文章编号:1004-0609(2009)03-0418-06

搅拌摩擦加工技术制备Ti颗粒增强AZ31镁基复合材料

王开东1,常丽丽1,王轶农1,黄志青2

(1. 大连理工大学 材料科学与工程学院 三束材料改性国家重点实验室,大连 116024;

2. 台湾国立中山大学 材料科学研究所,台湾高雄 804)

摘 要:利用搅拌摩擦加工技术制备Ti颗粒含量为20%(体积分数,下同)与40%的Mg-AZ31基复合材料。结果表明:碎化后的Ti颗粒平均尺寸约为200 nm,经4次搅拌摩擦加工处理后基体组织发生明显的细化,晶粒尺寸为3~5 μm。添加20% Ti颗粒的复合层中碎化的Ti颗粒在Mg基体中呈不均匀分布,复合层具有较低的强度和伸长率;当Ti颗粒添加量为40%时,复合层中碎化Ti颗粒在Mg基体中均匀分布,复合层强度有明显提高,伸长率较基体无明显降低。利用混合定律计算复合层的显微硬度,其结果与试验值相吻合。

关键词:镁合金;复合材料;搅拌摩擦加工;Ti颗粒

中图分类号:TB 331 文献标识码:A

Preparation of Mg-AZ31 based composites with Ti particles by friction stir processing

WANG Kai-dong1, CHANG Li-li1, WANG Yi-nong1, HUANG J. Chih-ching2

(1. State Key Laboratory of Materials Modification by Laser, Ion and Electron Beams,

School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China;

2. National Sun Yat-Sen University, Kaohsiung 804, China)

Abstract: Mg-AZ31 based composites with 20% (volume fraction) and 40% Ti particles were fabricated by friction stir processing (FSP). The results show that after four FSP passes the matrix structure of composite layers can be significantly refined within 3?5 μm obviously, and the fragments of the Ti particles are about 200 nm. The Ti fragments in the composite layer with 20% Ti particles have inhomogenous distribution and demonstrate poor tensile properties and low elongation. However, the Ti fragments in the composite layer with 40% Ti particles have homogenous distribution and the tensile properties of composite layer are greatly improved, and the elongation of composite layer has no obvious change compared with that of matrix. Using the rule of mixture to predict the microhardness values of composite layers, the results approximately match the experimental ones.

Key words: magnesium alloy; composites; friction stir processing (FSP); Ti particles

镁基复合材料是同类金属基复合材料中比强度和比刚度最高的一种,具有优异的阻尼性、高温蠕变性、尺寸稳定性和良好的冷热加工性能,在航空航天、军事和汽车等领域得到了广泛应用[1]。此外。镁基复合材料能够满足环保和可持续发展的要求,成为继铝基复合材料之后又一具有极强竞争力的轻金属基复合材 料[2]。制备镁基复合材料的方法很多,主要有反应浸渗法[3]、搅拌铸造法[4?5]、粉末冶金法[6?8]和喷射沉积法[9?10]等。

搅拌摩擦焊(FSW)是英国焊接技术研究所(TWI)在20世纪90年代提出的固态连接方法[11],该方法的特点是:焊接过程中产生大量热并且焊核组织材料在搅拌头的作用下发生强烈塑性变形,最终形成晶粒细小、成分均一的再结晶组织。近年来,由搅拌摩擦焊技术改进的搅拌摩擦加工技术(FSP)已被应用到镁合金的微观组织改性与沉淀相粒子均匀化方面[12]。CHANG等[13]利用搅拌摩擦加工技术在AZ31镁合金表面成功制得Mg-SiO2/ZrO2复合材料。由此可见,搅拌摩擦加工技术为制备镁基复合材料提供了又一切实可行的方法。本文作者利用搅拌摩擦加工技术通过添加Ti颗粒在镁合金表层一定深度制备AZ31-Mg/Ti复合层,并研究复合材料微观组织及力学性能。

