文章编号:1004-0609(2012)05-1283-09

垂直晶界铜双晶的拉伸变形行为

李发东,李玉龙,索 涛,汤忠斌,郭亚洲

(西北工业大学 航空学院,西安 710072)

摘 要:利用数字图像相关法研究了垂直晶界铜双晶试样的拉伸变形行为,获得了拉伸过程中试样表面的全场变形分布。结果表明:试样整体变形呈“双颈缩”现象,试样表面的应变分布不均匀,晶界附近的应变水平低于晶粒内部的,试样总是在软取向的晶粒内首先发生塑性变形并断裂。借助扫描电镜(SEM)原位拉伸实验观察到在拉伸过程中滑移带不能穿过晶界。以上结果说明,铜双晶试样拉伸变形行为与组元晶粒的晶体取向和晶界的属性有关,软取向的晶粒更容易发生塑性变形,而大角度晶界在拉伸过程中具有强化效应,对晶粒的滑移变形有阻碍作用。

关键词:铜双晶;晶界;连铸单晶铜;数字图像相关法;微拉伸

中图分类号:TG115.5; TG146.1 文献标志码:A

Tensile deformation behavior of copper bicrystal with perpendicular grain boundary

LI Fa-dong, LI Yu-long, SUO Tao, TANG Zhong-bin, GUO Ya-zhou

(School of Aeronautics, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The tensile deformation behavior of a copper bicrystal with a perpendicular grain boundary was investigated using digital image correlation (DIC) method, and the whole field deformation distribution on the specimen surface during the tensile test was obtained. The results show that the specimen is deformed in the “double necking” shape. The strain distribution on specimen surface is inhomogeneous, and strain level at the grain boundary is lower than that in the interior of grains. The specimens fracture within the grain with soft orientation. The in-situ tension by scanning electron microscopy (SEM) indicates that slip bands cannot pass through the grain boundary. The above results suggest that the tensile deformation behavior of the copper bicrystal is determined by the orientation of each grain and the property of grain boundary. The grain with soft orientation tends to deform plastically and fracture first. Large-angle grain boundary can impede slip bands and hence strengthen the material.

Key words: copper bicrystal; grain boundary; continuous casting single crystal copper; digital image correlation (DIC) method; micro-tensile

在过去的数十年里,为了揭示晶界在双晶体塑性变形中的影响,研究人员努力发现了许多研究方法。这些方法大致可以归为两类:一类是通过试验方法来研究晶界效应;另一类则是建立各种本构模型通过数值模拟来研究晶界的影响[1]。双晶的力学行为是理解晶界特性的基础[2]。研究中所采用的双晶体可以分为如下3类:1) 平行晶界双晶体(晶界平行于载荷方向);2) 垂直晶界双晶体(晶界垂直于载荷方向);3) 倾斜晶界双晶体(晶界与载荷方向成一定倾角)。邹风雷等[2-3] 对连铸单晶铜平行晶界双晶体试样进行了拉伸试验和原位观察,发现在拉伸过程中滑移线很容易穿过小角度晶界,晶界没有对滑移变形起阻碍作用。ZIEGLER等[4]对钽垂直晶界双晶体进行了单轴压缩试验,结果表明,晶界对变形局部化有很强的约束作用。SU等[5] 对取向差不同的Ni3Al“重合位置点阵”Σ3垂直晶界双晶体微小试样进行了拉伸试验,深入研究了晶界的几何特征与试样宏观力学特性之间的关系,结果表 明,晶界在试样变形过程中具有强化作用,但晶界并非在任何情况下都对滑移变形起阻碍作用,只有当两个晶粒具有共同的主滑移系时,滑移变形才能穿过晶界。张哲峰等[6-10]也对铜双晶在循环载荷下的力学行为进行了大量研究。研究了平行晶界和垂直晶界铜双晶体的循环变形行为,他们发现滑移带很容易穿过小角度平行晶界,而大角度平行晶界和大角度垂直晶界都阻碍滑移变形。在数值计算方面,CHEN等[11]建立了垂直晶界双晶体三维各向异性有限元模型,分析了铜双晶体的应变及分解切应力的分布。其计算结果显示,在较硬的晶粒内部,晶界附近的应变比远离晶界处的大,而在较软的晶粒内部,晶界附近的应变比远离晶界区域的小。FENG等[12]的垂直物理晶界双晶体拉伸变形有限元模拟结果显示,在均匀变形阶段,晶界附近存在应力和应变集中,在非均匀变形阶段,试样变形呈“双颈缩”现象,观察到晶界强化效应,在晶界附近应变水平较低,而在两个晶粒颈缩区域的应变水平很高。另外,采用分子动力学来建立双晶体模型研究晶界效应的也很多[13-16],尤其以“重合位置点阵”模型较为常见,分子动力学模拟的好处是可以直接观察原子的运动,从而可以在原子尺度上研究晶界的特性[13]。

