DOI: 10.11817/j.ysxb.1004.0609.2020-35736

闸片材料参数与制动盘温度关系

高 飞,吴波文,杨俊英

(大连交通大学 连续挤压教育部工程研究中心,大连 116028)

摘 要:闸片材料参数不仅关系到摩擦副的摩擦磨损性能,也是影响制动盘温度分布的一个重要因素。采用ADINA软件,建立列车制动盘和闸片的三维热机耦合有限元模型,在制动速度100 km/h、压力0.538 MPa和惯量23 kg·m2条件下,研究闸片材料热膨胀系数、弹性模量、热传导系数对制动盘温度和接触压力的影响。结果表明:当闸片热膨胀系数从0.5×10-5 K-1增大到2.5×10-5 K-1时,制动盘峰值温度升高8.4%,最大接触压力增大47%,闸片热膨胀系数的增大加剧接触压力分布不均匀程度而使制动盘温度变化明显;弹性模量增大9倍,接触压力的分布对弹性模量不敏感,弹性模量对盘面温度影响不明显。闸片热传导系数增大7倍,制动盘峰值温度下降4.3%,热传导系数增大,加快热量的扩散速度使制动盘峰值温度降低,该研究结论可为高速列车闸片材料的开发提供参考。

关键词:盘式制动;温度场;接触压力;热机耦合

文章编号:1004-0609(2020)-04-0837-10 中图分类号:U260 文献标志码:A

制动盘及闸片结构和材料对制动盘的温度场均有重要的影响,认识这些因素与制动盘温度的关系是设计可靠制动器的前提。由于摩擦热的产生与接触压力相关,而温度分布的不均匀性导致物体热变形差异影响到接触状态或接触压力,接触状态的改变又反过来影响摩擦热流输入,因此,摩擦制动器的热问题是温度场和应力场耦合问题,对于这类多场耦合问题的求解,数值模拟是目前最有效的方法。在这方面,学者们研究了制动工况[1-2],制动盘材料[3-4],闸片排布方式[5-6],闸片形状[7-8],接触面积[9]对制动盘温度分布的影响,这些研究对设计合理的闸片结构具有参考价值。同样,闸片材料参数如热膨胀系数、弹性模量、热传导系数也是影响摩擦副的热弹性行为的一个重要因素[10],早在1995年DUFRENOY和WEICHERT[11]基于二维轴对称热机耦合有限元模型,使用ANSYS软件,针对高速列车“TGV”盘式制动器,数值模拟了闸片材料参数对制动盘温度场的影响,发现弹性模量和热膨胀系数降低50%可使制动盘峰值温度下降200 ℃左右,而闸片热传导系数对制动盘温度影响不明显。CHOI和LEE[12]也使用二维模型计算了闸片材料热膨胀系数和弹性模量与接触面积的关系,发现热膨胀系数和弹性模量增大一倍可使接触面积减少50%以上。这些研究表明材料参数对摩擦温度影响程度是有区别的。然而,由于这些研究使用的是二维模型,忽略了接触条件和热传导在周向上的差异,无法反映闸片几何特征对制动器热弹性行为的影响,可能会导致与实际温度场和热变形有较大的偏差[13]。赵愿军[14]建立了三维热机耦合模型,对比了有无热膨胀系数对温度场的影响,表明热膨胀系数增加引起平均接触压力增大使得温度升高。但是,他们研究的材料弹性模量、热传导系数和热膨胀系数均处于较低的区间内。随着制动闸片材料的发展,材料参数的变化已超出这个区间。因此,建立三维热机耦合有限元模型,探讨闸片材料参数在更广区间内变化对制动器热弹性行为的影响具有重要意义。

本文以TM-I型惯性试验台为原型,采用ADINA软件,建立三角形摩擦块和制动盘的三维热-机耦合有限元模型,针对闸片材料的热膨胀系数为0.5× 10-5~2.5×10-5 K-1、弹性模量5.2~200 GPa和热传导系数10~80 W/(m·K)的变化范围,研究制动盘温度和接触压力的变化规律,从而期望为高速列车闸片材料的设计提供有意义的参考。

1 制动试验条件和方法

制动盘材料为4Cr5MoSiV1,闸片材料为自制铜基粉末冶金材料,材料参数如表1所列。制动盘厚度为20 mm,外径320 mm,内径90 mm,摩擦半径125 mm,试验所用的闸片形状为三角形,高度20 mm,摩擦面积2973 mm2。试验设备为TM-I型列车缩比制动试验台,为获得制动盘表面温度场情况,使用FlukeTi45型红外热像仪记录整个制动过程制动盘表面温度场,红外发射率设置为0.75[15]。

