DOI: 10.11817/j.issn.1672-7207.2016.09.048

间断级配纤维微表处性能及指标研究

姚晓光1, 2,张争奇1,罗要飞1,张苛1

(1. 长安大学 特殊地区公路工程教育部重点实验室,陕西 西安,710064;

2. 滁州学院 地理信息与旅游学院,安徽 滁州,239000)

摘要:为研究纤维种类、级配类型对微表处抗车辙及抗裂性能的影响情况,选用2种纤维、3种级配进行试验研究。在不同搭配情况下,利用汉堡车辙仪分别进行空气浴和水浴条件下的车辙试验,确定荷载作用6 000次后的车辙深度作为微表处抗车辙性能评价指标,指出蠕变速率评价指标的不足;并基于抗裂性能试验,提出疲劳断裂寿命指标。研究结果表明:随着荷载作用次数的增加,不同类型微表处抗车辙性能均会明显下降,在水浴情况下尤为显著,其中MS-3型聚丙烯纤维微表处最为典型,但其抗裂效果最优;间断级配纤维微表处也能满足规范要求,甚至更优,建议2种纤维的质量分数为0.10%。

关键词:道路工程;间断级配;纤维微表处;汉堡车辙试验

中图分类号:U416 文献标志码:A 文章编号:1672-7207(2016)09-3264-09

Research on performance and indicator of gap-graded fiber micro-surfacing

YAO Xiaoguang1, 2, ZHANG Zhengqi1, LUO Yaofei1, ZHANG Ke1

(1. Key Laboratory of Highway Engineering in Special Region of Ministry of Education, Chang’an University,

Xi’an 710064, China;

2. School of Geographic Information and Tourism, Chuzhou University, Chuzhou 239000, China)

Abstract: In order to study the influence of fiber type and gradation type on the anti-rutting and cracking resistance performance, two kinds of fibers and three kinds of gradations were selected. With different circumstances, the rutting tests were conducted by Hamburg wheel tracking test in the air and in the water respectively. The rut depth after loading 6 000 times was set as an evaluation indicator to evaluate anti-rutting performance, and the defects of creep rate indicator were pointed out. Then fatigue fracture life indicator was proposed based on the crack resistance test. The results show that the anti-rutting performances of different micro-surfacings all decrease significantly with the increase of loading times, especially in the water. And the anti-rutting performance of MS-3 graded polypropylene fiber micro-surfacing is the most typical. However, its cracking resistance performance is the best. The gap-graded fiber micro-surfacing can meet the requirements of specification and even better. The mass fraction of two kinds of fibers is suggested to be 0.10%.

Key words: road engineering; gap-graded; fiber micro-surfacing; hamburg wheel tracking test

微表处是一种常用的路面预防性养护措施,可以改善路面使用性能,也可用于对车辙的修复。1986年法国在微表处技术中首次尝试间断级配[1],并获得了良好效果,但PASAQUINI等[2-4]指出:虽然间断级配沥青混合料性能较好,但由于间断级配本身具有级配不连续特性,故常会出现混合料施工和易性差、易离析等现象,SHA等[5-7]也证明了此结论。而且对于普通微表处,其在应用过程中还会出现抗反射裂缝效果不佳、耐久性不足等问题。为解决微表处在施工和使用过程中出现的问题,很多学者对其进行了大量试验分析,其中侯曙光等[8-10]对掺入纤维的微表处混合料进行深入研究,发现纤维的加入可以改善微表处的抗裂性能和耐久性,提高路面的整体性能,并可克服间断级配混合料施工时的离析问题,显著提高路面的使用寿命。尽管间断级配沥青混合料和纤维微表处的研究已屡见不鲜,但国内外对使用间断级配的纤维微表处研究仍然较少,且关于间断级配的选用、纤维种类及掺量的选择缺少公认的评价标准,这在一定程度上阻碍了间断级配纤维微表处的发展,因此,有必要对其进行进一步研究。我国现有技术指南中采用轮辙变形试验评价微表处的抗车辙性能,但该试验方法未充分考虑路面实际所处的温度、水等影响条件,从而导致评价结果与实际路用性能相脱节。针对轮辙试验存在的弊端,本文作者以汉堡车辙试验系统[11-12]为加载平台,提出微表处抗车辙性能和抗裂性能评价方法,并对使用不同级配、不同纤维的微表处进行模拟试验研究,分析其高温性能和抗反射裂缝效果。

