文章编号: 1004-0609(2005)03-0478-07

Al3Ti4B中间合金对Mg-7Al-0.4Zn-0.2Mn合金

显微组织和性能的影响

陈晶阳1, 关绍康1, 林敦文1, 王利国1, 李建国2

(1. 郑州大学 材料科学与工程学院, 郑州 450002;

2. 清华大学 材料科学与工程系, 北京 100084)

摘 要: 研究了Al3Ti4B中间合金对Mg-7Al-0.4Zn-0.2Mn合金的显微组织、 力学性能及耐腐蚀性能的影响。 结果表明: 当Al3Ti4B加入量小于0.3%(质量分数)时, 合金的平均晶粒尺寸显著减小; 当Al3Ti4B加入量为0.3%时, 合金组织显著细化, 平均晶粒尺寸由未变质合金的135μm细化到30μm, 合金拉伸力学性能和耐腐蚀性能最好; 当加入量超过0.3%时, 晶粒粗化; 具有密排六方结构的高熔点化合物TiB2(θm=2980℃)和AlB2(θm=980℃)均可作为α-Mg的异质核心, 大量异质结晶核心的存在是导致α-Mg晶粒细化的主要原因。

关键词: Mg-7Al-0.4Zn-0.2Mn合金; Al3Ti4B; 晶粒细化; 异质形核 中图分类号: TG146.22

文献标识码: A

Effects of Al3Ti4B master alloy on microstructure and properties of Mg-7Al-0.4Zn-0.2Mn alloys

CHEN Jing-yang1, GUAN Shao-kang1, LIN Dun-wen1, WANG Li-guo1, LI Jian-guo2

(1. College of Materials Science and Engineering,

Zhengzhou University, Zhengzhou 450002, China;

2. Department of Materials Science and Engineering,

Tsinghua University, Beijing 100084, China)

Abstract: The effects of Al3Ti4B master alloy on microstructure, mechanical and corrosion resisting properties of Mg-7Al-0.4Zn-0.2Mn alloys were studied. The results show that the average grain size of alloy decreases when the addition of Al3Ti4B is less than 0.3%(mass fraction). The microstructure is refined remarkably when adding 0.3% Al3Ti4B, the average grain size decreases from 135 to 30μm. When the Al3Ti4B addition is more than 0.3%, the grain size increases with the increase of Al3Ti4B. The mechanical properties and corrosion resisting properties of alloys with 0.3%Al3Ti4B are the best. High melting point compounds (TiB2 and AlB2) with hexagonal closed-packed(HCP) crystal structure can serve as the nucleating sites of α-Mg during solidification, and heterogeneous nucleation is the main reason of the grain refinement of α-Mg grains.

Key words: Mg-7Al-0.4Zn-0.2Mn alloy; Al3Ti4B; grain refinement; heterogeneous nucleation

