DOI:10.19476/j.ysxb.1004.0609.2017.03.014

非平衡凝固W2C的原位生长机理及硬度分析

迟 静,李惠琪,王淑峰,李 敏,吴 杰,李建楠,赵 健

(山东科技大学 材料科学与工程学院,青岛 266590)

摘 要:利用直流电弧原位冶金技术制备WpC-Fe复合材料,通过物相分析、显微组织观察和硬度测试,研究非平衡凝固W2C的原位生成机制、形态演变以及含量和形貌对材料硬度的影响。结果表明:W和C原位反应时,熔池温度高于1652K,W2C比WC更易生成。直流电弧高温熔池非平衡凝固过程中,W2C的生长机制由小平面晶变为非小平面晶,逐渐偏离由晶体结构决定的六次等轴花状晶初生形貌,以平行连生的方式生长为定向枝晶。W2C的显微硬度低于WC的,由于受到形貌的影响,等轴花状晶的硬度(1993 HV0.2)明显高于定向枝晶的(1536HV0.2);工作电流由600A增到1000A时,复合材料中W2C的生成量增加,宏观硬度由84HRA下降为78HRA。

关键词:非平衡凝固;W2C;原位反应;生长形态;硬度

文章编号:1004-0609(2017)-03-0555-08 中图分类号:TB331 文献标志码:A

碳化钨(WC)具有硬度高、热膨胀系数小、化学性质稳定、与金属(Co、Ni、Fe等)润湿性好等优异特性,成为硬质合金和耐磨涂层的主要增强颗粒[1-2]。复合材料中WC增强相的获得主要通过两种途径:一种是外加法,即直接采用WC粉末作为原料;另一种是原位合成法,即在制备过程中通过元素间的化学反应形成WC,通常采用W和C的反应体系。近年来,高能量束流(如等离子、激光和电弧等)为热源的快速成形技术广泛应用于WC增强材料的制备。

王群等[3]以WC-12Co为原料,采用超音速火焰喷涂(HVOF)工艺在16Mn钢上制备涂层,涂层中除了WC和Co,还出现了W2C。OBADELE等[4]以 WC-10Ni为原料制备的激光涂层中W2C是主相,没有WC形成。关于外加法制备WC复合材料时生成的W2C已开展了大量研究,文献[5-9]中将其产生原因归于原料WC颗粒在高温环境中发生的脱碳现象,LIU等[7]和王群等[3]在研究中观察到W2C包裹在WC颗粒四周,呈现高亮度的环带状。然而,值得注意的是,刘发兰等[8]和袁有录等[10]指出WC颗粒在高温熔体中还存在溶解现象,分解为W和C元素。张宇等[11]和迟静等[12]研究发现熔体中的W和C会反应生成W2C。这就意味着,外加法中形成的W2C应是WC脱碳和W-C原位反应两种机理共同作用的结果,然而对于后者却缺少相关研究。另一方面,以W和C为原料,利用等离子冶金[13]、激光熔覆[11]和电弧冶金[12, 14]等技术原位合成WC增强材料时也出现了W2C。但大多数研究仅在X射线衍射(XRD)谱图中标明了W2C的存在,而对于原位反应过程中W2C的生成机理、形貌特征和对材料性能的影响却少有报道。因此,在高能热源快速成形技术所特有的非平衡凝固条件下,有必要对W2C的原位生成进行深入系统的研究。

本文作者以W和C为原料,利用直流电弧原位冶金技术制备了WpC-Fe(WpC为WC和W2C)复合材料,通过改变工作电流对比材料物相组成、微观组织和硬度的变化,探讨W2C的原位生成机理,研究非平衡凝固条件下W2C的形态演变过程,分析W2C含量和形貌对材料硬度的影响。

