文章编号:1004-0609(2013)07-1873-06

(Fe-Cr)(40)-Al(60)掺杂钨精矿粉激光烧结合金组织及性能

李 刚,韩 凤,沈 宇,沈金泽,王 妍

(辽宁工程技术大学 材料科学与工程学院,阜新 123000)

摘 要:往(Fe-Cr)(40)-Al(60)粉末中加入1%(质量分数)的钨精矿粉,利用激光引燃自蔓延烧结制备原位自生颗粒增强复合材料。通过SEM、XRD等微观组织结构表征手段及合金密度、孔隙率、硬度、磨损性能等宏观力学性能及腐蚀性能测试的方法,研究不同引燃功率对烧结合金组织及性能的影响。结果表明:烧结合金物相主要为AlFe、AlFe3、Al2O3、Al65Fe20W15、W及硬质颗粒相WO3。烧结合金组织为针片状,且随功率的增加,组织变得均匀细密。当功率达到1 100 W时,烧结合金密度最大,为4.47 g/cm3,孔隙率最小,为4.43%;硬度最高,表层区达到1 309.7HK,中部区达到1 003.1HK;合金耐蚀性能最好,钝化区最长为440 mV,钝化电流密度最小为5.570 μA/mm2。而当烧结功率为1 000 W时,试样磨损率最低,表层区为0.06 mg/mm2,中部区为0.05 mg/mm2。

关键词:Fe-Al金属间化合物;激光烧结;显微组织;性能

中图分类号:TG156.99 文献标志码:A

Microstructure and properties of (Fe-Cr)(40)-Al(60) with tungsten concentrate powders by laser sintering

LI Gang, HAN Feng, SHEN Yu, SHEN Jin-ze, WANG Yan

(College of Materials Science and Engineering, Liaoning Technical University, Fuxin 123000, China)

Abstract: By putting 1% (mass fraction) tungsten concentrate powders into(Fe-Cr)(40)-Al(60) powders and using laser ignition induced SHS, the in situ antigenic particle reinforced composite alloy was prepared. By means of SEM, XRD, alloy density, porosity, hardness test, abrasion test and corrosion resistance, the effect of different ignition powers on the sintered alloy microstructure and properties was studied. The results show that the product phases of the sintered alloys are AlFe, AlFe3, Al2O3, Al65Fe20W15, W and WO3. The sintered alloy exhibits batten organization, and with the increase of the laser sintering power, the battens get more homogeneous and even small. When the laser sintering power is up to 1 100 W, the sintered alloy achieves the maximum density of 4.47 g/cm3 and the minimum porosity of 4.43%; the highest hardness of the surface layer is 1 309.7HK, that of the middle layer is 1 003.1HK; the corrosion resistance is the best, the longest passivation area is 440 mV and the passivation current density is only 5.570 μA/mm2. When the laser sintering power gets to 1 000 W, the relative wear rate of the sintering alloy is the lowest, the abrasion rate of the surface layer is 0.06 mg/mm2 and that of the middle layer is 0.05 mg/mm2.

Key words: Fe-Al intermetallic compound; laser sintering; microstructure; property

Fe-Al系金属间化合物具有优异的高温抗氧化性能[1-2],较高的比模量和比强度、较好的耐磨性[3-4]及耐腐蚀性能[5-6],因此在能源、动力、化工、航空、航天和机械等领域[7]得到广泛应用。但Fe-Al系金属间化合物同时具有塑性和韧性差[8]、室温脆性大、抗蠕变性能差[9]和加工困难[10]等缺点,阻碍了其作为高温结构材料在工业生产中的大规模应用[11]。

