文章编号:1004-0609(2016)-08-1597-10

Mg-5Zn-1Mn合金高应变速率热压缩过程中的组织演变和流变行为

陈 潮1, 2,严红革1, 2,陈吉华1, 2,夏伟军1, 2,苏 斌1, 2,曹梦馨1,宋 旼3

(1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 湖南大学 喷射沉积技术及应用湖南省重点实验室,长沙 410082;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用Gleeble-3500热模拟试验机对Mg-5Zn-1Mn镁合金进行大变形(变形量为80%)热压缩实验,研究变形温度为250~400 ℃、应变速率为1~40 s-1范围内变形过程中合金的组织演变规律和流变行为。结果表明:该合金在上述工艺条件下进行热压缩变形时均发生了明显的动态再结晶,且高应变速率下获得的再结晶组织在较低应变速率下更为均匀、细小。通过分析流变应力变化过程中对应的微观机理,表明高应变速率更利于Mg-5Zn-1Mn镁合金实现大塑性变形。Mg-5Zn-1Mn合金的变形激活能随着变形温度的升高和应变速率的增大而减小。

关键词:Mg-5Zn-1Mn合金;流变行为;高应变速率;激活能

中图分类号:TG146.2 文献标志码:A

金属镁及其合金是迄今在工程中应用最轻的结构材料,具有较高的比强度和比刚度,阻尼性能及屏蔽性能好,在电子、汽车、航空航天等领域均有着较为广泛的应用前景,因此有“21世纪绿色工程金属结构材料”的美誉[1-3]。但由于镁的密排六方(HCP)晶体结构,滑移系较少,使其在常温下的变形能力较差,因而很大程度上限制了镁合金的应用[4-5]。通过细化镁 合金晶粒可以改善材料的组织和性能,使其获得优良的室温成形能力。目前,细化晶粒主要通过在熔炼过程中添加合金元素和热加过程中的动态再结晶两种方法来实现,其中研究较为广泛、有效的手段是通过大塑性变形[6-9]。然而,通过大塑性变形实现镁合金晶粒的细化,加工工艺的选择至关重要,热压缩变形则是研究变形温度和应变速率对合金流变行为和组织演变规律的有效手段。

Mg-Zn系镁合金具有较高的强度和良好的承载能力,其中,Mg-Zn-Mn系合金具备可时效强化、加工性能优异、耐蚀性能较好且不含Zr等贵金属元素的优点,已成为近年来研究及开发的重点。目前,该合金系研究较为成熟的牌号是ZM21(Mg-2Zn-1Mn),但存在因锌含量低而力学性能不高的缺点。因此,增加Zn含量是提高Mg-Zn-Mn系镁合金强度的重要途径之一。最早,PARK等[10]采用双辊铸轧工艺制备了Al合金化的ZM61 (Mg-6Zn-1Mn)合金,通过添加Al可细化晶粒并形成细小、弥散的Al8Mn5颗粒,经固溶+双级时效后,该合金的抗拉强度高达360 MPa。近年来,QI等[11]对ZM61合金进行大挤压比挤压和固溶+双级时效(T6)处理,其抗拉强度高达366 MPa,随后对ZM61合金添加Sn[12]及Sn+稀土RE[13-14]复合添加后进行挤压+T6处理,最终获得抗拉强度接近400 MPa的高强力学性能。但该系列镁合金由于合金化程度较高及经T6处理后晶粒尺寸长大,从而导致室温塑性均较差。

由于ZM61镁合金中Zn含量高达6%,使得该合金在铸造过程中的热裂倾向较严重,易形成缩孔、缩松等缺陷,故该合金不适于大塑性变形细化晶粒。目前,国内外对高锌Mg-Zn-Mn系镁合金的研究主要集中在合金化和热处理工艺优化等方面。有关高锌Mg-Zn-Mn系合金热加工变形行为的研究较少且主要集中在较低应变速率下(0.001~10 s-1)[15-16],其高应变速率下(10~40 s-1)的热变形行为研究尚未见报道。因此,本文作者选用Zn含量相对较低的Mg-5Zn-1Mn(ZM51)合金为研究对象,通过对均匀化态ZM51合金在高应变速率热压缩变形过程中的流变行为和微观组织进行研究,从而为实现大塑性变形,有效控制晶粒尺寸,制定合理的热加工工艺提供实验依据。