1 实验

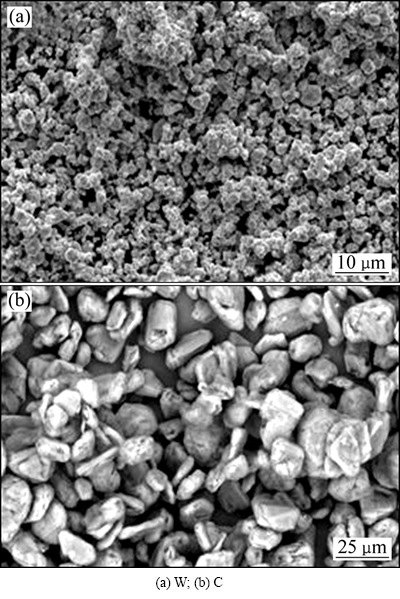

原始粉末为W粉和C粉,粉末形貌如图1所示。自耗电极管材为1Cr18Ni9Ti不锈钢管(成分见表1),内径9 mm,壁厚1 mm,长度150 mm。将W粉和C粉按照质量比93:7配成混合粉末,加入适量Na2SiO3·9H2O黏结剂,填充于不锈钢管内制成自耗电极,其中混合粉末的含量为75%(质量分数)。电极自然晾干后,置于炉内在150 ℃保温30 min,随炉冷却。实验用冶金坩埚底部为石墨片,坩埚壁为耐火材料,主要成分为Al2O3和MgO,内径13 mm,壁厚5 mm。

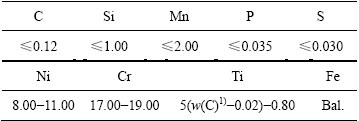

实验采用直流电弧原位冶金装置,图2所示为工作原理示意图。实验在大气环境中进行,电源的正负极分别连接冶金坩埚底部的石墨片和自耗电极,自动升降装置控制自耗电极匀速下降,与石墨电极接触后引燃电弧,在电弧热量作用下自耗电极迅速熔化,在坩埚中形成高温液相反应熔池。实验结束后,高温熔池在室温下冷却,得到WpC-Fe复合材料。

图1 原料粉末的形貌

Fig. 1 Morphologies of raw material powders

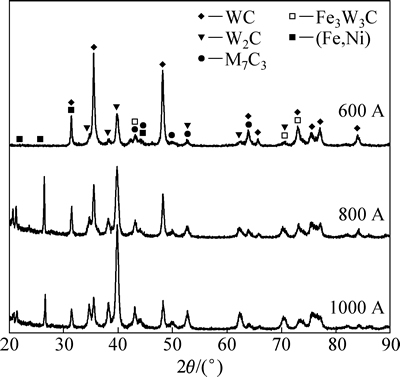

表1 不锈钢管的化学成分

Table 1 Nominal chemical composition of stainless steel tube (mass fraction, %)

分别采用600 A、800 A和1000 A 3种工作电流制备WpC-Fe复合材料,选择样品芯部沿轴线进行切割、镶嵌和抛光,腐蚀液为Murakami溶液(20%(NaOH+ K3Fe(CN)6)(质量分数))。物相分析采用D/Max 2500PC型X射线衍射仪(XRD,铜靶,Kα辐射),微观组织观察采用KYKY2008B型扫描电镜(SEM)。微区成分分析采用JXA-8230型电子探针(EPMA),波长色散谱仪(WDS)中配置可测定C含量的分光晶体LDE2。内部组织观察和电子选区衍射分析采用Tecnai 20U-TWIN高分辨透射电镜。显微硬度测定采用FM-700型维氏显微硬度计,载荷2 N,加载时间10 s;宏观硬度测试采用HR-150A型洛氏硬度计。

图2 直流电弧原位冶金工艺示意图

Fig. 2 Schematic diagram of direct current arc in-situ metallurgy process

2 结果与分析

2.1 物相分析

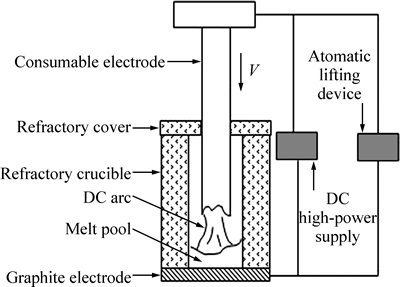

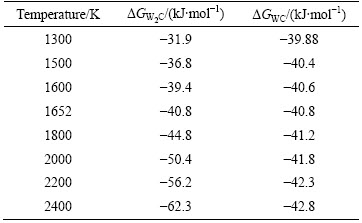

图3所示为WpC-Fe复合材料的XRD谱。由图3可知,试样的物相组成为 WC、W2C、M7C3(M=Fe,Cr,W)、Fe3W3C和(Fe,Ni);工作电流变化没有改变试样的物相组成,但影响了主要物相的相对含量。随电流增大,W2C的衍射峰强度升高,而WC衍射峰强度降低;根据X射线衍射运动学理论[15],由图3计算得出,当电流由600 A、800 A增加到1000 A时,W2C与WC的含量比分别为0.27、0.61和1.18,这表明工作电流增大导致了W2C生成量的增多。