综上所述,双晶粒试样的变形不仅与晶粒的取向有关,而且与材料的特性有关,是一个不均匀的复杂变形场。全场位移场和应变场只有数值模拟的结果,未见有实验结果的报道。为此,本文作者以铜双晶体为对象进行单轴拉伸试验,利用数字图像相关法来测量试样全场的位移场和应变场,并进行原位拉伸试验,观察晶界附近形貌的变化,从而进一步研究晶界和晶粒在塑性变形中所起的作用。

1 数字图像相关法的基本原理

数字图像相关法是通过处理被测对象表面变形前后的数字图像来获得位移和应变信息的测量方法,由于其具有非接触性和测量精度高等特点,目前已广泛应用于实验固体力学领域[17-18]。通常将变形前的图像称为“参考图像”(Reference image),变形后的图像称为“变形后图像”(Deformed image)。首先需要在参考图像中定义计算区域。计算区域进一步被均匀分解为虚拟网格,通过计算每个网格节点的位移而得到全场位移信息。数字图像相关法的基本原理在于对变形前后两幅图像中的相同像素点进行追踪或匹配,如图1所示。为了计算图中P点的位移,在参考图像的计算区域(Region of interest,ROI)内选择一个以P(x0,y0)为中心的正方形参考子区域(Reference subset),该区域包含(2M+1)×(2M+1)个像素。该子区域就用于在变形图像中追踪P点相应的位置。选择一个正方形子区域而不是一个单一像素点来进行追踪和匹配,会在更大范围内比较灰度的变化,这将使子区域之间更容易识别和区别出来,从而在变形后的图像中能唯一确定子区域。

图1 正方形参考子区域变形前后示意图[18]

Fig. 1 Schematic illustration of reference square subset before deformation (a) and target (or deformed) subset after deformation (b)[18]

为了衡量参考子区域与变形子区域的相似程度,必须预先定义相关函数作为评价准则。匹配的过程则通过寻找相关系数分布的峰值来完成。一旦相关系数的最大值被找到,目标子区域(Target subset)的位置也就确定了。参考子区域中心到目标子区域中心的距离就形成了平面内的位移向量(Displacement vector),如图1(b)所示。相关函数有很多,文献多采用归一化的最小平方距离函数(Zero-normalized sum of squared differences,ZNSSD)[19]:

(1)

(1)

其中:

;

;

;

;

;

;

。

。

式中:f(x, y)和g(x, y)分别是参考和目标子区域的灰度值。与其他相关函数相比,该相关函数的相关峰全场唯一且尖锐,因而能更准确地寻找到整个搜索区域的相关系数极值。对目标子区域的灰度值进行线性变换后得g′(x′, y′)=ag(x′, y′)+b,其中:a和b为常数,再用ZNSSD函数计算得到的相关系数将不发生改变,所以,ZNSSD函数具有很强的抗噪音能力,且对于照明光线线性偏移不敏感[18-19]。