1 试验材料及指标

1.1 改性乳化沥青

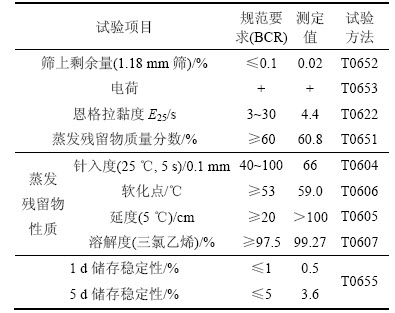

选用SBR改性乳化沥青作为结合料,经检验其性能指标如表1所示。

表1 SBR改性乳化沥青性能指标

Table 1 Performance indexes of SBR modified emulsion asphalt

1.2 矿料选取及级配

微表处中集料所占质量比例超过90%,集料的质量直接影响微表处的路用性能,因此,所选的集料应洁净、坚硬、粗糙、耐磨,不含泥土、有机物、杂质等有害物质。由于石灰岩、玄武岩具有较好的抗压性、耐磨耗性、黏附性,故常被选用,并且当粗集料使用玄武岩,细集料使用石灰岩时,微表处路用性能较好,更适用于试验研究[13]。

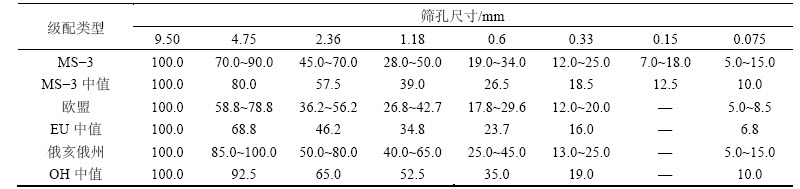

因此,本文作者选用2种不同岩性的石料,粗集料采用玄武岩,细集料采用石灰岩,经检验2种石料各项指标均符合规范要求。矿料级配分别选取MS-3型、欧盟型(EU)和俄亥俄州型(OH)3种级配中值[1],如表2所示,其中EU型级配是在原基础上通过内插法换算而得。为试验及工程需要,对OH中值、EU中值添加7.1 mm控制筛孔,且7.1~9.5 mm和4.75~ 7.1 mm之间的矿料质量比为3:1[14]。

1.3 纤维

选取聚丙烯纤维、玄武岩纤维进行研究,主要性能指标如表3所示。

表2 矿料级配(质量分数)

Table 2 Aggregate gradation %

表3 纤维的性能指标

Table 3 Performance indexes of fiber

2 微表处抗车辙性能试验

2.1 试件成型及试验条件

2.1.1 试件成型

常规的车辙试样及厚度与实际不符,而且成型后的试件不便于在汉堡车辙试验系统加载。因此,借鉴微表处轮辙变形试验原理,以水泥混凝土板作为养护载体,制备厚度为25 mm的试件。具体步骤为:1) 按照标准车辙试模成型C30水泥混凝土板,养护后放入高度为8 cm的车辙模中;2) 涂刷黏层油,在水泥混凝土板试件上撒铺改性乳化沥青,用量为0.3~0.5 L/m2;3) 将处理过的试样移到60 ℃的烘箱中保温,时间不少于16 h;4) 冷却后脱模,用石膏将试样固定在汉堡车辙试验模具中备用。

2.1.2 试验条件

1) 高温作用(空气浴):参考美国路面长期使用性能研究计划(LTPP)的成果[15],即沥青路面温度场的预估模型,结合试验所在地西安(北纬36°16′),可知对于加铺微表处的沥青路面而言,微表处结构层的温度为59.3 ℃,接近60 ℃。考虑到我国相应规范中评价沥青混合料高温抗车辙能力时的试验温度,试验温度为 60 ℃,因此,选取60 ℃作为微表处混合料加铺层抗车辙性能试验温度。

2) 高温及水耦合作用(水浴):考虑到夏季雨后潮湿沥青路面的温度大约为40 ℃,同时结合叶奋等[16-17]研究成果,选择水浴40 ℃研究高温及水耦合作用对微表处的影响。

2.2 评价指标及试验方案

汉堡车辙试验结果由车辙深度(rut depth)、蠕变速率(creep slope)、剥落点(stripping inflection point, SIP)以及剥落斜率(stripping slope)等评价指标构成,车辙深度评价时一般为荷载作用次数超过20 000次后所对应的车辙深度或者车辙深度达到20 mm所对应的荷载作用次数,车辙深度越小或作用次数越多,则抗车辙性能越好。蠕变速率反映的是沥青混合料在高温、水、荷载耦合作用下试样的变形速率,其值越大,说明变形速率越慢,抗车辙性能越好[18]。