在W2C晶体结构中W原子构成密排六方,C原子进入W原子形成的八面体空隙,但只填充了其中的一半,另一半为结构空位。由于C原子占据的空隙位置不同,W2C形成多种晶体结构[16-17],分别命名为α-W2C( )、β-W2C(

)、β-W2C( )、γ-W2C(

)、γ-W2C( )和ε-W2C(

)和ε-W2C( )。由图3的XRD衍射数据可知,WpC-Fe复合材料中原位生成的W2C为β-W2C,空间群为

)。由图3的XRD衍射数据可知,WpC-Fe复合材料中原位生成的W2C为β-W2C,空间群为 。

。

图3 WpC-Fe复合材料的XRD谱

Fig. 3 XRD patterns of WpC-Fe composites

2.2 显微组织分析

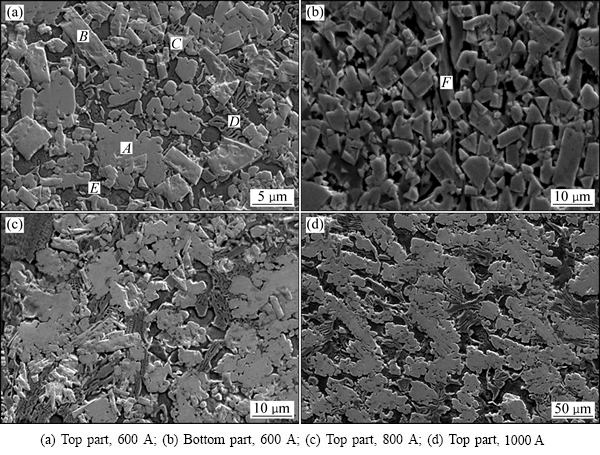

图4所示为电流为600 A时制备的WpC-Fe复合材料的显微组织形貌,相应的波谱分析结果列于表2。花状枝晶(图4(a)中A位置)含有大量的C和W,同时还有约为10.3%(摩尔分数)的Cr。由W-C二元相图可知,W2C中C元素的含量可在26%~34% (摩尔分数)范围内变化;BERGER等[18]的研究表明,Cr能够进入W2C晶体结构,占据W原子的晶格位置,形成置换型固溶体。同时结合XRD谱可知(见图3),确定花状枝晶为固溶了Cr的W2C。矩形颗粒(见图4(a)中B位置)和三角形颗粒(见图4(a)中C位置)成分相同,由W和C组成,且两者的摩尔比为1:1,确定为WC。文献[11-14,19-21]已对WC开展了大量研究,表明矩形和三角形是原位生成WC晶粒的典型二维形貌,文献研究结果进一步确认了上述有关WC组织分析的合理性。菊状共晶(见图4(a)中D位置)是由M7C3(M=Fe,Cr,W)和Fe基固溶体构成。POWELL等[22]对M7C3进行了详细研究,指出菊状形貌为其亚共晶组织。暗色基体相(见图4(a)中E位置)为Fe基固溶体,树枝晶(见图4(b)中F位置)为Fe3W3C,固溶了Cr、Ni元素。

试样的显微组织呈现区域分布的特点,上部(见图4(a))W2C枝晶数量较多,而WC晶粒主要分布于下部(见图4(b))。电流由600 A(见图4(a))和800 A(见图4(c))增大到1000 A(见图4(d)),试样具有相同的典型组织形貌和区域分布特征,但W2C枝晶数量明显增多,这与XRD结果(见图3)中W2C含量的变化规律一致。同时,随电流增加,W2C枝晶明显粗大,这是由于电流升高,热量增加,熔池持续时间延长,W2C生长充分。

图4 WpC-Fe复合材料的显微组织

Fig. 4 Microstructures of WpC-Fe composites

表2 图4(a)和(b)中WpC-Fe复合材料的波谱分析结果

Table 2 WDS analysis results of WpC-Fe composites in Fig. 4(a) and (b)

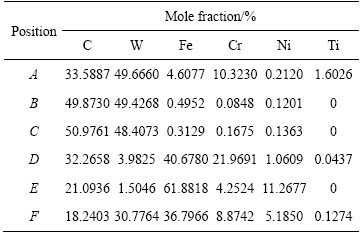

图5(a)为复合材料中W2C的TEM像,其选区电子衍射图如图5(b)所示,晶带轴为[101]。由图5(c)可以看出,WC晶粒具有明显的三角形形貌,界面洁净平直,这与依据SEM像(见图4)和WDS数据(见表2)对WC的分析结果一致;图5(e)和(f)分别为Fe3W3C的TEM像和选区电子衍射图。