在得到了离散的x和y方向的位移场U和V后,通过逐点局部最小二乘法(Pointwise local least squares algorithm)来计算位移的偏导数,即应变。由于拟合过程包含噪音的去除,因此,所得到的应变精度较直接差分法的有显著提高。对x和y方向位移场局部子区域中的离散数据u和v用二维一次多项式进行拟合,则有

(2)

(2)

得到拟合多项式的系数后,在小变形情况下的柯西(Cauchy)应变分量为

(3)

(3)

然后,将局部子区域移动到下一个数据区域,计算新的数据子区域内的中心点平滑和求导结果,直至求出全场水平方向应变场εx和竖直方向应变场εy。有关数字图像相关法的具体细节可进一步参阅文献[18- 21]。

2 实验

2.1 试样制备

本研究所用铜双晶体取自纯度为99.97%的连铸单晶铜棒,而连铸单晶铜具有高度定向性的纵向晶 粒[22]。取样时,首先将直径为8 mm的铜棒横截面抛光腐蚀,在金相显微镜下找到两个相邻且较大的晶 粒,如图2(a)所示,然后,从图示白色虚线位置处沿纵向将铜棒切开。对剖面进行金相腐蚀后得到铜棒纵向截面的组织形貌,如图2(b)所示,再用慢走丝线切割机在截面上割取铜双晶拉伸试样,试样标距段宽度为0.5 mm,长度为2 mm。先割取厚度为0.6 mm的试样,然后用1000#砂纸打磨试样上下表面,使试样厚度均匀减薄至0.3 mm,这样可以改善试样表面粗糙度,减小线切割加工痕迹对实验结果的影响。用于原位拉伸的试样,表面则需再进行抛光和腐蚀,以显示出晶界,所得试样如图2(b)中附图所示。

图2 垂直晶界铜双晶试样的取样示意图

Fig. 2 Schematic diagrams of preparation of copper bicrystal specimen with perpendicular grain boundary: (a) Cross-section; (b) Longitudinal cross-section

2.2 双晶试样晶粒取向的测定

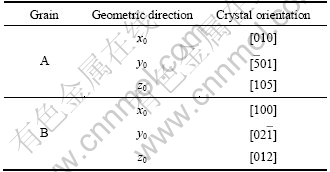

为了确定试样几何方向与晶体方向的关系,采用电子背散射衍射(Electron backscattered diffraction, EBSD)技术测定了试样两晶粒的晶体取向。EBSD试样即从图2(b)铜棒纵向剖面上得到:对剖面先进行机械抛光,再进行电解抛光,以消除表面应力。电解抛光的电解液为825 mL HPO3 + 175 mL 蒸馏水,电解电压2 V,抛光时间3 min。EBSD分析在装有牛津仪器INCA Crystal EBSD系统的Zeiss Supra 55扫描电镜上进行。图2(b)中x0代表轧向,y0代表横向,z0代表法向。为便于分析,定义图中左边的晶粒为A,右边晶粒为B。双晶试样的几何方向与晶体学取向如表1所列。经测算,两个晶粒的取向差为35.9°,晶界属大角度晶界。

表1 双晶试样的几何方向与晶体学取向

Table 1 Geometric direction and orientation of bicrystal specimen

2.3 实验过程

实验在室温环境下进行,实验装置简图如3所示,采用Instron 5848微拉伸试验机进行单轴拉伸加载。试验机载荷传感器分辨率为1×10-5 N,最大载荷为 2 kN,位移传感器分辨率为0.01 μm。采用台大恒DH- HV1303UM数字摄像机,分辨率为1 280 pixel×1 024 pixel,镜头为Computar MLM-3XMP变焦微距镜头。利用磁性底座将摄像机固定在基座上面,以保证摄像机光轴与试样表面垂直。同时用一台冷光源作为照明补充。为了增加图像散斑场的平均灰度梯度[23],先在试样表面喷涂油漆制造白色背底,再用雾化器在表面喷涂直径为0.5 μm的黑色碳素墨水颗粒。