镁合金是迄今在工程应用中最轻的金属结构材料, 具有比强度高, 比刚度高, 阻尼减震性能好, 电磁屏蔽性能和机械加工性能优异的特点, 被誉为“21世纪最具发展潜力和前途的绿色工程材料” [1-3]。 但由于镁具有密排六方(HCP)晶体结构, 滑移系少, 塑性变形能力差, 极大地限制了镁及其合金材料的应用[4]。 研究表明[5-8], 细小等轴的晶粒组织能改善镁合金的塑性变形能力, 晶粒细化是改善多晶镁变形结构特征和提高镁合金加工与使用性能的重要途径之一, 因此, 镁合金晶粒细化的研究具有非常重要的意义。 Mg-Al系合金的传统晶粒细化工艺是碳质孕育法和过热处理, 然而这些方法从工艺、 成本及环保角度考虑还存在一些问题, 效果好、 工艺简单、 成本低、 不污染环境的细化工艺尚有待于进一步开发[9]。 本文作者所研究的Mg-7Al-0.4Zn-0.2Mn合金在实际生产中已经以大尺寸(d350mm)半连续铸坯形式用于锻造汽车轮毂, 然而大尺寸半连续铸坯容易出现晶粒粗化及铸造缺陷等问题, 使合金的锻造性能变差。 因此, 解决Mg-7Al-0.4Zn-0.2Mn合金的晶粒粗化问题, 改善合金的塑性变形能力和为后期的锻造工序提供优良原料的任务比较紧迫。 本课题组早期研究了Al5TiB对Mg-8Zn-4Al-0.3Mn合金显微组织及力学性能的影响[10], 但合金的细化效果和力学性能并不理想。 研究表明[11]: 在不同Ti和B质量比的Al-Ti-B中间合金中, Ti和B元素含量及第二相具有较大差别, 从而使它们表现出不同的细化效果。 Al3Ti4B中间合金的Ti和B质量比为0.75(TiB2分子中的Ti与B的质量比为2.2), 组织中第二相为TiB2和AlB2, TiB2(θm=2980℃)和AlB2(θm=980℃)均为密排六方结构的高熔点化合物, 且它们的晶格常数均与镁相近, 基体铝元素为Mg-Al系合金所相容, 故Al3Ti4B中间合金可能是镁合金有效的晶粒细化剂, 而国内外就Al3Ti4B中间合金用于镁合金的研究报道极少, 因此, 本文作者通过添加微量Al3Ti4B于Mg-7Al-0.4Zn-0.2Mn合金中, 初步探索了Al3Ti4B对合金显微组织、 显微硬度及耐腐蚀性能的影响。

1 实验

实验选用工业纯镁、 纯铝、 纯锌、 Al-10Mn(质量分数, %)、 Al3Ti4B中间合金作为原材料, 采用上海交通大学研制的JDRJ熔剂保护, 在井式电阻坩埚炉中配制了6种合金。 表1所列为合金成分, 由于配料时考虑了合金元素的实收率, 因此所得合金的实际成分与设计成分基本相符。 精炼温度为730~760℃, 静置30min, 降温到720℃时浇铸到金属型模具中, 铸棒尺寸为d25mm×100mm。 为了消除取样位置对晶粒大小的影响, 所有样品都从试棒中部取样。 为使晶界清晰便于观测, 需对试样进行固溶处理, 固溶处理的工艺条件为410℃保温8h, 取出后立即水淬。 试样经研磨, 抛光后采用苦味酸((NO2)3C6H2OH)和冰乙酸(CH3COOH)的混合溶液浸蚀, 在Olympus H2-UMA金相采集系统下观察其组织, 并采用定量金相法测定平均晶粒尺寸, 采用Philips PW1820型X射线衍射仪进行X射线衍射分析, 实验条件为: CuKα线, 工作电压40kV, 工作电流40mA, 扫描速度4 (°)/min。

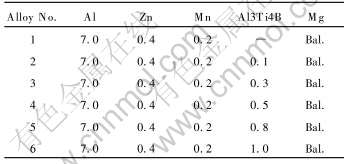

表1 合金的成分

Table 1 Composition of alloys (mass fraction, %)

采用HV-1000型显微硬度仪进行显微硬度测试, 载荷为1N, 加载持续时间为20s。 采用EG&G公司生产的M352腐蚀电化学测试系统进行自腐蚀电位监测, 采用标准三电极体系, 试样为工作电极, 碳棒为辅助电极, 饱和甘汞电极(SCE)为参考电极。 在温度为(25±1)℃的条件下, 监测铸态合金在3.5%NaCl溶液中的自腐蚀电位情况, 并通过计算机对测试结果进行处理后自动绘出曲线。

