文章编号:1004-0609(2009)09-1601-07

W-Ni-Fe高密度合金的微波烧结

周承商,易健宏,罗述东,彭元东,陈 刚

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:研究90W-7Ni-3Fe高密度合金的微波烧结工艺,探讨烧结温度和烧结时间等工艺参数对合金密度和力学性能的影响,并对W晶粒的生长规律进行分析。结果表明:该合金的微波烧结升温速度快,烧结周期短;微波烧结促进合金固结,在1 480 ℃,5 min条件下,获得相对密度为99.24%、拉伸强度为925 MPa和伸长率为23.64%的样品;在短时间内烧结时,微波烧结样品的W晶粒尺寸小于常规烧结的,但微波烧结样品的生长速率更快,微波烧结不宜过度延长烧结时间。

关键词:W-Ni-Fe合金;微波烧结;晶粒生长

中图分类号:TF 125.2;TG 146.4 文献标识码:A

Microwave sintering of W-Ni-Fe heavy alloys

ZHOU Cheng-shang, YI Jian-hong, LUO Shu-dong, PENG Yuan-dong, CHEN Gang

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: 90W-7Ni-3Fe heavy alloys was preliminarily sintered via microwave radiation, and the effects of sintering parameters, such as peak temperature and sintering time on the density and mechanical performance of alloy were investigated, the grain growth of W was analyzed. The results show that the heating rate of the alloy by microwave sintering technique is fast, therefore the sintering cycle reduces dramatically. The consolidating process is promoted and the as-sintered alloys have excellent properties, such as relative density of 99.24%, tensile strength of 925 MPa and elongation of 23.64% after sintering at 1 480 ℃ for 5 min. In spite of higher growth rate microwave sintering leads to finer W grain size after short time soaking, compared with conventional sintering, which suggests that microwave sintering leads to higher growth rate of W grains, and the prolongation of sintering time of W in heavy alloys is undesirable.

Key words: W-Ni-Fe alloy; microwave sintering; grain growth

微波烧结技术具有烧结周期短、能量消耗低以及环境友好等优点,符合当前发展绿色工业的形势,近20年来备受关注[1]。金属粉末冶金材料如铁基、铜基、镍基以及钨基材料等在粉末冶金工业中占据重要作用,被大量生产和应用,因此,金属粉末冶金材料的微波烧结具有重要的研究意义和巨大的市场前景。1999年,ROY等[2]首次报道利用微波烧结出Fe-Cu-C等典型金属粉末冶金材料,且其力学性能明显优于传统烧结产品的,自此各国材料学者对微波烧结金属粉末冶金材料进行了广泛的研究,获得大量有意义的结果[3]。研究表明,微波烧结将电磁能在材料内部直接转化为热能而引起粉末固结和合金化,是一种体积加热行为,获得的材料表现出快速致密、组织均匀和力学性能优异等特征[4-6]。

微波烧结具有细化显微组织的作用,如830 ℃烧结Cu-Sn合金时,微波烧结所得的Cu晶粒尺寸仅为常规烧结的58.6%,对于Sn-Ag合金,微波烧结的Ag3Sn相平均晶粒尺寸也明显小于常规烧结的Ag3Sn相平均晶粒尺寸,分别为(0.7±0.1) μm和(1.2±0.2) μm[4, 7-8]。事实上,部分研究建立在不同烧结参数的结果上而得此结论,即微波烧结通常采用更低的烧结温度或更短的保温时间[8-9]。而XIE等[10]研究认为,在相同的烧结条件下微波烧结获得的晶粒尺寸大于常规烧结获得的晶粒组织,本研究小组在W-Cu体系中也观察到此现象[11]。因此,有必要研究微波烧结过程中材料晶粒的生长行为,以便对显微组织和性能特征进行优化控制。