图3 实验装置简图

Fig. 3 Schematic experimental setup

实验时,沿y0方向进行单轴拉伸,即拉伸方向平行于晶粒A的[501]方向和晶粒B的[021]方向。试样装夹时晶粒A在下,晶粒B在上。加载时,试验机横梁的移动速度为0.03 mm/min,对应的应变率为2.5×10-3 s-1,处于准静态拉伸范围。试验机横梁每移动20 μm记录一张图像。典型的试样表面散斑场如图4所示,图4(a)所示为试样变形前的图像,图4(b)所示为变形后的图像。以变形前的图像为参考图像,以加载过程中记录的图像为变形后的图像,采用数字图像相关(DIC)技术确定试样表面的位移场和应变场。图4(a) 白色边框所围区域为计算区域,定义水平向右方向为x正向,竖直向上为y正向。

图4 试样表面图像

Fig. 4 Images of specimen surface: (a) Undeformed image (Image000), region enclosed by white frame is region of calculation; (b) Image040, σ=77.7 MPa

另一方面,为了观察晶界附近组织形貌的变化过程,将抛光腐蚀过的双晶试样置于Zeiss Supra 55扫 描电镜下进行原位拉伸试验。拉伸速率与前面的拉伸试验速率一致。在拉伸过程中,利用扫描电镜对晶界附近拍照。

3 结果

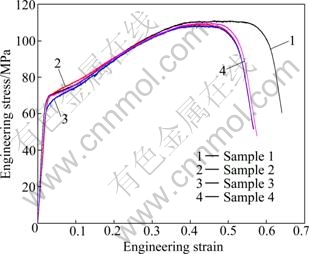

图5所示为4个不同试样的拉伸宏观名义应力—应变曲线。其中,宏观名义应变为试验机横梁位移除以试样标距段长度,宏观名义应力则按下式计算:

(4)

(4)

式中:F代表载荷;A代表试样初始截面积。由图5可以看到:4个试样的名义应力—应变曲线重合得较好,这一方面说明了试验时所夹持试样轴线和拉伸方向的一致性较好,另一方面也证明了本研究所采用的实验方法是可行的。