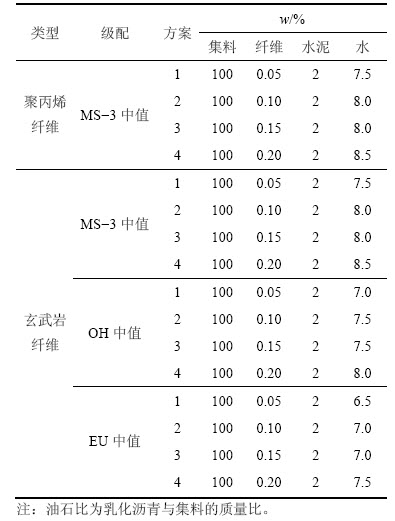

对于微表处而言,其摊铺厚度及使用要求与热拌沥青混合料并不相同,即用于填铺的车辙厚度也多在30 mm以下,若采用常规的车辙试样及厚度,则与实际不符,评价结果缺乏合理性。因此,借鉴微表处轮辙变形试验原理,采用合适的方法制备试件,并进行汉堡车辙试验,通过碾压后试件的车辙深度及蠕变速率来评价混合料的抗车辙性能。通过拌和试验等常规试验确定试验方案及各材料比例如表4所示。

表4 微表处抗车辙性能试验方案中各成分比例

Table 4 Component ratio in test programs of micro-surfacing rutting resistance

3 微表处抗车辙性能

3.1 高温条件下不同类型纤维微表处抗车辙性能

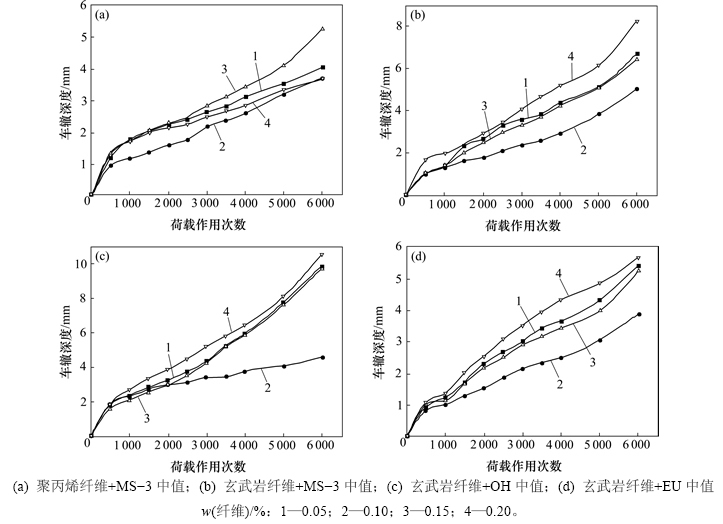

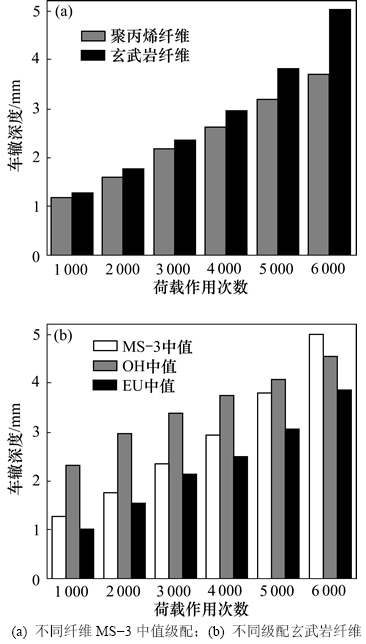

根据试验方案,拌和混合料并成型试件,养护后进行汉堡车辙试验,对不同条件下车辙深度作图,如图1所示。

由图1可知:1) 当荷载作用次数较小时,不同掺量的微表处混合料试样车辙曲线重合,这一阶段处于初始压密过程,显然不能真实地反映混合料的抗车辙性能,所以必须有足够的荷载作用次数。而实际摊铺时微表处混合料并没有采用压路机进行碾压,完全靠开放交通后车辆的渠化作用,这加剧了填铺车辙部位病害的形成。因此,纤维微表处摊铺后建议采用压路机进行相应碾压,不仅可以消除初始压密对性能的影响,而且可以增大路面的平整度,减少微表处路面的突起集料。2) 荷载作用6 000次后,少数纤维微表处试样的车辙深度已超过10 mm,这说明将常规的荷载作用20 000次后对应的车辙深度或车辙深度达20 mm时对应的荷载作用次数作为评价指标并不合适。这一方面是因为试件的厚度不足,按实际工程中微表处摊铺的情况,成型时试件的厚度仅为25 mm;另一方面是因为采用的矿料级配偏细,矿料中主要是粒径为 9.5 mm以下的颗粒,对车辙变形的抵抗作用有限。因此,以下探讨纤维微表处抗车辙性能时均采用荷载作用6 000次后的车辙深度作为评价指标。3) 聚丙烯纤维微表处抗车辙性能与其质量分数无明显规律,但在质量分数为0.15%时,其抗车辙性能最差,而玄武岩纤维微表处抗车辙性能随着纤维质量分数的增加先升后降。其原因是纤维的掺加增加了混合料的总比表面积,需要吸附较多的沥青,油石比过低导致沥青不足以完全裹附矿料,使集料表面的沥青膜厚度不足,使抗车辙性能未能达到最佳状况;而随着油石比的增加,纤维吸附能力不足,形成自由沥青,从而导致高温性能下降。