2 制动盘温度场的数值模拟

2.1 有限元模型的建立

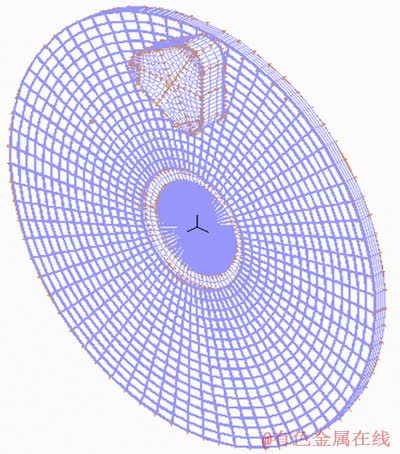

图1 有限元模型

Fig. 1 Finite element model

考虑到摩擦副实际结构是关于制动盘厚度中心面对称,为减少计算量,仅取摩擦副的1/2作为研究对象。本文采用ADINA软件,将制动盘和闸片分别划分为5904个和828个八节点3D实体单元,建立包括闸片和制动盘的热机耦合有限元模型(见图1),同时,以转动惯量代替制动载荷施加到中心参考点上,转动惯量为23 kg·m2。数值计算的基本假设如下:

1) 考虑到材料磨损消耗的能量只占摩擦热很小的一部分,因此,忽略材料的磨损;

2) 不考虑摩擦界面热阻的影响,在接触时,摩擦界面上温度相等;

3) 模拟中,使用弹性材料模型,计算中忽略温度对材料参数的影响;

4) 制动压力均匀分布在闸片上表面;

5) 整个制动过程中将摩擦因数作为常数处理,摩擦因数取为0.377;

6) 由于辐射换热量较小,不考虑辐射换热的影响。

2.2 边界条件和初始条件

1) 热流分配系数

接触界面上生成的热流q等于进入制动盘的热流qD与进入闸片的热流qP之和。热流在闸片和制动盘间的分配系数γ按下式计算[16]:

(1)

(1)

式中:ρ为密度;c为比热容;k为热传导系数;下标D,P分别表示制动盘和闸片。

2) 对流边界条件

制动盘表面的对流换热系数h可通过努赛尔特数Nu确定[17]:

(2)

(2)

式中:kg为空气的热传导系数;Nu为努赛尔特数;d制动盘直径。

(3)

(3)

(4)

(4)

式中:Pr为空气的普朗特数;Re雷诺数;ρg空气密度;μg空气动力学黏度;ν制动盘某一点的线速度。

3) 初始条件

根据制动试验条件,研究中将制动盘的初始温度取为40 ℃。

T(x, y, z)=40,t=0 (5)

表1 摩擦副材料物理参数

Table 1 Thermal parameters of friction pair

3 有限元模型的试验验证

3.1 数值模拟与试验测试的制动盘温度场的比较

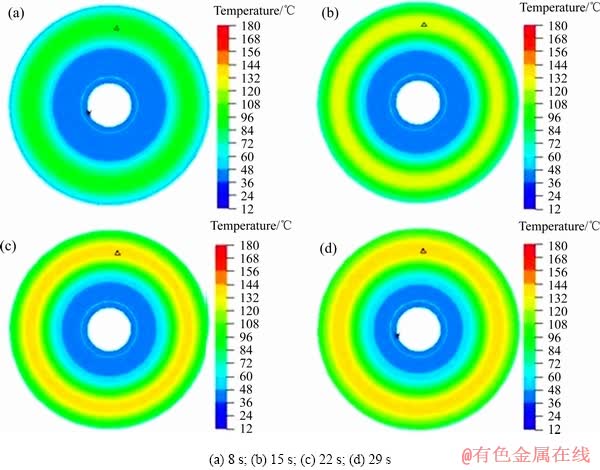

图2所示为制动初速度100 km/h、制动压力0.538 MPa条件下不同制动时刻制动盘表面温度场的数值模拟结果。可见,从制动8 s到29 s,到摩擦区域中部均存在一个较宽的环形带状高温区,并且随制动时间的延长,制动盘表面温度整体升高,高温区不断扩展,沿制动盘径向的温度梯度较大,周向温度梯度不明显。