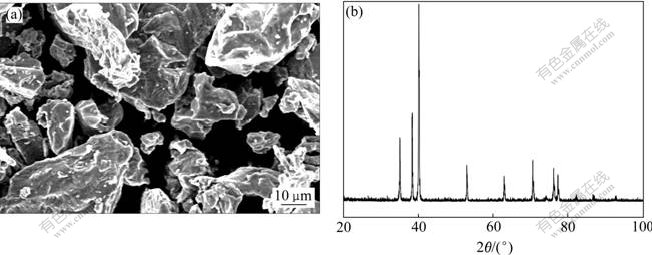

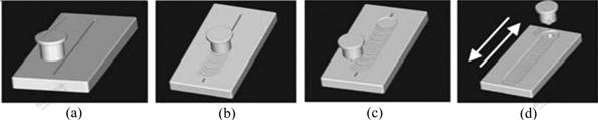

1 实验

实验材料为工业用铸态AZ31镁合金板,镁板尺寸为130 mm×60 mm×10 mm,其化学成分(质量分数,%)为:Mg-3.02Al-1.01Zn-0.30Mn,强化相Ti颗粒尺寸为30~40 μm。图1所示为强化相Ti颗粒的SEM像与XRD谱,Ti颗粒填入量(用颗粒体积占板表面沟槽的体积分数表示)分别为20%和40%,纯度均为99.9%。选用肩轴直径17 mm,搅拌针直径6 mm、高6 mm的搅拌头进行搅拌摩擦加工实验,搅拌头与垂直方向倾角为1.5?,转速为800 r/min,加工速度为45 mm/min,进行4次往返加工处理,如图2所示。图2(a)所示为在镁合金表面开出沟槽并填充Ti颗粒;图2(b)所示为用平的摩擦头做表面处理,防止后续加工时Ti颗粒外溢;图2(c)所示为搅拌摩擦加工;图2(d)所示为重复加工。加工完成后在样品中间复合层区取样,制成金相试样(1 g草酸,1 mL硝酸,1 mL乙酸,150 mL水溶液腐蚀30 s),在JSM?5600LV扫描电镜下观察复合层组织形貌,并对其进行拉伸强度试验。利用HV?1000显微硬度计进行显微硬度测试,选用载荷0.98 N,加载时间为15 s。

图1 Ti颗粒SEM像与XRD谱

Fig.1 SEM image(a) and XRD pattern(b) of Ti particles

图2 FSP工作示意图

Fig.2 Schematic diagrams for FSP: (a) Inserting Ti particles; (b) Repairing surface; (c) Conducting processing; (d) Repeating processing

2 结果与分析

2.1 微观组织

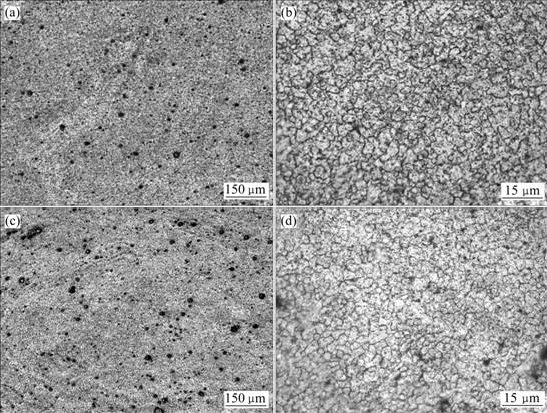

图3所示为经4次搅拌摩擦加工后,Mg-AZ31/Ti复合层的显微组织金相照片。低倍金相结果表明,在搅拌头作用下,加入的Ti颗粒发生不同程度的碎化并在复合层区呈均匀分布,随加入Ti颗粒量的增加,未碎化的Ti颗粒增多。复合层区细小晶粒组织是搅拌摩擦加工过程中强烈塑性变形与动态再结晶双重作用结果,金属材料在搅拌摩擦加工过程中,晶粒被拉长,在热机械搅拌的作用下被破碎,同时破碎的晶粒发生动态回复与再结晶过程,开始长大。由于镁合金导热系数比较大,散热快,晶粒来不及长大到原来粗大组织,于是保持了细小、等轴晶粒组织。高倍金相结果表明,加入Ti颗粒强化的复合层基体晶粒尺寸得到明显细化(3~5 μm),强化相Ti颗粒体积分数为40%的复合层,基体晶粒尺寸更加细小。这是因为加入的Ti颗粒量较多在经过4次搅拌摩擦处理后,由大尺寸Ti颗粒破碎而形成的纳米尺寸Ti颗粒数也增多,而由第二相粒子尺寸与体积分数对再结晶晶粒尺寸影响公式D*=4d/(3f ) [14]可以得出在强化相尺寸不变的条件下,大体积分数的第二相颗粒更有利于晶界的钉扎,从而获得更小尺寸的基体组织。

图3 经4次搅拌摩擦加工处理后Mg-AZ31/Ti复合层的金相照片

Fig.3 Optical images of Mg-AZ31/Ti composite layer after four FSP passes: (a), (b) With 20% Ti particles; (c), (d) With 40% Ti particles