在Fe-Al系金属间化合物研究中,采用微合金化[7]或者无压烧结、机械合金化、热压烧结等的合金制备方法[12]可以有效地提高材料的塑性和韧性以及高温综合性能,从而拓宽金属间化合物实用化进程。其中对粉体的微合金化,即在烧结过程中使粉体组元间相互反应形成原位颗粒增强复合材料, 利用细晶强化及弥散相强化机制,同时优化增强相与基体的界面结构,提高金属间化合物的室温、高温力学性能,是实现金属间化合物强韧化的关键技术[13-14]。例如,KIM等[15]、黄劲松等[16]对TiAl基合金中添加W的研究表明,少量的W对TiAl基合金起到强的固溶强化、钉扎作用和孪生位错等强化作用,能降低扩散控制的形变动力学,提高合金的力学性能。因此,钨作为一种具有熔点高、硬度大、耐磨和耐腐蚀等优良性能的元素,得到了广泛应用。

本课题组研究了Fe-Al合金体系掺杂钨精矿粉末在固定激光功率下的合金组织及性能的变化,并取得了一定的研究成果[17-18]。本文作者向Fe-Al合金体系中添加1%的钨精矿粉,利用激光引燃自蔓延烧结技术,通过改变烧结功率,进一步研究激光功率对烧结Fe-Al复合材料的组织及性能的影响规律。

1 实验

1.1 实验材料

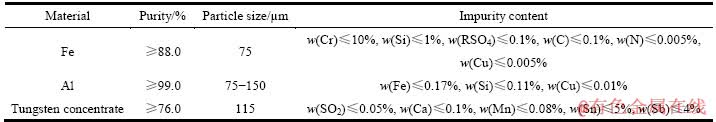

实验所用材料为铁基粉、铝粉,其摩尔比为 40:60。在此基础上添加1%的钨精矿粉末,其成分如表1所列。

1.2 实验设备及方法

将原料粉末均匀混合后,利用WE-30型液压万能试样机将粉末压制成d16 mm×10 mm的圆柱形试样,压制压力为100 kN。

在HL-1500无氦横流CO2激光加工机上进行压坯烧结,激光光斑直径为d15 mm,功率为800、900、1 000和1 100 W,引燃时间为15 s。

利用XRD-6000型X射线衍射仪进行物相结构分析及组织表征。X射线源为Cu靶,扫描起始角度为20°,终止角度为100°,扫描速度2 (°)/min。组织观察采用SSX-550型扫描电镜。

应用阿基米德法,在精度为0.000 1 g的FA1104N型电子天平上进行合金密度测量,并计算孔隙率,公式如下:

(1)

(1)

式中:ρ为试样烧结后密度,g/cm3;δ为液体在空气中的密度,g/cm3;m1为试样在空气中的质量,g;m2为试样排开液体的质量,g。

(2)

(2)

式中:θ为孔隙率,%; 为Fe-Al合金理论密度,g/cm3。

为Fe-Al合金理论密度,g/cm3。

使用ML-100型磨粒磨损实验机测试合金表面耐磨性(磨损时间5 min)。实验所用砂纸表面磨粒尺寸为40 μm,载荷为35 kN,磨损时间为5 min,测量式样表面的磨损面积及磨损质量。磨损率计算公式如下:

(3)

(3)

式中:ω为磨损率,mg/mm2;mb为磨损后质量,mg;ma为磨损前质量,mg;S为磨损面积,mm2。

采用DMH-2LS努氏硬度计测试烧结合金显微硬度,质量载荷为25 g,保载时间为20 s。在合金同一表层上任意选取3点,测试硬度,取其平均值即为该点硬度值。

在ZF-3型恒电位仪上进行腐蚀性能实验,测试阳极极化曲线。采用铂片作为阳极,汞柱作为阴极,溶液为0.5 mol/L的H2SO4溶液。

表1 实验原料、成分及粒度

Table 1 Experimental materials, ingredient and particle size

2 结果与分析

2.1 物相分析

图1所示为烧结功率1 100 W时烧结合金的XRD谱。由图1可知,烧结合金中物相主要为AlFe、 AlFe3、Al2O3、Al65Fe20W15、W及WO3。由铁铝相图可知,Fe、Al发生二元反应,生成共晶相AlFe和AlFe3等。同时,钨精矿粉在铝热还原反应中,被还原出来的W在遇到空气中的O2后又被氧化成硬质的WO3。原位自生的WO3颗粒相镶嵌在Fe-Al-W固溶体基体上,对提高基体硬度及耐磨性有积极的贡献。