刘发兰等[8]采用外加法,以Ni60A-WC为原料制备的激光熔覆涂层中也观察到了大量相同形貌的花状枝晶,并指出该枝晶是由原料WC分解出的W元素,与熔池中的C、Cr等反应形成的。而LIU等[7]和王群等[3]的研究表明,由原料WC脱碳形成的W2C是包裹在WC颗粒的四周,呈环带状。由此可以得出,基于W-C原位反应和WC脱碳两种机制生成的W2C,具有显然不同的形貌特征;本文作者探讨的W2C原位生长机制,同样适用于外加法中原位生成的W2C枝晶。

图5 WpC-Fe复合材料中W2C、WC和Fe3W3C的TEM像和选区电子衍射图

Fig. 5 TEM images ((a), (c), (e)) and selected area electron diffraction patterns ((b), (d), (f)) of WpC-Fe composites

2.3 W2C的原位生长机理

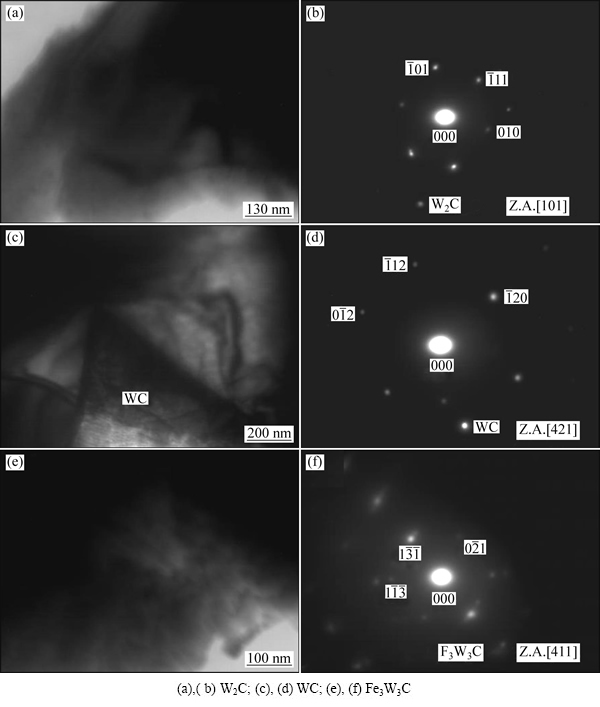

2.3.1 W2C原位生成的影响因素

在制备过程中,原料中的C在高能热源(如激光、等离子和电弧等)的作用下有一定程度的烧损,并且C易与O结合生成CO和CO2气体[11],因此,熔池中实际的C含量与原料配比存在偏差。根据W-C二元相图,W和C反应主要形成两种碳化物WC和W2C,其中WC是化学计量化合物,即W和C摩尔比为1:1;而W2C是非化学计量化合物,C含量的变化范围宽,为26%~34%(摩尔分数)。因此,反应熔池中W和C的原子比例是影响W2C生成的一个因素。

本文作者采用相同的原料,在不同的电流条件下制备试样,W2C含量发生了明显的规律性变化,而电流大小直接决定熔池温度,由此可以说明,W2C的原位生成还取决于熔池温度。根据热力学数据[23],对W和C原位反应生成W2C(见式1)和WC(见式2)的吉布斯自由能(ΔG)进行了计算,结果列于表3,其中 和

和 分别表示反应产物为W2C和WC的ΔG值。

分别表示反应产物为W2C和WC的ΔG值。

(1)

(1)

W+C=WC (2)

可以看出,当温度低于1652K时, >

> ;而温度高于1652K后,

;而温度高于1652K后, 下降趋势显著,明显低于

下降趋势显著,明显低于 。这表明,在高温条件下,W2C比WC更易形成。DMITRII等[24]利用第一性原理计算方法也证实了W2C为高温相。

。这表明,在高温条件下,W2C比WC更易形成。DMITRII等[24]利用第一性原理计算方法也证实了W2C为高温相。

直流电弧原位冶金制备WpC-Fe复合材料时,自耗电极在电弧作用下熔化,滴入冶金坩埚形成反应熔池。位于坩埚下部的熔池最先形成,有一部分热量会被室温下的坩埚吸收,造成温度降低;而上部熔池接受已形成熔池的热量供应,并与电弧直接接触,温度较高;此外,直流电弧原位冶金速度快,熔池在短时间内无法达到热量均匀,因此高温相W2C易于在上部熔池形成。随工作电流增大,单位时间内电弧产生的热量增加,熔池温度升高,为W2C的生成提供了更有利的热力学条件,W2C生成量增多。上述理论分析与XRD谱(见图3)和显微组织(见图4)中W2C的分布特点和变化规律相一致。