1 实验

本实验中选用经(330 ℃, 24 h)+(400 ℃, 2 h)均匀化处理后的Mg-5Zn-1Mn坯料(ZM51,Mg-5%Zn- 1%Mn,质量分数),线切割后获得d 8 mm×12 mm圆柱形热压缩试样。热压缩实验 在Gleeble-3500型热模拟试验机上进行。热压缩实验前,在试样两端涂敷石墨和机油作为润滑剂,从而减小试样与压头之间的摩擦力。为研究变形温度和应变速率对合金流变行为的影响,变形量控制为80%,对应真应变为1.61;选用4个变形温度(250、300、350和400 ℃)和5个应变速率(1、10、20、30和40 s-1)进行热压缩实验。试样加热速率为200 ℃/min,升温至设定温度后保温3 min,保证试样压缩时温度均匀。试样热压缩变形至预定尺寸后立即水冷,以保留热变形结束时的显微组织。根据计算机在变形过程中所采集的力-位移数据获得真应力-真应变曲线,选取曲线的相关拐点参数进行压缩实验,用以研究其组织演变规律。垂直于压缩方向取样制备金相样品,经过饱和苦味酸溶液(0.8 g苦味酸+2 mL乙酸+3 mL水+20 mL酒精)浸蚀后在Leitz MM-6型卧式金相显微镜上进行组织观察。采用截线法统计动态再结晶区域的晶粒尺寸,每个样品统计晶粒数不少于120个。使用Image-Pro Plus软件选区分析动态再结晶区域的面积分数以表征再结晶体积分数。

2 结果与分析

2.1 流变行为分析

Mg-5Zn-1Mn合金在不同温度和不同应变速率下的真应力-真应变曲线如图1所示。由图1可见,在所有的热压缩变形条件下,合金的流变应力均呈现出明显的动态再结晶曲线特征。其真应力均随着变形的进行先迅速增大,达到一定峰值后又逐渐减小,并趋于稳定,出现一个平台;当真应变继续增大时,真应力再次上升。当变形温度一定时,如图1(a)所示,峰值应力随着应变速率的增加而增大;值得注意的是,应变速率高于10 s-1时,峰值应力相差不大,但明显高于应变速率为1 s-1时的峰值应力。这是由于在较低应变速率下变形时,合金中产生位错的速度较慢,有足够的时间促使各滑移系协调位错滑移的进行。然而,在较高应变速率条件下变形时,合金会在较短的时间内产生大量的位错塞积,从而导致位错滑移响应时间短,加工硬化效应加剧。当应变速率一定时,如图1(b)所示,其真应力随着温度的升高而明显降低。这是由于随着温度的升高,ZM51镁合金中启动的滑移系增多且原子热运动能力增强,进而位错运动的晶格阻力减小,有利于塑性变形,导致位错塞积效应相对减弱,从而变形抗力有所降低。

图1 ZM51镁合金在不同条件下的真应力-真应变曲线

Fig. 1 True stress-true strain curves of ZM51 hot compressed at different temperatures and strain rates