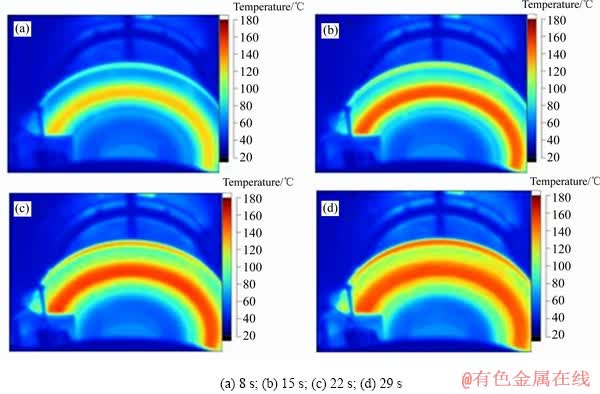

图3所示为同工况下通过制动试验测试的温度场变化情况。可见,试验和数值模拟的制动盘表面的温度分布形态是相似的,从云图的颜色比较,试验的温度高于数值模拟的。

图2 不同制动时刻制动盘表面温度场的数值模拟结果

Fig. 2 Numerical simulation results of temperature field on brake disc surface at different braking time

图3 不同制动时刻制动盘表面温度场的试验结果

Fig. 3 Experimental results of temperature field on brake disc surface at different braking time

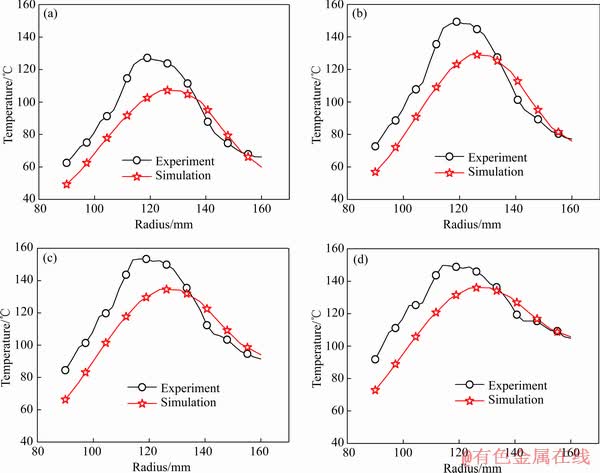

图4所示为制动初速度100 km/h、制动压力0.538 MPa条件下数值模拟和试验的制动盘表面径向温度的变化情况。可见,在制动前15 s,制动盘温度随制动时间的增加而快速上升,中部的温度上升最明显,径向温度梯度越来越大。制动到22 s时,中部的温度上升速度变慢,两侧的温度上升速度变快,径向温度梯度减小,同时,试验和模拟均达到整个制动过程的最高温度,分别为152 ℃和131 ℃。制动结束时,中部温度下降,两侧温度有所升高,制动盘表面温度分布变得均匀。

数值模拟和试验结果的偏差如下:峰值温度出现的位置有所不同,试验测得的峰值温度在盘半径110~130 mm内变化,而模拟的峰值温度始终在摩擦半径125 mm处;同一摩擦半径处,数值模拟和试验的温度大小不同。在盘半径90~130 mm的范围,试验测得的温度高于数值模拟的,而在盘半径130~160 mm范围,试验测得的温度是低于数值模拟的温度,数值模拟和试验的最大温差出现在摩擦区中部,约为20 ℃。

数值模拟和试验的温度存在偏差,这是由于数值模拟与实际试验条件的并不完全相同。制动试验时,受到闸片与制动盘贴合程度的影响,接触压力在闸片表面是非均匀分布的,试验中闸片和制动盘早期接触区出现在摩擦区域的内侧,制动盘上高温区出现在摩擦中部区域偏盘内径方向。数值模拟假设闸片与制动盘为完全接触,计算出的高温区出现在接触弧长最大的摩擦区域中部。可见,由于实际接触状态和模拟条件的差异使计算出的制动盘表面温度在摩擦半径90~130 mm间低于试验值,在130~160 mm间高于试验值。另一方面,使用红外热成像技术测得的温度受制动盘表面发射率的影响,发射率与制动盘的温度、位置和表面物理性质等相关[18],在制动过程中这些因素不断地发生变化,而试验中将发射率设成一个常数,测得的温度误差较大。此外,由于模拟中很难准确地确定散热边界条件,这也会引起试验和模拟数据的差异。

图4 数值模拟和试验的制动盘表面径向的温度变化情况

Fig. 4 Comparison of radial temperature on brake disc surface between numerical simulation and experiment