2 结果与讨论

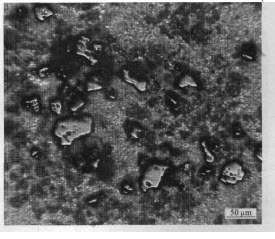

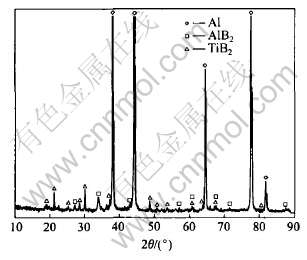

图1和2所示分别为实验所添加Al3Ti4B中间合金的铸态显微组织和X射线衍射谱。 由图1可 看出, 组织中只有弥散分布的颗粒第二相(AlB2和 TiB2相), 没发现长条状或块状的TiAl3相。

图1 添加Al3Ti4B的中间合金铸态显微组织

Fig.1 Cast microstructure of master alloy added with Al3Ti4B

图2 添加Al3Ti4B中间合金的X射线衍射谱

Fig.2 XRD pattern of master alloy added with Al3Ti4B

2.1 合金的铸态组织

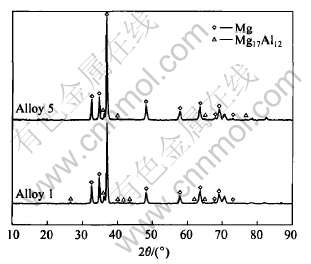

图3所示为铸态合金的X射线衍射谱。 图4所

图3 铸态合金的X射线衍射谱

Fig.3 XRD patterns of cast alloys

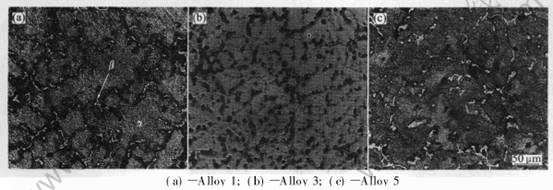

示为不同Al3Ti4B含量合金的铸态组织。 由图3和4可见, 未变质合金铸态组织主要由基体α-Mg相和离异共晶析出的化合物β-Mg17Al12相构成, 黑色颗粒相为Al-Mn化合物, 它是由Al溶入Mn形成的固溶体。 β相主要分布于晶界, 也有少量分布于晶粒内, Al-Mn化合物较多地分布于晶内与晶界处。 各合金的相组成并没有多大变化, 只是相的数量发生了变化。 由图4(a)可见, 未变质合金的晶粒粗大, 晶界上β相呈半连续网状分布且尺寸较大。 合金中加入0.3%Al3Ti4B时, 晶粒尺寸最小, β相细小且呈岛状分布, 但是随着Al3Ti4B加入量的进一步增加, 晶粒尺寸粗化, β相变得粗大且呈半连续网状分布。