2.2 显微组织分析

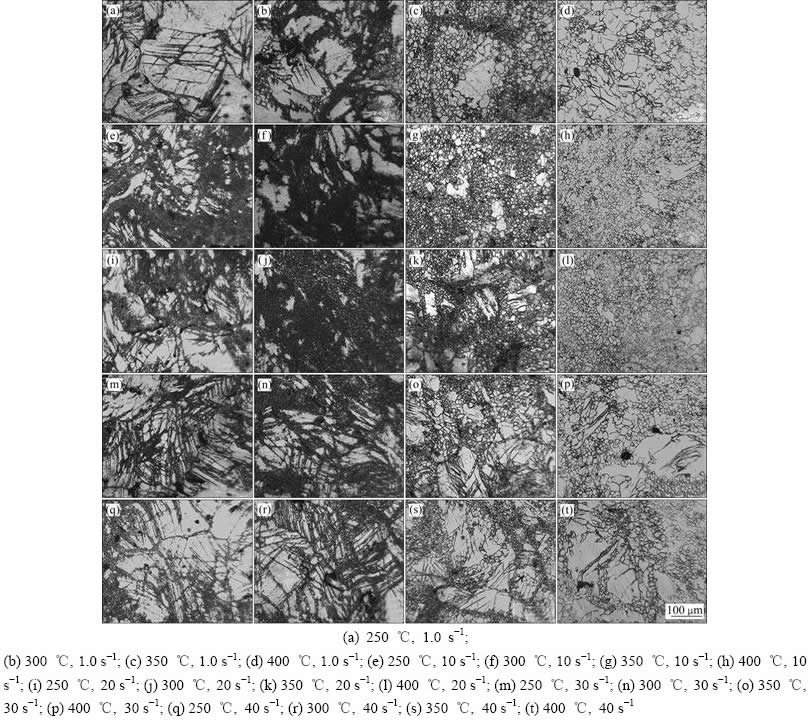

由图1可见,ZM51镁合金在上述热压缩变形条件下均发生了较为强烈的动态再结晶,其组织演变主要受变形温度和应变速率的影响。ZM51镁合金在不同应变速率和变形温度下热压缩后的金相组织如图2所示。在应变速率较低(1 s-1)和较低温度(250 ℃)时,动态再结晶晶粒在原始晶界处呈链状分布,并随温度的升高(≥300 ℃),再结晶程度加剧,且晶界处的再结晶晶粒明显小于晶内的晶粒,说明在较低应变速率下的动态再结晶主要通过晶界弓出形核或亚晶旋转吞并等方式向晶内扩展并长大[17]。应变速率较高(10和20 s-1)时,组织中产生了许多带状分布的再结晶晶粒,这是由于合金在较高应变速率下变形时会形成大量的孪晶,动态再结晶机制转变为孪晶再结晶为主导[18]。随着应变速率的进一步增大(30和40 s-1),在400 ℃以下,晶粒内部均产生了极高密度孪晶,孪晶内部没有发生再结晶或仅部分发生再结晶。这是由于应变速率过高,孪晶产生的速度过快,使得孪晶界上来不及发生再结晶。在400 ℃变形时,由于升温使得滑移系增加,仅在应变速率为30 s-1和40 s-1的条件下能看到少量的再结晶孪晶。

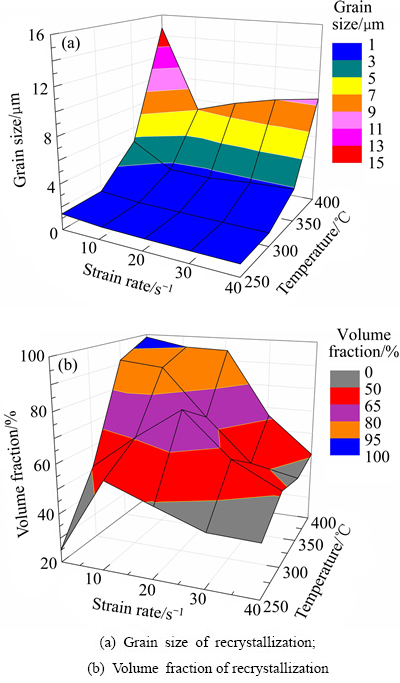

图3所示为不同热变形条件下镁合金中动态再结晶晶粒的平均尺寸和再结晶体积分数。由图3(a)可见,合金的动态再结晶晶粒平均尺寸随着变形温度的升高而增大,在400 ℃时长大趋势最显著。这是由于在 400 ℃变形时,产生的孪晶密度较小,使得再结晶核心减少,同时温度的升高使得原子扩散加快和晶界迁移能力增强,导致再结晶晶粒长大明显[19]。此外,动态再结晶晶粒的平均尺寸随着应变速率的升高而减小,且高应变速率下受变形温度的影响较小。这是由于在较高应变速率变形时,容易诱发孪晶,特别是交叉孪晶的形成,导致再结晶形核位置增加,从而有效细化合金晶粒[20]。由图3(b)可知,ZM51镁合金在热压缩变形过程中动态再结晶程度随着温度的升高而加剧,随着应变速率的升高先增强后减弱,在变形温度为300 ℃、应变速率为20 s-1变形时出现了一个再结晶体积分数的峰值(81.2%)。综合分析图3(a)和(b)可知,合金在300~350 ℃、应变速率为10~20 s-1变形时,其动态再结晶晶粒尺寸均小于3 μm,再结晶体积分数均大于70%。可见,ZM51镁合金在上述工艺下变形时能够获得晶粒细小且较均匀的组织。

图2 ZM51镁合金在不同应变速率和变形温度下热压缩后的金相组织

Fig. 2 Optical micrographs of ZM51 compressed at different strain rates and deformation temperatures

图3 ZM51镁合金在不同应变速率和变形温度下的再结晶组织特征

Fig. 3 Recrystallization microstructure evolution of ZM51 compressed at different strain rates and deformation temperatures

2.3 变形机制对流变应力的影响

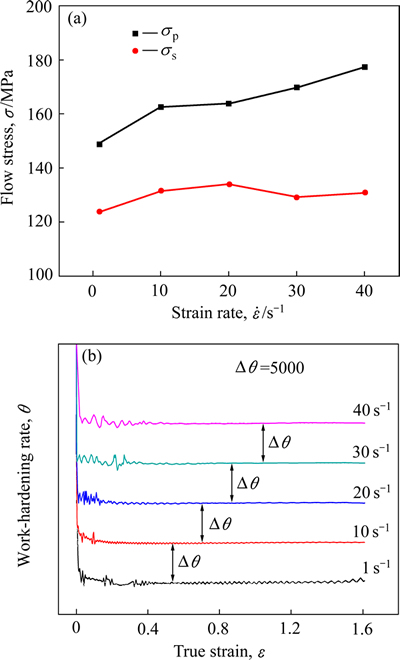

基于图1(a)中数据,可以获得应变速率对ZM51镁合金峰值应力、稳态应力和加工硬化率的影响规律,其结果如图4所示。从图4(a)可知,峰值应力 随着应变速率的增加而增大,但稳态应力

随着应变速率的增加而增大,但稳态应力 随应变速率的增加先增大后减小。且

随应变速率的增加先增大后减小。且 与

与 的差值随着应变速率的增加而逐渐增大,说明高应变速率过程中的动态再结晶能够有效地释放应力。从图4(b)可知,变形开始阶段,所有应变速率下均表现出较强的加工硬化行为,其加工硬化率

