DOI:10.19476/j.ysxb.1004.0609.2019.07.17

双脉冲参数对金属锰电沉积行为的影响

郭岚峰1, 2,刘仁龙1,刘作华1,舒建成1, 3,孙小龙1,陶长元1

(1. 重庆大学 化学化工学院,重庆 400044;

2. 湖北兴福电子材料有限公司,宜昌 443711;

3. 西南科技大学 固体废物处理与资源化教育部重点实验室,绵阳 621010)

摘 要:采用双向脉冲电沉积法制备金属锰,研究双脉冲电源的正向平均电流密度、反向脉冲系数、一组正向脉冲工作时间和反向脉冲工作时间系数对电流效率、单位功耗、阴极金属锰和阳极泥的微观形貌的影响。结果表明:双脉冲电流可有效消除浓差极化,抑制析氢反应,反向电流可溶解镀层表面的枝晶;脉冲参数过高或者过低都会造成金属锰层微观缺陷不断增加,镀层表面平整度与光亮度下降;而反向周期性电流的增大或者施加时间的延长可有效地防止阳极钝化,减少阳极泥的产生量。双脉冲电源的优化参数为:当正向平均电流密度为350 A/m2、反向脉冲系数α=1/10、一组正向脉冲工作时间为150 ms、反向脉冲工作时间系数为1/15时,电沉积2 h的电流效率最高为80.25%,阳极泥的产生量最低为2.93 g,而且金属锰镀层致密均匀、气孔少、基本无枝晶产生。

关键词:双向脉冲电沉积;电解金属锰;电流效率;微观形貌

文章编号:1004-0609(2019)-07-1486-11 中图分类号:O643 文献标志码:A

电解金属锰(简称电解锰)不仅是生产不锈钢、高强度的合金钢及铜、铝等有色金属合金的重要原料,在医药、化工等领域中也有广泛的应用。我国是电解锰生产、消费和出口大国[1-2]。电解锰属于高投入、高消耗、高污染、资源型的产业,节能降耗是电解锰生产企业当前亟待面对和解决的问题之一[3]。目前,广泛使用的直流电沉积制备金属锰,阴极上发生析氢和析锰2种竞争反应[4-6]。析氢反应不仅降低了电流效率,产生的气泡也造成了金属锰层多孔、结合强度不高容易脱落。电沉积过程中阴极表面会形成一些自电极表面向溶液中“突出生长”的枝晶,也是降低电流效率、减小产量、引起电极间短路、生产不稳定的主要因素之一[7-8]。

脉冲电沉积法可有效改善浓差极化,提高阴极极限电流密度、抑制副反应的产生、降低杂质含量、改善电解槽内电场分布等[9-11]。近年来,脉冲电沉积的研究已遍及贵金属(如 Au、Ag、Pt)、一般金属(如 Zn、Al、Ni)及其合金与复合镀层[12-18],脉冲电沉积的应用研究已从贵金属转向非贵金属,由此可见,研究脉冲电沉积工艺过程有着重要的意义和应用价值。

目前,金属锰的制备多采用直流电沉积法及单向脉冲电沉积法,单脉冲电沉积制备金属锰中试电流效率达到76.5%[19],仍然有较大提升空间,而双向脉冲电沉积法制备金属的研究较少。双向脉冲电沉积除了可有效抑制浓差极化之外,还可以有效控制晶粒形核速率、抑制金属镀层表面枝晶的生长、改善金属镀层结构与表面形貌[20-23]。本文从抑制析氢反应和阴极表面枝晶生长、改善金属锰表面形貌出发,采用双向脉冲电沉积法制备金属锰,考察了双脉冲电流参数对电沉积锰电流效率、阳极泥的质量及物相与形貌的影响。

1 实验

1.1 试剂与仪器

实验所用试剂MnSO4·H2O、(NH4)2SO4、NH3·H2O、SeO2均为分析纯;电解所用阳极材料为Pb-Sn-Ag-Sb四元合金(栅孔状,长×宽×高为7 cm×6 cm×0.8 cm,有效面积24.35 cm2),阴极材料为316L不锈钢(长×宽×高为7.2 cm×6.6 cm×0.2 cm),隔膜袋、抛光液和钝化液均来自重庆某公司。

仪器:电解实验所用电源为SMD30数控双脉冲电镀电源(邯郸市大舜电镀设备有限公司生产);扫描电镜VEGAⅡLMV(Tescan, Czech)。

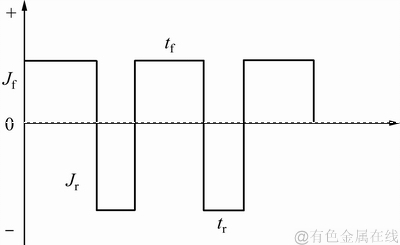

SMD30型双脉冲电镀电源(见图1)在输出一组正向脉冲电流之后又引入一组反向脉冲电流。为了能够输出如图2所示的波形电流,实验前需要将左边的正向脉冲与右边的反向脉冲串联起来。

图1 SMD30型双脉冲电镀电源

Fig. 1 SMD30 double pulse electroplating power supply

1.2 双脉冲电沉积金属锰

实验所用电解槽为有机玻璃黏合而成,可容纳1L电解液,聚氯乙烯隔膜将整个电解槽分成两个对称的阳极室和一个阴极室,两个阳极室的底部相连通。阳极板在使用前用61 μm砂纸打磨,不锈钢板在使用前,机械打磨后还需进行电化学抛光,然后干燥称量。电解液组成为:30 g/L Mn2+、120 g/L (NH4)2SO4、0.03 g/L SeO2,用氨水调节pH到7.0~7.2。保持极间距为5 cm,采用双脉冲电流进行恒温电解(水浴温度为40 ℃)2 h。电解结束后将阴极板放入钝化液(3% K2Cr2O7溶液)进行钝化处理,洗净电解锰表面后放入烘箱中烘干称量,并将阳极液进行过滤,将过滤物与未处理的阳极板烘干后称量。