图5 4个试样的宏观名义应力—应变曲线

Fig. 5 Nominal stress—strain curves of four samples

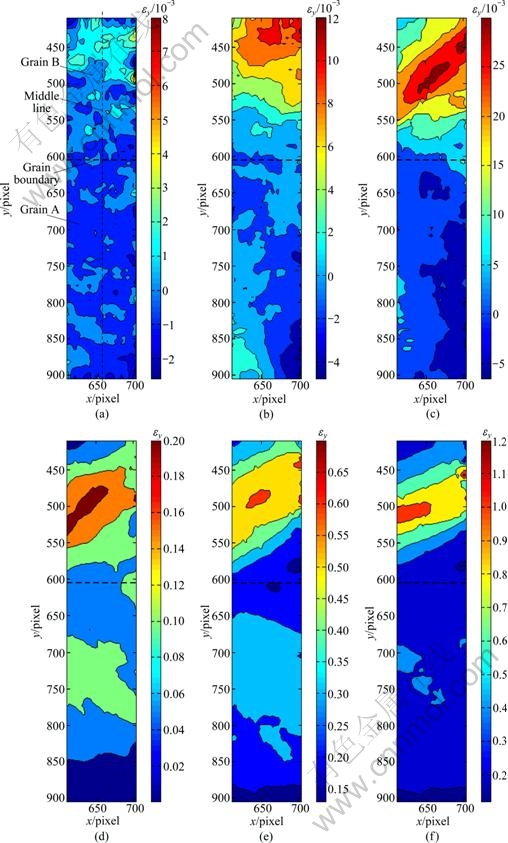

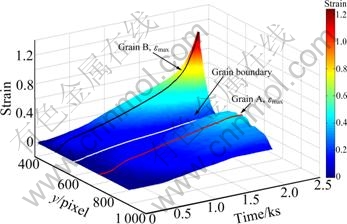

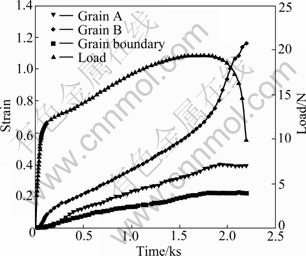

图6所示为试样3在不同的应力水平下y方向的应变场εy。由图6可以看出:整个计算区域内εy是不均匀的,特别是晶粒A和B在整个变形过程中的应变场明显不同,且随着变形的增大,晶粒A和B变形的差异越来越大,而晶界附近的应变在整个变形过程中始终很小。图7所示为计算区域中心线上各点的应变εy随时间的变化趋势。从图7可以看出:两个晶粒各自表现出不同的变形局部化,且晶粒B的应变始终比晶粒A的大,而晶界处的应变低于两个晶粒内部的应变。图8所示为图7中3条实线位置的应变—时间曲线以及载荷—时间曲线。由图8可以看出:在拉伸过程的最后阶段,载荷下降,晶粒A局部应变呈水平线,表明晶粒A已不再变形,而晶粒B的局部应变则继续增加。

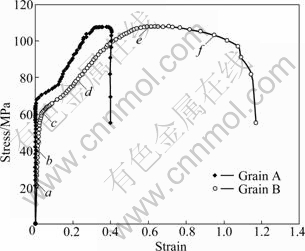

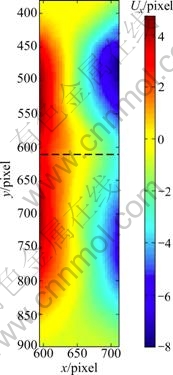

为了比较两个晶粒力学行为的差异,图9给出了图7中晶粒A和B实线位置的局部应力—应变曲线。这里需要说明的是,图9中晶粒B的应力—应变曲线上a~f 6个状态分别对应图6中(a)~(f) 6个变形时刻。从图6和9中可以看出:晶粒B更容易变形,当试样的宏观名义应力达到60.8 MPa(图9中c点)时,晶粒B中形成一个与载荷方向成50°夹角的高应变区(见图6(c))。而此时晶粒A仍然处在弹性变形阶段,整个晶粒内的变形场分布较均匀,直至宏观名义应力达到63 MPa时,晶粒A才发生屈服,之后在其内部也出现了一个与载荷方向成45°夹角的高应变区(见图6(d))。此时,对应试样的横向(即x方向)位移场如图10所示。由图10可以看到:x方向位移场Ux呈“双颈缩”型,晶粒B的颈缩比晶粒A的大,而晶界处x方向的位移小于晶粒内部的位移。当宏观名义应力应力达到108 MPa时(图9中e点)时,由于晶粒B的颈缩程度较为严重,导致载荷开始下降,这不足以维持晶粒A继续变形,故随后晶粒A中各点的应变保持不变(见图6(f))。与之不同的是,晶粒B则继续变形。这种趋势在图8所示的应变—时间曲线中也很容易看出来,在拉伸过程的最后阶段,晶粒A的局部应变达到40%以后就不再增大,甚至在弹性卸载的作用下略微减小,而晶粒B的局部应变则继续增加,直到应变达到117%被拉断为止。

