DOI: 10.11817/j.ysxb.1004.0609.2021-42048

CO2碳化法制备晶型碳酸钇的机理和工艺研究

柴周羿1,2,赖安邦1,2,高梦兰1,2,昝苗苗1,2,肖燕飞*1,2

(1. 江西理工大学材料冶金化学学部, 江西 赣州 341000;

2. 赣州市绿色冶金与过程强化工程技术研究中心, 江西 赣州 341000)

摘 要:氧化钇是一种重要的稀土氧化物,广泛应用于多个领域,而碳酸钇作为生产氧化钇的重要前驱体,其对氧化钇的制备和产品性能有重要影响。本文采用CO2碳化法制备晶型碳酸钇,通过XRD、SEM、TEM等方法对碳化过程进行表征,研究了碳酸钇晶体成核生长过程形貌结构演变机制及CO2流速、搅拌转速、YCl3浓度对结晶性能的影响。结果表明:在pH为5.0,体系温度为35 ℃的条件下可获得由大量针状晶体交织成的片状晶型二水碳酸钇,其生长是一个定向附着(OA)和奥斯特瓦尔德熟化(OR)机制并存的过程;在确定温度和pH后,碳化过程搅拌速率、CO2流速及YCl3浓度等对碳酸钇的结晶影响较小。CO2碳化法具有环保、操作简单、条件温和、易于工业化等优点,可为绿色高效制备其它晶型碳酸稀土提供借鉴。

关键词:CO2;碳化;碳酸钇;结晶机理;OA;OR

文章编号:1004.0609.2021-42048 中图分类号:TF845.2 文献标志码:

1 引言

氧化钇拥有极好的耐热性、耐腐蚀性、高温稳定性等物化性质,是一种重要的稀土氧化物,广泛应用于红色荧光粉、催化剂、磁性材料、玻璃着色、陶瓷材料、高温超导材料等领域 [1-5]。碳酸钇作为生产氧化钇的重要前驱体,其对氧化钇的制备和产品性能有重要影响。此外,碳酸钇是稀土元素钇精加工过程和新材料制备中广泛应用的一种中间原料,其易溶于酸、形成相应的盐,可方便地用于各种钇盐和钇配合物的合成。可见,碳酸钇在钇工业中具有重要作用,是高新技术向广度和深度飞速发展不可缺少的钇基化合物。

由于具有精确控制物料化学组成、原料成本低、工艺简单、操作方便等优点,沉淀法被广泛应用于碳酸稀土的工业化生产。目前工业上制备碳酸钇的沉淀剂有碳酸氢铵、碳酸氢钠、碳酸钠等;其中,碳酸氢铵沉淀法具有成本低、产品收率高、无毒性等优点[6];但碳酸氢铵的引入会产生大量氨氮废水,需要花费巨大代价才能将废水处理至达标排放。采用碳酸钠/碳酸氢钠沉淀法替代碳酸氢铵沉淀制备碳酸钇可有效减少环境污染,具有重要的经济和社会意义,是近年来业内共同关注的一个热点,然而碳酸钠或碳酸氢钠沉淀稀土料液,容易形成无定形絮状沉淀,结晶度低[7-9]。为解决这个问题,稀土工作者做了一系列的研究,如焦小燕等[7]对碳酸氢钠沉淀镧的结晶过程进行了研究,得到了碳酸镧结晶活性区域,获得了晶型碳酸镧;王嵩龄等[8]用碳酸钠作沉淀剂,在加晶种的条件下,通过沉淀条件控制,获得了易沉降、易过滤的碳酸镨钕;姜晓丽等[9]采用正加料方式,用碳酸钠作沉淀剂制备出了低钠片状碳酸镧;高习贵等[10]以工业碳酸氢钠作沉淀剂,通过加入晶种及沉淀条件的调控,得到晶型碳酸镨钕;Kozo等[11]分别以碳酸钠和碳酸氢钠为沉淀剂,对稀土碳酸盐的制备和结构进行了研究,阐明了温度对稀土碳酸盐形成影响。高国华等[12]对碳酸钠沉淀法的结晶过程进行研究,在1次晶种循环,80 ℃,pH 5.9~6.0的条件下制得到粒径12 μm且分散性均匀的晶型碳酸钇。贺强等[13]以正加料方式,在碳酸钠流速4.0 mL/min、反应温度15 ℃、LaCl3浓度1.0 mol/L,晶种循环2次的条件下,获得了沉降速度快,晶型良好的碳酸镧;然而,上述方法需要长时间的陈化及添加晶种进行循环沉淀,生产周期长,不利于工业化。

在湿法冶金和材料制备领域,经常使用碳化技术生成可溶性或不溶性的碳酸氢盐或碳酸盐[14-16] ,进而处理获得理想的材料。目前,该技术已经应用于科研与工业化生产,制备获得晶型碳酸钙、碳酸镁等前驱体,进而制备获得高值的超细粉体材料。课题组前期将CO2碳化法引入到碳酸稀土的制备过程[17,18],在25 ℃,pH=5、0.5 mol/L氯化镧、1.0 L/min的CO2流速下制备获得了片状晶型碳酸镧;为了拓宽碳化法制备晶型碳酸稀土的应用范围,同时获得其碳化结晶机理,本文以YCl3料液为原料,通入CO2进行碳化,并缓慢加入氢氧化钠控制体系pH值在4.0~6.0的酸性范围内,以达到类均相沉淀的效果,制备获得晶型碳酸钇,具体反应如下式所示[19]:

式(1)

式(1)

式(2)

式(2)

式(3)

式(3)

式(4)

式(4)