1.3 双脉冲参数

实验所需电流波形如图2所示。图2中:tf为一组正向脉冲工作时间;tr为一组反向脉冲工作时间;Jf为正向脉冲平均电流密度;Jr为反向脉冲平均电流密度。

图2 实验所用电流波形

Fig. 2 Current waveform used in experiment

双脉冲电源参数主要有占空比 、脉冲电流频率

、脉冲电流频率 和平均电流密度

和平均电流密度 ,这些参数与tf、tr、Jf和Jr之间的关系如下:

,这些参数与tf、tr、Jf和Jr之间的关系如下:

(1)

(1)

(2)

(2)

(3)

(3)

tf与tr、Jf和Jr之间的关系如下:

(4)

(4)

(5)

(5)

式中: 为反向脉冲系数;

为反向脉冲系数; 为反向脉冲工作时间系数。

为反向脉冲工作时间系数。

在上述众多参数中,只有正向平均电流密度Jf、反向脉冲系数 、一组正向脉冲工作时间tf和反向脉冲工作时间系数

、一组正向脉冲工作时间tf和反向脉冲工作时间系数 是独立变化的,其他参数都可以表示为这4个基本参数的函数,因此实验中选取Jf、

是独立变化的,其他参数都可以表示为这4个基本参数的函数,因此实验中选取Jf、 、tf、

、tf、 这4个参数为双脉冲电源研究参数。

这4个参数为双脉冲电源研究参数。

1.4 分析方法

采用VEGA ⅡLMV型扫描电镜(Tescan, Czech)在25 kV下观察阳极泥和电解锰的形貌。采用日本理学D/max2200PC型X射线衍射仪对阳极泥进行物相分析。

在电解锰的生产中电流效率和单位能耗为主要的经济衡量标准,其计算方法如下:

(6)

(6)

(7)

(7)

式中:m为电解过程产生的金属锰的质量,g;M为锰的物质的量,g/mol;n为电解液中锰离子的价态,1;F为法拉第常数,取96599 C/mol;t为电解时间,s;I为电流,A;Q为电化学当量,g/(A·h),锰的电化学当量为1.025 g/(A·h)。

2 结果与分析

2.1 双向脉冲参数对电沉积锰电流效率和阳极泥产量的影响

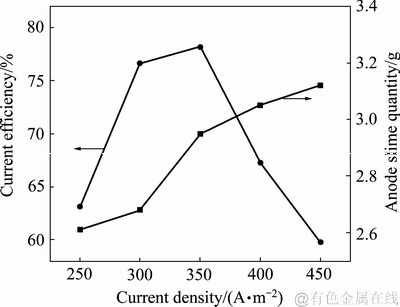

2.1.1 正向平均电流密度

实验保持其他参数不变,即反向脉冲系数 1/10、一组正向脉冲工作时间100 ms、反向脉冲工作时间系数β=1/10、在40 ℃下电解2 h,通过改变正向平均电流密度Jf来研究正向平均电流密度对电解金属锰过程电流效率、阳极泥的产量的影响。图3所示为不同正向平均电流密度Jf下电流效率和阳极泥产生量的变化规律。

1/10、一组正向脉冲工作时间100 ms、反向脉冲工作时间系数β=1/10、在40 ℃下电解2 h,通过改变正向平均电流密度Jf来研究正向平均电流密度对电解金属锰过程电流效率、阳极泥的产量的影响。图3所示为不同正向平均电流密度Jf下电流效率和阳极泥产生量的变化规律。

图3 正向平均电流密度对电流效率和阳极泥产生量的影响

Fig. 3 Effects of positive average current density on current efficiency and anode mud output

由图3可以看出,在 为1/10、tf为100 ms及β为1/10的条件下,正向平均电流密度为350 A/m2时的电流效率最高为78.19%,阳极泥的产生量也相对较低,为2.95 g。当正向平均电流密度大于350 A/m2,电流效率随正向平均电流密度的增大而快速降低,阳极泥的质量随着正向平均电流密度的增大而增大。

为1/10、tf为100 ms及β为1/10的条件下,正向平均电流密度为350 A/m2时的电流效率最高为78.19%,阳极泥的产生量也相对较低,为2.95 g。当正向平均电流密度大于350 A/m2,电流效率随正向平均电流密度的增大而快速降低,阳极泥的质量随着正向平均电流密度的增大而增大。

2.1.2 反向平均电流密度

实验固定正向平均电流密度为350 A/m2、一组正向脉冲工作时间100 ms、反向脉冲工作时间系数β=1/10、在40 ℃下电解2 h,通过改变反向脉冲系数 ,研究

,研究 对电解金属锰过程电流效率、阳极泥的产生量的影响,实验结果如图4所示。

对电解金属锰过程电流效率、阳极泥的产生量的影响,实验结果如图4所示。

图4 反向脉冲系数 对电流效率和阳极泥产生量的影响

对电流效率和阳极泥产生量的影响

Fig. 4 Effect of reverse pulse coefficient on current efficiency and anode mud output

由图4可以看出,在Jf=350 A/m2、tf为100 ms、β为1/10的条件下,反向脉冲 为1/10时,电流效率最高为78.19%,阳极泥的产生量为2.95 g;当

为1/10时,电流效率最高为78.19%,阳极泥的产生量为2.95 g;当 大于1/10时电流效率随

大于1/10时电流效率随 的增大而降低,阳极泥的产生量增加,到

的增大而降低,阳极泥的产生量增加,到 增加到1/15时,阳极泥的产生量随

增加到1/15时,阳极泥的产生量随 增加而降低。

增加而降低。

随着 减少,一组反向电流导通时间tr会相应地降低,阴极上金属锰的返溶量会相应降低,在没有溶解阴极板上平整的金属锰层的前提下,对阴极板上金属锰枝晶的返溶有利于金属锰的沉积,电流效率得到提高。但当