的差值随着应变速率的增加而逐渐增大,说明高应变速率过程中的动态再结晶能够有效地释放应力。从图4(b)可知,变形开始阶段,所有应变速率下均表现出较强的加工硬化行为,其加工硬化率 值较大;随着变形的进行,加工硬化率

值较大;随着变形的进行,加工硬化率 值开始急速下降,并在0值(图4(b)中虚线所示)附近上下波动。然而,在变形后期(ε>1.0),应变速率为1 s-1时,其加工硬化率波动幅度明显高于较大应变速率变形时的波动幅度。这主要与ZM51合金在不同应变速率下变形时组织演变规律不同有关。

值开始急速下降,并在0值(图4(b)中虚线所示)附近上下波动。然而,在变形后期(ε>1.0),应变速率为1 s-1时,其加工硬化率波动幅度明显高于较大应变速率变形时的波动幅度。这主要与ZM51合金在不同应变速率下变形时组织演变规律不同有关。

图4 应变速率对ZM51镁合金峰值应力、稳态应力和加工硬化率的影响

Fig. 4 Effects of strain rate on peak and steady state stress(a) and work-hardening rate(b)

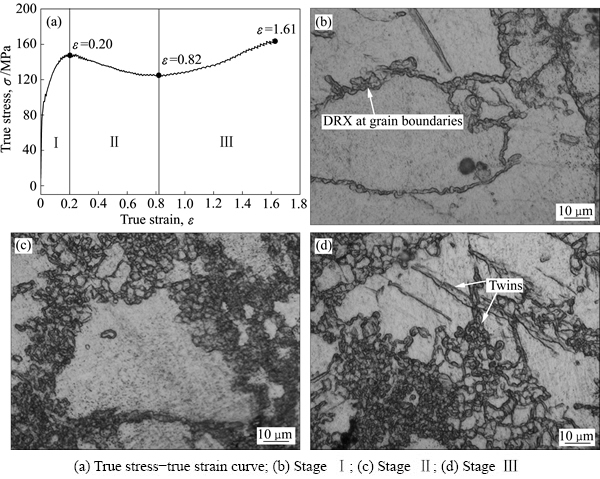

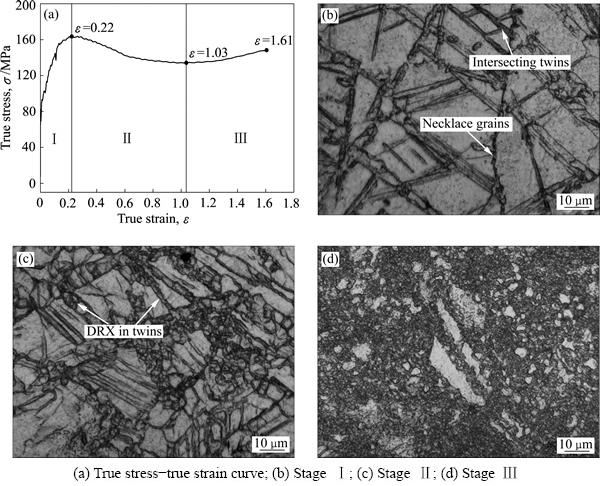

图5所示为ZM51低应变速率热压缩变形的应力-应变曲线及不同阶段的形貌。由图5可看出,在低应变速率下(≤1 s-1)变形时,第Ⅰ阶段(加工硬化阶段):随着变形的进行,位错密度不断增大,从而产生较严重的位错塞积,使得流变应力迅速增大,如图5(a)所示。当变形量达到一定时候,开始诱发原始晶界上的动态再结晶如图5(b)所示,使得流变应力达到峰值。第Ⅱ阶段(动态软化):随着变形量的进一步增大,晶界处的动态再结晶进一步加剧,并通过晶界处的弓出及亚晶的旋转形核与长大,使得再结晶区域由晶界向晶内不断扩大,如图5(c)所示;动态再结晶能够有效地降低变形组织中的位错密度,使得流变应力降低。第Ⅲ阶段(再次硬化阶段):由于动态再结晶消耗了大量的原始晶界,使再结晶的形核位置减少导致动态再结晶减缓,第Ⅱ阶段产生的再结晶晶粒在后续变形过程中将会起到细晶强化作用,使得真应变ε>0.82时,其硬化效应再次明显加剧,如图5(d)所示。此外,从图5中还可以看到明显的孪晶组织,说明变形量较大时,ZM51镁合金需要通过诱发孪生协调变形,而加工过程中不断产生的位错塞积将难以得到及时释放,必然导致加工后的合金材料室温变形能力差,不利于二次加工成型。因此,较低应变速率变形不利于ZM51镁合金的大变形热加工。