表3 W和C反应的ΔG值

Table 3 ΔG of tungsten reacting with carbon

2.3.2 非平衡凝固W2C的原位生长形貌

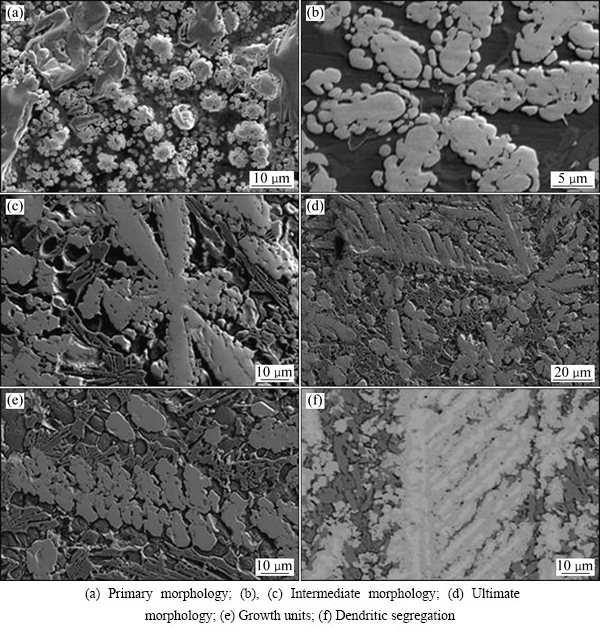

直流电弧原位冶金冷却速度快,在试样中可观察到非平衡凝固条件下W2C不同生长阶段的形貌。图6(a)是W2C枝晶的初生形貌,呈现径向六次对称的等轴花瓣状,棱角分明,具有典型的晶体学小平面晶特征。XRD(见图3)结果表明:本实验中生成的是β-W2C,属于六方晶系,因此初生枝晶的六次对称形貌是由晶体结构决定的。

在生长过程中,W2C枝晶棱角逐渐消失,界面变得圆滑,如图6(b)所示。根据晶体生长理论[25],小平面晶在原子尺度上具有光滑的固/液界面,液相溶质原子与界面的结合力弱不易附着,只能依靠固/液界面上出现的二维晶核和缺陷(如螺旋位错)等台阶来实现晶体长大。一般情况下,随冷却速度增大,缺陷密度明显增加,生长台阶数目增多,液相溶质原子可以随机附着在生长界面的任意位置,因而晶体微观生长机制由小平面晶转变为非小平面晶,宏观形貌上不再具有明显的结晶面特征,而是表现出光滑的界面。直流电弧原位冶金熔池冷却速度较快,从而导致了W2C枝晶的生长机制发生转变。图6(c)所示为W2C枝晶主干上逐渐生长出二次枝晶臂,当二次枝晶顶端进入相邻枝晶的扩散场时,生长就会受到限制。由于W2C枝晶呈现六次对称分布,一次枝晶臂间距小,因此二次枝晶的生长空间有限,尺寸短小。

图6 W2C枝晶生长形貌

Fig. 6 Growth morphologies of W2C dendrites

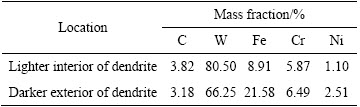

表4 图6(f)中W2C枝晶的能谱分析结果

Table 4 EDS analysis results of W2C dendrite in Fig.6(f)

在直流电弧原位冶金技术中,直流电弧定向作用强,W2C枝晶在定向热流的影响下,逐渐偏离由晶体结构决定的六次对称生长(见图6(c)),与热流方向相近的枝晶主干生长迅速,而与热流方向偏差较大的枝晶主干则生长缓慢,逐渐消失。枝晶生长过程中,枝晶尖端不断向熔体排出溶质,在熔池冷却速度较快的条件下,凝固析出的溶质不能充分扩散到熔体中,因此在枝晶尖端形成“成分过冷”,更加有利于枝晶的快速生长。伴随着枝晶主干不断深入熔体内部,二次枝晶受邻近枝晶扩散场的限制逐渐减弱,因而生长迅速,尺寸粗大,并且这些发达二次枝晶均与一次枝晶臂形成约为60°的夹角,如图6(d) 所示。从高倍SEM像中(见图6(e))发现,W2C枝晶是由形貌相似的生长基元平行排列组成,这些生长基元同时长大粗化,当其相互连结时即形成完整的枝晶臂,因此,W2C枝晶是以平行连生的方式生长。