减少,一组反向电流导通时间tr会相应地降低,阴极上金属锰的返溶量会相应降低,在没有溶解阴极板上平整的金属锰层的前提下,对阴极板上金属锰枝晶的返溶有利于金属锰的沉积,电流效率得到提高。但当 减少到1/10并继续减少时,tr会相应缩短,这不仅使阴极附近锰离子的浓度不能及时得到较好的恢复、浓差极化也会相应增大,也会减少反向电流对阴极板上金属锰枝晶的溶解,对金属锰的沉积不利,从而降低了脉冲电解的电流效率。综合考虑阳极泥和电流效率,在反向脉冲系数1/10时为最佳操作条件。

减少到1/10并继续减少时,tr会相应缩短,这不仅使阴极附近锰离子的浓度不能及时得到较好的恢复、浓差极化也会相应增大,也会减少反向电流对阴极板上金属锰枝晶的溶解,对金属锰的沉积不利,从而降低了脉冲电解的电流效率。综合考虑阳极泥和电流效率,在反向脉冲系数1/10时为最佳操作条件。

2.1.3 正向电流时间

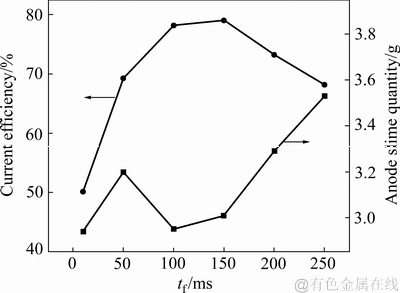

实验固定正向平均电流密度为350 A/m2、反向脉冲系数α=1/10、反向脉冲工作时间系数β=1/10、在40 ℃下电解2 h,通过改变tf来研究tf对电解金属锰过程电流效率、阳极泥的产生量的影响。图5所示为一组正向脉冲工作时间tf下电流效率和阳极泥产量的变化规律。由图5可以看出:在tf=150 ms时电流效率最高为79.01%,阳极泥的产生量也相对较低,为3.01 g。当tf大于150 ms时,电流效率随tf的增大而减小,阳极泥的质量也快速增大。

当其他参数固定时,随着tf的增加,正、反向电流施加间隔增加。tf较小,正向电流工作时间短,阴极表面锰的沉积量少,反向电流施加后阴极沉积的金属锰快速溶解,因此,一个周期内阴极表面金属锰的剩余量减少,电流效率随着tf的增加而增加。当tf大于150 ms后,正、反向电流施加时间增长,正、反向电流施加间隔增加,在正向电流工作时间内,金属锰在阴极表面大量沉积,阴极附近锰离子浓度快速降低,浓差极化严重,并伴随枝晶产生,此时正向电流工作时间因过长而不利于金属锰的沉积;在反向电流工作时,虽然反向电流工作时间的增加会使阴极附近锰离子浓度得到很好的恢复,但是也会增加金属锰的返溶量。因此正、反向电流施加时间也不可以过长。

图5 一组正向脉冲工作时间tf对电流效率和阳极泥产生量的影响

Fig. 5 Effect of a set of forward pulse working time on current efficiency and anode mud output

2.1.4 反向电流时间

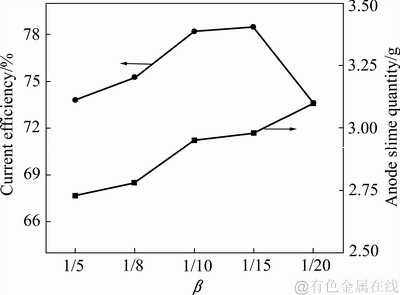

为了考察反向脉冲工作时间系数β对电解锰电流效率与阳极泥的产生量的影响,实验控制正向平均电流密度为350 A/m2、反向脉冲系数 为1/10、一组正向脉冲工作时间100 ms,实验结果如图6所示。

为1/10、一组正向脉冲工作时间100 ms,实验结果如图6所示。

由图6可得,当Jf=350 A/m2, =1/10,tf=100 ms时,随着β的增加,电流效率先增大后减小、阳极泥的产生量逐渐增加。当β=1/15时,电流效率最高为80.25%,阳极泥的产生量为2.93 g。

=1/10,tf=100 ms时,随着β的增加,电流效率先增大后减小、阳极泥的产生量逐渐增加。当β=1/15时,电流效率最高为80.25%,阳极泥的产生量为2.93 g。

双脉冲电解中,正向脉冲和单向脉冲电解过程相同;在反向脉冲中,反向电流是一个“返溶”的过程,即反向电流将正向电流所获锰层枝晶溶解,改善镀层厚度的均匀性,同时也优化了阴极附近锰离子浓度的分布。由图6可以看出,适当地延长反向电流施加时间有利于电解锰的沉积。反向电流施加时间过长会使阴极表面金属锰层返溶过多,电流效率降低;反向电流施加时间过短,法拉第电流波形将近似直流电流[24],尽管是脉冲电解,但却显不出脉冲电流的效果,浓差极化无法消除,金属锰镀层表面粗糙、电流效率降低。

图6 反向脉冲工作时间系数β对电流效率和阳极泥产生量的影响

Fig. 6 Effect of a set of reverse pulse working time on current efficiency and anode mud output