W-Ni-Fe 高密度合金由近球形W晶粒硬质相镶嵌在基体粘结相Ni-Fe-W 中的两相复合材料组成。该材料采用粉末冶金技术生产,其烧结属于典型的液相烧结类型[12]。传统的W-Ni-Fe合金烧结工艺采取缓慢的升温速度(约5~10 ℃/min)和中间温度保温等措施,以避免温度梯度过大而引起合金变形和鼓泡等缺陷,从而整个烧结周期较长和生产效率较低[13]。利用微波烧结提高合金致密化速度的优点,将其引入高密度合金的制备,其意义不言而喻。因此,本文作者对微波烧结W-Ni-Fe高密度合金进行了研究,揭示了烧结工艺参数对合金密度、显微组织以及力学性能的影响规律,重点分析W晶粒的生长行为。

1 实验

实验设计90W-7Ni-3Fe成分的合金,按质量分数配料,以丙酮为介质,球料质量比1?1、转速150 r/min,在不锈钢球磨筒中混合6 h。粉末在空气中干燥后以350 MPa压力压制标准拉伸样。表1所列为实验所用各种粉末的基本参数。

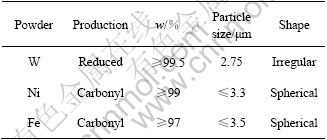

表1 W、Ni及Fe粉末原料特征

Table 1 Characteristics of W, Ni and Fe powders

微波烧结实验在微波频率2.45 GHz、功率5.5 kW的微波高温炉(型号为MW-L0616V,中国)中完成。实验采用SiC作为辅助加热材料,Al2O3纤维包套作为保温材料。微波烧结过程中采用红外测温仪(型号为Raytek MM2MH,United States。测温范围为450~ 2 250 ℃)控制温度,探测头发射率为0.75。在整个烧结过程中通过手动调节微波输入功率来控制温度,烧结气氛为90%N2+10%H2(体积分数)。同时在钼丝炉中进行常规烧结,烧结气氛为流动H2。

采用排水法测定烧结样品的密度,测量样品的拉伸强度及伸长率。在扫描电子显微镜(型号为JSM 6360LV,Japan)分析样品断口形貌以及抛光后的显微组织和成分。采用弦切法测量SEM像中的W晶粒尺寸,在对300个以上的对象进行测量后取平均值得到W的平均晶粒尺寸。

2 结果与讨论

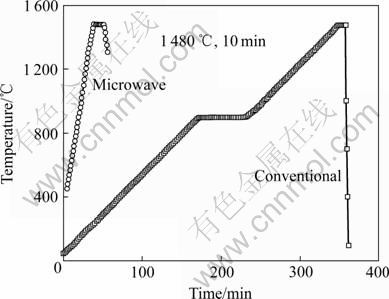

采用常规工艺烧结W-Ni-Fe高密度合金时,为避免因加热速度过快而引起样品变形和鼓泡等缺陷,通常将升温速度保持在较低水平。微波烧结是体积加热行为,可以采用以较快速度加热样品,从而整个烧结周期能够大幅度缩短。图1所示为微波烧结与常规烧结温度随时间的变化。常规烧结升温速度为5 ℃/min,并在900 ℃保温1 h。试样在烧结结束后快速冷却,以便更好地对比分析烧结时间对晶粒生长的影响。由图1可见,从室温到烧结温度(1 480 ℃),微波烧结平均升温速率为36.5 ℃/min,从升温至保温结束过程在50 min内完成,所需时间仅为常规烧结的1/7,体现出缩短烧结周期的优势。实验发现,微波烧结的升温速度可以进一步提高,烧结周期可以再度缩短,这对工业生产具有重要意义。