图6所示为ZM51合金高应变速率热压缩变形时应力-应变曲线及不同阶段的形貌。由图6可看出,高应变速率下(20 s-1)变形时,第Ⅰ阶段(加工硬化):同样,位错塞积将产生较强的加工硬化,由于变形速度快,位错滑移来不及进行,故在此阶段主要通过孪晶来协调变形。随着变形的进行,原始晶粒被交错孪晶分割、细化,只有部分残留的原始晶界上形成了“链状”再结晶晶粒如图6(b)所示,使得流变应力达到峰值。第Ⅱ阶段(动态软化):随着变形量的进一步增大,同样会诱发动态再结晶的发生,此时原始晶界和孪晶界将成为动态再结晶的主要形核位置。由于变形前期及后续变形中产生了大量的孪晶,为动态再结晶提供了大量的形核位置,如图6(c)所示,致使动态再结晶的软化效应大于应变硬化效应,使得流变应力下降,且该阶段在较大变形量范围内持续发生。第Ⅲ阶段(再次软化阶段):由于前期消耗了大量的再结晶形核位置(孪晶界和原始晶界),使得再结晶减缓,由于加工硬化及细晶强化效应使得材料的流变应力增大。但由于应变速率较高,随着变形的进行,依旧会产生大量的孪晶,甚至在已形核的动态再结晶晶粒内仍然会诱发孪生变形,继续发生动态再结晶[21]。因此,即便当真应变达到1.16时,其硬化效应依旧较弱。随着变形量的继续增大,其流变应力上升速率增加,但相对低应变速率变形时更为缓慢,其硬化效应较弱。因此,适当提高ZM51镁合金在热加工变形中的应变速率将更有利于其实现大塑性变形,并能保证再结晶组织细小、均匀的同时使得组织内部应力集中较小。

图5 ZM51合金低应变速率热压缩变形的应力-应变曲线及不同阶段的形貌

Fig. 5 True stress-true strain curve of ZM51 alloy during low strain rate hot compression(a) and morphologies((b)-(d)) of ZM51 alloy at different stages

图6 ZM51合金高应变速率热压缩变形时的应力-应变曲线及不同阶段的形貌

Fig. 6 True stress-true strain curve of ZM51 alloy during high strain rate hot compression and morphologies of ZM51 alloy at different stages

2.4 热变形参数对变形激活能的影响

变形激活能又称为动态软化激活能,是塑变金属材料再结晶转变的势垒,反映了高温塑性变形时应变硬化与动态软化之间的平衡关系,是对再结晶转变过程进行动力学分析和探讨再结晶机制的重要依据[22]。为了研究变形工艺对ZM51镁合金变形行为及其再结晶行为的影响,本文作者将计算不同应变速率和变形温度下对应的变形激活能,从而探明变形参数对再结晶行为的影响。

LI等[23]关于合金的流变应力、应变速率和变形温度之间联系,建立了两种不同应力条件下的关系式:

(1)

(1)

(2)

(2)

采用双曲正弦形式的修正Arrhenius关系来描述变形激活能Q与变形温度T两者之间的关系[24]:

(3)

(3)

通过对式(3)两边求偏微分可得变形激活能的求解公式:

(4)

(4)

式中: 为应变速率;A、A1、A2、n1、

为应变速率;A、A1、A2、n1、 和

和 均为材料常数;n为应力指数,反映变形速率与应力之间的关系;R为摩尔气体常数,8.314 J/(mol·K);T为绝对温度,K;Q为变形激活能,kJ/mol。根据ZM51镁合金在不同变形条件下的峰值应力,可以得到

均为材料常数;n为应力指数,反映变形速率与应力之间的关系;R为摩尔气体常数,8.314 J/(mol·K);T为绝对温度,K;Q为变形激活能,kJ/mol。根据ZM51镁合金在不同变形条件下的峰值应力,可以得到 和