2.2 双向脉冲参数对金属锰与阳极泥微观形貌的影响

2.2.1 正向平均电流密度

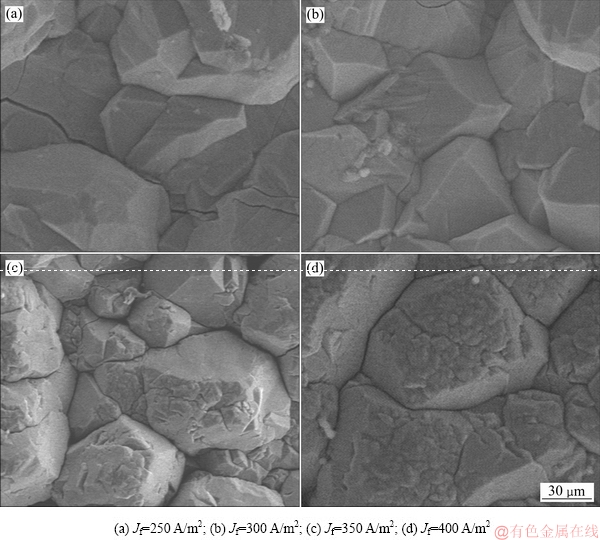

实验固定反向脉冲系数 、一组正向脉冲工作时间100 ms、反向脉冲工作时间系数β、在40 ℃下电解2 h,分别考察不同正向平均电流密度Jf对金属锰与阳极泥形貌表面形貌的影响,图7与图8所示分别为不同正向平均电流密度条件下得到的金属锰与阳极泥表面形貌。

、一组正向脉冲工作时间100 ms、反向脉冲工作时间系数β、在40 ℃下电解2 h,分别考察不同正向平均电流密度Jf对金属锰与阳极泥形貌表面形貌的影响,图7与图8所示分别为不同正向平均电流密度条件下得到的金属锰与阳极泥表面形貌。

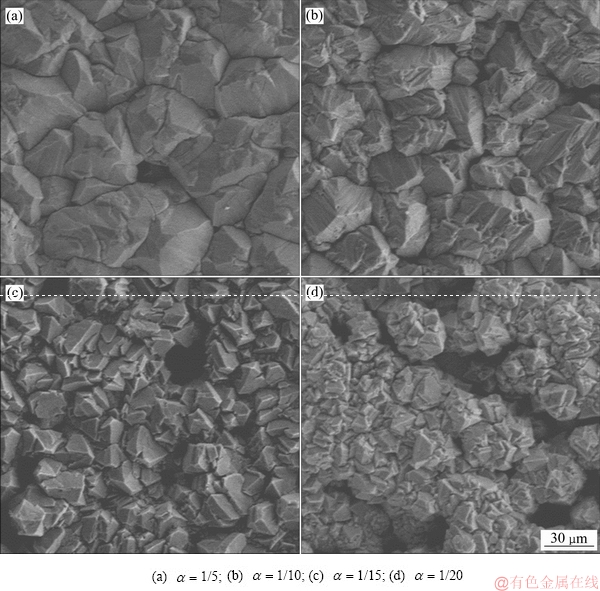

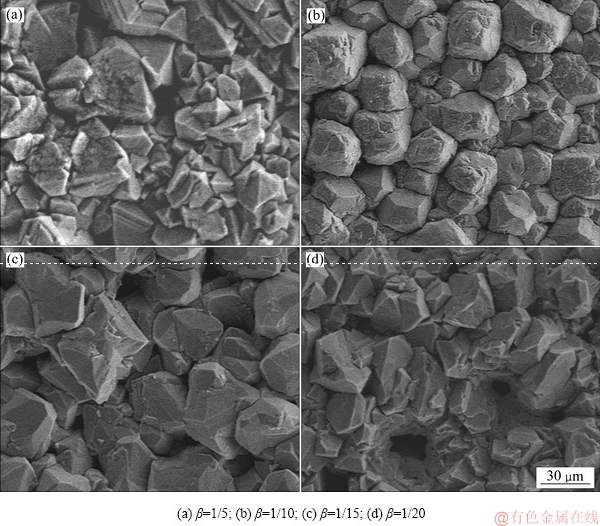

由图7可以看出,不同正向平均电流密度下得到的电解锰的晶型主要为棱椎体,这是由于晶体的螺旋位错生长。

从电沉积2 h后的SEM像(见图7)可以看出,随着正向平均电流密度的增大,金属锰镀层越加致密,而且裂痕减少,在正向平均电流密度超过350 A/m2时,锰层外观缺陷不断增加,镀层表面平整度与光亮度下降。从上述结果可以看出,正向电流密度过大容易导致金属锰镀层缺陷的产生。这是由于当正向电流密度较大时,阴极表面附近预镀锰离子浓度较低,在棱角、极板边缘或者突出部位放电较大,易形成枝状结晶。若正向电流密度继续增大,析氢反应加重,导致电流效率降低,金属锰镀层出现氢脆、裂痕[25]。