图1 微波与常规烧结的温度随时间的变化

Fig.1 Change of temperature with time for microwave and conventional sintering

2.1 烧结参数对合金密度和性能影响规律

表2所列为不同温度条件下的微波和常规烧结所得的样品密度及力学性能数据。结果显示,就合金密度而言,经1 480 ℃微波烧结保温10 min后合金密度达到99.24%,高于常规烧结的最佳值(1 500 ℃,30 min,99.05%),更高的烧结温度引起合金密度下降。从力学性能分析,提高烧结温度,微波烧结样品拉伸强度降低、伸长率增大,而常规烧结在1 480 ℃烧结后结果最好。在实验范围内,微波烧结样品力学性能均优于常规烧结。从烧结时间对合金密度和性能的影响结果来看(见图2),采用微波烧结时,合金最大密度、最高拉伸强度和伸长率分别出现在5、0和5 min处,而对于相同温度(1 480 ℃)下的常规烧结,上述性能分别出现在30、10和10 min处,所有参数均落后于微波烧结的。这些实验结果表明,使合金要达到相同密度和力学性能,微波烧结比常规烧结所需温度更低或烧结时间更短,这显然符合活化烧结的表象特征。

表2 烧结模式与温度对合金性能的影响

Table 2 Effects of sintering mode and temperature on properties of sintered alloys

图2 保温时间对合金密度、抗拉强度以及伸长率的影响

Fig.2 Effect of duration time on sintered density(a), tensile strength(b) and elongation(c) of sintered alloys

在W-Ni-Fe高密度合金体系中,Ni-Fe二元合金共晶点为1 435 ℃,Ni-Fe-W三元合金共晶点为1 465 ℃。在烧结W-Ni-Fe合金过程中,随着温度的升高,压坯内依次出现粉末间的固相烧结、液相出现后的溶解—再析出以及W晶粒的固相烧结等阶段。在前两阶段,颗粒重排等烧结机构对提高合金致密度贡献最大,中间阶段对促进各组元间的合金化效果最显著,而后两阶段却最大程度决定着W晶粒最终的尺寸,这表明各烧结阶段分别对控制合金密度和显微组织起着关键作用[12, 14]。表2和图2实验结果表明,微波烧结在合金的前两个阶段发挥作用大于常规烧结,从而能够在1 460 ℃和1 480 ℃保温仅10 min后达到99.04%和99.24%的相对密度,明显高于相同温度、常规烧结保温30 min的98.35%和99.02%。微波烧结具有的此种优势,可以从固相烧结W粉压坯的实验结果进一步证实[15]。SAITOU等[16]研究了多种金属粉末(包括Fe、Co、Ni、Cu和316L不锈钢)压坯的致密化行为,发现微波烧结压坯的收缩系数明显高于常规烧结的,说明前者能促进材料的致密化。但计算得到两者的烧结活化能并无明显差异,暗示微波烧结的致密化机理与常规烧结工艺是一致的。因此,微波烧结促进材料烧结可能不是改变了烧结机构,而仅仅是提高致密化速度而已。

图3所示为1 460和1 520 ℃微波烧结及常规烧结试样断口的SEM像。由图3可看出,1 460 ℃烧结样品中W晶粒虽然已经长大,但呈现多边形,而非典型的球形形貌,表明烧结过程中W晶粒固相烧结占据主导作用。烧结时虽然出现液相,但其流动不充分,W晶粒之间的直接结合比例高,从而断口以W晶粒之间或W晶粒与基体相之间的直接分离形式为主,不存在基体相撕裂这样的韧性断裂形式,样品伸长率较低。而微波固相烧结样品相对密度和拉伸强度均较高,分别达到99.04%和965 MPa,均明显高于相同温度下常规烧结样品的。该现象一方面归结于微波烧结样品具有更高的密度,另一方面W晶粒尺寸细小也有重要影响。在烧结温度提高至1 520 ℃后,W大量溶解于基体液相中,饱和之后再析出于W晶粒表面。溶解—再析出过程不仅促进W晶粒形状和尺寸的快速变化,同时也增强了固相W晶粒与基体相Ni-W-Fe间的结合,进而引起合金断裂方式和力学性能的变化。从1 520 ℃烧结样品断口看出,在固相与液相之间充分合金化之后,出现W晶粒穿晶断裂和基体相撕裂等方式,合金同时具有较高拉伸强度和伸长率。

图3 样品经1 460 ℃和1 520 ℃微波烧结10 min和常规烧结30 min后断口的SEM像

Fig.3 SEM images of fracture of samples after 1 460 ℃(a) and 1 520 ℃(c) microwave sintered for 10 min and 1 460 ℃(b) and 1 520 ℃(d) conventional sintered for 30 min