图1 60 ℃时车辙深度与荷载作用次数的关系

Fig. 1 Relationship between rut depth and load times at 60 ℃

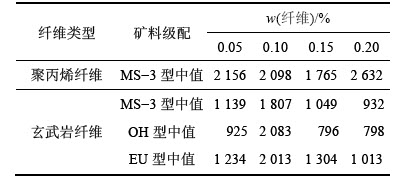

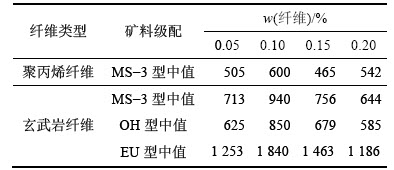

为直观分析纤维种类、级配类型对60 ℃时的微表处混合料影响情况,选取纤维质量分数为0.10%,荷载作用次数分别为1 000,2 000,3 000,4 000,5 000和6 000时各种类型微表处的车辙深度进行比较,见图2。通过汉堡车辙试验可得不同类型纤维微表处的蠕变速率,如表5所示。

由图2和表5可知:1) 对于MS-3级配中值,当油石比相同,纤维质量分数为0.10%时,聚丙烯纤维微表处的抗车辙性能优于玄武岩纤维微表处。陈永 慧[19]认为,根据复合材料的应力传递特点,纤维沥青混合料的高温性能取决于界面黏结力和纤维抗拉强度。纤维的吸油率高可有效提高沥青的黏度,增加界面强度;纤维的抗拉强度高能保证有效的应力传递。聚丙烯纤维吸油率较高,而玄武岩纤维抗拉强度较高,出现这种情况是因为微表处混合料中吸油率的影响程度比抗拉强度大,因吸油率较小导致玄武岩纤维微表处的油石比过大,抑制了高温性能。2) 掺加0.10%玄武岩纤维时,在3种矿料级配中,欧盟矿料级配微表处混合料试样的车辙深度最小,故欧盟矿料级配微表处的抗车辙性能最好。这主要是因为混合料采用的矿料级配存在差别,其中欧盟矿料级配中粗集料含量比较高,形成了以粗集料为主的骨架结构,混合料受荷载作用时不易变形,故使欧盟矿料级配微表处混合料的抗车辙性能比较好。3) 采用蠕变速率评价纤维微表处混合料的高温抗车辙性能区分度不明显,例如OH矿料级配微表处混合料,纤维质量分数为0.15%与0.20%时混合料蠕变速率仅仅相差2次/mm,而最终车辙深度相差0.43 mm,由此可见采用蠕变速率评价微表处混合料抗车辙性能而言存在一定的局限性,只能作为辅助指标来考虑。

图2 60 ℃时车辙深度对比

Fig. 2 Comparison of rut depths at 60 ℃

表5 60 ℃时纤维微表处的蠕变速率

Table 5 Creep rate of fiber micro-surfacing at 60 ℃ 次·mm-1

综上可知,高温环境加剧了混合料车辙病害的形成,虽然与常规沥青混合料相比,纤维微表处混合料的抗车辙性能偏低,但车辙形成过程仍存在不同的3阶段;另外,抗车辙性能评价时需有足够的荷载作用次数,以消除初始压密阶段对结果的影响;当荷载作用次数较少时,评价结果存在一定偏差。因此,建议采用车辙稳定阶段的试验数据来评价抗车辙性能。