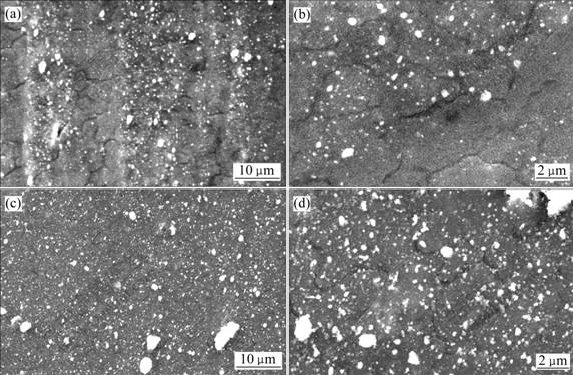

图4所示为Mg-AZ31/Ti复合材料扫描电镜照片。经4次搅拌摩擦加工后,两组样品中Ti颗粒破碎程度基本相同,破碎后的Ti颗粒平均尺寸约为200 nm。加入20% Ti颗粒的样品中碎化的Ti颗粒在Mg基体中呈不均匀分布;而加入Ti颗粒量为40%的样品中碎化后的Ti颗粒在基体中均匀分布。Ti颗粒的存在不但影响着塑性变形过程中应力应变的分布,同时对动态再结晶过程也有很大的影响,不同尺寸的Ti颗粒对动态再结晶过程的影响不同。HANSEN等[14]研究表明,对于颗粒尺寸0.1~1 ?m的第二相粒子会促进再结晶过程的进行,而尺寸小于0.1 ?m的第二相粒子,则会抑制动态再结晶过程的发生。Ti颗粒的尺寸与分布状态随FSP过程的进行而变化,经过一次FSP处理后Ti颗粒发生不同程度的碎化,在大尺寸Ti颗粒周围由于位错的塞积作用而产生很大的应力集中使形变储能增加,这一区域便成为有利于动态再结晶发生的形核区域。随着FSP次数的增加Ti颗粒碎化程度增大,小尺寸的Ti颗粒数量增加,这时Ti颗粒周围位错塞积较少,形变储能与前者相比也较低,对动态再结晶的发生起到阻碍作用。

图4 经4次搅拌摩擦加工处理后Ti颗粒在复合层分布的SEM像

Fig.4 SEM micrographs showing Ti particles dispersion in composite layer after four FSP passes: (a), (b) With 20% Ti particles; (c), (d) With 40% Ti particles

2.2 显微硬度

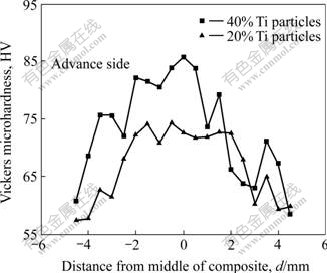

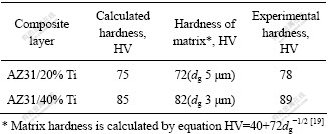

图5所示为Mg-AZ31/Ti复合材料显微硬度沿复合层中心分布曲线。由图5可以看出,两组试样复合层的维氏显微硬度实际值(以复合层中心为基准向两侧每0.5 mm取点测量,共取11点取其平均值)相差较大,加入20% Ti颗粒复合层的显微硬度值为HV 72左右,而加入40% Ti颗粒复合层显微硬度值约为HV 85,相对基体HV 55均有较大提高。可见,Mg-AZ31/Ti复合材料显微硬度的提高是第二相颗粒强化与细晶强化双重作用的结果。复合材料宏观力学性能的预测对材料的应用与设计十分重要。对复合材料宏观力学性能进行预测的方法很多,例如:平均场理论[15]、剪切滞后理论[16]、有限元方法[17](FEM)和混合定律[18](ROM)等。其中混合定律是一种简单而有效的预测方法。在此利用混合定律对复合层显微硬度进行预测。由于Ti颗粒硬度值较低(约HV 100),与镁基体硬度(HV 50~HV 90,取决于晶粒尺寸大小)接近,当进行显微硬度测试时Mg基体与Ti颗粒在载荷作用下同时发生塑性变形,满足混合定律的Voigt模型(见图6),利用该模型下有效硬度计算公式(1)对复合层显微硬度进行计算:

图5 Mg -AZ31/ Ti复合层区显微硬度分布曲线

Fig.5 Microhardness distribution in Mg-AZ31/Ti composites layer

图6 Voigt模型示意图

Fig.6 Schematic diagram for Voigt model

利用公式(1)计算复合层显微硬度并与实际测量值相比较,结果表明利用该模型能够准确地对Mg-AZ31/Ti复合层进行显微硬度计算,计算结果如表1所列。

Hh fh+ Hs fs (1)

Hh fh+ Hs fs (1)

式中 Hh和Hs分别为Ti颗粒与镁基体显微硬度,fh和fs分别为其体积分数。

表1 复合层硬度计算值与实际测量值的比较

Table 1 Comparison of experimental hardness and calculated hardness in composite layers

2.3 拉伸性能

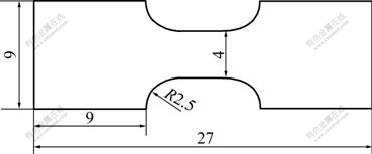

从加工好的试样上去除起始加工点和结束匙孔点,用电火花切割制备拉伸试验试样。试样在焊后工件上横向截取,复合层位于试样的中心部位,中心位置截面积为2 mm×4 mm。为保证实验结果的准确性,每个样品制成3个拉伸试样,对拉伸结果求平均值。试样尺寸如图7所示。

图7 拉伸试样设计图

Fig.7 Design of tensile test sample (unit: mm)

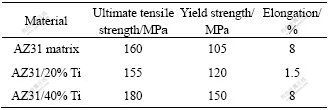

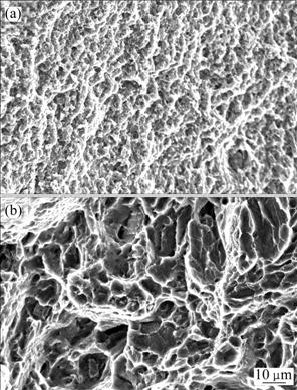

表2所列为AZ31镁合金基体与Mg-AZ31/Ti复合层拉伸性能对比结果。拉伸试验结果表明,添加强化相Ti颗粒量为20%的复合层的抗拉强度为155 MPa,较基体略有下降。屈服强度为120 MPa与抗拉强度接近,这表明加入20% Ti颗粒的复合层在发生拉伸断裂之前几乎无塑性变形发生,其伸长率约为1.5%。这是由于破碎后的Ti颗粒微观分布不均而导致复合层区晶粒尺寸不均匀(富Ti颗粒区晶粒尺寸较小,贫Ti颗粒区晶粒尺寸较大),因此复合层组织变形协调性差,具有较低的强度与伸长率。图8(a)所示为拉伸断口形貌,断口为高密度浅小韧窝组织且断口较平。对于加入40% Ti颗粒的复合层,由于破碎后的Ti颗粒分布相对较为均匀,复合层组织成分均一,变形协调性较好,故此复合层抗拉强度与屈服强度较基体分别有较大提高,分别提高至180 MPa与150 MPa,其伸长率与基体相同约为8%。图8(b)所示为其拉伸断口形貌,断口为大尺寸等轴韧窝组织与明显撕裂棱。

表2 AZ31镁合金和AZ31/ Ti复合层拉伸性能的比较

Table 2 Comparison of tensile properties of AZ31 alloy and AZ31/ Ti composite layers

图8 Mg-Ti复合层拉伸断口的SEM像

Fig.8 SEM images of tensile composite layer: (a) With 20% Ti particles; (b) With 40% Ti particles

3 结论

1) 通过搅拌摩擦加工技术(FSP)在AZ31镁板表层一定深度成功制备Mg-AZ31/Ti复合材料。经过4次搅拌摩擦加工后复合层组织发生明显细化,平均晶粒尺寸为3~5 μm,Ti颗粒添加量为20%的复合层碎化后的Ti颗粒呈不均匀分布。碎化后Ti颗粒的平均尺寸为200 nm左右,添加40% Ti颗粒的复合层碎化后的Ti颗粒均匀分布,碎化后的Ti颗粒平均尺寸与前者相同,约为200 nm。

2) 添加20% Ti颗粒的复合层的强度与伸长率均较低,拉伸过程中无明显塑性变形发生;添加40% Ti颗粒的复合层强度有较大提高,复合层伸长率与基体相比无明显降低,约为8%。Ti颗粒的加入使复合层显微硬度值有较大提高,最高可达HV 85左右。利用混合定律Voigt模型计算Mg-AZ31/Ti复合层显微硬度,计算结果与试验结果相吻合。

REFERENCES

[1] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004: 19?20.

