文章编号:1004-0609(2010)S1-s0981-05

沸腾氯化用高品质金红石的生产工艺

熊雪良,杨 智,欧阳红勇,王康海

(长沙矿冶研究院 矿产资源开发技术研究所,长沙 410012)

摘 要:对原矿、氧化改性矿、还原改性矿3种矿物进行搅拌浸出、加压浸出和流态化浸出3种方式的浸出工艺研究。结果表明:采用搅拌浸出时,3种矿物浸出产品人造金红石中TiO2含量从大到小的次序为氧化改性矿、还原改性矿、原矿;3种浸出工艺得到人造金红石中TiO2含量从大到小的次序为流态化浸出、加压浸出、搅拌浸出;氧化改性矿的矿物表面生成了新的金红石相;钛铁矿采用氧化预处理—盐酸流态化浸出工艺,得到的产品人造金红石是金红石型TiO2,其中TiO2含量(质量分数)为92.96%,CaO+MgO含量为0.30%,粒度大于100 μm的占94%,产品人造金红石是沸腾氯化生产的理想原料。

关键词:钛铁矿;氧化预处理;流态化浸出;人造金红石;沸腾氯化

中图分类号:TF111 文献标志码:A

Producing process of high quality synthetic rutile for fluidizing chlorination

XIONG Xue-liang, YANG Zhi, OUYANG Hong-yong, WANG Kang-hai

(Research Institute of Mineral Resource Development Technology,

Changsha Research Institute of Mining and Metallurgy, Changsha 410012,China)

Abstract: Three samples i.e. ilmenite, oxidation-modified ilmenite and reduction-modified ilmenite were leached by agitation leaching, pressure leaching and fluidization leaching. The results show that descending order of TiO2 content of products is oxidation-modified ilmenite, reduction-modified ilmenite and ilmenite when three samples are leached by agitation leaching. The maximum TiO2 content of product is obtained by fluidization leaching. The second is obtained by pressure leaching, and the minimum is obtained by agitation leaching. A new rutile phase appears on the surface of mineral by oxidation treating. The synthetic rutile produced from ilmenite by oxidation and fluidization acid leaching has characteristics as rutile-type titanium(IV) dioxide, with TiO2 content of 92.96%, CaO and MgO total content of 0.30%, 94% particle with size bigger than 100 μm, which is the ideal raw material of fluidizing chlorination process.

Key words: ilmenite; oxidation-modified; fluidization leaching; synthetic rutile; fluidizing chlorination

钛白粉是一种重要的优质颜料,被广泛用于油墨、塑料、化纤、造纸、航空、航天、冶金等领域。2010年,我国消费量预计约为110万t,占世界总消费量的1/5。在全球高端的钛白粉市场上,70%以上产品是由氯化法工艺生产的,生产厂家主要有美国的杜邦(Dupont)、美礼联(Millennium)、科美基(Kerr-McGee)、亨斯迈公司(Hunstman)和日本石原产业等。而我国钛白粉的产能为150余万t,其中,氯化法钛白粉仅为1.5万t,主要生产厂商是攀锦钛业和山东东佳集团等。由于钛白粉的盲目扩张,形成了中低档硫酸法锐钛型钛白粉大量过剩,出口受阻,而高档氯化法金红石型钛白大量进口的被动局面。随着2009年我国10万t/a氯化法钛白粉成套技术的引进开发以及国家的技术扶持和资金支助,氯化法钛白粉的生产将得到飞速发展[1]。

影响氯化法钛白粉的一个关键的生产环节是高品质金红石原料的供应,目前,我国氯化钛白粉生产的高品质原料主要从澳大利亚进口。只有掌握了高品质原料的生产技术,特别是用各类钛铁矿生产高品质人造金红石的技术,才能保证我国钛行业生产的可持续性发展,提升我国在钛行业的技术水平和影响力。

中国的钛资源居世界之首。钛矿床根据矿石工业类型,可分为90%的原生矿床和10%的次生矿床。原生矿床是我国的主要工业类型,是在岩浆分异作用下形成的复杂多金属共伴生矿床。该类矿分选难度大,TiO2品位低,钙镁杂质含量高,回收率低,生产成本高,资源综合利用率仅为6%。目前,为了得到较高品位的铁矿,将钛铁矿磨至小于74 μm的颗粒占总量的70%以上。由原生矿床得到的钛铁矿,因粒度细、钙镁杂质含量高,只能作为硫酸溶渣的原料,无法达到沸腾氯化钛白粉对钛铁矿原料的要求[2]。

