料科学与工程学报, 2008, 26(1): 61-63.

NING Baoqun, LIU Yongchang, GAO Zhiming, et al. Effect of quenching rate on martensite transformation starting temperature of T91 ferritic heat-resistant steel[J]. Journal of Materials Science& Engineering, 2008, 26(1): 61-63.

[16] 雍兴平, 刘刚, 吕坚, 等. 低碳钢表面纳米化处理及结构特征[J]. 金属学报, 2002, 38(2): 157-160.

YONG Xingping, LIU Gang, L Jian, et al. Fabrication and characterization of nanostructured surface layer of low carbon steel[J]. Acta Metallurgica Sinica, 2002, 38(2): 157-160.

Jian, et al. Fabrication and characterization of nanostructured surface layer of low carbon steel[J]. Acta Metallurgica Sinica, 2002, 38(2): 157-160.

[17] 巨彪, 武会宾, 唐荻, 等. 微观组织演变对超高强耐磨钢板力学性能的影响[J]. 金属学报, 2014, 50(9): 1055-1062.

JU Biao, WU Huibin, TANG Di, et al. Effect of microstructure evolution on mechanical properties of ultra-high strength wear resistance steel[J]. Acta Metallugica Sinica, 2014, 50(9): 1055-1062.

[18] GUO X, OUYANG Q D, WENG G J, et al. The direct and indirect effects of nanotwin volume fraction on the strength and ductility of coarse-grained metals[J]. Materials Science & Engineering A, 2016, 657: 234-243.

(编辑 赵俊)

收稿日期:2016-05-12;修回日期:2016-09-13

基金项目(Foundation item):国家自然科学基金资助项目(51461006);贵州省工业攻关项目(GZ(2014)3018);贵州省科技合作计划项目(LH(2015)7646) (Project(51461006) supported by the National Natural Science Foundation of China; Project(GZ(2014)3018) supported by Guizhou Province Science and Technology Key Program Plan; Project(LH(2015)7646) supported by Guizhou Province Scientific and Technological Cooperation Program)

通信作者:梁益龙,教授,从事新型金属材料、材料强度与断裂以及热加工装备的研究;E-mail: liangyilong@126.com