图1 烧结Fe-Al合金XRD谱

Fig. 1 XRD pattern of sintered Fe-Al alloy

2.2 烧结合金组织形貌

图2所示为烧结功率为800和900 W时试样表层的SEM像。由图2可见,随烧结功率的增加,合金内部组织变得细小致密,组织形貌主要呈条状。从铁铝相图中可知,当Al含量为60%时,形成富铝的FeAl和FeAl3,体系的放热量增大,元素扩散变得活跃,晶界能量增大,晶粒内有大量的析出相,因此促进了烧结体的致密性,使组织更加均匀细小。

图3所示为烧结功率为1 100 W时试样表层区与中部区的SEM像。由图3可知,表层区的组织比中部区的更细小且均匀。可能的原因如下:表层为激光直接烧结区,由高能束直接注入,烧结温度高且均匀,反应快速彻底,得到的组织也比较细小;中部区是由表层区点燃后发生的自蔓延烧结,由于内部各处成分及物相差异较大,所以在相对于表面的低温下,孔隙率较大,组织形貌相对于表层区粗大。

图2 不同功率时试样表层SEM像

Fig. 2 SEM images of sample surface at different sintering powers

图3 同一烧结功率下试样表层区与中部区的SEM像

Fig. 3 SEM images of sample surface layer (a) and middle layer (b) at the same sintering power

2.3 烧结合金密度与孔隙率

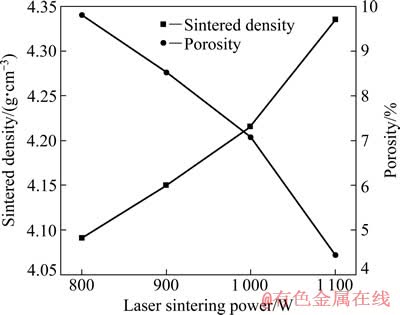

图4所示为不同烧结功率下合金的孔隙率与密度的变化曲线。由图4可见,随烧结功率的增加,烧结合金的孔隙率下降,密度升高。烧结功率为1 100 W时,烧结合金的孔隙率达到最小值,为4.43%,密度达到最大值,为4.47 g/cm3。这是由于随烧结功率的增大,铝粉在高温条件下与其他元素反应生成各种物相,使压坯烧结后密度增加;烧结功率的提高使粉末被充分烧结,烧结深度增大,致密性增加;烧结功率的提高使烧结时产生的共晶液相填充压坯中的孔隙,提高了压坯的致密性。同时,基体中添加的钨精矿粉的熔解温度较高,从钨精矿粉中还原出钨需要的能量较大,所以在外界所提供能量一定的情况下,烧结功率增大可使反应进行得更彻底充分,液相能很好地充满粉末间的空隙,从而减小孔隙率。

图4 不同烧结功率下合金的孔隙率与密度变化曲线

Fig. 4 Porosity and density change curves of alloys at different sintering powers

2.4 硬度测试

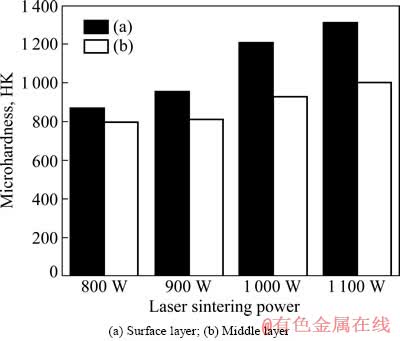

图5所示为烧结功率对试样表层区与中部区显微硬度的影响。由图5可知,随烧结功率的增加,试样表层与中层的显微硬度增大,且表层的显微硬度要高于中层的;当烧结功率为1 100 W时,显微硬度达到最大值,表层的为1 309.7HK;中层的为1 003.1HK。