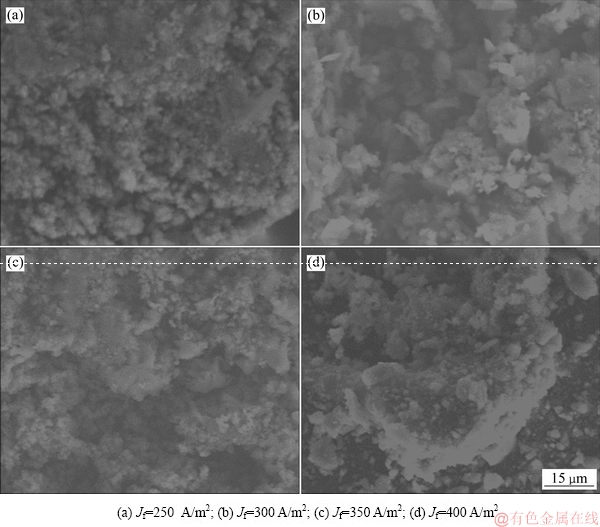

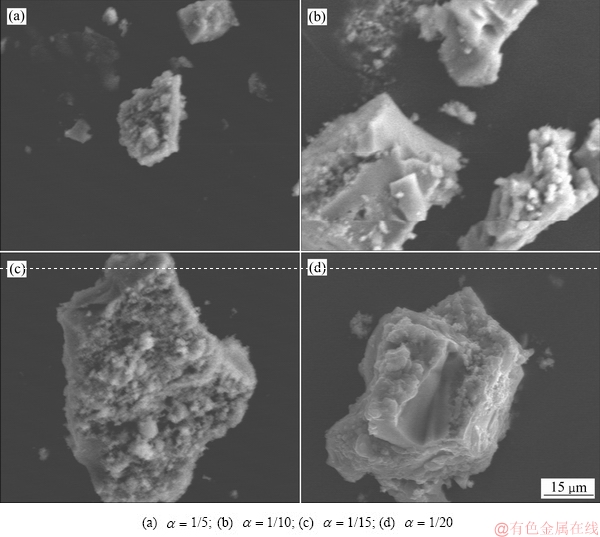

由图8可以看出,正向平均电流密度对阳极泥形貌影响较小,其表面均为疏松多孔,且块状较大。

图7 不同正向平均电流密度Jf下得到的金属锰表面SEM像

Fig. 7 Surface SEM images of metal manganese after electrodeposition for 2 h at different positive average current densities

图8 不同正向平均电流密度Jf下得到的阳极泥表面SEM像

Fig. 8 Surface SEM images of anode mud after electrodeposition for 2 h at different positive average current densities

2.2.2 反向脉冲系数

实验固定正向平均电流密度为350 A/m2、一组正向脉冲工作时间100 ms、反向脉冲工作时间系数β、在40 ℃下电解2 h,分别考察不同反向脉冲系数 下,金属锰与阳极泥形貌表面形貌,结果分别如图9和图10所示。

下,金属锰与阳极泥形貌表面形貌,结果分别如图9和图10所示。

随着反向脉冲系数的降低,镀层表面粗糙度增加,晶粒的棱角越来越明显,而且晶粒细小。当 为1/5、1/10时,镀层表面致密均匀;当

为1/5、1/10时,镀层表面致密均匀;当 为1/15、1/20时,镀层出现较大气孔与裂痕,镀层表面由大量细小晶粒堆积而成,晶粒的棱角越来越明显,镀层表面凹凸不平。这是由于

为1/15、1/20时,镀层出现较大气孔与裂痕,镀层表面由大量细小晶粒堆积而成,晶粒的棱角越来越明显,镀层表面凹凸不平。这是由于 较大时,反向电流通电时间较长,氧化还原反应消耗离子较少,在反向脉冲时,消耗的锰离子可迅速得到补充,使得阴极附近的锰离子浓度保持稳定,抑制析氢反应,并且反向电流溶解锰镀层表面的枝晶,所得镀层表面光滑致密;当

较大时,反向电流通电时间较长,氧化还原反应消耗离子较少,在反向脉冲时,消耗的锰离子可迅速得到补充,使得阴极附近的锰离子浓度保持稳定,抑制析氢反应,并且反向电流溶解锰镀层表面的枝晶,所得镀层表面光滑致密;当 减小时,正向电流通电时间延长,锰离子还原反应时间增长,阴极附近锰离子浓度快速降低,消耗的锰离子无法快速得到补充,使得锰离子分布不均,局部电沉积速率分布不均,镀层产生凸起,而凸起部位的电流密度大于其他部位,凸起部位的电镀沉积速率越来越大,且快与于其他部位,从而加快枝晶的生长速度[26]。

减小时,正向电流通电时间延长,锰离子还原反应时间增长,阴极附近锰离子浓度快速降低,消耗的锰离子无法快速得到补充,使得锰离子分布不均,局部电沉积速率分布不均,镀层产生凸起,而凸起部位的电流密度大于其他部位,凸起部位的电镀沉积速率越来越大,且快与于其他部位,从而加快枝晶的生长速度[26]。

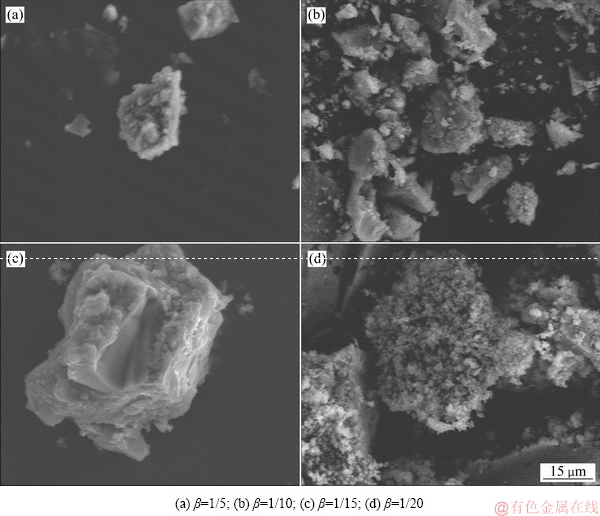

由图10可知,随着反向脉冲系数 的减小,阳极泥的块状变大,堆积厚度增厚。这是因为

的减小,阳极泥的块状变大,堆积厚度增厚。这是因为 较大时,反向电流通电相对时间较长,反向电流施加时间的增长较好地消除阳极表面的浓度梯度、剥离阳极泥,使阳极泥的厚度与块状变小。

较大时,反向电流通电相对时间较长,反向电流施加时间的增长较好地消除阳极表面的浓度梯度、剥离阳极泥,使阳极泥的厚度与块状变小。

2.2.3 正向电流时间

实验固定正向平均电流密度为350 A/m2、反向脉冲系数 =1/10、反向脉冲工作时间系数β=1/10、在40 ℃下电解2 h,通过改变一组正向脉冲工作时间来研究其对金属锰与阳极泥微观形貌的影响。图11和12所示分别为一组正向脉冲工作时间下金属锰与阳极泥的微观形貌。

=1/10、反向脉冲工作时间系数β=1/10、在40 ℃下电解2 h,通过改变一组正向脉冲工作时间来研究其对金属锰与阳极泥微观形貌的影响。图11和12所示分别为一组正向脉冲工作时间下金属锰与阳极泥的微观形貌。