由图6(f)的背散射图像可以看出,尺寸粗大的W2C枝晶存在明显的成分偏析。表4的EDS分析结果表明,枝晶中心亮色区域的W含量为80.50%(质量分数),而暗色边缘区域W含量降为66.25%(质量分数)。分析认为, W2C枝晶的生长消耗了熔体中大量的W元素,随着枝晶尺寸不断粗大,周围熔体中W含量逐渐下降,而在熔池冷却速度较快的条件下,远处熔体中的W原子没有足够的时间充分扩散,因此后结晶的边缘区域W含量低于先结晶的枝晶主干。

综上所述,在直流电弧原位冶金非平衡凝固条件下,W2C枝晶的生长机制由小平面晶转化为非小平面晶,受熔池热流影响逐渐偏离六次对称花状晶的初生形貌,与热流相近方向一次枝晶粗大,二次枝晶生长迅速,以平行连生的方式成为定向生长的发达树枝晶,存在明显的枝晶偏析。

2.4 硬度测试分析

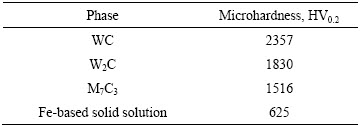

表5所列为试样主要物相的平均显微硬度,其中W2C的硬度为1830 HV0.2,低于WC的(2357 HV0.2),但显著高于M7C3的(1516 HV0.2)和Fe基体相的(625 HV0.2)。W2C的硬度受枝晶形貌的影响,粗大定向枝晶的硬度(1536HV0.2)明显低于等轴花状晶的(1993 HV0.2)。分析认为:在直流电弧原位冶金的非平衡凝固条件下,以平行连生方式生长的粗大枝晶可能发育不完全,生长基元未能连接成为一个整体,从而降低了硬度值。随着电流由600 A、800 A增大到1000 A,试样的宏观硬度呈下降趋势,分别为84HRA、81HRA和78HRA,这是由于电流增大时W2C含量增加,WC含量降低而造成的。

表5 WpC-Fe复合材料的显微硬度

Table 5 Microhardness of WpC-Fe composites

3 结论

1) 利用直流电弧原位冶金技术快速制备WpC-Fe复合材料,主要物相为WC、W2C、M7C3(M=Fe,Cr,W) 和 (Fe,Ni); W2C枝晶主要分布于试样上部,随工作电流由600 A和800 A增大到1000 A,W2C含量增加,枝晶尺寸粗化。

2) 原料成分一定时,熔池温度是影响W2C生成的主要因素,热力学计算结果表明温度高于1652K后,W2C比WC更易生成。

3) 在直流电弧原位冶金非平衡凝固条件下,W2C的生长机制由小平面晶转化为非小平面晶,受熔池热流影响逐渐偏离六次对称等轴花状晶的初生形貌,以平行连生的方式成为定向生长的发达树枝晶,并存在明显的成分偏析。

4) W2C的显微硬度(1830 HV0.2)低于WC(2357 HV0.2),并受到枝晶形貌的影响,等轴花状晶的硬度(1993 HV0.2)明显高于定向枝晶的(1536HV0.2)。随着电流由600 A增大到1000 A时,WpC-Fe复合材料的宏观硬度由84HRA下降为78HRA。

REFERENCES

[1] SHI Kai-hua, ZHOU Ke-chao, LI Zhi-you, ZHANG Dou, ZAN Xiu-qi. Microstructure and formation process of Ni-pool defect in WC-8Ni cemented carbides[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 873-878.

[2] 王建升, 张占哲, 闫镇威, 李 刚, 唐明奇, 冯在强. 电火花沉积WC-4Co复合层界面行为[J]. 中国有色金属学报, 2014, 24(11): 2849-2855.

WANG Jian-sheng, ZHANG Zhan-zhe, YAN Zhen-wei, LI Gang, TANG Ming-qi, FENG Zai-qiang. Interface behavior of WC-4Co coating by electro-spark deposition[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2849-2855.

[3] 王 群, 屈帮荣, 唐曌肸, 熊浩奇. 超音速火焰喷涂碳化钨-钴涂层磨粒磨损行为[J]. 中国有色金属学报, 2015, 25(7): 1920-1928.

WANG Qun, QU Bang-rong, TANG Zhao-xi, XIONG Hao-qi. Abrasive wear behavior of WC-Co coating deposited by high velocity oxygen flame process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1920-1928.