2.2 显微组织演变分析

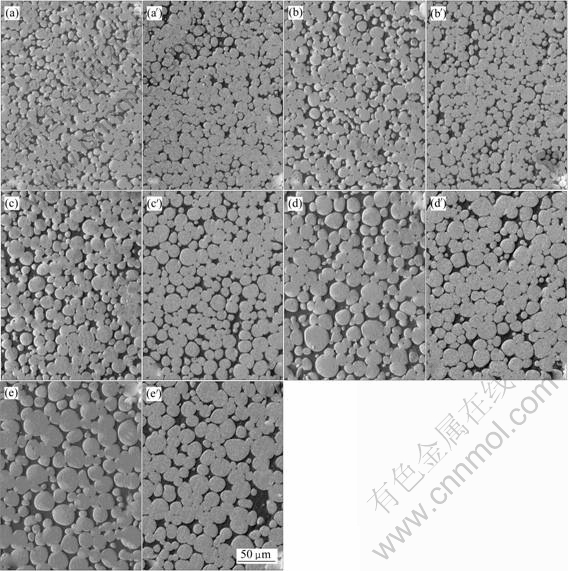

液相烧结W-Ni-Fe合金过程中,W晶粒通过溶解—再析出和晶粒合并等方式生长,尺寸逐渐增大。图4所示为合金显微组织随烧结时间的演变。由于常规烧结加热速度慢的缘故,W晶粒暴露于高温环境的时间长,从而在达到最高烧结温度时,晶粒已经明显生长,尺寸大于微波烧结晶粒的尺寸。此外,延长烧结时间后,W晶粒平均尺寸显著增加,其分布受烧结方式影响也较大,即微波烧结样品中存在较多细小W晶粒,而且其尺寸分布比常规烧结的宽。W晶粒平均尺寸与烧结时间的关系曲线见图5(a)。测量结果表明:在0~10 min范围内,常规烧结样品的W晶粒生长速度大于微波烧结的;延长保温时间后,虽然两者的生长速度均有所减缓,但前者的减慢速度明显高于后者的,以至于在烧结30 min后两者晶粒尺寸十分接近(约18 μm)。W晶粒尺寸的演变规律与样品的致密化进程相关(见图2),微波烧结样品在10 min内达到完全致密,而常规烧结则在30 min后仍在进行,且还有致密化空间。该实验结果证明,当烧结时间较短或者在材料致密化过程结束之前,微波烧结获得的晶粒尺寸低于常规烧结,这与大多数文献报道的结论一致[7]。但由于致密化过程结束之后,微波烧结样品的晶粒生长速度超过常规烧结,那么晶粒尺寸则可能前者大于后者。因此,鉴于晶粒尺寸关系取决于烧结时间因素,上述结论并不违背在W-Cu和Al2O3体系中获得的结果[10-11]。

图4 合金显微组织随保温时间的演变

Fig.4 Microstructural development of microwave ((a)-(e)) and conventional ((a′)-(e′)) sintering alloys with duration time: (a), (a′) 0 min; (b), (b′) 5 min; (c), (c′) 10 min; (d), (d′) 20 min; (e), (e′) 30 mi

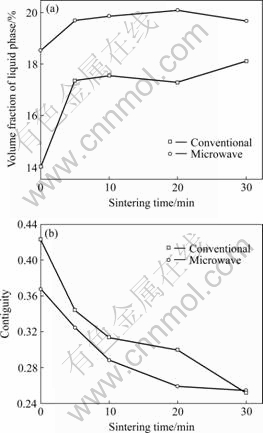

图5 液相体积分数(a)和接触度(b)随保温时间的变化

Fig.5 Change of volume fraction of liquid(a) and contiguity(b) with duration time