本文详细考察了反应pH及温度对碳化产物晶型的影响,研究碳酸钇晶体成核生长过程形貌结构演变机制。同时,在固定反应温度和pH条件下,考察了CO2流速、搅拌转速、YCl3浓度对碳酸钇结晶的影响,获得晶型碳酸钇制备的最佳工业化条件。CO2碳化法制备晶型碳酸钇具有条件温和、原料价格低廉、易规模化生产等优点,本文的研究拓宽了碳化法制备晶型碳酸稀土的应用范围,为碳化制备不同特殊物性的稀土化合物提供实验基础和理论指导。

2 实验部分

2.1 实验过程

取一定体积的高纯YCl3(99.99%,由虔东稀土集团股份有限公司提供),加入蒸馏水配置成0.1~0.5 mol/L的YCl3溶液500 mL,置于1 L烧杯中;然后向YCl3溶液中以一定流速通入CO2进行碳化反应,并采用蠕动泵泵入0.33~1.67 mol/L的NaOH溶液以稳定控制反应过程pH;采用水浴锅控制反应过程温度,采用搅拌器控制搅拌速度,最终使CO2碳化沉淀反应在一定温度、pH、搅拌速度下进行。反应结束后进行过滤并充分洗涤滤饼,将滤饼在50 ℃真空干燥箱中烘干48 h,获得碳化产物。同时,为了研究碳化过程,在不同碳化时间下取样过滤、洗涤并干燥留样进行分析测试。

2.2 测试方法

采用X射线衍射仪(XRD,Bruker D8,Advance)测定物相,获得样品衍射图谱;采用扫描电子显微镜(SEM, MLA650F,美国FEI公司)及透射电子显微镜(JEM-2100F,TEM,JEM-2100F,日本电子株式会社JEOL)对粉体的微观形貌,团聚状况进行观察。

3 实验结果与讨论

3.1 碳酸钇碳化结晶过程的研究

3.1.1 碳化pH值对碳化产物结晶的影响

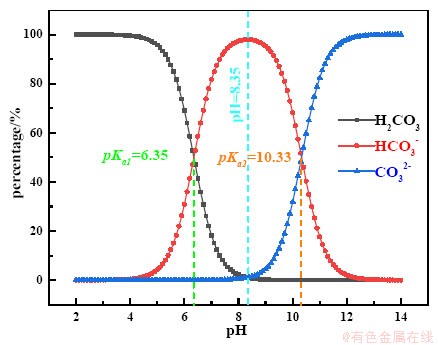

pH是影响碳酸钇过饱和度的重要因素,对碳酸钇的结晶扮演着重要的角色,图1为25 ℃下H2CO3溶液中各种形态分布与pH值的关系曲线(Ka1,Ka2为H2CO3的一级和二级解离常数;pK=-lgK)[20]。结合式(1)-(4)碳化反应方程式可知,当pH过低时溶液中碳酸氢根离子浓度低,导致反应速率过慢增大了反应能耗,而当pH值较高时溶液中的碳酸氢根离子过量,导致反应速度过快,碳酸钇大量成核不利于晶体生长。为达到一个类似均相沉淀的反应过程并探究pH值对碳化产物结晶的影响,控制体系不同pH值进行碳化,并对碳化产物进行XRD、SEM及粒度分析,结果如图2所示。

图1 25 ℃下H2CO3溶液中各种形态分布与pH值的关系曲线

Fig. 1 The relationship between pH value and morphology distribution in H2CO3 solution at 25 ℃

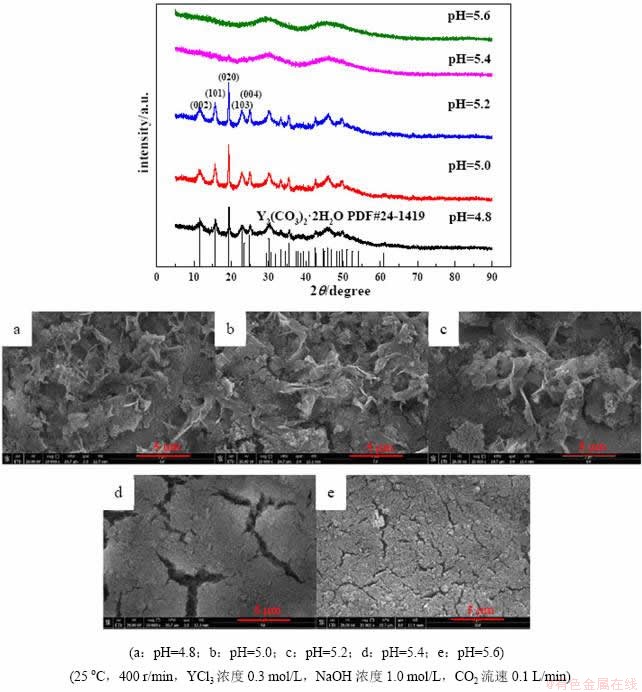

从图2 XRD图谱中可见,当维持pH值于较高水平(pH=5.4、5.6)时,产物为无定型沉淀,这是由于溶液中碳酸氢根离子浓度较高,体系过饱和度较大,碳酸氢根离子迅速与钇离子结合,生成碳酸钇并释放出氢离子,此时需要快速通入氢氧化钠溶液以保持溶液pH值稳定,而氢氧化钠溶液的加入将更快的促进碳酸氢根的生成,使反应形成链式循环。此时,碳酸钇成核速率远大于生长速率,将产生大量无定型的细小颗粒,进而团聚形成无定型沉淀,导致沉淀产物的XRD衍射峰不明显。而当pH值较低时,体系过饱和度较小,碳酸钇的成核速率远远小于生长速率,可达到类似于均相沉淀的效果,从而获得晶型碳酸钇。当pH值为4.8、5.0和5.2时,沉淀产物衍射峰强度较小,宽度较大,特征峰与Y2(CO3)3·2H2O标准卡片(PDF-24-1419)相吻合,说明形成了部分晶型碳酸钇。