3.2 高温及水耦合作用下不同类型纤维微表处抗车辙性能

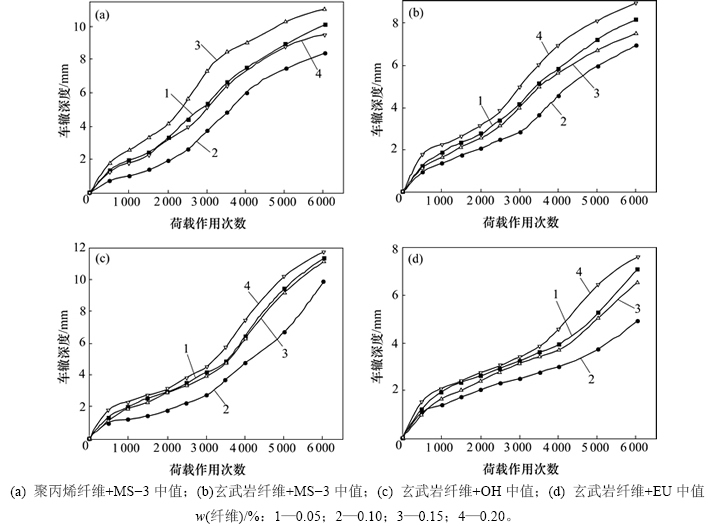

按试验方案成型试件,养生后浸入温度为40 ℃的水浴中保温,时间不短于30 min,然后进行试验加载,试验数据曲线如图3所示。

由图3可知:1) 水和高温耦合作用下纤维微表处混合料的抗车辙性能下降明显。这是因为水存在于沥青薄膜与集料之间,荷载应力引起的动水压力和高速水流会对沥青与矿料的界面进行反复冲击,使沥青与集料之间的黏附力减弱,加速沥青膜的剥落;而且在持续碾压下,微表处混合料因抗剪强度不足产生侧向流动变形,形成严重车辙。2) 微表处在聚丙烯纤维掺量为0.15%时,抗车辙性能最差,而从图3(b)~(d)易知,当玄武岩纤维质量分数从0.05%增至2.00%时,混合料的车辙深度都是先减小后增大,说明玄武岩纤维微表处抗车辙性能随纤维质量分数的增加先升后降。在掺加等量玄武岩纤维条件下,3种矿料级配中欧盟矿料级配微表处的抗车辙性能最好,这与上述高温环境条件下得到的结论相一致。然而,在高温浸水条件下,混合料的抗车辙性能下降明显,车辙深度大都在7 mm左右,有的甚至接近12 mm。

图3 40 ℃水浴条件下车辙深度与荷载作用次数的关系

Fig. 3 Relationship between rut depth and load times in water at 40 ℃

为直观分析纤维种类、级配类型对40 ℃水浴条件下的微表处混合料影响情况,同样选取纤维质量分数为0.10%,荷载作用次数分别为1 000,2 000,3 000,4 000,5 000和6 000时各种类型微表处的车辙深度进行比较,见图4。通过汉堡车辙试验可得不同类型纤维微表处的蠕变速率,如表6所示。

由图4和表6可知:对于MS-3级配中值,在相同油石比,纤维质量分数为0.10%时,玄武岩纤维微表处的抗车辙性能比聚丙烯纤维微表处的性能好,这与高温环境条件下得到的结论相反,可知聚丙烯纤维微表处混合料抗车辙性能受水的影响较大。其原因是:一方面,2种纤维的加工原材料不同导致,玄武岩纤维的原材料为玄武岩矿石,与聚丙烯纤维相比,玄武岩与沥青的黏附性比较好,水环境下受其影响比较小;另一方面,水的作用使沥青与集料之间的黏附力减弱,而通过分析可知,此时玄武岩纤维微表处油石比较大,可提供足够黏结力使玄武岩微表处具有较好的抗车辙能力。此结论也验证了高温60 ℃时结果的准确性。

在玄武岩纤维质量分数为0.10%时,不同矿料级配微表处的车辙变化趋势略有差别,其中欧盟矿料级配微表处的车辙深度变化趋势较缓慢,其余2种矿料级配微表处,在荷载作用3 000次后,车辙深度急剧增加。这是因为另外2种矿料级配以细集料为主,经3 000次碾压后混合料矿质骨架被破坏,因此,高温性能急剧下降,蠕变速率计算结果也验证了这一点。

蠕变速率计算结果与车辙深度结果相矛盾:如表6所示,由蠕变速率可知,当纤维质量分数为0.10%时,聚丙烯纤维微表处(MS-3中值)抗车辙性能比玄武岩纤维微表处(MS-3中值)的性能较差,且在不同级配的玄武岩纤维中,OH型间断级配的抗车辙性能最差;对比图4,当纤维质量分数为0.1%,荷载作用次数较小时,其结果与表6所得的结果不符,这再一次说明蠕变速率指标评价微表处抗车辙性能存在一定弊端。栗培龙等[20]也认为蠕变速率评价抗车辙性能存在局限性,只能作为辅助指标评价混合料高温性能。

图4 40 ℃水浴条件下车辙深度对比

Fig. 4 Comparison of rut depth in water at 40 ℃

表6 40 ℃水浴纤维微表处的蠕变速率

Table 6 Creep rate of fiber micro-surfacing in water at 40 ℃ 次·mm-1

综上分析,高温、高温及水耦合作用均导致微表处混合料抗车辙性能下降,但高温及水耦合作用更加明显。因此,在实际工程中,车辙填铺微表处混合料后要加强路面排水,防止路面积水长时间浸泡混合料,在车辆反复作用下再次形成车辙。