[4] OBADELE B A, OLUBAMBI P A, JOHNSON O T. Effects of TiC addition on properties of laser particle deposited WC-Co-Cr and WC-Ni coating[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3634-3642.

[5] HOMG Sheng, WU Yu-ping, WANG Bo, ZHENG Yu-gui, GAO Wen-wen, LI Gai-ye. High-velocity oxygen-fuel spray parameter optimization of nanostructured WC-10Co-4Cr coatings and sliding wear behavior of the optimized coating[J]. Materials and Design, 2014, 55: 286-291.

[6] HE Long, TAN Ye-hua, TU Yi-qiang, ZHANG Zhong-wei. Microstructure and tribological properties of WC-CeO2/Ni-base alloy composite coatings[J]. Rare Metal Materials and Engineering, 2014, 43(4): 823-829.

[7] LIU De-jian, CHEN Yan-bin, LI Li-qun, LI Fu-qun. In situ investigation of fracture behavior in monocrystalline WCp-reinforced Ti-6Al-4V metal matrix composites produced by laser melt injection[J]. Scripta Materialia, 2008, 59: 91-94.

[8] 刘发兰, 赵树森, 高文焱, 周春阳, 王奕博, 林学春. 基材属性对Ni60A-WC激光熔覆涂层性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1319-1326.

LIU Fa-lan, ZHAO Shu-sen, GAO Wen-yan, ZHOU Chun-yang, WANG Yi-bo, LIN Xue-chun. Effect of substrate on Ni60A-WC laser cladding coatings[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1319-1326.

[9] WANG Qun, ZHANG Shi-ying, CHENG Ying-liang, XIANG Jing, ZHAO Xin-qi, YANG Gui-bin. Wear and corrosion performance of WC-10Co4Cr coatings deposited by different HVOF and HVAF spraying processes[J]. Surface & Coatings Technology, 2013, 218: 127-136.

[10] 袁有录, 李铸国. Ni60A+WC增强梯度涂层中WC的溶解与碳化物的析出特征[J]. 材料工程, 2013(11): 12-25.

YUAN You-lu, LI Zhu-guo. Dissolving and precipitating characteristics of WC and carbides in the Ni60A+WC graded coating[J]. Journal of Materials Engineering, 2013(11): 12-25.

[11] 张 宇, 钟敏霖, 刘文今. 送粉激光熔覆合成制备WC/Ni硬质合金涂层及其耐磨性[J]. 金属热处理, 2005, 30(11): 1-5.

ZHANG Yu, ZHONG Min-lin, LU Wen-jin. WC/Ni cemented carbide coating and its wear resistance synthesized by laser powder feeding cladding[J]. Heat Treatment of Metals, 2005, 30(11): 1-5.

[12] 迟 静, 李惠琪, 王淑峰, 李 敏, 李建楠, 王 梅, 高旭杰. 直流电弧原位冶金制备粗晶碳化钨块体复合材料[J]. 中国有色金属学报, 2013, 23(5): 1262-1268.

CHI Jing, LI Hui-qi, WANG Shu-feng, LI Min, LI Jian-nan, WANG Mei, GAO Xu-jie. Coarse-grain bulk WC composites prepared by direct current arc in-situ metallurgy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1262-1268.

[13] 王淑峰, 李惠琪, 迟 静, 李 敏, 柴 禄, 许 慧. 等离子原位冶金复合碳化钨合金组织特性与结晶机理研究[J]. 材料工程, 2011(8): 72-76.

WANG Shu-feng, LI Hui-qi, CHI Jing, LI Min, CHAI Lu, XU Hui. Microstructure and crystallization mechanism of composite WC alloy produced by plasma in-situ metallurgy[J]. Journal of Materials Engineering, 2011(8): 72-76.

[14] LI Jian-nan, LI Hui-qi, WANG Mei, WANG Shu-feng, JI Qiang, LI Min, CHI Jing. Applications of WC-based composites rapid synthesized by consumable electrode in-situ metallurgy to cutting pick[J]. International Journal of Refractory Metals and Hard Materials, 2012, 35: 132-137.

[15] 周 玉. 材料分析方法[M]. 北京: 机械工业出版社, 2004.

ZHOU Yu. Materials analysis methods[M]. Beijing: China Machine Press, 2004.

[16] KURLOV A S, GUSEV A I. Neutron and X-ray diffraction study and symmetry analysis of phase transformations in lower tungsten carbide W2C[J]. Physcial Review B, 2007, 76: 1-16.