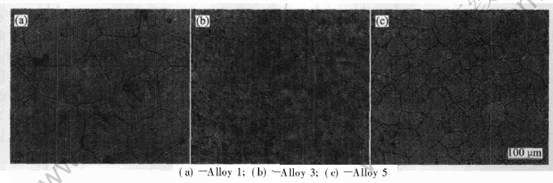

2.2 合金的固溶组织及平均晶粒尺寸

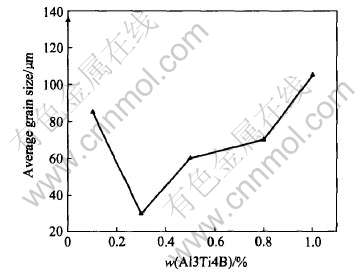

由于Mg-7Al-0.4Zn-0.2Mn合金的铸态组织不能看到清晰的晶界, 无法比较其晶粒大小, 因此需对合金进行固溶处理。 图5所示为不同Al3Ti4B含量合金的固溶组织。 固溶处理后, 晶粒并没有长大, β相完全溶入α-Mg基体, 组织为单相过饱和的α-Mg固溶体, 无规则分布于晶界及基体上的黑色颗粒相为Al-Mn化合物, 该化合物在固溶温度下并未溶入α-Mg基体。 研究[9]表明, Al-Mn化合物对Mg-Al系合金没有细化作用。 图6所示为Al3Ti4B加入量对Mg-7Al-0.4Zn-0.2Mn合金平均晶粒尺寸的影响。 从图中可看出, Al3Ti4B的加入使晶粒得到不同程度细化, 当Al3Ti4B的加入量小于0.3%时, 随着Al3Ti4B加入量的增加, 合金的平均晶粒尺寸急剧减小; 当Al3Ti4B加入量为0.3%时, 合金晶粒显著细化, 平均晶粒尺寸由未变质合金的135μm细化到30μm; 当加入量超过0.3%时, 晶粒又开始变粗。

图4 不同Al3Ti4B含量合金的铸态组织

Fig.4 Cast microstructures of magnesium alloys with different Al3Ti4B additions

图5 不同Al3Ti4B含量合金的固溶组织

Fig.5 Solid solution microstructures of magnesium alloys with different Al3Ti4B additions

图6 Al3Ti4B加入量对Mg-7Al-0.4Zn-0.2Mn 合金平均晶粒尺寸的影响

Fig.6 Effect of Al3Ti4B addition on average grain size of Mg-7Al-0.4Zn-0.2Mn alloys

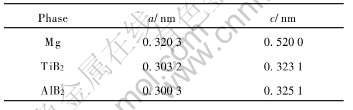

根据Johnson的溶质晶粒细化理论[12], 有效的形核质点和偏析能力良好的溶质是晶粒细化过程必不可少的两个因素。 本课题组早期研究了Al5TiB对Mg-8Zn-4Al-0.3Mn合金显微组织及力学性能的影响[10,11], 但合金的细化效果和力学性能并不理想。 研究表明[13], 在不同Ti和B质量比的Al-Ti-B中间合金中, Ti和B元素含量及第二相具有较大差别, 使它们表现出不同的细化效果。 Al5TiB中间合金中Ti和B质量比为5(TiB2分子中, Ti与B的质量比为2.2), 熔体中Ti与B反应生成TiB2相后, 熔体中过剩的Ti与Al生成TiAl3相, TiAl3属于四方结构, 对镁合金的细化及性能不利; 而Al3Ti4B中间合金的Ti和B质量比为0.75, 熔体中生成TiB2相后, 剩余的B原子与Al反应生成AlB2相, TiB2(θm=2980℃)和AlB2(θm=980℃)均为密排六方结构的高熔点化合物, 在镁液中以固态质点形式存在, 其晶格常数均与镁相近。 表2所列为Mg、 TiB2和AlB2的晶格常数[14]。

表2 Mg、 TiB2和AlB2的晶格常数

Table 2 Lattice parameters of Mg, TiB2 and AlB2

一般认为[15], 异质形核能力的大小取决于形核基底与结晶相之间的界面能, 而影响界面能的因素主要包括基底与结晶相间的点阵错配度、 基底表面形态、 化学性质以及基底与结晶相间的静电位。 当点阵错配引起弹性能急剧升高时, 则错配度是决定界面能的主要因素。 新相在固体(衬底)上形核应满足低指数晶面的错配度要小于15%的条件。

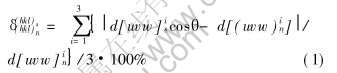

根据Bramfitt[16]的二维点阵错配度模型, 其计算公式为:

式中 (hkl)s为基底的低指数晶面; (hkl)n为晶核的低指数晶面; [uvw]s为(hkl)s晶面上的低指数晶向; [uvw]n为(hkl)n晶面上的低指数晶向; d[uvw]s, d[uvw]n分别为沿[uvw]晶向的原子间距; θ为[uvw]s和[uvw]n间的夹角。