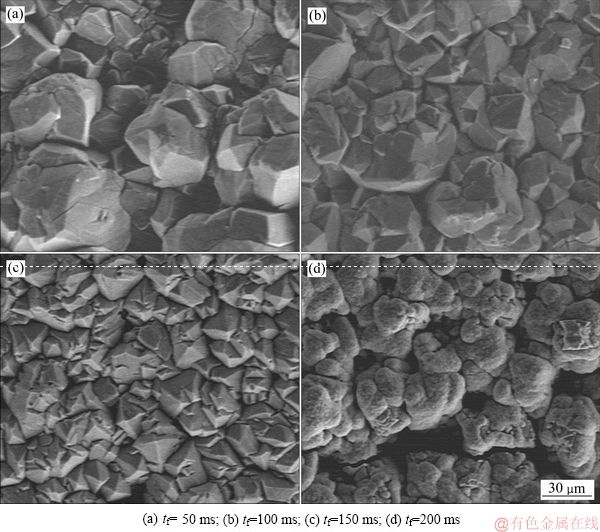

由图11可以看出,当反向脉冲工作时间系数β一定、一组正向脉冲工作时间较长时,双脉冲频率较低,金属锰镀层表面凹凸不平,晶型无规则,晶粒颗粒尺寸变化范围较大。这主要是因为在实验过程中,一组正向脉冲工作时间tf超过200 ms时,正向电流施加时间过长,锰离子浓度降低过快,此时浓差极化严重、并伴随枝晶产生,使得镀层厚度不均。而随着一组正向脉冲工作时间tf降低,镀层表面凸起和凹坑越来越少,越来越平整均匀,晶型呈规则棱椎体。这是由于当tf较小时,正向电流通电时间较短,锰离子消耗较小,在反向脉冲时,阴极附近的锰离子可达到补充,离子浓度分布均匀,浓差极化得到有效抑制,不会出现金属锰镀层局部较厚的现象。但是当tf小到50 ms时,镀层形貌较差。这主要是因为β一定时,tf过小导致整个脉冲周期过短,这使得下一个双脉冲周期到来后,前一个双脉冲周期的放电电流仍未结束。电解槽内的电流密度在平均电流附近微小波动,此时双脉冲电流的作用大大削弱,近似于直流电沉积。

图9 不同反向脉冲系数 下得到的金属锰表面SEM像

下得到的金属锰表面SEM像

Fig. 9 Surface SEM images of metal manganese after electrodeposition for 2 h at different reverse pulse coefficients

图10 不同反向脉冲系数 下得到的阳极泥表面SEM像

下得到的阳极泥表面SEM像

Fig. 10 Surface SEM images of anode mud after electrodeposition for 2h at different reverse pulse coefficients

图11 不同正向脉冲工作时间tf下得到的金属锰表面SEM像

Fig. 11 Surface SEM images of metal manganese after electrodeposition for 2 h at different forward pulse working time

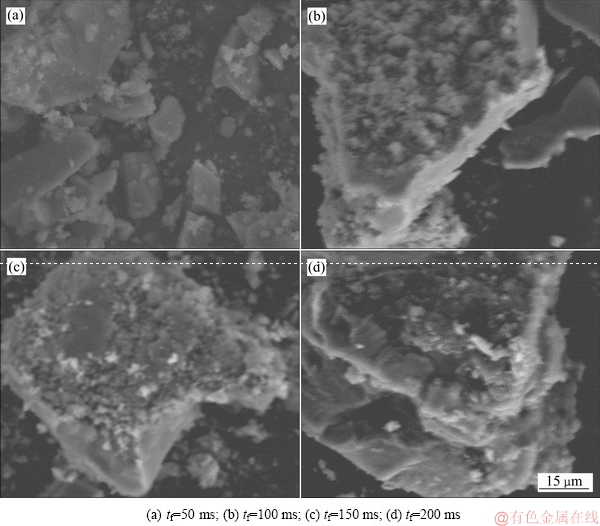

图12 不同正向脉冲工作时间tf下得到的阳极泥表面SEM像

Fig. 12 Surface SEM images of anode mud after electrodeposition for 2 h at different forward pulse working time

由图12可知,随着正向脉冲工作时间的延长,阳极泥的聚集程度增大,块状越来越大,堆积厚度增厚,阳极泥的产生量也相应增加。

2.2.4 反向脉冲工作时间系数

为了考察反向脉冲工作时间系数β对金属锰与阳极泥表面形貌的影响,实验控制正向平均电流密度为350 A/m2、一组正向脉冲工作时间100 ms、反向脉冲系数 1/10、在40 ℃下电解2 h。金属锰与阳极泥表面形貌如图13所示。

1/10、在40 ℃下电解2 h。金属锰与阳极泥表面形貌如图13所示。

由图13可以看出,随着β的减小,镀层表面粗糙度增加,晶粒的棱角越来越明显。当β为1/10时,镀层表面致密均匀;当β为1/15时,镀层表面晶粒呈块状;当β为1/20时,镀层出现较大气孔与裂痕,镀层表面由大量棱角凸出的堆积晶粒而成,表面不平整。

这是由于β较大时,反向电流也较大,较大的反向电流有利于消除浓差极化,抑制析氢反应,并且反向电流溶解镀层表面的枝晶,所以镀层表面比较均匀;而随着β的减小,反向电流减小,对浓差极化与析氢反应的抑制作用减弱,析氢加剧,镀层表面的枝晶溶解量降低,局部电沉积速率较快,镀层产生凸起,这就使得镀层表面凹凸不平且产生大量气孔。

图14所示为不同反向脉冲工作时间系数β下得到的阳极泥表面形貌。由图14可知,随着反向脉冲工作时间系数β的减小,阳极泥的块状变大,堆积厚度增厚。这是因为β较大时,反向电流减小,不利于迅速消除阳极表面的浓度梯度、剥离阳极泥,使阳极泥的厚度变厚与块状变大。