3.2 数值模拟和试验测试的制动盘角速度的比较

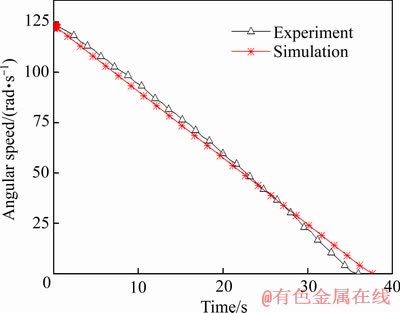

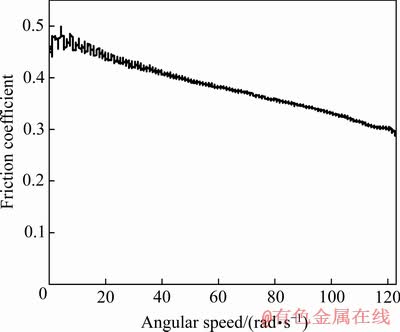

图5所示为数值模拟和试验的制动盘角速度时间历程曲线。数值模拟和试验的制动时间分别为38 s和36.6 s,两者相对偏差为3.7%。试验的制动时间略小于数值模拟的,这可能与制动过程中摩擦因数的变化有关。实际制动试验中,闸片发生磨损,闸片与制动盘贴合程度不断提高,机械啮合作用增强。同时,表面温度在一定范围内的升高,有利于提高摩擦面的黏着力,这两个因素导致摩擦因数随制动速度的降低逐渐增大(见图6),因此,试验中制动盘的减速度是不断变大的。数值模拟时,取平均摩擦因数,并假设整个制动过程中恒定不变,模拟得出的制动盘的减速度基本不变。因此,数值模拟的制动时间略高。

由上述可知,数值模拟计算出的制动盘温度场与试验测得的温度场在分布规律上吻合良好。数值模拟的制动时间和制动盘角速度变化与试验结果的偏差在可接受的范围内,这说明了本研究中所建立的有限元模型是可靠的,可以以此为基础来研究闸片材料参数对制动盘温度场的影响。

图5 试验和数值模拟的制动盘角速度时间历程曲线

Fig. 5 Comparison of angular speed with time in experimental and numerical simulations

图6 试验测得的瞬时摩擦因数

Fig. 6 Instantaneous friction coefficient measured by experiment

4 闸片材料参数对接触压力和温度场的影响

4.1 闸片热膨胀系数对制动盘温度场和接触压力的影响

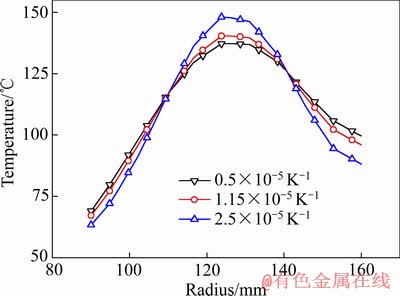

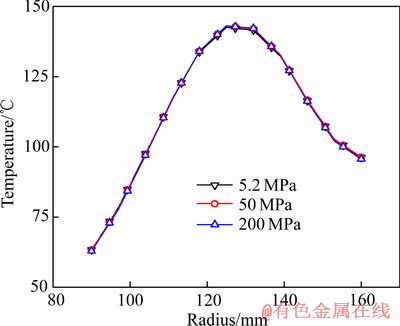

图7所示为闸片弹性模量5.2 GPa、热传导系数30 W/(m·K)时热膨胀系数对最高温度时刻制动盘表面温度径向分布的影响。可见,三种热膨胀系数下最高温度均出现在盘半径125 mm处,热膨胀系数从0.5×10-5 K-1分别增大到1.15×10-5 K-1和2.5×10-5 K-1时,最高温度分别由139.3 ℃升高到142.6 ℃和151 ℃,在盘半径110~140 mm的范围,盘面温度随闸片热膨胀系数的增大而升高,在盘半径90~110 mm和140~160 mm范围,盘面温度随闸片热膨胀系数的增大而降低。

图7 闸片热膨胀系数对最高温度时刻制动盘表面径向温度分布的影响

Fig. 7 Effect of thermal expansion coefficient on radial temperature on brake disc surface at highest temperature

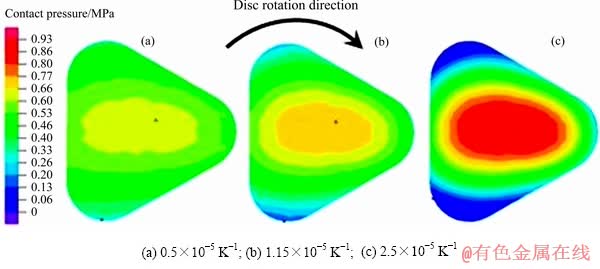

图8所示为闸片弹性模量5.2 GPa、热传导系数30 W/(m·K)时不同闸片热膨胀系数下最高温度时刻的接触压力。可见,在摩擦区中部形成椭圆形高接触压力区,接触压力从中心向上下边部逐渐变小,最小接触压力出现在闸片上下侧(偏盘外径和内径处)。随着热膨胀系数的增大,接触压力的分布形态相近,接触压力梯度明显增大。当热膨胀系数从0.5×10-5 K-1增大到1.15×10-5 K-1时,如图8(a)和(b)所示,闸片摩擦面保持良好接触,摩擦面中部的接触压力明显变大,闸片上下侧的接触压力变小。当热膨胀系数进一步增大到2.5×10-5 K-1时,接触区面积明显变小,闸片上下侧边缘开始脱离接触,接触压力几乎为零,中部接触压力增大到0.93 MPa(见图8(c)),可见,接触压力对闸片热膨胀系数的变化较敏感。