图2d、e中碳化产物SEM图中可以明显看到,当pH为5.4和5.6的较高值时,产生大量无定型纳米颗粒,此时产物为大量小颗粒团聚而成的块状物,块状物存在裂纹,这与XRD分析结果一致。而从图2a、b、c(当pH值为4.8、5.0及5.2时)中可见,碳化产物已经产生部分片状晶体,但依旧存在着部分无定型纳米颗粒附着于片状晶体之上。综合分析碳化产物晶型以及碳化过程pH控制稳定性来考虑,pH=5.0为较合适的碳化pH值。

图2 不同pH值下碳化产物XRD及SEM

Fig. 2 XRD and SEM of carbonization products at different pH values

3.1.2 碳化温度对碳化产物晶型的影响

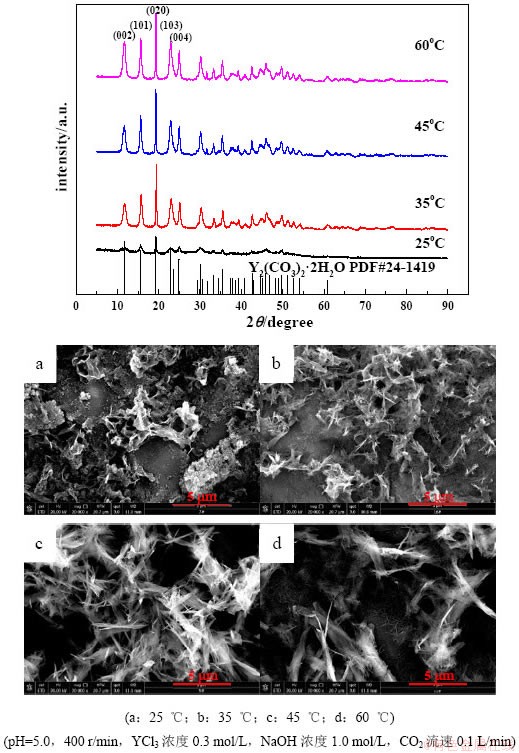

温度对CO2的溶解、扩散及碳酸钇的溶解度也有很重要的影响,为此考察了不同碳化温度对碳化产物晶型的影响,并对获得的碳化产物进行XRD、SEM分析,结果如图3所示。

从图3碳化产物的XRD图谱可见,随着温度升高,产物的XRD衍射峰不断增强,说明碳化产物结晶度提高,且表现出(020)晶面取向生长的特性,这与文献[21]报道的水菱钇型晶状碳酸钇特性相吻合。这是因为低温下碳酸水溶液的过饱和度大,有利于晶体成核,而高温下其过饱和度低有利于晶体取向长大。而且温度越高,所提供结晶所需的能量就越高,碳化产物越容易克服晶体表面的能垒而朝着优势晶面生长。从图3可见,25 ℃碳化所得产物衍射峰强较弱,结晶转化不完全;当温度上升到35 ℃时,碳化产物特征峰明显,且峰窄而高,结晶度明显提高,继续提高温度到45 ℃、60 ℃,碳化产物衍射主峰强度无明显变化,其余衍射峰略有增强,说明继续升高温度碳化产物表现出其他晶面的取向生长特性。

从图3中SEM可以清晰的看到,25 ℃时为少量片状晶体和大量无定型纳米颗粒团聚体,团聚体颗粒较大。随着温度升高到35 ℃,无定型纳米颗粒消失,碳化产物形成由大量针状晶体交织而成的片状微结构,而当温度升高到45、60 ℃,碳化产物表现由一维生长转变为二维生长特性,针片状晶体颗粒明显变大。结合XRD图谱的衍射峰强度,综合考虑CO2利用率、能耗等因素,选择35 o℃为较为合适的碳化结晶温度,以期获得晶型较好的碳酸钇晶体。

图3 不同温度碳化产物XRD及SEM

Fig. 3 XRD and SEM of carbonization products at different temperature

3.1.3 碳化产物碳化结晶机理的研究

(1)碳化过程碳化产物结晶生长的变化规律

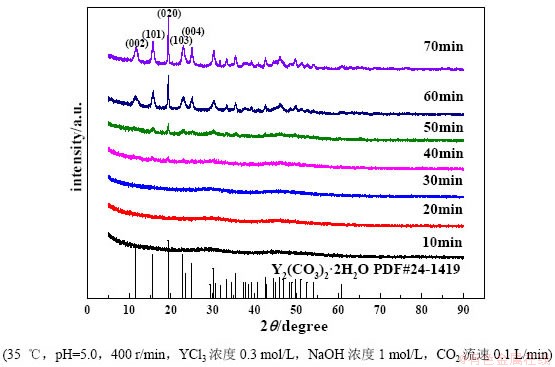

上述研究表明在35 ℃,pH=5.0的条件下获得了结晶较好的碳酸钇,为明晰碳化过程中碳化产物物相及形貌的变化规律和机理,实验在35 ℃,pH=5.0的条件下对不同时间碳化产物进行了XRD、SEM及TEM等分析。

