文章编号:1004-0609(2013)S1-s0092-05

钛合金精密铸造用氧化钙型芯烧结初期性能

高 鹏,周铁涛

(北京航空航天大学 材料科学与工程学院,北京 100091)

摘 要:在精密铸造中,型芯的性能直接影响铸件内腔的精度及性能。氧化钙对熔融钛具有良好的高温稳定性,且在铸造后具有良好的易脱除性能。本文作者建立了热力学模型,对氧化钙陶瓷型芯的烧结初期进行模拟,并进行浇铸实验以验证氧化钙型芯在钛合金精密铸造中的低化学反应活性和无污染特性。根据型芯在900~1 600 ℃烧结范围内的烧结收缩量,计算出相应的吉布斯自由能以及烧结平衡常数。通过热力学方程

,得到此温度区间内烧结反应的

,得到此温度区间内烧结反应的 =240 998 J/mol,

=240 998 J/mol, =150.7 J/(K·mol);计算得出的最低烧结温度与实际结果吻合较好。TC4合金浇铸实验验证了氧化钙型芯的强度满足钛合金浇铸要求并且其对铸钛界面无污染的优良特性。

=150.7 J/(K·mol);计算得出的最低烧结温度与实际结果吻合较好。TC4合金浇铸实验验证了氧化钙型芯的强度满足钛合金浇铸要求并且其对铸钛界面无污染的优良特性。

关键词:氧化钙;钛合金;精密铸造;陶瓷型芯;烧结模型

中图分类号:TG146.2,TG249.5 文献标志码:A

Initial-sintering stage properties of calcium oxide ceramic cores during titanium alloy precision casting

GAO Peng, ZHOU Tie-tao

(School of Material Science and Technology, Beihang University, Beijing 100091, China)

Abstract: In precision casting, the ceramic cores can directly influence the casting’s properties and internal precision. The calcium oxide has an excellent chemical inertness to the melting titanium and the cores can be easily removed after casting. The CaO ceramic cores’ thermodynamic model was established to analyze its initial-sintering stage. Casting experiment was also designed to prove the cores’ low activity and contaminate. The model was established through the sintering shrink between 900 ℃ to 1 600 ℃, using formula  , calculating the enthalpy and entropy of the sintering progress (

, calculating the enthalpy and entropy of the sintering progress ( =240 998 J/mol,

=240 998 J/mol,  =150.7 J/(K·mol)). The theory sintering temperature fully agrees with the real sintering temperature. The experiment also verifies that strength is enough for titanium casting and its low activity satisfies the surface requirement of titanium alloy without any contamination.

=150.7 J/(K·mol)). The theory sintering temperature fully agrees with the real sintering temperature. The experiment also verifies that strength is enough for titanium casting and its low activity satisfies the surface requirement of titanium alloy without any contamination.

Key words: CaO; titanium alloy; precision casting; ceramic core; sintering model

在钛合金熔模精密铸造工艺中,高温耐火材料制型芯对铸件内腔的成型具有重要的影响,决定了铸件内腔结构的尺寸精度及性能。在钛合金熔炼和精密铸造过程中,由于钛熔体具有极高的化学反应活性,因此对其所使用陶瓷型芯的要求与其他金属不同。熔融钛铸件表面极易形成富氧α相污染层,严重时会引起铸件表面粗糙化、脆化、出现裂纹,降低其力学性能,使成品率降低。氧化钙对熔融钛的高温稳定性好,且具有无相变、型芯易脱除等优点;因此作为钛合金铸造型芯、型壳,具有广阔的应用前景。

精铸型芯的制备,多通过烧结来完成。而目前在粉体烧结领域中,对陶瓷粉体材料的烧结研究则主要集中在微观传质领域。各种动力学模型被用于解释不同阶段的烧结过程[1-6]。由于测量高温下材料的热力学数据较为困难,目前对烧结的相关研究多为金属粉体的单原子烧结过程模拟[4],对粉体烧结阶段热力学方面的研究则为数不多[7]。通过明确不同温度下材料的吉布斯自由能、焓、熵的变化以及烧结常数的条件,可以通过平衡方程方便地计算各烧结阶段反应的热力学参数,对材料的变化趋势做出精确判断。在粉体材料的实际烧结过程中,由于多孔结构的复杂性,物质同时受到几种传递方式作用发生扩散,所以很难对烧结过程进行精确模拟。因此,本文作者期望通过建立热力学模型,以线收缩率表征烧结常数,计算出一定温度区间内熵、焓、吉布斯自由能的变化及其趋势。从而在限定范围内建立陶瓷粉体的烧结时间、烧成收缩等更精确的相关曲线,对动力学模型进行补充。