4 微表处抗裂性能试验

4.1 试件成型及试验方案

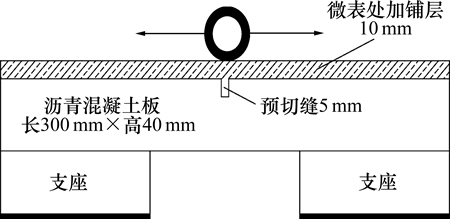

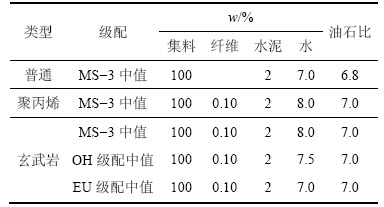

采用由厚度为40 mm沥青面层和10 mm微表处加铺层组合而成的梁式结构,长×宽×高为300 mm×100 mm×50 mm,加铺前在沥青混凝土板中间切割宽5 mm、深10 mm的横向裂缝,如图5所示,以模拟存在裂缝的沥青路面。利用汉堡车辙仪作为加载设备,轮载为0.7 MPa,碾压频率为52次/min,试验温度为15 ℃[21]。试验中纤维采用聚丙烯纤维和玄武岩纤维,质量分数均为0.10%;集料级配选用MS-3、欧盟、俄亥俄州用矿料级配中值,具体试验方案见表7。

4.2 评价指标及结果分析

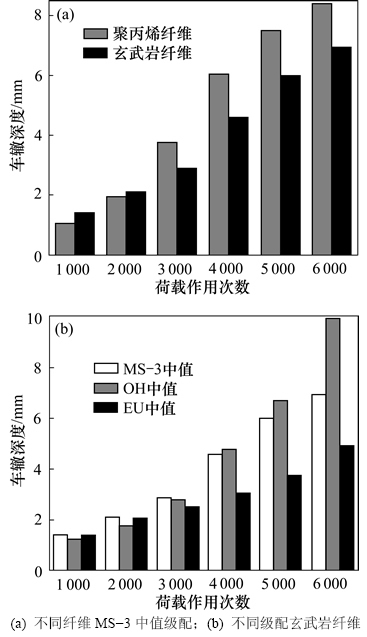

在往返轮载试验方法的基础上,提出疲劳断裂寿命指标,即通过裂缝贯穿面层时荷载循环作用的次数评价沥青路面微表处抗裂性能。抗裂性能试验结果如图6所示。

图5 往返轮辙试验模型

Fig. 5 Test model of round trip wheel load

表7 微表处抗裂性能试验方案

Table 7 Test programs of crack resistance

图6 往返轮载试验结果

Fig. 6 Test results of round trip wheel load

由图6可以看出:普通微表处掺加纤维后其疲劳断裂寿命明显增加,在相同矿料级配条件下,聚丙烯纤维、玄武岩纤维微表处的断裂寿命分别提高661次和525次。这主要是因为纤维在其中起到了阻裂的作用,断裂力学认为材料内部存在缺陷和裂纹,在温度应力和行车荷载的共同作用下,裂缝尖端会产生应力集中,使裂纹逐渐扩展。由于纤维具有抗拉强度高、模量高、直径较小、数量较多等优点,在微表处混合料中均匀分散后形成三维网状结构,对裂纹的扩展起到抑制作用,阻滞裂纹或缺陷的进一步发展,从而达到提高抗裂性能的效果。

不同纤维对混合料疲劳断裂寿命的改善效果并不相同,聚丙烯纤维微表处的抗裂性能比玄武岩纤维微表处的性能好。这是由于采用的2种纤维断裂伸长率不同,纤维的断裂伸长率越大,则材料的韧性越好,受力时越不易被拉断,掺入混合料后其抗变形能力提高,可以承受更大的拉伸力和拉伸应变。

当掺加纤维相同时,不同矿料级配微表处的抗裂性能并不同,其中俄亥俄州矿料级配微表处的疲劳断裂寿命最长,即抗裂性能最好。这主要是因为其矿料级配组成中,以细料居多,纤维的掺加更易形成致密的网状结构,吸收并分散车辆荷载,有效地抑制了裂缝的发展。