综合考虑各因素对阴极电流效率、镀层宏观形貌的影响和实际操作,优化后的脉冲电沉积工艺参数为:正向平均电流密度Jf=350 A/m2、反向脉冲系数 1/10、一组正向脉冲工作时间tf=150 ms和反向脉冲工作时间系数β=1/10。

1/10、一组正向脉冲工作时间tf=150 ms和反向脉冲工作时间系数β=1/10。

图13 不同反向脉冲工作时间系数β下得到的金属锰表面SEM像

Fig. 13 Surface SEM images of metal manganese after electrodeposition for 2 h at different reverse pulse working time coefficients

图14 不同反向脉冲工作时间系数β下得到的阳极泥表面SEM像

Fig. 14 Surface SEM images of anode mud after electrodeposition for 2 h at different reverse pulse working time coefficients

3 结论

1) 正向平均电流密度、反向脉冲系数、一组正向脉冲工作时间、反向脉冲工作时间系数过高或者过低都会严重影响金属锰与阳极泥的微观形貌,而且微观形貌与电流效率均有着密切的关系,微观形貌越好,电流效率越高,且比直流电沉积的电流效率高5%左右、比单脉冲电流效率高3.75%。

2) 当正向平均电流密度Jf=350 A/m2、反向脉冲系数 1/10、一组正向脉冲工作时间tf=150 ms、反向脉冲工作时间系数β=1/15时,电沉积2 h的电流效率最高为80.25%,阳极泥的产生量最低为2.93 g,而且金属锰镀层致密均匀、气孔少,基本无枝晶产生。

1/10、一组正向脉冲工作时间tf=150 ms、反向脉冲工作时间系数β=1/15时,电沉积2 h的电流效率最高为80.25%,阳极泥的产生量最低为2.93 g,而且金属锰镀层致密均匀、气孔少,基本无枝晶产生。

REFERENCES

[1] 严旺生. 锰加工产业发展现状[J]. 中国锰业, 2014, 32(4): 5-10.

YAN Wang-sheng. Mn processing industry in China and its development status[J]. China’s Manganese Industry, 2014, 32(4): 5-10.

[2] 谭柱中. 2013年中国电解金属锰工业回顾和展望[J]. 中国锰业, 2014, 32(3): 1-4.

TAN Zhu-zhong. A review and prospect of EMM in 2013[J]. China’s Manganese Industry, 2014, 32(3): 1-4.

[3] ALLMAND A J, CAMPBELL A N. The electrodeposition of manganese (Part I)[J]. Transactions of the Faraday Society, 1924, 19(5): 559-570.

[4] RADHAKRISHNAMURTHY P, REDDY A K N. The mechanism of manganese electrodeposition[J]. Journal of Applied Electrochemistry, 1974, 4(4): 317-321.

[5] LU J, DREISINGER D, GLüCK T. Manganese electrodeposition: A literature review[J]. Hydrometallurgy, 2014, 141: 105-116.

[6] 詹锡松. 电解金属锰电解槽节能技术的探讨[J]. 中国锰业, 2008, 26(4): 48-50.

ZHAN Xi-song. A technical research of thrifty of energy of EMM channel[J]. China’s Manganese Industry, 2008, 26(4): 48-80.

[7] 熊素玉, 张在峰. 我国电解金属锰工业存在的问题与对 策[J]. 中国锰业, 2005, 23(1): 14-16.

XIONG Su-yu, ZHANG Zai-feng. Existing problem and countermeasure of Chinese of Chinese market of EMM[J]. China’s Manganese Industry, 2005, 23(1): 14-16.

[8] TANG J, MENGH M, LI S, YU M, LI H, SHI J. The energy saving mechanism of gas diffusion electrode based on Pt/C catalyst for saving energy and green electrodeposition of manganese dioxide[J]. Electrochimica Acta, 2015, 170: 92-97.

[9] LEISNER P, FREDENBERG M, BELOV I. Pulse and pulse reverse plating of copper from acid sulphate solutions[J]. Transactions of the Institute of Metal Finishing, 2010, 88(5): 243-247.

[10] CHANDRASEKAR M S, PUSHPAVANAM M. Pulse and pulse reverse plating: Conceptual, advantages and applications[J]. Electrochimica Acta, 2008, 53: 3313-3322.

[11] 孙健哲, 陈虎魁, 郭进宝, 杨新科. 脉冲电解制备电解金属锰的研究[J]. 中国锰业, 1998, 16(2): 24-27.

SUN Jian-zhe, CHEN Hu-kui, GUO Jin-bao, YANG Xin-ke. Study on the preparation of electrolytic manganese metal by pulse electrolysis[J]. China’s Manganese Industry, 1998, 16(2): 24-27.

[12] 王胜利, 吴云峰, 胡波洋, 苗 玲, 夏 涛, 戴 磊. 近期脉冲电镀的研究进展[J]. 电镀与环保, 2016, 35(16): 873-877.

WANG Sheng-li, WU Yun-feng, HU Bo-yang, MIAO Ling, XIA Tiao, DAI Lei. Recent progress of pulse electroplating[J]. Electroplating & Pollution Control, 2016, 35(16): 873-877.

[13] HOTOIU E L, van DAMME S, ALBU C. Simulation of nano-second pulsed phenomena in electrochemical micromachining processes: Effects of the signal and double layer properties[J]. Electrochimica Acta, 2013, 93: 8-16.

[14] YOUSSEF K M, KOCH C C, FEDKIW P S. Influence of pulse plating parameters on the synthesis and preferred orientation of nanocrystalline zinc from zinc sulfate electrolytes[J]. Electrochimica Acta, 2008, 54: 677-683.

[15] GAOY X, ZHOU Y, WANG H T, LIN W, WANG Y, SUN D, HONG J, LI Q. Simultaneous silver recovery and cyanide removal fromelectroplating wastewater by pulse current electrolysis using static cylinder electrodes[J]. I&EC Research, 2013, 52: 5871-5879.