CHEN Zhen-hua. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004: 19?20.

[2] YE H Z, LIU X Y. Review of recent studies in magnesium matrix composites[J]. J Mater Sci, 2004, 39: 6153?6171.

[3] DONG Q, CHEN L Q, ZHAO M J, BI J. Synthesis of TiCp reinforced magnesium matrix composites by in situ reactive infiltration process[J]. Mater Lett, 2004, 58(6): 920?926.

[4] ROHATGI P K. Advances in cast MMCs[J]. Advanced Materials & Processes, 1990, 1: 37?39.

[5] DEONATH, BHAT R T, ROHATGI P K. Preparation of cast aluminium alloy-mica particle composite[J]. Journal of Materials Science, 1980, 15(5): 1241?1251.

[6] JIANG Q C, WANG H Y, MA B X, WANG Y, ZHAO F. Fabrication of B4C particulate reforced magnesium matrix composite by power metallurgy[J]. Journal of Alloys and Compounds, 2005, 386(1/2): 177?181.

[7] WANG H Y, JIANG Q C, WANG Y, MA B X, ZHAO F. Fabrication of TiB2 particulate reinforced magnesium matrix composites by powder metallurgy[J]. Materials Letters, 2004, 58(27/28): 3509?3513.

[8] XIU K, JIANG Q C, MA B X. Fabrication of TiCp/Mg composites by powder metallurgy[J]. Journal of Materials Science, 2006, 41(5): 1663?1666.

[9] CHEN C Y, TSAO C Y A. Spray forming of silicon added AZ91 magnesium alloy and its workability[J]. Mater Sci Eng A, 2004, 383(1): 21?29.

[10] 张修庆, 腾新营, 王浩伟. 镁基复合材料的制备工艺[J]. 热加工工艺, 2004(3): 58?61.

ZHANG Xiu-qing, TENG Xin-ying, WANG Hao-wei. Preparation technics of magnesium matrix composites materials[J]. Hot Working Technology, 2004(3): 58?61.

[11] RHODES C G, MAHONEY M W, BINGEL W H. Effect of friction stir welding on microstructure of 7075 aluminum[J]. Scripta Materialia, 1997, 36(1): 69?75.

[12] SATO Y S, PARK S H C, MATSUNAGA, HONDA A, KOKAWA H. Novel production for highly formable Mg alloy plate[J]. Journal of Material Science, 2005, 40(3): 637?642.

[13] CHANG C I, WANG Y N, PEI H R, LEE C J, DU X H, HUANG J C. Microstructure and mechanical properties of nano-ZrO2 and nano-SiO2 particulate reinforced AZ31-Mg alloy[J]. Key Engineering Materials, 2007, 351: 114?119.

[14] HANSEN N, IENSEN D J. Recrystallization’90[M]. CHANDRA T, ed. The Mineral, Metals and Materials Society, 1990: 79?88.

[15] 张为民, 张淳源, 张 平. 微观力学中的平均场理论[J]. 湘潭大学自然科学学报, 2003, 4(25): 64?69.

ZHANG Wei-min, ZHANG Chun-yuan, ZHANG Ping. Average-field theory in micromechanics[J]. Natural Science Journal of Xiangtan University, 2003, 4(25): 64?69.

[16] NARDONE V C, PREWO K M. On the strength of discontinuous silicon carbide reinforced aluminum composites: Scripta Metall, 1986, 20(1): 43?48.

[17] DONG M, SCHMAUDER S. Modeling of metal matrix composites by a self-consistent embedded cell model[J]. Acta Mater, 1996, 44(6): 2465?2478.

[18] CHANG C I, WANG Y N, PEI H R, LEE C J, HUANG J C. On the hardening of friction stir processed Mg-AZ31 based composites with 5?20% nano-ZrO2 and nano-SiO2 particles[J]. Materials Transactions, 2006, 47(12): 2942?2949.

[19] CHANG C I, LEE C J, HUANG J C. Relationship between grain size and Zener-Holloman parameter during friction stir processing in AZ31 Mg alloys[J]. Scripta Materialia, 2004, 51: 509?514.

基金项目:国家自然科学基金资助项目(50471069)

收稿日期:2008-07-18;修订日期:2008-11-28

通讯作者:王轶农,教授,博士;电话:0411-84708441;E-mail: wynmm@dlut.edu.cn

(编辑 李向群)