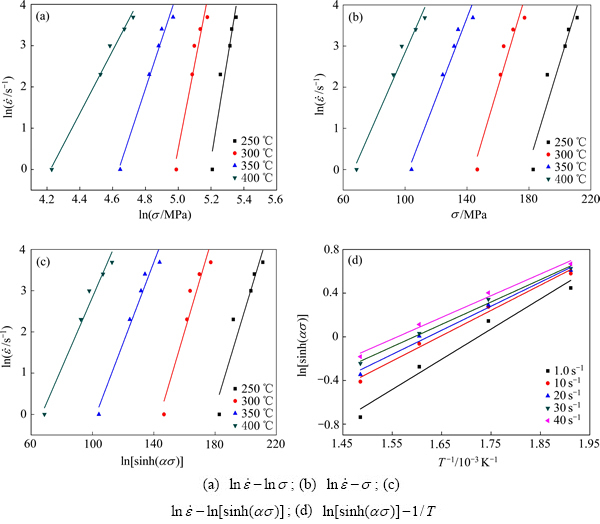

和 关系,分别对应图7(a)和(b)。对图7(a)中4条直线的斜率求平均值得n1=16.065,对图7(b)中4条直线的斜率求平均值得

关系,分别对应图7(a)和(b)。对图7(a)中4条直线的斜率求平均值得n1=16.065,对图7(b)中4条直线的斜率求平均值得 =0.108。则

=0.108。则 = 0.00672,可得到

= 0.00672,可得到 、

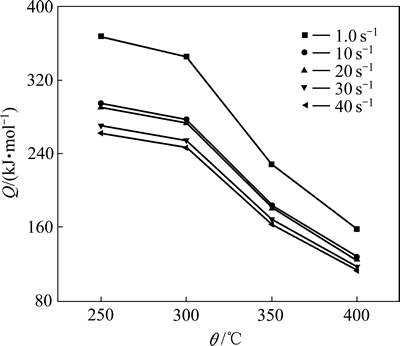

、 关系,分别对应图7(c)和(d)。根据式(4) 求出不同变形参数对应的变形激活能Q,如图8所示。

关系,分别对应图7(c)和(d)。根据式(4) 求出不同变形参数对应的变形激活能Q,如图8所示。

图7 ZM51镁合金热压缩变形峰值应力与应变速率、变形温度的关系

Fig. 7 Relationships between peak stress and strain rate, deformation temperature of ZM51 alloy

图8 ZM51镁合金在不同热压缩条件下的变形激活能变化

Fig. 8 Relationships among activation energy, strain rate and deformation temperature

从图8中可以看出,ZM51镁合金的变形激活能随着应变速率的增加和变形温度的升高均呈现下降的趋势,说明适当地提高应变速率和变形温度将更有利于ZM51镁合金的热塑性变形。由于均匀化态ZM51镁合金的晶粒尺寸较大(120 μm),其主要塑性变形机制为位错滑移和孪生变形两种[25]。从热力学角度分析,位错的运动需要克服一定的能量势垒才能进行;从动力学角度分析,只有当剪切应力大于最小临界剪切应力时,位错才能运动[26]。

因此,随着变形温度的升高,一方面,位错的交滑移和晶界的迁移将变得更容易,棱柱滑移面的临界切应力将会减小,使得合金中启动的滑移系增加,合金变形的临界应力减小;此外,由于变形温度的升高,合金在变形过程中的动态再结晶加剧,将大量消耗位错,使得位错塞积减弱,合金的变形抗力减小,从而使合金所需的变形激活能减小。另一方面,随着应变速率的增加,所产生的外加应力越大[27],将有利于克服位错运动的障碍,使得位错运动所需的热激活能减小。同时,在较高应变速率下会产生大量的位错增殖及交叉孪晶,为动态再结晶形核提供条件,从而促进再结晶的进行,使得位错密度降低,也将降低塑性变形所需的激活能。TAHREEN等[28]在应变速率为0.001~1.0 s-1范围内研究ZM31+6Y的热压缩行为时,同样发现激活能会随变形温度升高和应变速率的增大而下降。因此,在选用合适的变形温度的同时,可以通过适当地提高应变速率来提高ZM51合金的成形性。

3 结论

1) ZM51在较低应变速率(1 s-1)下热压缩变形 时,动态再结晶主要发生在原始晶界处,并通过晶界弓出形核或亚晶旋转吞并等方式向晶内扩展并长大,使得再结晶组织不均匀;随着应变速率的增加( ≥10 s-1),交错孪晶将原始晶粒分割、细化,使得再结晶形核位置增加,最终获得更加均匀、细小的再结晶组织。

≥10 s-1),交错孪晶将原始晶粒分割、细化,使得再结晶形核位置增加,最终获得更加均匀、细小的再结晶组织。

2) ZM51在较低应变速率(1 s-1)下热压缩变形 时,当真应变ε>0.82时,由于原始晶界的消耗使得再结晶形核位置减少,其硬化效应再次显著加剧;然而,在高应变速率下( ≥10 s-1),由于始终伴随孪晶动态再结晶,当真应变达到1.16时,才再次产生硬化效应,且明显较低应变速率时的弱,说明在高应变速率更有利于ZM51镁合金进行大塑性变形及后续成型加工。

≥10 s-1),由于始终伴随孪晶动态再结晶,当真应变达到1.16时,才再次产生硬化效应,且明显较低应变速率时的弱,说明在高应变速率更有利于ZM51镁合金进行大塑性变形及后续成型加工。

3) ZM51在高应变速率下进行热压缩变形时,其激活能随温度的升高和应变速率的增加而减小,说明适当地提高变形温度和应变速率将更有利于该合金的塑性加工成形。

4) 基于微观组织分析及其流变行为研究结果,优化出ZM51镁合金热加工变形的合适工艺参数为应变速率10~20 s-1、变形温度300~350 ℃。

REFERENCES

[1] HIRSCH J, AL-SAMMAN T. Superior light metals by texture engineering: optimized aluminum and magnesium alloys for automotive applications[J]. Acta Materialia, 2013, 61(3): 818-843.