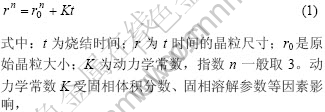

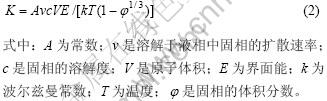

对图4中各SEM像进行分析可得到保温时间变化对液相体积分数和接触度的影响如图5所示。结果显示,微波烧结液相的体积分数均大于常规烧结相的,在保温0 min时,前者液相体积分数仅为18.54%,大大高于后者的14.02%;取决于液相体积分数的接触度表现出必然结果,即微波烧结样品的接触度小于常规烧结的,但在30 min时,两者接近。液相体积分数以及接触度的演变对合金致密化行为和力学性能差异提供了很好解释。在W-Ni-Fe合金中,W晶粒的长大主要发生在液相烧结的溶解-再析出和W晶粒固相烧结阶段,它们分别以Oswald ripening和晶粒合并方式生长。一般认为在固相体积分数较高的情况下,液相烧结中晶粒合并生长为一种较重要的机制[17]。总体来说,本实验中液相烧结阶段两种烧结模式均以溶解-析出为主,在这一机制中,以扩散控制生长的晶粒尺寸随时间呈线性增长,一般可表示为[18]:

可表示为:

可表示为:

对图6(a)晶粒尺寸按式(1)处理,结果如图6(b)所示。经过式(1)计算得出微波烧结的动力学常数K为2.93 μm3/s,略大于常规烧结的2.50 μm3/s,即晶粒生长速度较大。W晶粒生长动力学常数受烧结条件和合金成分影响较大,如当n=3时,在88 W至95 W合金中,动力学常数大约在2.1~2.6 μm3/s范围[13, 19]。本实验测的常规烧结动力学常数处在上述区间,虽然微波烧结的偏大,但仅是数量上的微小差异,因此晶粒生长模型没有变化[16]。从式(2)可以看出,影响动力学常数的因素主要为固液界面能E和扩散速率v。由图4可看出,在微波烧结样品的显微组织中,二面角明显小于常规烧结的,表明其固液界面能高于后者的,这对提高动力学常数K有积极作用。此外,本研究不能排除微波烧结时固相在液相中的扩散速率更大的可能,因为在氧化铝材料中的确存在此现象[20]。

图6 晶粒尺寸随时间延长的变化曲线(a)以及生长动力学(b)曲线

Fig.6 Curves of W grain growth with duration time(a) and dynamic curves(b) of grain growth

3 结论

1) 采用微波烧结能快速制备高致密及力学性能优异的W-Ni-Fe高密度合金,烧结周期缩短为常规烧结的1/7。

2) 与常规烧结相比,微波烧结促进了W-Ni-Fe压坯的致密化,即能以更低的烧结温度或更短的保温时间获得综合性能优异的合金;在1 480 ℃,5 min条件下,获得相对密度99.24%、拉伸强度925 MPa、伸长率23.64%性能优异的样品。

3) 当烧结时间较短(30 min内)时,微波烧结W-Ni-Fe合金的W晶粒尺寸小于常规烧结的,但微波烧结的生长速率更快。

REFERENCES

[1] BYKOV Y V, RYBAKOV K I, SEMENOV V E. High-temperature microwave processing of materials[J]. J Phys D: Appl Phys, 2001, 34: 55-75.

[2] ROY R, AGRAWAL D, CHENG J, GEDEVANISHVILI S. Full sintering of powder metal bodies in a microwave field[J]. Nature, 1999, 399(17): 668-670.

[3] 彭元东, 易健宏, 罗述东, 李丽娅, 陈 刚, 冉俊铭. 微波技术在金属材料制备中的应用现状[J]. 稀有金属材料与工程, 2009, 38(4): 742-747.

PENG Yuan-dong, YI Jian-hong, LUO Shu-dong, LI Li-ya, CHEN Gang, RAN Jun-ming. Review of microwave energy application in metallic materials preparation[J]. Rare Metal Materials and Engineering, 2009, 38(4): 742-747.