同时,也对氧化钙基陶瓷型芯的使用性能进行了一定的研究。通过浇铸试验验证其在金属液环境下的高温强度和热变形量;通过对型芯与熔融钛的反应界面的分析,明确型芯材料对钛合金表面的污染程度。

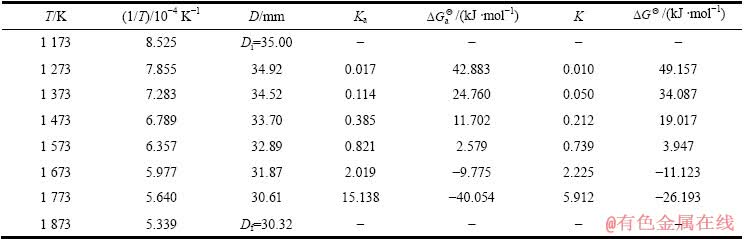

1 实验

实验原料采用的氧化钙粉体颗粒粒度分布为0.5~2.8 μm,团聚粒度分布为10~158 μm。取8 g氧化钙粉体在30 MPa压力下保压15 s后形成直径为35 mm、高为5 mm左右的圆柱形密实试片。试样的平均密度为1.606 g/cm3,平均孔隙率为51.18%。随后以5 ℃/min的升温速率加热至900~1 600 ℃,保温2 h后随炉冷却。测量其平均烧结收缩值对烧结常数进行表征。不同温度烧结后试样的直径、平衡常数、吉布斯自由能见表1。

当烧结过程为平衡态时,定义实验平衡常数Ka由烧成线收缩的变量表示[7]:

(1)

(1)

其中:D为900~1 600 ℃间不同温度下烧结后的试片直径;Di为烧结前试片直径;Df为1 600 ℃烧结后试片直径;(Di-D)为已发生的烧成收缩;(D-Df)为尚未发生的烧成收缩。

2 结果与讨论

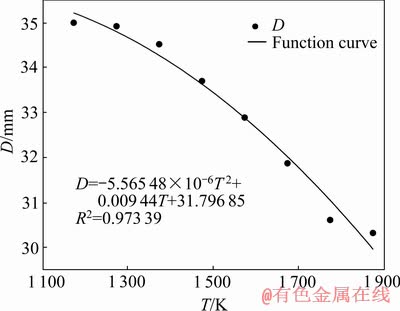

不同温度烧结后的氧化钙试样的直径见表1。经过对试样的分析,可以认为经过2 h保温后试样已基本达到平衡。烧成收缩与烧结温度的关系可近似表达成一元二次方程(见图1)。

2.1 模型的热力学分析

熵、焓、吉布斯自由能等基本热力学数据随着烧结温度的升高而改变。由于其无法准确测量,所以这里通过实验平衡常数对试样的线收缩进行表征,进而计算出相应温度区间内粉体颗粒发生烧结时的热力学数据。该热力学模型满足如下条件:

(1) 试样烧结时要有足够的保温时间以建立平衡态。

(2) 烧结完成后试样的物理性质如直径、密度、孔隙率在冷却过程中不应发生改变。

(3) 在认为烧结过程为平衡态的情况下,定义实验平衡常数Ka(如式(1))。

(4) 按照基本热力学公式对熵、焓、吉布斯自由能等热力学数据进行计算。

(2)

(2)

表1 烧结初期氧化钙的烧结收缩,反应常数以及理论、实验吉布斯自由能变化

Table 1 Linear shrinkage, experimental equilibrium constant, experimental change in Gibbs energy, real change in Gibbs energy and real equilibrium constant for initial-stage sintering of CaO compacts ( )

)

图1 不同温度烧结后氧化钙试片直径(D)的变化曲线

Fig. 1 Variation of diameter curve (D) of compacts sintered at different temperatures

2.2 热力学计算

不同温度下的实验平衡常数(Ka)及相应的吉布斯自由能( )按照式(1)和(2)进行计算,进而可以得到

)按照式(1)和(2)进行计算,进而可以得到 和

和 。所得出Ka及

。所得出Ka及 的数据如表1所示。

的数据如表1所示。

图2所示为 与1/T及

与1/T及 与T的线性关系。且根据拟合曲线可知:当温度为1 326.04 ℃时Ka=1,即此平衡态下

与T的线性关系。且根据拟合曲线可知:当温度为1 326.04 ℃时Ka=1,即此平衡态下 。随后通过式(2)可以计算出900~1 600 ℃温度区间内的熵变

。随后通过式(2)可以计算出900~1 600 ℃温度区间内的熵变 及焓变

及焓变 ,分别为150.7 J/(K·mol-1)和240 998 J/mol。

,分别为150.7 J/(K·mol-1)和240 998 J/mol。

在此温度范围内氧化钙粉体烧结时吉布斯自由能的变化可由式(3)表示为:

(3)

(3)

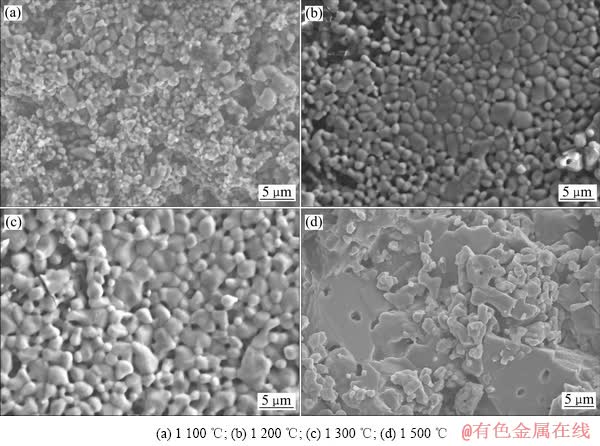

从化学势的角度分析,当温度低于1 326.04 ℃时,反应不会自发进行。当温度高于1 326.04 ℃时,粉体开始发生烧结。但由于粉体颗粒粒度及其表面曲率的影响,增加了局部化学势的差值及表面能,相应地会使烧结温度发生一定程度降低。通过对试样表面观察可知:该试样在1 200~1 300 ℃即开始发生烧结(见图4)。

同样, 与1/T及

与1/T及 与T的线性关系见图2。图3还列出了Ka和K在不同温度的变化,可知:900~ 1 500 ℃平衡常数K曲线与实验结果Ka曲线近似程度很好。1 600 ℃后由于颗粒和气孔的微观结构发生大幅变化,烧结进程加快,故Ka值上升更快。即1 500 ℃后试样应进入烧结中期阶段,通过对试样断口的观察发现颗粒发生明显变形和结合(见图4)。

与T的线性关系见图2。图3还列出了Ka和K在不同温度的变化,可知:900~ 1 500 ℃平衡常数K曲线与实验结果Ka曲线近似程度很好。1 600 ℃后由于颗粒和气孔的微观结构发生大幅变化,烧结进程加快,故Ka值上升更快。即1 500 ℃后试样应进入烧结中期阶段,通过对试样断口的观察发现颗粒发生明显变形和结合(见图4)。

图2 实验/模型烧结平衡常数的范德霍夫方程和吉布斯自由能变方程

Fig. 2 Van’t Hoff function of sintering/real equilibrium constant (Ka, K)(a) and function of experimental/model Gibbs free energy(b)

图3 Ka和K随温度变化曲线

Fig. 3 Variation of Ka and K at different temperatures

图4 不同温度氧化钙试样烧结后形貌

Fig. 4 Morphologies of compact at different sintering temperatures

3 浇铸实验

使用所制备型芯进行TC4钛合金浇铸实验,以检验氧化钙基陶瓷型芯在实际铸造中的使用性能。按照钛合金结构件通常的生产工艺,即使用石墨型壳以离心铸造的方式以250 r/min的转速进行试样的浇铸。浇铸好后的试样辅以机械手段可将型芯轻易去除,随后将合金试样沿界面垂直剖开,通过线扫描分析铸件界面纵向污染情况。

浇铸后,经测量,2 mm壁厚铸件的内孔直径为4.14 mm,相对应的型芯浇铸前直径为4.20 mm。即在浇铸过程中,由于受金属液凝固时的压应力,型芯的收缩率为1.43%。同时对其内腔进行观察,发现氧化钙基陶瓷型芯与钛合金无反应发生;内腔形状完整,表面光洁度良好。如图5所示。

随后对试样内侧界面处进行线扫描分析,结果见图6。

已知难熔氧化物对钛合金的污染主要为游离氧元素的扩散带来的富氧α污染层,如刚玉会使铸件表层形成约20 μm左右的氧污染层,并且Al和Zr元素均会向合金中进行扩散,影响铸件表面质量[8-9];也存在Zr与C、N、O的化合物对铸件造成污染,严重时可达200 μm[10]。