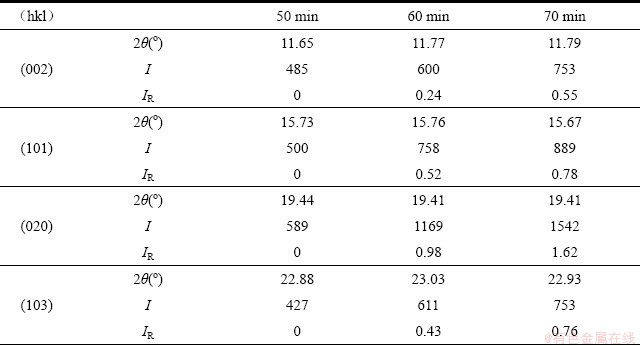

图4为不同时间段碳化产物的XRD图谱,从图4中可见,随着碳化时间的延长,碳化产物的衍射峰强度也不断增大,碳化到50 min时表现出(020)晶面取向生长的特征,到70 min时碳化沉淀反应结束获得结晶度较高的水菱钇型碳酸钇。表1对比了不同碳化时间下所得碳化产物不同晶面所对应的衍射强度(其中IR为相对强度,It0为初始衍射强度,It为t时刻衍射强度)。结果表明:(020)晶面的衍射强度最大且增加最为明显,由此可得,随着碳化时间的延长可明显提高碳酸钇的结晶性,且更加有利于晶型碳酸钇沿着b轴生长。从表1中不同晶面相对衍射强度IR值变化可以看出,不同晶面的相对衍射强度变化有如下顺序:(020)>(101)>(103)> (002),分别为162%、78%、76%、55%。可见,在碳化过程中碳酸钇晶体各个晶面的生长速度的次序如下:b轴>a轴>c轴[22]。

图4 碳化过程XRD变化

Fig. 4 XRD changes during carbonization process

表1 不同时间各晶面衍射峰强度变化(相对强度IR=(It-It0)/It0)

Table 1 Variation of diffraction intensity of each crystal plane at different time (relative intensity IR=(It-It0)/It0)

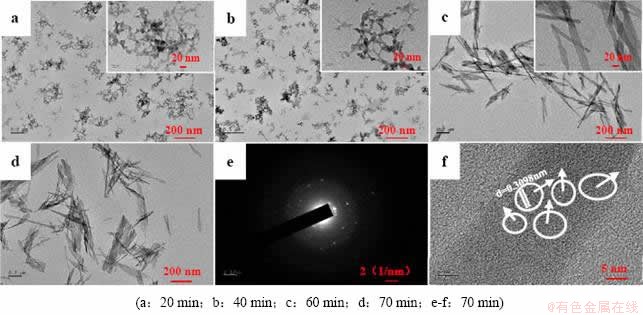

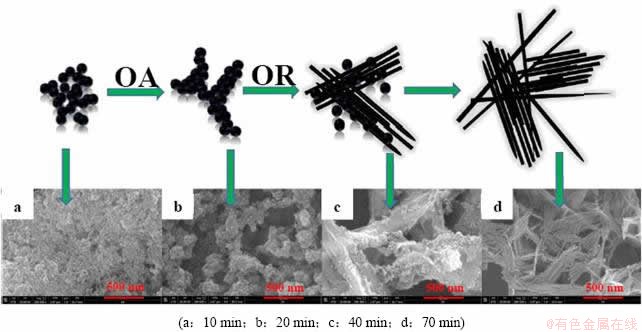

为明确碳酸钇沉淀的晶体生长过程,取不同碳化时间的产物进行SEM测试,结果如图5所示。由图5a-c可知,随碳化时间的延长,碳酸钇由大量类球形纳米颗粒形成的大块团聚体向珊瑚块状聚集体发生转变,到t=40 min时沉淀向针片状转变,但此时依旧存在着大量纳米颗粒附着于表面,对比此时的XRD图谱,可知此时沉淀为无定型;碳化到60-70 min沉淀反应结束,XRD图显示此时沉淀物已经从无定型转变为水菱钇型碳酸钇。如图5d、5e所示,此时沉淀呈现大量长条针状组成的片状堆叠结构,与XRD分析中沿着(020)晶面生长即b轴生长相符。

图5 碳化过程SEM变化

Fig. 5 SEM changes during carbonization

为了更加清晰直观的了解碳化过程晶型的变化,对碳化不同阶段所得碳化产物进行TEM分析,结果如图6所示。由图5a可知,碳化前期t≤20 min时,溶液过饱和度的形成导致大量纳米颗粒的形成,其表面能量太高趋于团聚。随着碳化时间的延长至40 min,碳化沉淀形成的类球形纳米粒子通过自组装连接而成如图6b所示的网状结构和少量小片状晶型结构;而当碳化到60 min时,碳化产物形貌变为图6c所示分散性较好的纳米线状结构;碳化结束,得图6d所示的由针状晶体拼接而成的片状结构,与图5中对应时间SEM图有较好的一致性。从图6e和6f的斑点衍射和晶格条纹图可以看出,拼接片状结构碳酸钇对应的针状晶体宽度在10-20 nm之间,其针状结构为许多取向不一致的5-10 nm左右的纳米晶自组装而成。

图6 碳化过程TEM变化

Fig. 6 TEM changes during carbonization

(2)碳化产物结晶生长机制

通常人们以表面溶解沉积为特征的奥斯特瓦尔德熟化(OR)理论来解释传统的晶体生长过程,但是随着人们对纳米材料研究的不断深入,越来越多的研究发现,当材料的粒径较小时,其生长方式无法用 OR 机制来解释,于是人们提出定向附着(OA)机制用于解释许多各向异性纳米结构的生长[23]。基于OA和OR机制的原理,本文根据不同阶段碳化产物物相和形貌变化,提出了由纳米颗粒通过自组装而成碳酸钇纳米线团聚体的形成机制,如图7所示;在整个碳化过程时,碳酸钇晶体生长是一个OA和OR机制并存的过程,OA使得纳米粒子重排形成新的晶体,OR促使小颗粒溶解,并附着于新生成的晶体表面生长,从而使得界面融合[24-26]。碳化初期t≤20 min时,由于碳酸钇的过饱和度较大,会沉淀生成大量的碳酸钇纳米颗粒,这些颗粒处于一种无序的动力学控制的亚稳状态,表面积大,表面电荷也高,为减小表面能,颗粒倾向于团聚在一起,形成如图5a所示的纳米粒子团聚物,产物呈现无定形结晶。随着碳化进行到40 min时纳米粒子在搅拌作用下剧烈运动并相互碰撞,此时OA生长机制占主导地位,两个晶格取向一致的无定型纳米颗粒可通过直接接合和结构调整,从而长成一个新的晶体。图6b的TEM所示由纳米粒子连接而成的网状结构和少量小片状结构晶体,从SEM图5c中看到的少量晶型沉淀和尚未融合的纳米颗粒以及图6f所示纳米线为许多5-10 nm左右粒子拼接而成的现象都证明了碳化过程中碳化产物在OA机制下的生长过程。