图5 烧结功率对试样显微硬度的影响

Fig. 5 Influence of sintering power on microhardness of sample

由图2可知,随烧结功率的增加,合金组织变得细密,致密性增加,铝热还原反应更加剧烈,合金中添加的钨精矿粉,在烧结过程中发生了一些化学反应,生成了W及WO3等硬质颗粒相。硬质颗粒和粗大的基体晶粒均匀分布,对Fe-Al烧结合金起到很强的固溶强化及钉扎作用。硬质颗粒与基体中的位错发生交互作用,阻止位错运动,使基体显微硬度上升。而在相同成分与烧结功率下,试样表层比中层的硬度高。原因可能为试样表区层为直接激光烧结区,因此产生的硬质颗粒多,而试样中层完全靠高温自蔓延进行烧结,Fe、Al与钨精矿粉的反应不完全,因此试样中层区的显微硬度没有表层区的高。

2.5 耐磨性能测试

烧结功率与试样磨损率的关系柱形图如图6所示。由图6可见,随烧结功率的增大,试样的表层区和中部区的耐磨性能均增加。当烧结功率为1 000 W时,试样的耐磨性最佳,磨损率最低,表层磨损率为0.06 mg/mm2,中层磨损率为0.05 mg/mm2。且试样中部区的耐磨性优于表层区的。原因如下:随着烧结功率的增大,烧结后的合金成分和组织更均匀,缺陷减少;激光的快速加热和冷却会使试样晶粒细化,并且随烧结功率的增大,合金粉末中的钨精矿粉参与的铝热还原反应温度升高,可还原出更多的W及WO3硬质相,所以磨损率降低。表层区为激光直接注入,热量的集中使得铝热反应剧烈,基体中的水分与空气未来得及排出,且易产生元素烧损,导致表层致密性差,所以不耐磨。而中层为激光自蔓延烧结形成,不会有集中的热量,又不会产生硬质相的枝晶偏析,因此中部比表层耐磨。

图6 烧结功率与试样磨损率的关系柱形图

Fig. 6 Relationship bar charts of sintering power and wear rate of samples

2.6 耐蚀性能测试

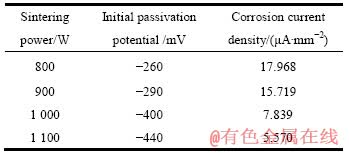

图7所示为激光烧结后测得的合金的阳极极化曲线。不同功率下的合金腐蚀参数见表2。由图7和表2可见,随烧结功率的增大,合金的活化区缩短,同时钝化区增长,具有最低的维钝电流密度5.570 μA/mm2,说明在1 100 W下烧结的合金具有最好的耐腐蚀性能。这是由于在不同的烧结功率下,试样成分和组织随烧结功率的升高而更加均匀,缺陷减少;烧结功率大,加热时间短,快速加热和冷却会使试样晶粒细化,从而提高耐蚀性能。

图7 不同烧结功率下激光烧结合金的极化曲线

Fig. 7 Polarization curves of laser sintered alloys at different sintering powers

表2 不同烧结功率下试样的腐蚀参数

Table 2 Corrosion parameters of samples at different sintering powers

3 结论

1) 烧结合金中的物相主要为AlFe、AlFe3、Al2O3、Al65Fe20W15、W及硬质颗粒相WO3。

2) 随烧结功率的增加,合金组织变得细小、致密,同时表层比中层的组织更细小、均匀。当烧结功率为1 100 W时,烧结合金的孔隙率达到最小值,为4.43%,密度达到最大值,为4.33 g/cm3。