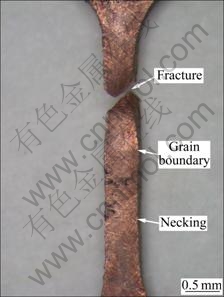

图11所示为试样的断口宏观形貌。由图11可以看到:试样在晶粒B的高应变处断裂,且断口倾斜角大约为45°。此外,晶粒A也有局部颈缩现象。

4 讨论

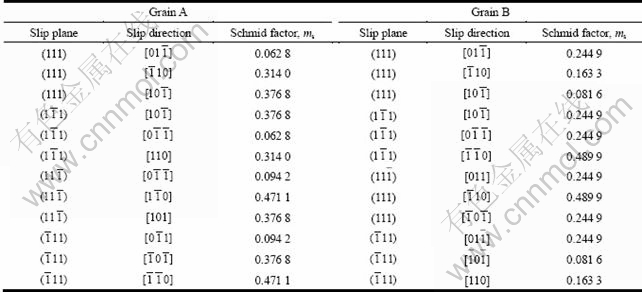

铜双晶试样只包含两个晶粒,试样的变形也就是两个晶粒的变形。由前面的实验结果可知:在拉伸过程中两个晶粒的变形不同,造成这种力学行为差异的根本原因是晶粒A与B取向的不同以及两个晶粒之间的晶界。就单个晶粒而言,其变形行为应符合施密特(Schmid)定律。本研究中,载荷方向为沿着晶粒A的[501]和晶粒B[021]方向。通过晶体学分析,计算出拉伸时两个晶粒各滑移系的取向因子,结果如表2所列。由表2可以看出:两个晶粒的最大取向因子分别为0.471 1(晶粒A)和0.489 9(晶粒B)。很显然,晶粒B的取向因子比晶粒A的大,因而晶粒B比较软,更容易发生塑性变形,这与前面的实验结果相吻合。

图6 不同应力水平时试样3在y方向的应变场εy

Fig. 6 Strain fields εy of sample 3 in y direction under different stress levels: (a) σ=24 MPa; (b) σ=40.6 MPa; (c) σ=60.8 MPa; (d) σ=77.7 MPa; (e) σ=108 MPa; (f) σ=103.3 MPa

图7 计算区域中心线上的应变—时间的变化曲线

Fig.7 Strain—time curve of middle line in calculated area

图8 晶粒A和B的局部应变—时间曲线及载荷—时间曲线

Fig. 8 Local strain—time and load—time curves of grains A and B

图9 晶粒A和B的局部应力—应变曲线

Fig. 9 Local stress—strain curves of grains A and B

图10 σ=77.7 MPa时试样在x方向的位移场Ux

Fig. 10 Displacement field Ux of specimen in x direction at σ= 77.7 MPa

图11 试样的断口宏观形貌

Fig. 11 Macrostructure of fractured specimen

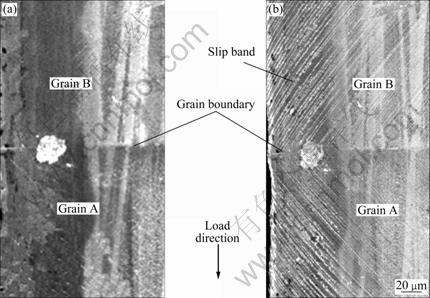

图12(a)和(b)所示分别为原位拉伸实验前后试样表面晶界附近的微观形貌。对比拉伸前后晶界附近的微观形貌可以看出:拉伸后晶界两侧的晶粒表面出现大量平行的滑移带,且两个晶粒各自的滑移带在晶界处终止。SU等[5]提出,只有当晶界两边的晶粒具有共同的主滑移系时,滑移才可能容易地穿过晶界,得到均匀的塑性变形,否则晶界都会对滑移变形产生阻碍作用。本研究中双晶试样两个晶粒的取向差为35.9°,且从晶体学分析及SEM观察结果(见图12)来看,晶界两侧的晶粒没有共同的主滑移系,因此,晶界会对塑性变形产生阻碍作用。

表2 晶粒A和B在各个滑移系上的取向因子

Table 2 Schmid factors of grains A and B in all slip systems

图12 铜双晶的原位拉伸SEM像

Fig. 12 SEM images of copper bicrystal in-situ tensile: (a) Before tension; (b) After tension