根据沸腾氯化的生产要求,原料必须具备以下特点:1) 金红石的品位较高,TiO2含量高于92%;2) 含有害杂质少,其CaO+MgO含量小于1%;3)金红石粒度分布好,粒径大于100 μm的颗粒占总量的85%以上[3-4]。目前,有关针对我国原生矿生产人造金红石已有报道[5],但是,有关生产供沸腾氯化用的高品质人造金红石的文献甚少。本文作者根据某钛铁矿的特性,进行盐酸浸出的工艺研究,制备满足沸腾氯化生产需要的高品质人造金红石。

1 实验

1.1 实验原料

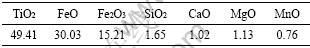

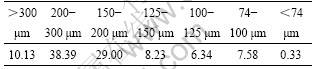

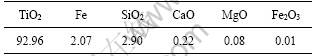

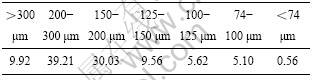

实验所用的矿样来自广西某钛铁矿,其主要化学成分分析如表1所列,粒度分布组成如表2所列。

1.2 实验方法

氧化预处理:称取一定量的钛铁矿装于瓷舟中,将瓷舟置于配有鼓风的马弗炉内并保温一定时间,取出得到改性矿。

还原预处理:将钛铁矿与还原剂按配比混合均匀后,混合料装于坩埚中,将坩埚置于马弗炉内并保温

表1 钛铁矿的主要化学成分

Table 1 Main chemical composition of ilmenite (mass fraction, %)

表2 钛铁矿粒度分布组成

Table 2 Size distribution composition of ilmenite (mass fraction, %)

一定时间,取出得到改性矿。

搅拌浸出:将原矿或改性矿加入装有盐酸浸出液的三颈烧瓶内,再与回流冷凝装置后的三颈烧瓶相连置于砂浴中加热,浸出一段时间后,过滤分离,酸洗水洗,烘干煅烧,得到产品人造金红石。

加压浸出:将原矿或改性矿加入装有盐酸浸出液石英管内,密封后放入油浴锅中,浸出一段时间后,过滤分离,酸洗水洗,烘干煅烧,得到产品人造金红石。

流态化浸出:将原矿或改性矿加入充有盐酸浸出液的流态化浸出塔中,浸出液采用电阻丝加热,浸出一段时间后,过滤分离,酸洗水洗,烘干煅烧,得到产品人造金红石。

2 结果与讨论

2.1 钛铁矿原矿的矿物工艺学

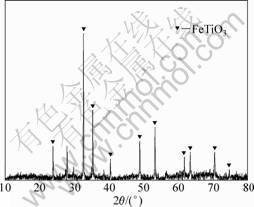

利用D8 ADVANCE型X线衍射仪分析,钛铁矿原矿的XRD谱如图1所示。

从图1可见,该钛铁矿主要有六方的钛铁矿(FeTiO3)的结构,基本上不含有游离的单质Fe和FeO的衍射峰,杂质硅钙镁的含量少,衍射峰难以突显。

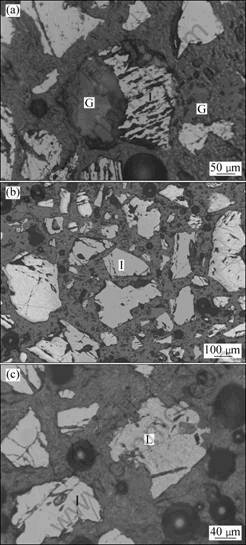

在反光显微镜下观察钛铁矿原矿的形貌,如图2 所示。其中:I为钛铁矿;G为脉石;L为褐铁矿。

图1 钛铁矿原矿的XRD谱

Fig.1 XRD pattern of ilmenite

图2 钛铁矿原矿的显微形貌

Fig.2 Microstructures of ilmenite observed under reflected light microscope

从图2可见,原矿中钛铁矿FeTiO3形貌为粒状、棱角粒状等,粒度一般为0.04~0.3 mm,大部分呈单体产出,有少部分与脉石矿物辉石、长石及黏土类矿物连生。少部分褐铁矿也以单体形式存在。