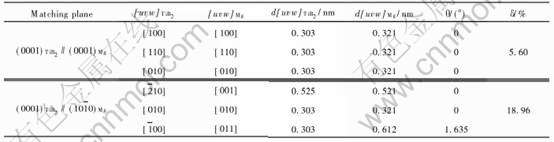

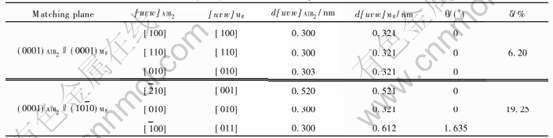

根据式(1)可以计算出TiB2和AlB2的(0001)面与Mg的(0001)面和(101[TX-]0)面的错配度, 计算结果分别如表3和4所列。 由表可见, TiB2和AlB2的(0001)面与α-Mg的(0001)面的错配度分别为5.6%和6.2%, 基本满足共格对应的错配度条件, 因此, TiB2和AlB2均可作为α-Mg良好的异质核心, 使得α-Mg晶粒细化。 当Al3Ti4B的加入量增大时, 异质核心的数量随之增加, 细化能力随之增强, 晶粒尺寸也随之下降。 然而, 变质剂对合金的细化存在一个最佳量的问题[10], 当Al3Ti4B含量增加到一定程度之后, 由于镁液中的TiB2和AlB2第二相质点的弥散度过高, 使得质点聚集, 细化效果变差, 这可能是Al3Ti4B加入量超过0.3%使合金晶粒尺寸粗化所致。

Ti和B都是表面活性元素, 在铸锭凝固过程中, 偏聚在固/液界面前沿, 在枝晶生长的固/液界面前沿产生成分过冷区, 从而阻碍了枝晶组织的生长。 由于基体组织得以细化, 使得随后沿晶界析出的离异共晶相β-Mg17Al12分布也更趋弥散。

2.3 Al3Ti4B对合金力学性能的影响

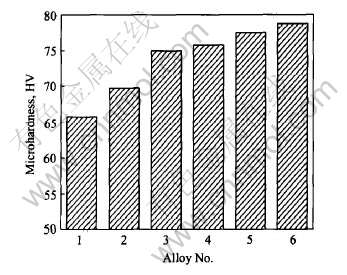

图7所示为不同Al3Ti4B含量合金基体的显微硬度。 由图可见, 不同含量Al3Ti4B的加入均提高了Mg-7Al-0.4Zn-0.2Mn合金基体的显微硬度。 且随着Al3Ti4B加入量的增加, 合金的显微硬度也呈增加趋势, 当Al3Ti4B加入量为1.0%时, 提高达19.6%。 当Al3Ti4B加入量小于0.3%时, 随着Al3Ti4B加入量的增加, 显微硬度的提高幅度较 快; 当加入量超过0.3%后, 显微硬度的提高幅度变缓, 这是细晶强化和固溶强化共同作用的结果。

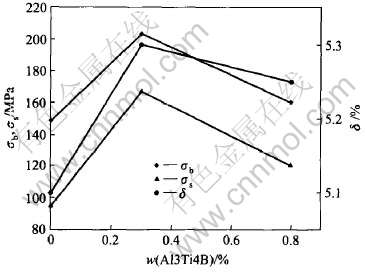

图8所示为不同Al3Ti4B含量合金的力学性能。 由图可见, 当Al3Ti4B加入量为0.3%时, 合金的力学性能最好, 合金3的抗拉强度(σb)、 屈服强度(σs)和延伸率(δ)分别比未变质合金提高36.6%、 76.3%和3.9%, 细晶强化是提高合金力学性能的主要机制。 随着Al3Ti4B加入量的进一步增大, 合金晶粒粗化, 力学性能变差。