图5 铸件内腔结构

Fig. 5 Internal structure of casting

在本实验条件下,根据铸件内侧界面处的分析结果可以认为氧化钙基陶瓷型芯在TC4钛合金薄壁铸件的铸造过程中未发生界面反应,观察铸件与型芯的界面显示其表面粗糙度表现良好,可视为无污染层存在。

图6 TC4钛合金与氧化钙基型芯接触界面处的元素分布

Fig. 6 Element distribution of titanium alloy near interface with CaO

4 结论

1) 在陶瓷粉体颗粒的固相烧结过程中,动力学和热力学分析都有助于加深对烧结时物质变化的理解。动力学的模型建立主要着眼于微观孔洞结构的演化及物质的迁移模式定量分析,是近年来研究的热点之一。热力学方面则通过烧成收缩以确定一定温度区间内的烧结平衡常数,进而可以更加精确地掌握烧结时焓、熵、吉布斯自由能等热力学数据的变化。随后确定1 100~1 500 ℃区间内氧化钙粉体的热力学公式为 T,对于在热力学平衡态下动力学模型的建立、分析起到补充、加强的作用。

T,对于在热力学平衡态下动力学模型的建立、分析起到补充、加强的作用。

2) 经实际浇铸验证可知氧化钙基陶瓷型芯的抗弯强度符合实际使用需要,且型芯与钛合金未发生反应,用于钛合金精密铸造中可有效地防止型芯对铸件内腔表面的污染。

REFERENCES

[1] DJOHARI H,  J I, DERBY J J. Transport mechanisms and densification during sintering: Ⅰ. Viscous flow versus vacancy diffusion[J]. Chemical Engineering Science, 2009, 64: 3799-3809.

J I, DERBY J J. Transport mechanisms and densification during sintering: Ⅰ. Viscous flow versus vacancy diffusion[J]. Chemical Engineering Science, 2009, 64: 3799-3809.

[2] DJOHARI H, DERBY J J. Transport mechanisms and densification during sintering: Ⅱ. Grain boundaries[J]. Chemical Engineering Science, 2009, 64: 3810-3816.

[3] ZHANGT W, SCHNEIBEL J H. The sintering if tow particles by surface and grain and grain boundary diffusion—A two dimensional numerical study[J]. Acta Metall Mater, 1995, 43(12): 4377-4386.

[4] DU Ji-xiang, LIANG Shu-hua, WANG Xian-hui, FAN Zhi-kang. Simulation of the neck growth of non-isometric biosphere during initial sintering[J]. Acta Metall Sin: Engl Lett, 2009, 22(4): 263-274.

[5] HANSEN J D, RUSIN R P, TENG M H, JOHNSON D L. Combined-stage sintering mold[J]. Am Ceram Soc, 1992, 75(5): 1129-1135.

[6] CH’NG H N, PAN Jing-zhe. Sintering of particles of different sizes[J]. Acta Materialia, 2007, 55: 813-824.

[7] SARIKAYA Y, ADA K,  M. A model for initial-stage sintering thermodynamics of an alumina powder[J]. Powder Technology, 2008, 188: 9-12.

M. A model for initial-stage sintering thermodynamics of an alumina powder[J]. Powder Technology, 2008, 188: 9-12.

[8] 陈玉勇, 肖树龙, 徐丽娟, 韩杰才. 不同型壳材料条件下钛合金显微组织及界面反应[J]. 中国科技论文在线, 2010, 5(4): 269-273.

CHEN Yu-yong, XIAO Shu-long, XU Li-juan, HAN Jie-cai. Microstructure and interface reaction of titanium alloys casting into different mould shells[J]. Sciencepaper Online, 2010, 5(4): 269-273.

[9] 陈艳飞, 陈玉勇, 田 竟, 肖树龙, 徐丽娟. 离心熔模精铸TiAl合金与ZrO2型壳的界面反应[J]. 中国有色金属学报, 2010, 20(S1): s198-s202.

CHEN Yan-fei, CHEN Yu-yong, TIAN Jing, XIAO Shu-long, XU Li-juan. Interfacial reactions between TiAl alloys and ZrO2 mould under centrifugalinvestment casting conditions[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s198-s202.

[10] 李 婷. 钛合金熔模铸造用氧化物陶瓷型壳的制备工艺研究[D]. 南京: 南京航空航天大学, 2013: 51-55.

LI Ting. Study on oxide ceramic shell mold fabrication for the investment casting of titanium alloy[D]. Nanjing:Nanjing University of Aeronautics and Astronautics, 2013: 51-55.

(编辑 何运斌)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:周铁涛,教授,博士;电话:010-82317125;E-mail: zhoutt@buaa.edu.cn