[16] LIU Z W, WES A C. Modeling of galvanostatic pulse and pulsed reverse electroplating of gold[J]. Electrochimica Acta, 2011, 56: 3328-3333.

[17] KWAK S I, JEONG K M, KIM S K. Current distribution and current efficiency in pulsed current plating of nickel[J]. Journal of the Electrochemical Society, 1996, 143(9): 2770-2776.

[18] 向国朴. 脉冲电镀的理论和应用[M]. 天津: 天津科学技术出版社, 1989: 1-11.

XIANG Guo-pu. Theory and application of pulse electroplating[M]. Tianjin: Tianjin science and Technology Press, 1989: 1-11.

[19] 陈 燕. 脉冲电场强化金属锰沉积行为研究[D]. 重庆: 重庆大学, 2012: 44-47.

CHEN Yan. Enhancement of pulse current on the performances of manganese electrodeposition[D]. Chongqing: Chongqing University, 2012: 44-47.

[20] 陈 玲, 李雪莉, 赵 强, 蔡文斌, 江志裕. 双向脉冲充电法对锂枝晶生成的抑制[J]. 物理化学学报, 2006, 22(9): 1155-1158.

CHEN Lin, LI Xue-li, ZHAO Qiang, CAI Wen-bin, JIANG Zhi-yu. Bipolar pulse current charge method for inhibiting the format ion of lithium dendrite[J]. Journal of Physical Chemistry, 2006, 22(9): 1155-1158.

[21] 王立平, 肖少华, 高 燕, 刘惠文, 徐 洮. 脉冲电流密度对电沉积纳米晶镍织构和硬度的影响[J]. 电镀和精饰, 2005, 27(3): 40-42.

WANG Li-ping, XIAO Shao-hua, GAO Yan, LIU Hui-wen, XU Tao. Effect of pulse current density on the texture and hardness of electrodeposited nanocrystalline nickel[J]. Plating and Finishing, 2005, 27(3): 40-42.

[22] XUJ X, WANG K Y. Pulsed electrodeposition of monocrystalline Ni nanowire array and its magnetic properties[J]. Applied Surface Science, 2008, 254(20): 6623-6627.

[23] CHENE O, LANDOLT D. Influence of mass transport on the deposit morphology and the current efficiency in pulse plating of copper[J]. Journal of Applied Electrochemistry, 1989, 19(2): 188-194.

[24] FAN X, HOU J, SUNDG, XI S Y, LIU Z H, GU, DU J, LUO J J, TAD C Y. Mn-oxides catalyzed periodic current oscillation on the anode[J]. Electrochimica Acta, 2013, 102: 466-471.

[25] BORISSOV D, TSEKOV R, FREYLAND W. Pulsed electrodeposition of two-dimensional Ag nanostructures on Au(111)[J]. J Phys Chem B, 2006, 110(32): 15905-15911.

[26] 庞 梅, 李洪友, 李哲煜, 江开勇, 黄 超. 双向脉冲电铸镍的研究[J]. 电镀与环保, 2010, 30(1): 11-14.

PANG Mei, LI Hong-you, LI Zhe-yu, JIANG Kai-yong, HUANG Chao. A study of Ni electroforming by bidirectional pulse[J]. Electroplating and Pollution Control, 2010, 30(1): 11-14.

Influence of bidirectional pulse parameters on process of manganese electrowinning

GUO Lan-feng1, 2, LIU Ren-long1, LIU Zuo-hua1, SHU Jian-cheng1, 3, SUN Xiao-long1, TAO Chang-yuan1

(1. College of Chemistry and Chemical Engineering, Chongqing University, Chongqing 400044, China;

2. Hubei Sinophorus Electronic Materials Co., Ltd., Yichang 443711, China;

3. Key Laboratory of the Ministry of Education of Solid Waste Disposal and Resources, Southwest University of Science and Technology, Mianyang 621010, China)

Abstract: The preparation of electrolytic manganese metal by bidirectional pulse electrodeposition was studied, the influence of positive average current density, reverse pulse coefficient, a set of forward pulse working time and reverse pulse working time coefficient on current efficiency, unit energy consumption, micro-morphology of the cathode metal manganese and the anode mud were investigated. The results show that bipolar pulse current can effectively eliminate the concentration polarization, inhibit the hydrogen evolution reaction, and dissolve the dendrite on the surface of the coating. Moreover, the irrationality of pulse parameter will cause the metal manganese layer micro defects increasing, coating surface smoothness and brightness decreasing, while the extended of average current density or the applied time can effectively prevent the anode passivation and reduce production of anode slime. The optimal parameters of bidirectional pulse are as follows: the current efficiency achieves 80.25% and the quality of anode mud is 2.93 g, when positive average current density is 350 A/m2, reverse pulse coefficient is 1/10, a set of forward pulse working time is 150 ms and reverse pulse working time coefficient is 1/15. Moreover, the metal manganese coating is dense and uniform, with few stomata and almost no dendrite formation.

Key words: bidirectional pulse electrodeposition; electrolytic manganese metal; current efficiency; micro-morphology

Foundation item: Project(2015BAB17B00) supported by the National Science and Technology Support Plan, China; Project(2014BA10016) supported by the Key Common Technologies and Technology Key Projects of the Guangxi Science Office, China

Received date: 2018-01-24; Accepted date: 2018-04-25

Corresponding author: LIU Ren-long; Tel: +86-23-65104910; E-mail: lrl@cqu.edu.cn

(编辑 龙怀中)

基金项目:国家科技支撑计划资助项目(2015BAB17B00);广西科技厅千亿元产业关键共性技术科技攻关计划项目(2014BA10016)

收稿日期:2018-01-24;修订日期:2018-04-25

通信作者:刘仁龙,教授,博士;电话:0 23-65104910;E-mail:lrl@cqu.edu.cn