图7 不同Al3Ti4B含量合金基体的显微硬度

Fig.7 Microhardness of magnesium alloys with different A13Ti4B additions

表3 TiB2(0001)面与α-Mg(0001)面和  面的错配度

面的错配度

Table 3 Matching degree of (0001)TiB2 to (0001)Mg and  Mg

Mg

表4 AlB2(0001)面与α-Mg(0001)面和 面的错配度

面的错配度

Table 4 Matching degree of (0001)AlB2 to (0001)Mg and  Mg

Mg

图8 不同Al3Ti4B含量合金的拉伸力学性能

Fig.8 Mechanical properties of magnesium alloys with different Al3Ti4B additions

2.4 Al3Ti4B对合金自腐蚀电位的影响

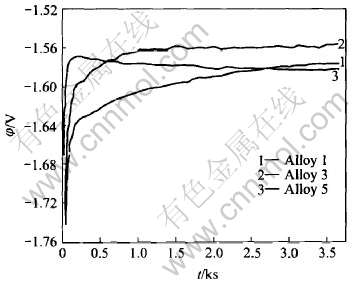

图9所示为不同Al3Ti4B含量合金的自腐蚀电位。 由图可看出, 合金3的自腐蚀电位要高于合金1, 提高幅度约为30mV。 由于晶粒尺寸, β相的尺寸、 分布和体积分数对镁合金的腐蚀行为将产生重要的影响。 当Al3Ti4B加入量为0.3%时, 晶粒细化效果最好, β相尺寸也最细小, 这使得β相对α相腐蚀的阻碍作用增加, 从而使合金的耐腐蚀性能有所提高; 当Al3Ti4B加入量超过0.3%时, 晶粒尺寸粗化, β相变得粗大, 从而导致合金耐腐蚀性能的下降。 由此可见, 3种试验合金的自腐蚀电位大小顺序依次为φalloy 3>φalloy 1>φalloy 5。

图9 不同Al3Ti4B含量合金的自腐蚀电位

Fig.9 Corrosion potential of magnesium alloys with different Al3Ti4B additions

3 结论

1) Mg-7Al-0.4Zn-0.2Mn合金铸态显微组织主要由基体α-Mg相、 离异共晶析出的化合物β-Mg17Al12相和Al-Mn化合物构成。

2) Al3Ti4B的加入不同程度细化了合金组织, 当Al3Ti4B加入量为0.3%时的细化效果最佳, 平均晶粒尺寸由未变质合金的135 μm细化到30 μm, 当Al3Ti4B加入量超过0.3%时, 晶粒又开始变粗。 具有密排六方结构的高熔点化合物TiB2和AlB2均可作为α-Mg的异质核心, 大量异质结晶核心的存在是导致α-Mg晶粒细化的主要原因。

3) Al3Ti4B加入量为0.3%时, 合金的力学性能最好, 合金3的抗拉强度、 屈服强度和延伸率分别比未变质合金提高36.6%、 76.3%和3.9%。 随着Al3Ti4B加入量的增加, 合金的显微硬度呈增加的趋势, 加入量为1.0 %时, 显微硬度值比未变质合金提高达19.6%。

4) Al3Ti4B加入量为0.3%时, 合金的耐腐蚀性能有所提高, 其自腐蚀电位比未变质合金提高约30 mV, 3种实验合金的自腐蚀电位大小顺序依次为φalloy 3>φalloy 1>φalloy 5。

REFERENCES

[1]Decker, Raymond F. The renaissance in magnesium[J]. Advanced Mater & Proc, 1998, 154(3): 31-33.

[2]Clow B B. Magnesium industry overview[J]. Advanced Mater & Proc, 1996, 150(4): 33-36.

[3]曾小勤, 王渠东, 吕宜振, 等. 镁合金应用新进展[J]. 铸造, 1998, 47(11): 39-43.

ZENG Xiao-qin, WANG Qu-dong, LV Yi-zhen, et al. Recent development of magnesium alloy application[J]. Foundry, 1998, 47(11): 39-43.

[4]Erchov S, Riehemann W, Gabor P, et al. Damping capacity of sand cast magnesium alloy AZ91[J]. Mater Sci Tech, 2002, 18(2): 198-200.