图8 不同闸片热膨胀系数下最高温度时刻的接触压力

Fig. 8 Contact pressure at highest temperature under different thermal expansion coefficient

由图7~8可知,随闸片热膨胀系数的增大,制动盘面温度和接触压力分布的不均匀程度变大。这可通过接触压力和温度间的相互作用来解释,由于闸片不同半径处接触弧长的差异,导致摩擦面上温度分布不均匀,使闸片产生非均匀的热变形,从而引起摩擦面上接触压力分布不均匀,最大接触压力出现在接触弧长最大的区域。温升相同时,闸片热膨胀系数越大,热变形越大,接触压力越向摩擦区中部集中。由于进入制动盘的热流强度与接触压力成正比,随闸片热膨胀系数的增大,进入摩擦区中部(高接触压力区)的热流增加,而进入两侧(低接触压力区)的热流减少,因此,制动盘表面的温度出现上述的变化规律。可见,闸片热膨胀系数的增大会导致制动盘表面径向温度梯度增大,使制动盘表面产生更大的热应力。

4.2 闸片弹性模量对制动盘温度场和接触压力的 影响

图9所示为闸片热传导系数30 W/(m·K)、热膨胀系数1.15×10-5 K-1时闸片弹性模量对最高温度时刻制动盘表面径向温度分布的影响。可见,随闸片弹性模量的增大,制动盘面径向温度变化不明显,最高温度出现在盘半径125 mm处。闸片弹性模量从5.2 GPa分别增加到50 GPa和200 GPa时,最高温度从142.6 ℃仅增加了0.4 ℃和0.5 ℃。可见,三种弹性模量下,制动盘摩擦区域径向上的温度分布差异不明显。

图9 闸片弹性模量对最高温度时刻制动盘表面径向温度分布的影响

Fig. 9 Effect of elastic modulus on radial temperature on brake disc surface at highest temperature

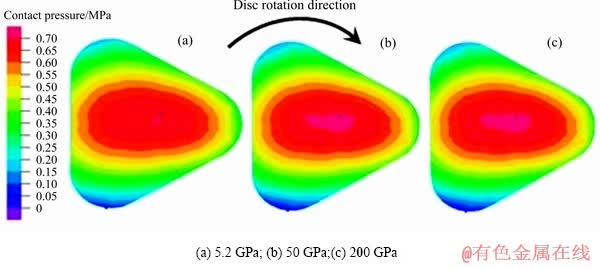

图10所示为闸片热传导系数30 W/(m·K)、热膨胀系数1.15×10-5 K-1时,不同闸片弹性模量下最高温度时刻的接触压力。可见,随闸片弹性模量的增大,摩擦面的接触压力分布形态一致,最大接触压力略有增加,闸片弹性模量为5.2 GPa时,最大接触压力为0.721 MPa,见图10(a),当闸片弹性模量分别增大到50 GPa和200 GPa时,如图10(b)和(c)所示,最大接触压力分别增加到0.730 MPa和0.731 MPa。随闸片弹性模量增大,闸片摩擦面上压力分布向摩擦区中部集中,但变化量较小,闸片摩擦面绝大部分区域接触良好。

由图9~10可知,随闸片弹性模量的增大,制动盘最高温度和闸片接触压力均出现轻微的增加。这是由于弹性模量越小,闸片抵抗弹性变形的能力越小,在压力的作用下与制动盘贴合越充分,接触压力分布越均匀。因此,当弹性模量增大时,闸片摩擦面上的接触压力向中部集中,使进入制动盘摩擦区中部(高接触压力区)的热流强度增大,导致制动盘最高温度出现上述变化规律。但由于接触压力变化量较小,进入制动盘的热流密度变化不明显,故制动盘表面的温度场变化不明显。