2.2 浸出实验结果与分析

2.2.1 不同改性矿的浸出实验

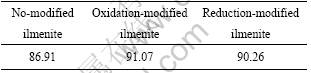

选择未处理原矿、氧化改性矿、还原改性矿3种矿物,采用搅拌浸出方式,温度为108 ℃,固液比(g/L)为6,时间为12 h,得到的实验结果如表3所示。

从表3可见,由氧化改性钛铁矿制备的人造金红石TiO2含量最高为91.07%,比原矿提高了5%,比还原矿多1.7%。该钛铁矿原矿的表面受风化蚀变的影

表3 3种钛铁矿中浸出的TiO2含量

Table 3 TiO2 content leached from three ilmenite samples (mass fraction, %)

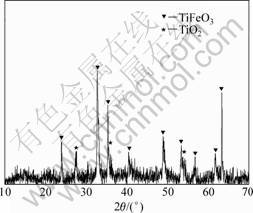

响,自身酸溶性比原生钛铁矿差,由原矿直接盐酸浸出所制备的人造金红石中TiO2含量不高,经过还原改性作用,可以将三价铁还原成为二价铁,也将以褐铁矿形式存在的Fe2O3还原为FeO,有利于Fe的浸出,相应的产物人造金红石中的TiO2含量比原矿中的高一些,但是氧化改性矿的产物人造金红石中TiO2含量更高。这是因为在还原矿的浸出过程中,溶液中存在很多黄色细粉,经分析为钛的水解物,钛在酸浸的过程中损失较多,导致其含量下降,而氧化改性矿的浸出溶液中黄色的水解物相对少一些。改性矿的XRD谱如图3所示。与图1 相比可见,改性后钛铁矿的表面生成了新的金红石相TiO2,并且表面结构比较稳定,该金红石相作为钛铁矿酸浸过程中的晶种,有利于钛酸解后再水解的产物表面沉积,浸出溶液中钛水解物就少,相应的TiO2含量最高[6]。

图3 氧化改性钛铁矿的XRD谱

Fig.3 XRD pattern of oxidation-modified ilmenite

2.2.2 不同浸出方式的浸出实验

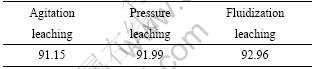

以氧化改性矿为实验样,选择搅拌浸出、加压浸出、流态化浸出3种方式,温度为108 ℃,固液比(g/L)为6,时间为12 h,得到的实验结果如表4所示。

从表4可见,加压浸出的TiO2含量比搅拌浸出的高。在有压力的作用下,钛铁矿中的铁、钙、镁、锰、铝等物质酸解的速度大大增加,酸溶后都以离子形式存在溶液中,最后除出率也相应增加,产物杂质少而

表4 采用3种浸出方式浸出氧化改性矿产物中TiO2的含量

Table 4 TiO2 content in product of oxidation-modified ilmenite after leaching by three leaching ways (mass fraction, %)

TiO2相应增加。流态化浸出的产物中TiO2含量高达92.96%,这是因为流态化浸出的床层保持一定的孔隙度,固体颗粒处于湍流状态,两相接触界面不断更新,大大提高两相的接触程度。流态化浸出的液固两相间的热、质传递加快,固体颗粒表面的接触交换加快,使其所进行的物理化学过程更完全、更充分[7]。因此,杂质脱出率更彻底,杂质含量也减少。

同时,在实验中观察到流态化浸出的浸出溶液中几乎没有黄色钛水解物,这是因为流态化浸出时,钛铁矿颗粒近似悬浮于浸出液中,其表面附有连续的流体,该流体起了缓冲固体颗粒间的碾磨、硬碰,具有保护矿粒本身的作用,防止沉积在表面的钛沉积物流失,这也进一步增加了产物人造金红石TiO2含量。

2.3 产品人造金红石的分析

2.3.1 人造金红石的X线衍射分析

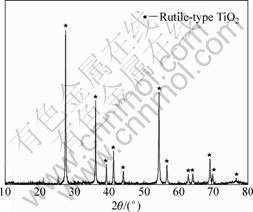

根据上述实验结果分析讨论后,钛铁矿采用氧化预处理,盐酸流态化浸出工艺,实验得到的产品人造金红石,其XRD谱如图4所示。

由图4可见,产品人造金红石是一种金红石型的TiO2,产品纯度高,杂质少。

2.3.2 人造金红石的化学分析

产品人造金红石的主要化学分析如表5所示。

图4 人造金红石的XRD谱

Fig.4 XRD pattern of synthetic rutile

表5 人造金红石化学成分

Table 5 Main chemical composition of synthetic rutile (Mass fraction, %)