[5]Lee Y C, Dahle A K, St John D H. The role of solute in grain refinement of magnesium [J]. Metallurgical and Materials Transactions A, 2000, 31(11): 2895-2906.

[6]张诗昌, 段汉桥, 蔡启舟, 等. 镁合金的熔炼工艺现状及发展趋势[J]. 特种铸造及有色合金, 2000, 21(6): 51-54.

ZHANG Shi-chang, DUAN Han-qiao, CAI Qi-zhou, et al. Melting technics status and development tendence of magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2000, 21(6): 51-54.

[7]余琨, 黎文献, 王日初, 等. 变形镁合金的研究、 开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, et al. Research, exploitation and application of deformation magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[8]Yosuke T, Tetsuichi M, Norio K, et al. Effect of minor elements on grain size of Mg-9%Al alloy[J]. Materials Science Forum, 2000, 350-351(6): 199-204.

[9]Nishino N, Kawahara H, Shimizu Y, et al. Grain refinement of magnesium casting alloys by boron addition[J]. Mater Sci Tech, 2000, 16(10): 59-64.

[10]王迎新, 杨明珊, 李立明, 等. Al5TiB对Mg-8Zn-4Al-0.3Mn合金显微组织的影响[J]. 机械工程材料, 2003, 27(9): 36-39.

WANG Ying-xin, YANG Ming-shan, LI Li-ming, et al. Effects of Al5TiB on microstructure of Mg-8Zn-4Al-0.3Mn magnesium alloys[J]. Materials for Mechanical Engineering, 2003, 27(9): 36-39.

[11]王迎新, 王建强, 关绍康. Al5TiB对Mg-8Zn-4Al-0.3Mn合金时效过程的影响[J]. 中国有色金属学报, 2003, 13(6): 1514-1518.

WANG Ying-xin, WANG Jian-qiang, GUAN Shao-kang. Effects of Al5TiB on aging process of Mg-8Zn-4Al-0.3Mn alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1514-1518.

[12]刘子利, 沈以赴, 李子全, 等. 铸造镁合金的晶粒细化技术[J]. 材料科学与工程学报, 2004, 22(1): 146-149.

LIU Zi-li, SHEN Yi-fu, LI Zi-quan, et al. Review of the grain refinement technology of cast magnesium alloys[J]. Journal of Materials Science & Engineering, 2004, 22(1): 146-149.

[13]马洪涛, 李建国, 张柏清, 等. Al-Ti-B合金的组织分析[J]. 中国有色金属学报, 2001, 11(5): 801-805.

MA Hong-tao, LI Jian-guo, ZHANG Bai-qing, et al. Analysis of microstructure in Al-Ti-B alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 801-805.

[14]Jonas F, Anders E W J, Lena S. Experimental analysis of the intermediary phases AlB2, AlB12 and TiB2 in the Al-B and Al-Ti-B systems[J]. Journal of Alloys and Compounds, 1999, 283(1-2): 192-197.

[15]袁广银, 刘满平, 王渠东, 等. Mg-Al-Zn-Si合金的显微组织细化[J]. 金属学报, 2002, 38(10): 1105-1108.

YUAN Guang-yin, LIU Man-ping, WANG Qu-dong, et al. Microstructure refinement of Mg-Al-Zn-Si alloys[J]. Acta Metallurgica Sinica, 2002, 38(10): 1105-1108.

[16]Bramfitt B L. The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron[J]. Metallurgical Transactions A, 1970, 1(7): 1987-1995.

(编辑李艳红)

基金项目: 河南省高校创新人才工程资助项目(豫2001-6); 河南省科技攻关资助项目(0224360015)

收稿日期: 2004-08-10; 修订日期: 2005-01-18

作者简介: 陈晶阳(1979-), 男, 硕士研究生.

通讯作者: 关绍康, 教授, 博士; 电话: 0371-3887508; E-mail: skguan@zzu.edu.cn