图10 不同闸片弹性模量下最高温度时刻的闸片接触压力

Fig. 10 Contact pressure at highest temperature under different elastic modulus

这与文献[11]和[12]所得结果有所不同,文献[11]发现弹性模量0.105~10.5GPa范围内每降低50%可使制动盘峰值温度降低200 ℃,文献[12]在二维轴对称有限元模型下,针对汽车盘式制动器数值模拟了循环制动过程中摩擦副温度场和接触压力,发现闸片弹性模量对接触压力的影响非常明显,当弹性模量从1 GPa增大到2 GPa时,闸片和制动盘间的接触面积明显减小,最大减少了62%。造成所得结果差异的原因可能是:首先,二维模型未考虑制动盘周向上的热传导和周期性接触的影响,导致摩擦界面上计算出的温度过高使制动盘和闸片变形过大,加强了接触压力分布的不均匀程度,弹性模量增大使系统更容易发生热弹性失稳。其次,文献[11]中研究的是汽车制动器,制动时,一侧制动闸片固定不动,另一侧闸片施加制动压力,导致制动盘两侧接触压力分布存在较大差异,而列车制动器中两边闸片同时加压,制动盘两侧接触压力相同,两种制动器接触压力分布的差异导致制动盘和闸片变形方式不同,汽车盘式制动器变形更加不均匀,更容易随弹性模量的增加而出现热弹性失稳。最后,所取弹性模量变化范围不同,本文中弹性模量在5.2~200 GPa范围内变化,而文献[11-12]弹性模量在小于5 GPa范围内变化,可见,弹性模量在不同变化范围内对制动器的热弹性行为的影响是不同的。在研究闸片材料参数对温度场和接触压力的影响时,在采用合理有限元模型的基础上,需要综合考虑制动器结构与材料参数变化范围的影响。

4.3 闸片热传导系数对制动盘温度场和接触压力的影响

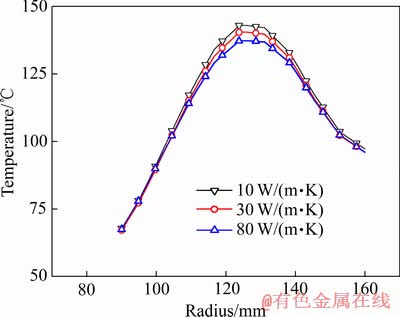

图11所示为闸片弹性模量5.2 GPa、热膨胀系数1.15×10-5 K-1时闸片热传导系数对最高温度时刻制动盘表面径向温度分布的影响。可见,制动盘表面径向温度随闸片热传导系数的增大而降低,尤其在摩擦半径125 mm附近的区域,当闸片热传导系数从10 W/(m·K)分别增加到30 W/(m·K)和80 W/(m·K)时,最高温度从145.4 ℃下降2.8 ℃和6.3 ℃。

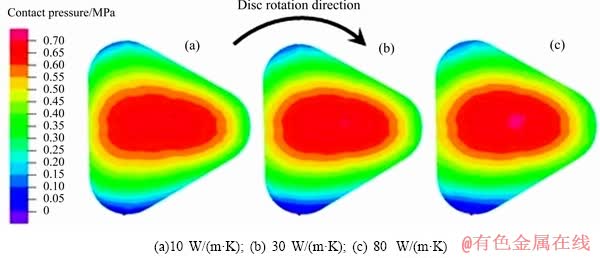

图12所示为闸片弹性模量5.2 GPa、热膨胀系数1.15×10-5 K-1时不同闸片热传导系数下最高温度时刻闸片接触压力。可见,随闸片热传导系数的增大,摩擦面中部椭圆形高接触压力区径向上的宽度变大,接触压力梯度减小。最大接触压力略有增加,当闸片热传导系数10 W/(m·K)时,最大接触压力为0.702 MPa(见图12(a)),热传导系数增大到30 W/(m·K)和80 W/(m·K)时,最大接触压力分别增大到0.721 MPa和0.725 MPa(见图12(b)和(c))。

图11 闸片热传导系数对最高温度时刻制动盘表面径向温度分布的影响

Fig. 11 Effect of thermal conductivity on radial temperature on brake disc surface at highest temperature

图12 不同闸片热传导系数下最高温度时刻的闸片接触压力

Fig. 12 Contact pressure at highest temperature under different thermal conductivity

由图11~12可知,随闸片热传导系数的增大,制动盘面的温度降低,摩擦面上接触压力分布和大小未发生明显的变化。这是由于当闸片热传导系数增大时,更多的热量被闸片吸收,但是热量在闸片内传导速度较快,对接触表面影响较小,因此,接触压力对热传导系数不敏感。制动盘表面温度降低主要是由于闸片热传导系数改变影响到热流在制动盘和闸片间的分 配[19],由公式(1)可知,当闸片热传导系数增大时,进入闸片的热流密度将变大,相应地,进入制动盘的热流密度将变小,因此,制动盘表面的温度随闸片热传导系数的增加而降低。可见,提高闸片的热传导系数可以降低制动盘表面的温度,从而提高制动盘的使用寿命。