3) 随烧结功率增加,合金显微硬度增大,在1 100 W时显微硬度达到最大值,表层显微硬度为1 309.1HK,中层显微硬度为1 003.1HK。当烧结功率为1 000 W时,合金磨损率最低,中部区磨损率为0.05 mg/mm2,表区层磨损率为0.06 mg/mm2。

4) 随烧结功率的增加,合金的耐蚀性能增强,在烧结功率为1 100 W时,合金具有最好的耐蚀性能,钝化区最长,为440 mV;钝化电流密度最小,为5.570 μA/mm2。

REFERENCES

[1] YU X Q, SUN Y S. The oxidation improvement of Fe3Al based alloy with cerium addition at temperature above 1 000 ℃[J]. Materials Science and Engineering A, 2003, 363: 30-39.

[2] LANG F Q, YU Z M, GEDEVANISHVILI S. Corrosion behavior of Fe-40Al sheet in N2-11.2O2-7.5CO2 atmospheres with various SO2 contents at 1 273 K[J]. Intermetallics, 2003, 11: 135-141.

[3] 高 伟, 李艳红, 李镇江. Q235钢材表面等离子重熔制备Fe-Al金属间化合物[J]. 稀有金属快报, 2008, 27(8): 25-28.

GAO Wei, LI Yan-hong, LI Zhen-jiang. Study on Fe-Al intermetallics prepared by plasma surface remelting[J]. Rare Metals Letters, 2008, 27(8): 25-28.

[4] 程广萍, 何宜柱. 激光熔覆制备Fe-Al金属间化合物覆层[J]. 焊接学报, 2006, 27(6): 37-40.

CHENG Guang-ping, HE Yi-zhu. Preparation of deposited coating of Fe-Al inter metallic compound by laser cladding[J]. Welding Journal, 2006, 27(6): 37-40.

[5] 李婷婷, 彭超群, 王日初, 王小锋, 刘 兵, 王志勇. Fe-Al、 Ti-Al和Ni-Al系金属间化合物多孔材料的研究进展[J]. 中国有色金属学报, 2011, 21(4):787-788.

LI Ting-ting, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LIU Bing, WANG Zhi-yong. Research progress in porous Fe-Al, Ti-Al and Ni-Al intermetallic compound porous materials[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 787-788.

[6] STOLOFF N S. Iron aluminides: Present status and future prospects[J]. Materials Science Engineering A, 1998, 258: 1-14.

[7] 王 建, 汤慧萍, 邢建东, 王建永, 李亚宁, 杨保军, 谈 萍, 葛 渊. Fe-Al金属间化合物研究概况与发展方向[J]. 稀有金属材料与工程, 2011, 40(7): 545-549.

WANG Jian, TANG Hui-ping, XING Jian-dong, WANG Jian-yong, LI Ya-ning, YANG Bao-jun, TAN Ping, GE Yuan. Present status and future prospects of Fe-Al intermetallics[J]. Rare Metal Materials and Engineering, 2011, 40(7): 545-549.

[8] DORFRNAN S. Non-empirical study of energy parameters in B2 and DO3 phases of Fe-A1 alloy[J]. Computational Materials Science, 2000, 17: 186-190.

[9] 王 峰, 奚正平, 汤慧萍, 汪强兵, 杨保军. Fe-Al合金多孔材料研究进展[J]. 粉末冶金技术, 2010, 28(6): 463-466.

WANG Feng, XI Zheng-ping, TANG Hui-ping, WANG Qiang-bing, YANG Bao-jun. Research progress in Fe-Al alloy porous materials[J]. Powder Metallurgy Technology, 2010, 28(6): 463-466.

[10] 田保红, 胡军志, 徐滨士, 马士宁, 张 伟. 高速电弧喷射沉积Fe3Al涂层研究[J]. 金属热处理, 2000, 25(7): 24-27.

TIAN Bao-hong, HU Jun-zhi, XU Bing-shi, MA Shi-ning, ZHANG Wei. Development of Fe3Al intermetallic coating produced by high velocity arc spraying deposition[J]. Heat Treatment of Metals, 2000, 25(7): 24-27.