[2] KAPLAN H, HRYN J N, CLOW B B. Magnesium technology 2000[M]. American: The Minerals Metals & Materials Society, 2000: 89-98.

[3] 申利权, 杨 旗, 靳 丽, 董 杰. AZ31B 镁合金在高应变速率下的热压缩变形行为和微观组织演变[J]. 中国有色金属学报, 2014, 24(9): 2195-2204.

SHEN Li-quan, YANG Qi, JIN Li, DONG Jie. Deformation behavior and microstructure transformation of AZ31B Mg alloy under high strain rate compression[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2195-2204.

[4] 丁文江, 靳 丽, 吴文祥, 董 杰. 变形镁合金中的织构及其优化设计[J]. 中国有色金属学报, 2011, 21(10): 2371-2381.

DING Wen-jiang, JIN Li, WU Wen-xiang, DONG Jie. Texture and texture optimization wrought Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2371-2381.

[5] MA Q, LI B, WHITTINGTON W R, OPPEDAL A L, WANG P T, HORSTEMEYER M F. Texture evolution during dynamic recrystallization in a magnesium alloy at 450 ℃[J]. Acta Materialia, 2014, 67: 102-115.

[6] ZHU S Q, YAN H G, CHEN J H, WU Y Z, DU Y G, LIAO X Z. Fabrication of Mg-Al-Zn-Mn alloy sheets with homogeneous fine-grained structures using high strain-rate rolling in a wide temperature range[J]. Materials Science and Engineering A, 2013, 559: 765-772.

[7] LI Yun-ping, WU Shuo, BIAN Hua-kang, TANG Ning, LIU Bin, KOIZUMI Y, CHIBA A. Grain refinement due to complex twin formation in rapid hot forging of magnesium alloy[J]. Scripta Materialia, 2013, 68(3): 171-174.

[8] ESTRIN Y, VINOGRADOV A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science[J]. Acta Materialia, 2013, 61(3): 782-817.

[9] FATEMI-VARZANEH S M, ZAREI-HANZAKI A, PAUL H. Characterization of ultrafine and nano grained magnesium alloy processed by severe plastic deformation[J]. Materials Characterization, 2014, 87: 27-35.

[10] PARK S S, BAE G T, KANG D H, JUNG I, SHIN K S, KIM N J. Microstructure and tensile properties of twin-roll cast Mg-Zn-Mn-Al alloys[J]. Scripta Materialia, 2007, 57(9): 793-796.

[11] QI F G, ZHANG D F, ZHU Z T, XU X X, SHI G L. Effect of heat treatment on microstructure and mechanical properties of extruded ZM61 magnesium alloy[J]. Materials Science and Technology, 2012, 28(12): 1426-1433.

[12] QI F G, ZHANG D F, ZHANG X H, XU X X. Effect of Sn addition on the microstructure and mechanical properties of Mg-6Zn-1Mn (wt.%) alloy[J]. Journal of Alloys and Compounds, 2014, 585: 656-666.

[13] HU G S, ZHANG D F, GUO F, JIANG L Y, YU D L, PAN F S. Microstructure and mechanical properties of Mg-Zn-Mn-Sn-Nd wrought alloys[J]. Journal of Rare Earths, 2014, 32(1): 52-56.

[14] HU G S, ZHANG D F, ZHAO D Z, SHEN X, JIANG L Y, PAN F S. Microstructures and mechanical properties of extruded and aged Mg-Zn-Mn-Sn-Y alloys[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3070-3075.

[15] 彭 建, 童小山, 吕滨江, 彭 毅, 潘复生. Mg-6Zn-1Mn 镁合金热压缩流变行为及动态再结晶[J]. 材料热处理学报, 2013, 34(5): 180-185.

PENG Jian, TONG Xiao-shan, L Bin-jiang, PENG Yi, PAN Fu-sheng. Hot compression deformation behaviour and dynamic recrystallization of Mg-6Zn-1Mn magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2013, 34(5): 180-185.

Bin-jiang, PENG Yi, PAN Fu-sheng. Hot compression deformation behaviour and dynamic recrystallization of Mg-6Zn-1Mn magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2013, 34(5): 180-185.

[16] 张丁非, 方 霖, 段红玲, 戴庆伟. ZM61 镁合金的热变形行为[J]. 材料热处理学报, 2011, 32(4): 25-29.

ZHANG Ding-fei, FANG Lin, DUAN Hong-ling, DAI Qing-wei. Constitutive equation of thermal compression deformation for ZM61 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2011, 32(4): 25-29.

[17] 王 斌, 易丹青, 方西亚, 刘会群, 吴春萍. ZK60 镁合金高温动态再结晶行为的研究[J]. 材料工程, 2009, 37(11): 45-50.