图7 碳化过程结晶生长机制示意图

Fig. 7 Schematic diagram of crystallization growth mechanism during carbonization

随着碳化时间的继续延长,纳米粒子取向连接的同时也发生着由无定型沉淀转化为晶型沉淀的过程,此阶段OR熟化机制起了重要作用。在这个过程中,由于晶体表面离子的扩散和重新分配,会使颗粒表面的构晶离子的离子积稍大于其离子积常数 ksp,这为构晶离子的有序堆积成核创造了极好的条件[22,24]。此时无定型纳米颗粒有序化重组,其驱动力来源于亚稳态小颗粒与有序大颗粒之间的表面能差值,小颗粒不断溶解减小,溶解的离子扩散沉积到大颗粒上使其长大重结晶,这一过程是个慢过程,是整个结晶过程的速度控制步骤[21,27]。

当有序晶核形成后,溶液中碳化产物的溶解再结晶过程一般都比较快,当碳化到t=60-70 min时,纳米粒子连接而成的网状结构不平整界面已经完全融合,形成如上述图6c、6d分析所示结晶较好的碳酸钇。由于OR生长机制是通过原子或离子沉积的方式长大的,因而得到的晶体形貌一般比较规整,晶体边缘比较光滑,这与上述TEM图6a、6b、6c观察到随着碳化进行由颗粒边界明显的网状转变为表面光滑平整的纳米线状晶体的过程相符合。

3.2 CO2碳化制备晶型碳酸钇工艺探索

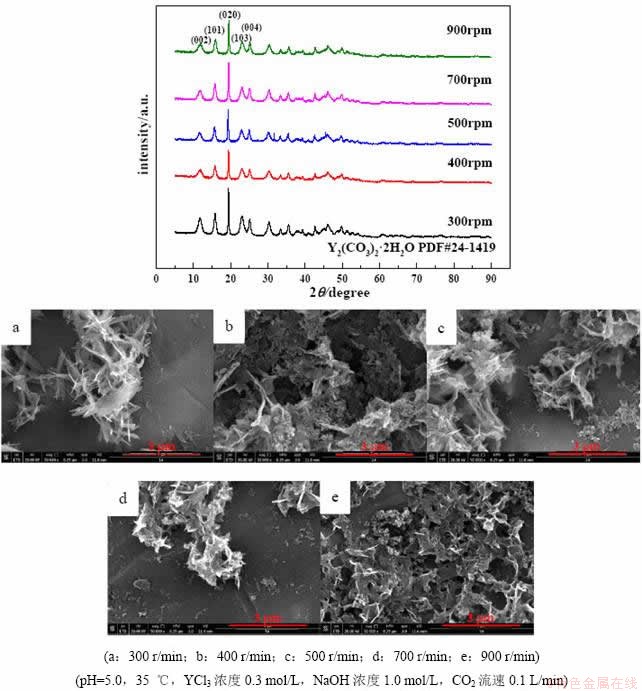

3.2.1 搅拌速度对碳酸钇结晶的影响

在沉淀结晶过程中,当扩散是沉淀反应速度控制环节时,可以借助搅拌来加快化学反应,同时破坏晶粒的团聚现象,使得晶粒更小更均匀。因此改变搅拌速度进行了碳化实验,并对产物进行XRD及SEM测试,结果如图8所示。由图8可知不同搅拌速度下的产物衍射峰强度相差较小,均存在明显的衍射峰,且其衍射峰强度变化不大。通过SEM图可知不同转速下的产物均为针片状晶型碳酸钇。而当转速过高时,由于搅拌桨剪切力过大,生成的晶体被破坏从而导致其形貌与其余各组存在一定的差异,但其依旧为晶型碳酸钇。可见,在CO2碳化法制备晶型碳酸钇的过程中,搅拌转速的影响较小。

图8 不同搅拌速度碳化制备碳酸钇XRD及SEM

Fig. 8 XRD and SEM of yttrium carbonate prepared by carbonization at different stirring speed