5 结论

1) 采用数字图像相关法获得了垂直晶界铜双晶单轴拉伸过程中的全场变形。

2) 晶界对塑性变形具有强化作用,晶界及其附近的应变水平一直很低。

3) 晶体取向分析及扫描电镜原位拉伸试验结果表明:本研究所用铜双晶拉伸试样的晶界为大角度晶界,在拉伸过程中,大角度垂直晶界对滑移变形有阻碍作用,使滑移带不能穿过晶界,导致试样变形不均匀,整体变形呈现出“双颈缩”现象。

REFERENCES

[1] 杜正兴, 温志勋, 侯乃先, 岳珠峰. 考虑两种晶界的各向异性双晶和三晶体晶界附近弹塑性应力场分析[J]. 计算力学学报, 2008, 25(5): 627-633.

DU Zheng-xing, WEN Zhi-xun, HOU Nai-xian, YUE Zhu-feng. Elastic-plastic stress distribution near grain boundary in anisotropic bicrystals and tricrystals considering two kinds of grain boundaries [J]. Chinese Journal of Computational Mechanics, 2008, 25(5): 627-633.

[2] 邹风雷, 高克玮, 谢建新. 双晶体拉伸变形的原位观察分析[J]. 科技信息, 2007, 34: 33.

ZOU Feng-lei, GAO Ke-wei, XIE Jian-xin. In-situ observation and analysis of bicrystal tensile deformation [J]. Science & Technology Information, 2007, 34: 33.

[3] 邹风雷, 高克玮, 朱其芳, 谢建新. 纯铜双晶体拉伸变形的介观力学分析[J]. 金属学报, 2008, 44(3): 297-301.

ZOU Feng-lei, GAO Ke-wei, ZHU Qi-fang, XIE Jian-xin. Mesomechanical analysis of the tensile deformation of pure copper bicrystal [J]. Acta Metallurgica Sinica, 2008, 44(3): 297-301.

[4] ZIEGLER A, CAMPBELL G, KUMAR M, ST?LKEN J. Effect of the grain boundary on the evolution of deformation in a bicrystal [J]. Journal of Materials Science, 2005, 40(12): 3225-3229.

[5] SU J Q, DEMURA M, HIRANO T. Mechanical behaviour of Σ3 boundaries in Ni3Al [J]. Acta Materialia, 2003, 51(9): 2505-2515.

[6] 张哲峰, 王中光. 双晶体的取向因子[J]. 力学与实践, 1998, 20(1): 15-16.

ZHANG Zhe-feng, WANG Zhong-guang. Orientation factor of bicrystal [J]. Mechanics in Engineering, 1998, 20(1): 15-16.

[7] 张哲峰, 王中光, 李广义. 铜双晶体循环变形的晶界强化效应[J]. 材料研究学报, 1998, 12(6): 587-593.

ZHANG Zhe-feng, WANG Zhong-guang, LI Guang-yi. Strengthening effect of grain boundary on copper bicrystal under cyclic loading [J]. Chinese Journal of Material Research, 1998, 12(6): 587-593.

[8] 张哲峰, 王中光, 苏会和. 垂直晶界铜双晶体的循环形变行为[J]. 金属学报, 1998, 34(8): 841-846.

ZHANG Zhe-feng, WANG Zhong-guang, SU Hui-he. Cyclic deformation behavior of a copper bicrystal with a perpendicular grain boundary [J]. Acta Metallurgica Sinica, 1998, 34(8): 841-846.

[9] ZHANG Z F, WANG Z G. Grain boundary effects on cyclic deformation and fatigue damage deformation and cracking behavior of copper bicrystals [J]. Progress in Materials Science, 2008, 53(7): 1025-1099.

[10] ZHANG Z F, WANG Z G. Effects of grain boundaries on cyclic deformation behavior of copper bicrystals and columnar crystals [J]. Acta Materialia, 1998, 46(14): 5063-5072.