综上可知,不同类型微表处的抗裂效果从大到小依次为聚丙烯纤维(MS-3型)、玄武岩纤维(OH型)、玄武岩纤维(MS-3型)、玄武岩纤维(EU型)、普通微表处。

5 结论

1) 在水浴40 ℃的条件下,玄武岩纤维微表处的抗车辙性能比聚丙烯纤维微表处的性能好,此结果与60 ℃时的结果恰好相反。结合纤维应用情况,建议2种纤维的合理掺量为0.10%。

2) 随着荷载作用次数的增加,不同级配类型玄武岩纤维微表处抗车辙性能从优至劣依次为欧盟间断级配微表处、MS-3型微表处、俄亥俄州间断级配微表处。

3) 随着荷载作用次数的增加,水浴条件下抗车辙性能下降明显,蠕变速率作为微表处抗车辙性能评价指标,区分度不明显,存在一定局限性,建议只能作为辅助指标。

4) 采用汉堡车辙系统提出沥青路面微表处抗裂性能评价指标即疲劳断裂寿命,也就是裂缝贯穿面层时荷载作用循环次数。应用该指标对比分析不同类型纤维微表处的抗裂性能发现,MS-3型聚丙烯纤维微表处抗裂效果最优。

5) 断级配同样满足性能要求,且就玄武岩纤维微表处而言,欧盟间断级配形成的微表处,其抗车辙性能明显比连续级配的性能好。因此,有必要进一步研究间断级配微表处性能及其影响因素,并可进一步完善汉堡车辙试验条件下的微表处高温性能评价指标。

参考文献:

[1] 黄颂昌, 徐剑, 秦永春. 改性乳化沥青与微表技术[M]. 北京: 人民交通出版社, 2010: 213-215.

HUANG Songchang, XU Jian, QIN Yongchun. Modified emulsion asphalt and micro-surfacing technology[M]. Beijing: China Communications Press, 2010: 213-215.

[2] PASAQUINI E, CANESTRARI F, CARDONE F, et al. Performance evaluation of gap graded asphalt rubber mixture[J]. Construction and Building Material, 2011, 25(4): 2014-2022.

[3] HDABI A, AL N A, SETON H, et al. Performance ofgap gradedcold asphalt containing cement treated filler[J]. Construction and Building Material, 2014, 69(2): 362-369.

[4] 关永胜, 谈至明, 张志祥. 间断级配橡胶沥青混合料抗车辙性能[J]. 同济大学学报(自然科学版), 2013, 41(5): 705-709.

GUAN Yongsheng, TAN Zhiming, ZHANG Zhixiang. Rutting performance of gap graded asphalt rubber mixtures[J]. Journal of Tongji University(Natural Science), 2013, 41(5): 705-709.

[5] SHA Aimin, ZHAO Xin,LEI Yu. Research on relationship between gradation type and segregation degree of asphalt mixture[J]. International Journal of Pavement Research and Technology, 2009, 2(4): 171-175.

[6] 刘红英, 叶松, 谭发茂, 等. 大粒径沥青混合料级配离析测量和评价方法[J]. 郑州大学学报(工学版), 2014, 35(2): 24-27.

LIU Hongying, YE Song, TAN Famao, et al. Evaluation method of gradation segregation of large size asphalt mixture[J]. Journal of Zhengzhou University(Engineering Science), 2014, 35(2): 24-27.

[7] 李立寒, 马旭荣. 级配离析沥青混合料性能的试验研究[J]. 同济大学学报(自然科学版), 2007, 35(12): 1622-1626.

LI Lihan, MA Xurong. Influence research of gradation segregation on performance of asphalt mixture[J]. Journal of Tongji University(Natural Science), 2007, 35(12): 1622-1626.

[8] 侯曙光, 侯强. 纤维微表处混合料性能试验[J]. 南京工业大学学报(自然科学版), 2013, 35(3): 20-24.

HOU Shuguang, HOU Qiang. Experimental study on performances of fibre reinforced micro-surfacing mixture[J]. Journal of Nanjing University of Technology(Natural Science Edition), 2013, 35(3): 20-24.

[9] 黎侃, 李新伟, 王瑞宜. 聚丙烯单丝纤维微表处路用性能研究[J]. 公路交通科技, 2013, 30(8): 17-22.

LI kan, LI Xinwei, WANG Ruiyi. Study on road performances of micro-surfacing mixed with polypropylene filament fiber[J]. Journal of Highway and Transportation Research and Development, 2013, 30(8): 17-22.

[10] 王磊, 吕璞, 郝培文. 微表处混合料路用性能影响因素[J].长安大学学报(自然科学版), 2014, 34(2): 29-33.

WANG Lei, L Pu, HAO Peiwen. Factors affecting pavement performance of micro-surfacing mixture[J]. Journal of Chang’an University(Natural Science Edition), 2014, 34(2): 29-33.