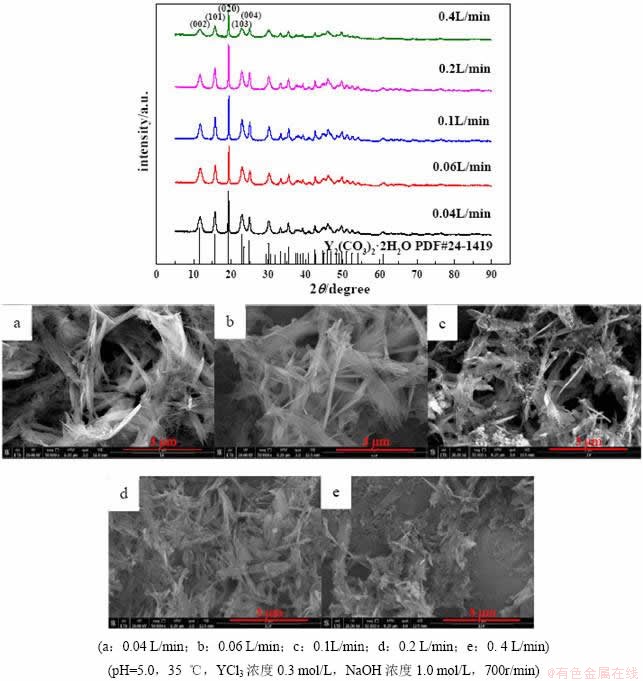

3.2.2 CO2流速对碳酸钇结晶的影响

CO2流速影响其利用率和沉淀速率,也是晶型沉淀的一个关键因素。实验控制不同CO2 流速进行了实验,对产物进行XRD及SEM测试。从图9所示XRD图谱中观察到,不同流速下的碳酸钇均有明显的衍射峰存在。当CO2流速达到0.4 L/min时,碳酸钇的衍射峰强度出现减弱,出现这一现象归因于体系过饱和度的变化;CO2流速较小时反应速率慢,碳化时间长,体系过饱和度小,碳酸钇晶体形核后在小的过饱和度下经历长时间慢慢长大,有利于碳酸钇晶体的生长,但反应时间过长。当CO2流速偏大,沉淀过程容易爆发成核,造成沉淀产物的非晶化。通过SEM图可知不同CO2流速下制备的碳酸钇晶体所得产物为针片状,但当流速过高时出现少量无定形纳米颗粒团聚,该现象的出现与XRD分析的爆发二次形核产生部分无定型纳米粒子团聚有良好的一致性。可见,碳化过程中CO2流速不宜过大,以防止爆发二次形核产生部分无定型纳米粒子团聚。

图9 不同CO2流速碳化制备碳酸钇XRD及SEM

Fig. 9 XRD and SEM of yttrium carbonate prepared by carbonization at different CO2 flow rate

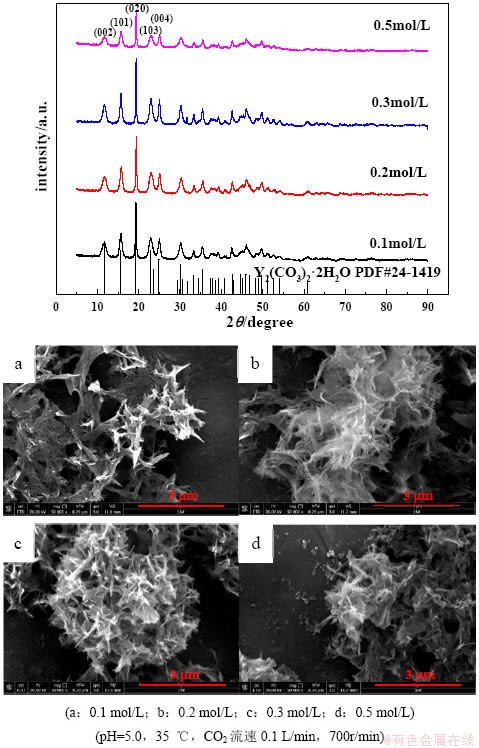

3.2.3 YCl3浓度对碳酸钇结晶的影响

YCl3浓度直接影响碳化沉淀反应速度及晶粒成核和生长速度,如果YCl3浓度较高,体系的过饱和度大,则有利于晶体成核;如果YCl3浓度较低,过饱和度较小,则有利于晶体的生长。为探究YCl3浓度对碳酸钇结晶的影响,改变YCl3浓度(氢氧化钠浓度是YCl3浓度的3.33倍)进行实验,对产物进行XRD及SEM测试结果如图10所示,由图10可知各组产物均存在明显的衍射峰,说明在不同浓度的YCl3溶液中碳酸钇均可得到良好的结晶。浓度为0.5 mol/L时衍射峰强度出现下降的现象,该现象的出现是由于此时YCl3浓度过高,导致搅拌不充分而导致部分晶粒出现黏聚现象形成无定形团聚体。通过SEM图可知高浓度YCl3条件下大部分碳酸钇呈现针片状结晶,而少部分无定形碳酸钇颗粒发生团聚,其结果与XRD测试结果有较好的一致性。因此YCl3浓度对碳酸钇的结晶过程无较大影响。结合搅拌速度及CO2 流速实验可知,在工业生产中以CO2碳化法在高浓度YCl3进行反应时可以通过加大搅拌速度与CO2 流速制备出性能优良的针片状晶型碳酸钇。

图10 不同YCl3浓度碳化制备碳酸钇XRD及SEM

Fig. 10 XRD and SEM of yttrium carbonate prepared by carbonization at different YCl3 concentration

4 结论

1) CO2碳化沉淀YCl3溶液的过程与体系pH、温度有很密切的联系。在YCl3浓度为0.3 mol/L,碳化pH为5.0,体系温度为35 ℃的条件,通过CO2碳化法可沉淀获得由大量针状晶体交织成的片状结晶,该晶体的化学组分为Y2(CO3)2·2H2O。

2) 碳化结晶是一个定向附着OA主导的纳米粒子定向连接和奥斯特瓦尔德熟化OR机制主导的无定型沉淀转化为晶型沉淀及粒子界面融合过程并存的过程,最终形成针片状结构晶体。

3) 碳化过程搅拌速度、CO2流速及YCl3浓度对碳酸钇的结晶影响较小,仅在高YCl3浓度和CO2流速下,碳酸钇的结晶度会略有降低。CO2碳化工艺制备晶型碳酸钇,具有能耗低,原料来源广泛,工艺简单可控等优点,应用潜力巨大。

REFERENCES

[1] Wakefield G, Holland E, Dobson P J, et al. Luminescence Properties of Nanocrystalline Y2O3:Eu3+[J]. Advanced Materials, 2001, 13(20):1557-1560.

[2] WU Yang, CHEN Jian-jun, DENG Jie, et al. Mesoporous yttria-zirconia solid solution with improved textural properties prepared via lauric acid-assisted synthesis[J]. Ceramics International, 2020, 46(16):25211-25219.

[3] 刘志强, 梁振锋, 李杏英. 纳米氧化钇的制备及表征[J]. 矿冶工程, 2006, 26(3):78-80.