5 结论

1) 数值模拟和试验获得的制动盘表面温度均呈现环带状分布,周向温度分布较均匀,径向温度梯度明显。在盘半径90~130 mm范围,试验温度高于数值模拟温度约20 ℃;在盘半径130~160 mm范围,试验温度稍低于数值模拟温度。这种偏差是由于模拟中假设闸片和制动盘完全接触,而试验中闸片与制动盘为非均匀接触。

2) 闸片热膨胀系数对盘面温度影响明显,闸片热膨胀系数从0.5×10-5 K-1增大到2.5×10-5 K-1时,制动盘最高温度增加11.7 ℃,增幅为8.4%,这是由于闸片热膨胀系数增大,摩擦面热变形不均匀程度增加,从而加剧接触压力和摩擦热的非均匀性,导致制动盘摩擦区中部温度升高,径向温度梯度变大。

3) 闸片的弹性模量对盘面温度和接触压力影响不明显,闸片弹性模量增大约9倍,制动盘最高温度仅升高0.4 ℃,闸片摩擦面最大接触压力仅升高0.009 MPa。

4) 闸片热传导系数增大,制动盘表面温度降低,闸片热传导系数增大7倍,制动盘最高温度降低6.3 ℃,降幅为4.3%。其原因在于闸片热传导系数增大,提高了摩擦热在闸片内的扩散速度,使得进入闸片内的热流增加,相应地,进入制动盘的热流减少,从而制动盘的温度随闸片热传导系数的增大而减小。

REFERENCES

[1] 周素霞, 孙晨龙, 赵兴晗, 秦 霞, 赵 方. 城际快速列车铸钢制动盘三维瞬态温度场和应力场仿真分析[J]. 铁道学报, 2017, 39(8): 33-38.

ZHOU Su-xia, SUN Chen-long, ZHAO Xing-han, QIN Xia, ZHAO Fang. Simulation and analysis of 3D transient temperature field and stress field of cast steel brake disc of intercity trains[J]. Journal of the China Railway Society, 2017, 39(8): 33-38.

[2] JIANG L, JIANG Y L, YU L,SU N, DING Y D. Thermal analysis for brake disks of SiC/6061 Al alloy co-continuous composite for CRH3 during emergency braking considering airflow cooling[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2783-2791.

[3] ADAMOWICZ A, GRZES P. Three-dimensional FE model for calculation of temperature of a thermosensitive disc[J]. Applied Thermal Engineering, 2013, 50(1): 572-581.

[4] 金文伟, 王长川, 方明刚, 黄 彪. 高速列车制动盘材料参数热敏感性分析[J]. 铁道机车车辆, 2016, 36(4): 22-27.

JIN Wwen-wei, WANG Chang-chuan, FANG Ming-gang, HUANG Biao. Thermal sensitivity analysis of material on brake disc used on high-speed train[J]. Railway Locomotive & Car, 2016, 36(4): 22-27.

[5] 孙 超, 高 飞, 符 蓉, 农万华. 制动闸片结构特征的表征方法研究[J]. 铁道机车车辆, 2012, 32(4): 49-54.

SUN Chao, GAO Fei, FU Rong, NONG Wan-hua. Research of structure characterization method of brake pad[J]. Railway Locomotive & Car, 2012, 32(4): 49-54.

[6] 农万华, 高 飞, 符 蓉, 韩晓明. 摩擦块形状对制动盘温度及热应力影响[J].润滑与密封, 2012, 37(8): 52-56.

NONG Wan-hua, GAO Fei, FU Rong, HAN Xiao-ming. Influence of brake pad shape on friction temperature and thermal stress of brake disc[J]. Lubrication Engineering, 2012, 37(8): 52-56.

[7] 高 飞, 孙 野, 杨俊英, 符 蓉. 摩擦副结构与制动盘温度关系的试验与模拟研究[J]. 机械工程学报, 2015, 51(9): 182-188.

GAO Fei, SUN Ye, YANG Jun-ying, FU Rong. Experimental and simulation research on relationships of the pattern of a friction pair and temperature[J]. Journal of Mechanical Engineering, 2015, 51(19): 181-188.

[8] 杨俊英, 高 飞, 孙 野, 韩晓明. 闸片摩擦块形状对制动盘温度及摩擦性能的影响[J]. 中国有色金属学报, 2018, 28(7): 1351-1360.

YANG Jun-ying, GAO Fei, SUN Ye, HAN Xiao-ming. Influence of geometry of brake pad on disc temperature and friction performance[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(7): 1351-1360.

[9] 张金煜, 虞大联, 林 鹏. 基于旋转热源法和均布热源法的列车踏面制动温度场分析[J]. 机械工程学报, 2018, 54(6): 93-101.