Pu, HAO Peiwen. Factors affecting pavement performance of micro-surfacing mixture[J]. Journal of Chang’an University(Natural Science Edition), 2014, 34(2): 29-33.

[11] 崔文博, 郝培文. 基于Hamburg车辙试验的沥青路面车辙损坏分析[J]. 中外公路, 2014, 34(1): 95-98.

CUI Wenbo, HAO Peiwen. Rutting damage analysis of asphalt pavement based on Hamburg wheel tracking test[J]. Journal of China & Foreign Highway, 2014, 34(1): 95-98.

[12] 栗培龙, 张争奇, 李洪华, 等. 沥青混合料汉堡车辙试验方法[J]. 交通运输工程学报, 2010, 10(2): 30-35.

LI Peilong, ZHANG Zhengqi, LI Honghua, et al. Methods of Hamburg wheel tracking tests for asphalt mixture[J]. Journal of Traffic and Transportation Engineering, 2010, 10(2): 30-35.

[13] 张争奇, 姚晓光, 罗要飞. 间断级配纤维微表处路用性能[J]. 北京工业大学学报, 2015, 41(6): 890-898.

ZHANG Zhengqi, YAO Xiaoguang, LUO Yaofei. Pavement performance of gap-graded fiber micro-surfacing[J]. Journal of Beijing University of Technology, 2015, 41(6): 890-898.

[14] 刘伟亮. 微表处混合料性能及应用技术研究[D]. 西安: 长安大学公路学院, 2011: 25-26.

LIU Weiliang. Research on mixture performance and application technology of micro-surfacing[D]. Xi’an: Chang’an University. Highway School, 2011: 25-26.

[15] RADA G R, ELKINS G E, HENDERSON B, et al. LTPP seasonal monitoring program: instrumentation installation and data collection guidelines[R]. McLean, VA: Federal Highway Administration, 1994: 47-50.

[16] 叶奋. 浸水车辙试验用于评价沥青混合料水稳定性研究[J]. 交通标准化, 2011(8): 21-23.

YE Fen. Using immersion rutting test to evaluate water stability of asphalt mixture[J]. Transport Standardization, 2011(8): 21-23.

[17] 张方方. 沥青混合料抗车辙性能研究[D]. 西安: 长安大学公路学院, 2004: 30-31.

ZHANG Fangfang. Study on rutting resistance of hot mixed asphalt[D]. Xi’an: Chang’an University. School of Highway, 2004: 30-31.

[18] 齐琳, 沙爱民, 陈凯. 沥青混合料水稳定性汉堡车辙试验研究[J]. 武汉理工大学学报, 2009, 31(8): 42-45.

QI Lin, SHA Aimin, CHEN Kai. Research on the water stability of asphalt mixtures based on the HWTD[J]. Journal of Wuhan University of Technology, 2009, 31(8): 42-45.

[19] 陈永慧. 新型玄武岩纤维对沥青混合料路用性能影响研究[D]. 西安: 长安大学材料科学与工程学院, 2012: 37-38.

CHEN Yonghui. The study of influence of the new basalt fiber on asphalt mixture’s pavement performance[D]. Xi’an: Chang’an University. School of Materials Science and Engineering, 2012: 37-38.

[20] 栗培龙, 张争奇, 李洪华, 等. 沥青混合料汉堡车辙试验条件及评价指标研究[J]. 武汉理工大学学报(交通科学与工程版), 2011, 35(1): 113-117.

LI Peilong, ZHANG Zhengqi, LI Honghua, et al. Research on conditions of hamburg wheel tracking test and evaluating indicator for asphalt mixture[J]. Journal of Wuhan University of Technology(Transportation Science & Engineering), 2011, 35(1): 113-117.

[21] 高涛涛. 橡胶沥青封层防治反射裂缝的性能研究[D]. 西安: 长安大学公路学院, 2012: 55-56.

GAO Taotao. Research on preventing reflection cracks of stress absorbing membranes interlayer-rubber[D]. Xi’an: Chang’an University. School of Highway, 2012: 55-56.

(编辑 刘锦伟)

收稿日期:2015-09-15;修回日期:2015-11-07

基金项目(Foundation item):国家自然科学基金资助项目(51008031);交通运输部应用基础研究项目(2014319812151);陕西省交通科技项目(2014-01K) (Project(51008031) supported by the National Natural Science Foundation of China; Project(2014319812151) supported by the Applied Basic Research Project of Ministry of Transport; Project(2014-01K) supported by the Transportation Science and Technology Project of Shanxi Province)

通信作者:张争奇,教授,博士生导师,从事沥青路面结构与材料性能研究;E-mail: Z_Zhengqi@126.com