[11] 宋海霞, 吴运新, 巩前明, 袁 帅. B2型FeAl金属间化合物的制备及性能研究进展[J]. 粉末冶金技术, 2009, 27(5): 381-386.

SONG Hai-xia, WU Yun-xin, GONG Qian-ming, YUAN Shuai. Research advances in preparation and properties of FeAl (B2) intermetallics[J]. Powder Metallurgy Technology, 2009, 27(5): 381-386.

[12] 望 斌, 彭志方, 张 凡, 夏 力. 粉末冶金制备Fe-Al金属间化合物材料研究进展[J]. 材料导报, 2007, 21(1): 75-82.

WANG Bin, PENG Zhi-fang, ZHANG Fan, XIA Li. Research progress in preparing iron aluminide intermetallics materials by powder metallurgy[J]. Materials Review, 2007, 21(1): 75-82.

[13] KOCH C C. Intermetallic matrix composites prepared by mechanical alloying: A review[J]. Materials Science and Engineering A, 1998, 214: 39-48.

[14] 韩 啸, 汤文明, 任 榕, 汪峰涛, 吴玉程, 郑治祥. 原位颗粒增强 Fe3Al基纳米复合材料的显微结构与力学性能[J]. 金属功能材料, 2010, 17(1): 47-52.

HAN Xiao, TANG Wen-ming, REN Rong, WANG Feng-tao, WU Yu-cheng, ZHENG Zhi-xiang. Microstructures and mechanical properties of in-situ reinforced Fe3Al matrix nanocomposites[J]. Metallic Functional Materials, 2010, 17(1): 47-52.

[15] KIM H Y, SOHN W H, HONG S H. High temperature deformation of Ti(46-48)Al-2W intermetallic compounds[J]. Materials Science and Engineering A, 1998, 251: 216-225.

[16] 黄劲松, 张永红, 刘 彬, 刘 咏, 贺跃辉, 黄伯云. 钨对TiAl合金1 265 ℃, 18 h热处理微观组织的影响[J]. 材料科学与工艺, 2007, 15(1): 1-5.

HUANG Jin-song, ZHANG Yong-hong, LIU Bin, LIU Yong, HE Yue-hui, HUANG Bo-yun. Effect of tungsten on microstructure of as-cast TiAl alloy after annealed and heat treated at 1 265 ℃ for 18 h[J]. Materials Science Technology, 2007, 15(1): 1-5.

[17] 李 刚, 陈永君, 水东莉, 唐海鹏, 刘 丽, 侯俊英. 高能激光束引燃Fe-Al系合金的制备与性能研究[J]. 材料热处理学报, 2011, 32(4): 17-20.

LI Gang, CHEN Yong-jun, SHUI Dong-li, TANG Hai-peng, LIU Li, HOU Jun-ying. Preparation and properties of Fe-Al alloy by laser-induced self-propagating reaction synthesis[J]. Transactions of Materials and Heat Treatment, 2011, 32(4): 17-20.

[18] 李 刚, 于君娜, 唐明忠. 激光燃烧合成掺杂钨精矿Fe-Al复合材料的组织及性能[J]. 复合材料学报, 2012, 29(4): 138-141.

LI Gang, YU Jun-na, TANG Ming-zhong. Microstructure and properties of Fe-Al composite material blended with tungsten concentrate powder prepared by laser combustion synthesis[J]. Acta Mater Comp Sinica, 2012, 29(4): 138-141.

(编辑 何学锋)

基金项目:辽宁省科学事业公益研究基金资助项目;辽宁省教育厅科学研究一般项目(L2012108);三束材料改性教育部重点实验室开放课题(DP1051201)

收稿日期:2012-10-12;修订日期:2013-04-08

通信作者:李 刚,男,教授,博士;电话:0418-3352431;E-mail:stars2387@vip.sina.com