LIU Zhi-qiang, LIANG Zhen-feng, LI Xing-ying. Prepararion and characterization od nanometer yttrium oxide[J]. Mining and Metallurical Engineering, 2006, 26(3):78-80.

[4] Lemeshev D O, Lukin E S, Makarov N A, et al. Prospects for creating new optically transparent materials with yttrium oxide and yttrium aluminum garnet (review)[J]. Glass and Ceramics, 2008, 65(3):128-130.

[5] 梁晓宇, 李海涛, 翟蕾, 等. 高温超导带材制备工艺的发展现状[J]. 低温与超导, 2019, (8):1-9.

LIANG Xiao-yu, LI Hai-tao, ZHAI Lei, et al. The present situation of the preparation process for high-temperature superconducting tapes[J]. Cryo. &Supercond, 2019, 47(8):1-9

[6] 熊晓柏, 刘铃声, 李明东, 等. 沉淀法制备纳米稀土氧化物的研究现状[J]. 稀土, 2013, 34(2):81-86.

XIONG Xiao-bai, LIU Ling-sheng, LI Ming-dong,et al. Status in Study of Nanometer Rare Earth Oxides Prepared by Precipitation Methods[J]. Chinese Rare Earths,2013, 34(2):81-86

[7] 焦小燕, 罗贤满, 杨宇俊, 等. 碳酸氢钠沉淀镧及碳酸镧的结晶过程研究[J]. 稀有金属与硬质合金, 2001, 000(002):4-8.

JIAO Xiao-yan, LUO Xian-man, YANG Yu-jun, et al. Study of Crystallization Process during La and La2(CO3)3 Precipitation with Sodium Bicarbonate[J]. Rare Metals & Cemented Carbides, 2001, (02):4-8.

[8] 王嵩龄, 刘艳, 程福祥, 等. 碳酸钠作沉淀剂制备碳酸稀土的研究[J]. 矿冶, 2015, 24(02):44-46.

WANG Song-ling, LIU Yan, CHENG Fu-xiang, et al. A study on preparation of rare earth carbonates using sodium carbonate[J]. Mining and Metallurgy, 2015, 24(02):44-46.

[9] 姜晓丽, 陈建博, 国树山, 等. 用碳酸钠作沉淀剂制备低钠碳酸镧[J]. 稀土, 2015, 36(6):118-122.

JIANG Xiao-li, CHEN Jian-bo, GUO Shu-shan, et al. Preparation of low sodium lanthanum carbonate with precipitant of sodium carbonate[J]. Chinese Rare Earths, 2015, 36(6):118-122.

[10] 高习贵, 孙明华, 孙明霞, 等. 正交试验法优选碳酸氢钠制备碳酸镨钕的研究[J]. 中国资源综合利用, 2019, 37(5):17-19.

GAO Xi-gui, SUN Ming-hua, SUN Ming-xia, et al. Study on preparation of barium carbonate by orthogonal test method and sodium bicarbonate[J]. China Resources Comprehensive Utilization2019, 37(5):17-19.

[11] Nagashima K, Wakita H, Mochizuki A. The Synthesis of Crystalline Rare Earth Carbonates[J]. Bulletin of the Chemical Society of Japan, 1973, 46(1):152-156.

[12] 高国华, 赖安邦, 周小芳, 等. 碳酸钇沉淀结晶过程及其影响因素[J]. 中国有色金属学报, 2020, 259(10):217-234.

GAO Guo-hua, LAI An-bang, ZHOU Xiao-fang, et al. Precipitation crystallization process of yttrium carbonate and its influencing factors[J]. The Chinese Journal of Nonferrous Metals, 2020, 259(10):217-234

[13] 贺强, 赖安邦, 高国华, 等. 碳酸钠沉淀制备晶型碳酸镧的研究[J]. 稀土, 2020, 41(06):21-30.

HE Qiang, LAI An-bang, GAO Guo-hua, et al. Preparation of Crystalline Lanthanum Carbonate by Sodium Carbonate Precipitation[J]. Chinese Rare Earths, 2020, 41(06):21-30.

[14] Jun-Hwan Bang, Jang Young-Nam , Kim Won-baek, et al. Specific surface area and particle size of calcium carbonate precipitated by carbon dioxide microbubbles[J]. Chemical Engineering Journal, 2012, 198-199(1):254-260.

[15] Fricker K J, Park A H A. Effect of H2O on Mg(OH)2 carbonation pathways for combined CO2 capture and storage[J]. Chemical Engineering Science, 2013, 100(30):332-341.

[16] 伊文涛, 闰春燕, 马培华, 等. 碳酸锂碳化三相反应动力学研究[J].化学工程, 2008, 36(1):37-40.

YI Wen-tao, YAN Chun-yan, MA Pei-hua, et al. Kinetic study on direct carbonation of Li2CO3 slurries by CO2[J]. Chemical Engineering (China), 2008, 36(1):37-40

[17] 肖燕飞, 王猛, 冯宗玉, 等. 二氧化碳碳化法制备氧化镧粉体研究[J]. 中国稀土学报, 2014, 32(02):197-204.

XIAO Yan-fei, WANG Meng, FENG Zong-yu, et al. Preparation of Lanthanum Oxide Powder by Carbonation with Carbon Dioxide[J].Journal of the Chinese Rare Earth Society,, 2014, 32(02):197-204.

[18] LAI An-bang, HE Qiang, RAO Ming-lu, et al. Synthesis of highly uniform ceria nanosheets by carbon dioxide carbonization and their growth mechanism[J]. Journal of Solid State Chemistry, 2020, 290(9):121593.