WANG Bin, YI Dan-qing, FANG Xi-ya, LIU Hui-qun, WU Chun-ping. Thermal simulation on hot deformation behavior of ZK60 magnesium alloy[J]. Journal of Materials Engineering, 2009, 37(11): 45-50.

[18] ZHU S Q, YAN H G, CHEN J H, WU Y Z, LIU J Z, TIAN J. Effect of twinning and dynamic recrystallization on the high strain rate rolling process[J]. Scripta Materialia, 2010, 63(10): 985-988.

[19] WANG X, HU L X, LIU K, ZHANG Y L. Grain growth kinetics of bulk AZ31 magnesium alloy by hot pressing[J]. Journal of Alloys and Compounds, 2012, 527: 193-196.

[20] BASU I, ALSAMMAN T. Twin recrystallization mechanisms in magnesium-rare earth alloys[J]. Acta Materialia, 2015, 96: 111-132.

[21] ZHU S Q, YAN H G, LIAO X Z, MOODY S J, SHA G, WU Y Z, RINGER S P. Mechanisms for enhanced plasticity in magnesium alloys[J]. Acta Materialia, 2015, 82: 344-355.

[22] 王宏伟, 易丹青, 王 斌, 蔡金伶, 钱 锋, 陈缇萦. Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd镁合金的高温塑性变形行为的热压缩模拟[J]. 中国有色金属学报, 2010, 20(3): 378-384.

WANG Hong-wei, YI Dan-qing, WANG Bin, CAI Jin-ling, QIAN Feng, CHEN Ti-ying. Hot compressive deformation simulation of Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd magnesium alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 378-384.

[23] LI L , ZHOU J, DUSZCZYK J. Determination of a constitutive relationship for AZ31B magnesium alloy and validation through comparison between simulated and real extrusion[J]. Journal of Materials Processing Technology, 2006, 172(3): 372-380.

[24] MCQUEEN H J, RYAN N D. Constitutive analysis in hot working[J]. Materials Science and Engineering A, 2002, 322(1): 43-63.

[25] 余 琨, 黎文献, 王日初. 镁合金塑性变形机制[J]. 中国有色金属学报, 2005, 15(7): 1081-1086.

YU Kun, LI Wen-xian, WANG Ri-chu. Plastic deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1081-1086.

[26] YANILKIN A V, KRASNIKOV V S, KUKSIN A Y U, MAYER A E. Dynamics and kinetics of dislocations in Al and Al-Cu alloy under dynamic loading[J]. International Journal of Plasticity, 2014, 55: 94-107.

[27] DIXIT NEHA, XIE KELVIN Y, HEMKER KEVIN J, RAMESH K T. Microstructural evolution of pure magnesium under high strain rate loading[J]. Acta Materialia, 2015, 87: 56-67.

[28] TAHREEN N, ZHANG D F, PAN F S, JIANG X Q, LI C, LI D Y, CHEN D L. Characterization of hot deformation behavior of an extruded Mg-Zn-Mn-Y alloy containing LPSO phase[J]. Journal of Alloys and Compounds, 2015, 644: 814-823.

Microstructure evolution and flow behaviour of Mg-5Zn-1Mn alloy during high strain rate hot compression

CHEN Chao1, 2, YAN Hong-ge1, 2, CHEN Ji-hua1, 2, XIA Wei-jun1, 2, SU Bin1, 2, CAO Meng-xin1, SONG Min3

(1. College of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. Hunan Provincial Key Laboratory of Spray Deposition Technology and Application,

Hunan University, Changsha 410082, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The hot compression tests were performed on Mg-5Zn-1Mn alloy with the large deformation of 80% by the Gleeble-3500 material simulation machine. The microstructure evolution and flow behaviour were studied at the deformation temperature range from 250 to 400 ℃ and the strain rate range from 1 to 40 s-1. The dynamic recrystallization (DRX) occurs obviously during hot deformation, the DRX microstructure developed at high strain rate is more uniform, and the grain size is smaller than that developed at low strain rate. The severe plastic deformation of ZM51 magnesium alloy can be achieved more effectively at high strain rate compared to low strain rate by analyzing the microscopic mechanism during the change of flow stress. The hot deformation activation energy decreases with increasing the deformation temperature and strain rate.

Key words: Mg-5Zn-1Mn magnesium alloy; flow behaviour; high strain rate; activation energy

Foundation item: Projects(51471066, 51274092) supported by the National Natural Science Foundation of China; Project(20120161110040) supported by the National Research Foundation for the Doctoral Program of Higher Education of China

Received date: 2015-05-23; Accepted date: 2016-01-13

Corresponding author: YAN Hong-ge; Tel: +86-731-88664005; E-mail: yanhg68@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51471066,51274092); 高等学校博士学科点专项科研基金资助项目(20120161110040)

收稿日期:2015-05-23;修订日期:2016-01-13

通信作者:严红革,教授,博士:电话:0731-88664005;E-mail: yanhg68@163.com