[4] UPADHYAYA A, SETHI G. Effect of heating mode on the densification and microstructural homogenization response of premixed bronze[J]. Scripta Materilia, 2007, 56(6): 469-472.

[5] ANKLEKAR R M, BAUER K, AGRAWAL D K, ROY R. Improved mechanical properties and microstructural development of microwave sintered copper and nickel steel PM parts[J]. Powder Metallurgy, 2005, 48(11): 39-46.

[6] ANKLEKAR R M, AGRAWAL D K, ROY R. Microwave sintering and mechanical properties of PM copper steel[J]. Powder Metallurgy, 2001, 44(4): 355-362.

[7] PANDA S S, SINGH V, UPADHYAYA A, AGRAWAL D. Sintering response of austenitic (316L) and ferritic (434L) stainless steel consolidated in conventional and microwave furnaces[J]. Scripta Mater, 2006, 54(12): 2179-2183.

[8] BABAGHORBANI P, GUPTA M. Enhancing the mechanical response of a lead-free solder using an energy-efficient microwave sintering route[J]. J Electronic Mater, 2008, 37(6): 860-866.

[9] UPADHYAYA A, TIWARI S K, MISHRA P. Microwave sintering of W-Ni-Fe alloy[J]. Scripta Materialia, 2007, 56(1): 5-8.

[10] XIE Zhi-peng, YANG Jin-long, HUANG Yong. Densification and grain growth of alumina by microwave processing[J]. Materials Letters, 1998, 37(44): 215-220.

[11] LUO Shu-dong, YI Jian-hong, GUO Ying-li, PENG Yuan-dong, LI Li-ya, RAN Jun-ming. Microwave sintering W-Cu composites: Analyses of densification and microstructural homogenization[J]. Journal of Alloys and Compounds, 2009, 43: 5-9.

[12] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 2004: 310-314.

HUANG Pei-yun. Theory of powder metallurgy[M]. Beijing: Metallurgical Industry Press, 2004: 310-314.

[13] BOLLINA R, GERMAN R M. Heating rate effects on microstructural properties of liquid phase sintered tungsten heavy alloys[J]. Int J Refractory Metals Hard Mater, 2004, 22(2): 117-127.

[14] PARK J, KANG S L, EUN K Y, YOON D N. Microstructural change during liquid phase sintering of W-Ni-Fe alloy[J]. Metallurgical Transactions A, 1989, 20(5): 837-845.

[15] JAIN M, SKANDAN G, MARTIN K, CHO K, KLOTZ B, DOWDING R, KAPOOR D, AGRAWAL D, CHENG J. Microwave sintering: a new approach to fine-gain tungsten (Ⅱ)[J]. Int J Powder Metall, 2006, 42(2): 45-50.

[16] SAITOU K. Microwave sintering of iron, cobalt, nickel, copper and stainless steel powders[J]. Scripta Materialia, 2006, 54(5): 875-879.

[17] YANG S C, MANI S S, GERMAN R M. The effect of contiguity on growth kinetics in liquid-phase sintering[J]. JOM, 1990, 42(4): 16-19.

[18] BOSE.A, GERMAN R M. Microstructural refinement of W-Ni-Fe heavy alloys by alloying additions[J]. Metallurgical Transactions A, 1988, 19(2): 3100-3103.

[19] RABIN B H, GERMAN R M. Microstructure effects on tensile properties of tungsten-nickel-iron composites[J]. Metallurgical Transaction A, 1988, 19(6): 1523-1532.

[20] BYKOV Y V, EGOROV S V, EREMEEV A G, RYBAKOV K I, SEMENOV V E, SOROKIN A A, GUSEV S A. Evidence for microwave enhanced mass transport in the annealing of nanoporous alumina membranes[J]. J Mater Sci, 2001, 36(1): 131-136.

基金项目:中国博士后科学基金资助项目(20060400882);中南大学博士后基金资助项目

收稿日期:2008-09-26;修订日期:2008-11-10

通信作者:易健宏,教授,博士;电话:0731-88876420;E-mail: yijianhong2007@sohu.com

(编辑 李艳红)