[11] CHEN C R, LI S X, WANG Z G. Characteristics of strain and resolved shear stress in a bicrystal with the grain boundary perpendicular to the tensile axis [J]. Materials Science and Engineering A, 1998, 247(2): 15-22.

[12] FENG Lu, ZHANG Guang, ZHANG Ke-shi. Grain boundary effects on the inelastic deformation behavior of bicrystals [J]. Materials Science and Engineering A, 2003, 361(1/2): 83-92.

[13] IWASAKI T, SASAKI N, CHIBA N, ABE Y. Molecular dynamics study of shear and tensile deformation of bicrystalline aluminum [J]. Computational Mechanics, 1995, 16(2): 69-73.

[14] SPEAROT D E, CAPOLUNGO L, QU J, CHERKAOUI M. On the elastic tensile deformation of á100? bicrystal interfaces in copper [J]. Computational Materials Science, 2008, 42(1): 57-67.

[15] SPEAROT D E, JACOB K I, MCDOWELL D L. Dislocation nucleation from bicrystal interfaces with dissociated structure [J]. International Journal of Plasticity, 2007, 23(1): 143-160.

[16] SPEAROT D E, TSCHOPP M A, JACOB K I, MCDOWELL D L. Tensile strength of á100? and á110? tilt bicrystal copper interfaces [J]. Acta Materialia, 2007, 55(2): 705-714.

[17] 金观昌. 计算机辅助光学测量[M]. 第2版. 北京: 清华大学出版社, 2007: 140-170.

JIN Guan-chang. Computer-aided optical measurement [M]. 2nd ed. Beijing: Tsinghua University Press, 2007: 140-170.

[18] PAN B, QIAN K, XIE H, ASUNDI A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review [J]. Measurement Science and Technology, 2009, 20(6): 1-17.

[19] 潘 兵, 谢惠民. 数字图像相关中基于位移场局部最小二乘拟合的全场应变测量[J]. 光学学报, 2007(11): 1980-1986.

PAN Bing, XIE Hui-min. Full-field strain measurement based on least-square fitting of local displacement for digital image correlation method [J]. Acta Optica Sinica, 2007(11): 1980- 1986.

[20] SUTTON M A, YAN J H, TIWARI V, SCHREIER H W, ORTEU J J. The effect of out-of-plane motion on 2D and 3D digital image correlation measurements [J]. Optics and Lasers in Engineering, 2008, 46(10): 746-757.

[21] PAN B, ASUNDI A, XIE H, GAO J. Digital image correlation using iterative least squares and pointwise least squares for displacement field and strain field measurements [J]. Optics and Lasers in Engineering, 2009, 47(7): 865-874.

[22] 胡 锐, 何 平, 李金山, 毕晓勤, 李玉龙, 傅恒志. 连铸单晶铜的力学性能及断裂特征[J]. 机械科学与技术, 2005, 24(6): 716-718.

HU Rui, HE Ping, LI Jin-shan, BI Xiao-qin, LI Yu-long, FU Heng-zhi. Analysis of mechanical properties and fracture characteristic of continuous casting single crystal copper [J]. Mechanical Science and Technology, 2005, 24(6): 716-718.

[23] 潘 兵, 吴大方, 夏 勇. 数字图像相关方法中散斑图的质量评价研究[J]. 实验力学, 2010(2): 120-129.

PAN Bing, WU Da-fang, XIA Yong. Study of speckle pattern quality assessment used in digital image correlation [J]. Journal of Experimental Mechanics, 2010(2): 120-129.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(10932008,10902090);西北工业大学基础研究基金资助项目(JC201001);111计划资助项目(B07050)

收稿日期:2011-10-12;修订日期:2012-01-13

通信作者:李玉龙,教授,博士;电话:029-88494859; E-mail: liyulong@nwpu.edu.cn