[17] KURLOV A S, GUSEV A I. Phase equilibria in the W-C system and tungsten carbides[J]. Russian Chemical Reviews, 2006, 75(7): 617-636.

[18] BERGER L M, SAARO S, NAUMANN T,  Influence of feedstock powder characteristics and spray processes on microstructure and properties of WC-(W,Cr)2C-Ni hardmetal coatings[J]. Surface and Coatings Technology, 2010, 205(4): 1080-1087.

Influence of feedstock powder characteristics and spray processes on microstructure and properties of WC-(W,Cr)2C-Ni hardmetal coatings[J]. Surface and Coatings Technology, 2010, 205(4): 1080-1087.

[19] LAY S, ALLIBERT C H, CHRISTENSEN M, WAHNSTROM G. Morphology of WC grains in WC-Co alloys[J]. Materials Science and Engineering A, 2008, 486: 253-261.

[20] LAY S, DONNADIEU P, LOUBRADOU M. Polarity of prismatic facets delimiting WC grains in WC-Co alloys[J]. Micron, 2010, 41: 472-477.

[21] ZHONG Min-lin, LIU Wen-jin, ZHANG Yu, ZHU Xiong-feng. Formation of WC/Ni hard alloy coating by laser cladding of W/C/Ni pure element powder blend[J]. International Journal of Refractory Metals and Hard Materials, 2006, 24: 453-460.

[22] POWELL G L F, CARLSON R A, RANDLE V. The morphology and microtexture of M7C3 carbides in Fe-Cr-C and Fe-Cr-C-Si alloys of near eutectic composition[J]. Journal of Materials Science, 1994, 29(18): 4889-4896.

[23] 叶大伦, 胡建华. 实用无机热力学数据手册[M]. 北京: 冶金工业出版社, 2002.

YE Da-lun, HU Jian-hua. Practical inorganic thermodynamics data handbook[M]. Beijing: Metallurgical Industry Press, 2002.

[24] DMITRII V S, IGOR R S, ALEXANDER L I. Structural, electronic properties and stability of tungsten mono- and semi-carbides: A first principles investigation[J]. Journal of Physics and Chemistry of Solids, 2009, 70(1): 64-71.

[25] 胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2000.

HU Han-qi. Fundamentals of metal solidification[M]. Beijing: China Machine Press, 2000.

In-suit growth mechanism and hardness of W2C under non-equilibrium solidification conditions

CHI Jing, LI Hui-qi, WANG Shu-feng, LI Min, WU Jie, LI Jian-nan, ZHAO Jian

(College of Materials Science and Engineering, Shandong University of Science and Technology, Qingdao 266590, China)

Abstract: WpC-Fe composites were successfully fabricated by direct current arc in-situ metallurgy. Through the examination of phase composition, microstructure and hardness for the resultant materials, the in-situ growth mechanism and morphology transformation for W2C as well as the influence of content and shape of W2C on hardness were also carried out. The results show that, when the temperature of molten pool over 1652 K, W2C is formed more easily than WC in the in-situ reaction between W and C. During the non-equilibrium solidification process, the growth mechanism of W2C transits from lateral growth to non-lateral growth, the morphology gradually deviates from the petal-like shape with hexagonal symmetry determined by crystal structure, and grows into directional dendrite with the pattern of parallel intergrowth. The microhardness of W2C is lower than that of WC, and influenced by shape. 1993 HV0.2 of the equiaxed dendrite is higher significantly than 1536HV0.2 of the directional dendrite. As the current increasing from 600 A to 1000 A, the W2C content increases, and the hardness of materials decreases to 78HRA from 84HRA.

Key words: non-equilibrium solidification; W2C; in situ reaction; growth morphology; hardness

Foundation item: Project (14-7-2-42-gx) supported by the Technological Innovation Construction Program of Qingdao City, China; Project (2013-1-51) supported by the Key Science and Technology Development Program of Qingdao Economic and Technological Development Zone, China; Project (ZR2014EMM009) supported by the Natural Science Foundation of Shandong Province, China

Received date: 2015-12-04; Accepted date: 2016-09-29

Corresponding author: WU Jie; Tel: +86-532-86057927; E-mail: wujie0537@163.com

(编辑 李艳红)

基金项目:青岛市技术创新平台建设计划(14-7-2-42-gx);青岛经济技术开发区重点科技发展计划(2013-1-51); 山东省自然科学基金(ZR2014EMM009)

收稿日期:2015-12-04;修订日期:2016-09-29

通信作者:吴 杰,副教授,博士;电话:0532-86057927;E-mail:wujie0537@163.com