ZHANG Jin-yu, YU Da-lian, LIN Peng. Aanlysisof temperature field of train tread braking based on rotating heat source method and uniformity distributed heat soure method[J]. Journal of Mechanical Engineering, 2018, 54(6): 93-101.

[10] JOACHIM-AJAO D, BARBER J R. Effect of material properties in certain thermoelasticcontact problems[J]. Journal of Applied Mechanics, 1998, 65(4): 889-893.

[11] DUFRENOY P, WEICHERT D. Prediction of railway disc brake temperatures taking the bearing surface variations into account[C]// Proceedings of the Institution of Mechanical Engineers, Part F, Journal of Rail and Rapid Transit, 1995, 209(2): 67-76.

[12] CHOI J H, LEE I. Finite element analysis of transient thermoelastic behaviors in disk brakes[J]. Wear, 2004, 257(1): 47-58.

[13] FLOQUET A, DUBOURG M C. Realistic braking operation simulation of ventilated disk brakes[J]. Journal of Tribology, 1996, 118(3): 466-472.

[14] 赵愿军. 盘式制动器热力耦合瞬态温度场仿真与分析[D]. 武汉: 华中科技大学, 2013.

ZHAO Yuan-jun. Simulation and analysis of disc brake coupled thermal-stress transient temperature[D]. Wuhan: Huazhong University of Science and Technology, 2013.

[15] PANIER S, DUFRENOY P, WEICHERT D. An experimental investigation of hot spots in railway disc brakes[J]. Wear, 2004, 256 (7): 764-773.

[16] XU H J, HUANG B Y. Influence of matrix carbon texture on the temperature field of carbon-carbon composites during braking[J]. Tribology International, 2011, 44(1): 18-24.

[17] SAKAMOTO H. Heat convection and design of brake discs[C]// Proceedings of the Institution of Mechanical Engineers, Part F, Journal of Rail and Rapid Transit, 2004, 218(3): 203-212.

[18] KASEM H, THEVENET J, BOIDIN X, SIROUX M, DESPLANQUES Y. An emissivity-corrected method for the accurate radiometric measurement of transient surface temperatures during braking[J]. Tribology International, 2010, 43(10): 1823-1830.

[19] THURESSON D. Influence of material properties on sliding contact braking applications[J]. Wear, 2004, 257(5): 451-460.

Relationship of pad material parameters and brake disc temperature field

GAO Fei, WU Bo-wen, YANG Jun-ying

(Engineering Research Center of Continuous Extrusion (Ministry of Education), Dalian Jiaotong University, Dalian 116028, China)

Abstract: The material parameters of pad have important effects on the tribological properties of the friction pairs and the brake disc temperature distribution. Based on ADINA software, a 3D thermo-mechanical coupling model for brake disc and pad was established. The effect of thermal expansion coefficient, elastic modulus and thermal conductivity of pad material on brake disc temperature distribution and contact pressure at the interface was investigated under the brake conditions that the initial velocity was 100 km/h, brake pressure was 0.538 MPa and the inertia was 23 kg·m2. The results show that when the thermal expansion coefficient of the pad increases from 0.5×10-5 K-1 to 2.5×10-5 K-1, the disc peak temperature rises by 8.4%, the maximum contact pressure increases by 47% at the same time. With the increase of the thermal expansion coefficient, the contact pressure distribution becomes more uneven, which makes the disc temperature change significantly. The elastic modulus increases by 9 times, the distribution of contact pressure is not sensitive to the elastic modulus of pad material, and the elastic modulus has little influence on the temperature of brake disc. The thermal conductivity increases by 7 times, the peak temperature can be reduced by 4.3%, the increase of thermal conductivity promotes the heat diffusion rate, which can reduce the disc peak temperature. The research results can provide references for the development of high-speed train pad materials.

Key words: disc brake; temperature field; contact pressure; thermo-mechanical coupling

Foundation item: Project(2016YFB0301403) supported by the National Key Research and Development Program of China; Project(20170520374) supported by the Natural Science Foundation of Liaoning Province, China; Project (2017RQ135) supported by the Dalian Youth Science and Technology Star, China; Project (JDL2016022) supported by the Liaoning Provincial Education Department, China

Received date: 2019-04-16; Accepted date: 2019-06-17

Corresponding author: YANG Jun-ying; Tel: +86-411-84109397; E-mail: yangjy@djtu.edu.cn

(编辑 王 超)

基金项目:国家重点研发计划重点专项(2016YFB0301403);辽宁省自然科学基金(20170520374);大连市青年科技之星项目(2017RQ135);辽宁省教育厅项目(JDL2016022)

收稿日期:2019-04-16;修订日期:2019-06-17

通信作者:杨俊英,副教授,博士;电话:0411-84109397;E-mail:yangjy@djtu.edu.cn