对比表1和表5可以看出,杂质Fe,Ca,Mg和Mn含量大大减少,说明盐酸浸出过程中,这些物质溶于酸而除出率高,SiO2由于未溶于盐酸而得到富集,特别是CaO+MgO含量只有0.30%。

2.3.3 人造金红石的粒度分析

产品人造金红石的粒度组成如表6所示。

表6 人造金红石的粒度分布组成

Table 6 Size distribution composition of synthetic rutile (Mass fraction, %)

对比表2和表6的结果可见,产物人造金红石与原矿的粒度和粒级分布相差很小,粒度大于100 μm的占94%。

3 结论

1) 对广西某钛铁矿的矿物分析可知,原矿中主要含六方结构的钛铁矿(FeTiO3),成粒状、棱角粒状等,粒度一般在0.04~0.3 mm之间,大部分呈单体产出,有少部分与脉石矿物辉石、长石及黏土类矿物连生。少部分的褐铁矿也以单体形式存在。

2) 对于未处理原矿、氧化改性矿和还原改性矿3种矿物,采用搅拌浸出方式时,产物人造金红石TiO2含量从大到小依次为氧化改性矿,还原改性矿,未处理原矿, 氧化改性矿的矿物表面生成了新的金红石相。

3) 对于搅拌浸出、加压浸出和流态化浸出3种方式,产物人造金红石TiO2含量从大到小依次为流态化浸出,加压浸出,搅拌浸出。

4) 钛铁矿采用氧化预处理,盐酸流态化浸出工艺,得到的产品人造金红石是金红石型TiO2,TiO2含量为92.96%,CaO+MgO含量为0.30%,粒度大于100 μm的占94%,产品人造金红石是沸腾氯化生产的理想原料。

REFERENCES

[1] 徐高栋. 中国钛白产业环保现状与节能减排策略[J]. 新材料产业, 2010(1): 37-40.

XU Gao-dong. Current situation of environmental protection and strategy for energy saving and emission reduction in china titanium dioxide industry[J]. Advanced Materials Industry, 2010(1): 37-40.

[2] 吴 贤, 张 健. 中国的钛资源分布及特点[J]. 钛工业进展, 2006, 23(6): 8-12.

WU Xian, ZHANG Jian. Geographical distribution and characteristics of titanium resources in China[J]. Titanium Industry Progress, 2006, 23(6): 8-12.

[3] 汪镜亮. 钛白生产及钛矿物原料的需求[J]. 钒钛, 1995(3): 18-27.

WANG Jing-liang. Titanium dioxide process and needs of raw ilmenite mineral material[J]. Vanadium Titanium, 1995(3): 18-27.

[4] 戚 蓉. 氯化法钛白粉的粒径与粒径分布[J]. 现代涂料与涂装, 2007, 10(5): 44-47.

QI Rong. Particle size and distribution of titanium dioxide produced by chloride procedure[J]. Modern Paint and Finishing, 2007, 10(5): 44-47.

[5] 周忠华, 黄焯枢, 王康海. 钛铁矿流态化酸浸法扩大试验报告[R]. 长沙: 长沙矿冶研究院, 1981.

ZHOU Zhong-hua, HUANG Zhuo-shu, WANG Kang-hai. Report on industrial test of fluidization leaching ilmenite[R]. Changsha: Changsha Mining and Metallurgy Research Institute, 1981.

[6] 刘子威, 黄焯枢, 王康海. 攀枝花钛铁矿流态化盐酸浸出的动力学研究[J]. 矿冶工程, 1991, 11(2): 48-52.

LIU Zi-wei, HUANG Zhuo-shu, WANG Kang-hai. The kinetics of the fluidized bed leaching of Panzhihua ilmenite[J]. Mining and Metallurgical Engineering, 1991, 11(2): 48-52.

[7] 李佑楚. 流态化过程工程导论[M]. 北京: 科学出版社, 2008: 2-5.

LI You-chu. Introduction of fluidized engineering process[M]. Beijing: Science Press, 2008: 2-5.

(编辑 赵 俊)

基金项目:国家重点基础研究发展计划资助项目(2007CB613502);科技部院所开发专项(2009EG113036)

通信作者:熊雪良,高级工程师,硕士研究生;电话:0731-88655696;E-mail:xiong9550@163.com