[19] Konishi Y, Noda Y. Precipitation Stripping of Rare-Earth Carbonate Powders from Rare-Earth-Loaded Carboxylate Solutions Using Carbon Dioxide and Water[J]. Industrial & Engineering Chemistry Research, 2001, 40(8):1793-1797.

[20] 闫志为, 刘辉利, 陶宗涛. 温度对水中碳酸平衡的影响浅析[J]. 中国岩溶, 2011, 30(002):128-131.

YAN Zhi-wei, LIU Hui-li, TAO Zong-tao. Temperature effect on carbonic acid balance in water[J].Carsologica Sinica, 2011, 30(02):128-131

[21] 朱伟, 邱东兴, 裴浩宇, 等. Y2(CO3)3的沉淀结晶过程与晶粒大小控制[J]. 中国稀土学报, 2016, 34(2):180-188.

ZHU Wei, QIU Dong-xing, PEI Hao-yu, et al. Precipitation Crystallization Process of Yttrium Carbonate and Size Controlling Synthesis of Ytterium Oxide Particles[J].Journal of the Chinese Society of Rare Earths, 2016, 34(2):180-188

[22] 黄婷. 碳酸钇、碳酸钕的结晶及相关技术研究[D]. 南昌大学, 2005.

HUANG Ting. Research on the Crystallization and Related Technology of Yttrium Carbonate and Neodymium Carbonate[D].Nanchang: Nanchang University,2005.

[23] Penn R L, Banfield J F. Imperfect Oriented Attachment: Dislocation Generation in Defect-Free Nanocrystals[J]. Science, 1998, 281(5379):969-971.

[24] 薛小刚, 黄丰, 林璋. 纳米晶取向接合生长动力学研究及其在量子点发光性质调控中的应用[J].中国科学(化学), 2012, 42(11):1554-1575.

XUE Xiao-gang, HUANG Feng, LING Zhang. Oriented attachment crystal growth kinetics and its roles in tailoring optical properties of quantum dots[J]. SCIENTIA SINICA Chimica,2012, 42(11):1554-1575.

[25] LI Jing, ZENG Hua-chun . Hollowing Sn-doped TiO2 nanospheres via ostwald ripening.[J]. Journal of the American Chemical Society, 2007, 129(51):15839-47.

[26] Greer H F, 于丰娇, 周午纵. 非传统晶体生长的早期观察[J]. 中国科学:化学, 2012, 42(1):74-83.

GREER Heather F, YU Feng-jiao, ZHOU Wu-zong.Early stages of non-classic crystal growth[J].SCIENTIA SINICA Chimica,2012, 42(1):74-83.

[27] 李永绣, 黎敏, 何小彬, 等. 碳酸稀土的沉淀与结晶过程[J]. 中国有色金属学报, 1999, 9(1):165-165.

LI Yong-xiu, LI Min, HE Xiao-bing, et al. Predipitation and crystallization process of rare earth carbonate[J].The Chinese Journal of Nonferrous Metals, 1999, 9(1):165-165.

Study on the mechanism and technology of preparing crystalline yttrium carbonate by CO2 carbonization

CHAI Zhou-yi1,2,LAI An-bang1,2,GAO Meng-lan1,2,ZAN Miao-miao1,2,XIAO Yan-fei*1,2

(1. Faculty of Materials Metallurgy and Chemistry, Jiangxi University of Science and Technology, Ganzhou 341000, Jiangxi, China;

(2. 2. Ganzhou Engineering Technology Research Center of Green Metallurgy and Process Intensification, Ganzhou 341000, Jiangxi, China)

Abstract: Yttrium oxide is an important rare earth oxide, which is widely used in many fields, and yttrium carbonate, as an important precursor for the production of yttrium oxide, has an important influence on the preparation and product performance of yttrium oxide. In this paper, CO2 carbonization method is used to prepare crystalline yttrium carbonate, and the carbonization process is explored by XRD, SEM, TEM. The morphology and structure evolution mechanism of yttrium carbonate crystal nucleation and growth process and the effects of CO2 flow rate, stirring speed, and YCl3 concentration on the crystallization performance were studied. The results show that a large number of needle-like crystals intertwined flake crystal yttrium carbonate dihydrate can be obtained under the conditions of pH 5.0 and system temperature of 35 ℃, and its growth is a coexistence process of Oriented attachment (OA) and Ostwald ripening (OR) mechanisms. Moreover, after determining the temperature and pH, the stirring rate, CO2 flow rate and the concentration of YCl3 during the carbonization process have little effect on the crystallization of yttrium carbonate. The CO2 carbonization method has the advantages of environmental protection, simple operation, mild conditions, easy industrialization, etc., which can provide a reference for the green and efficient preparation of other crystalline rare earth carbonates.

Key words: CO2; carbonization; yttrium carbonate; crystallization mechanism; OA; OR

Foundation item:National Natural Science Foundation of China(51964018); Natural Science Foundation of Jiangxi province (20202ACB214003); Double Thousand Plan in Jiangxi Province(jxsq2019201116); The YouthJinggang Scholars Program in Jiangxi Province(QNJG2019056);the cultivation project of the State Key Laboratory of GreenDevelopment and High-value Utilization of Ionic Rare EarthResources in Jiangxi Province (20194AFD44003)

Received date: 2021-07-15

Corresponding author:XIAO Yan-fei; Tell: 18379727723;E-mail: xiaoyanfei0906@163.com;

基金项目:国家自然科学基金项目(51964018);江西省青年科学基金项目(20202ACB214003)江西省“双千计划”科技创新高端人才(青年)项目(jxsq2019201116);江西省青年井冈学者奖励计划(QNJG2019056);江西省离子型稀土资源绿色开发与高值利用国家重点实验室培育计划(20194AFD44003)

收稿日期:2021-07-15

通信作者:肖燕飞 (1988-),副教授,博士;电话:18379727723;E-mail: xiaoyanfei0906@163.com