DOI:10.19476/j.ysxb.1004.0609.2017.11.03

挤压温度对Al-Zn-Mg-Cu合金动态再结晶、时效组织和力学性能的影响

薛 杰,王有为,张志豪,谢建新

(北京科技大学 新材料技术研究院 材料先进制备技术教育部重点实验室,北京 100083)

摘 要:以Al-Zn-Mg-Cu合金为对象,研究了挤压温度对合金组织、织构及力学性能的影响。结果表明:当挤压温度为390~500 ℃时,随着挤压温度的升高,挤压态棒材发生动态再结晶程度由2.4%逐渐增大到41.3%,动态再结晶晶粒尺寸逐渐增大,而经固溶时效后,晶粒尺寸呈先增大后减小的变化趋势,其中挤压温度为430 ℃时的晶粒尺寸最大。挤压棒材固溶时效后的强度和伸长率均呈先增大后减小的趋势,其中挤压温度为430 ℃时的抗拉强度、屈服强度和伸长率均较高,分别为678.1 MPa、618.3 MPa和9.2%。与晶粒尺寸较小的时效态挤压棒材相比,晶粒尺寸较大的棒材具有更高的强度,其原因是由于大晶粒棒材中存在较多的硬取向Copper织构({112}<111>)和S型织构({123}<634>)。

关键词:Al-Zn-Mg-Cu合金;挤压温度;晶粒尺寸;力学性能;织构

文章编号:1004-0609(2017)-11-2204-08 中图分类号:TG146.2 文献标志码:A

Al-Zn-Mg-Cu铝合金属于超高强度变形铝合金,具有高比强度和硬度、较高韧性,良好的加工性能,较好的耐蚀性等优点,是国防军工、航空航天、轨道交通等领域的重要结构材料[1-2]。

Al-Zn-Mg-Cu合金的挤压温度范围较宽,一般为350~500 ℃[3-4],但有研究表明,不同温度下合金变形过程中的再结晶行为的差异较大。例如,陈学海等[5]研究了7085铝合金在350~450 ℃的热压缩变形,发现当变形温度为400 ℃时,合金才开始发生轻微的动态再结晶,且随着变形温度的升高,变形后合金的位错密度降低,动态再结晶的晶粒尺寸增大,合金热变形过程中软化机制由动态回复转为动态再结晶。闫亮明等[6]研究了7055铝合金在300~450 ℃的多道次热压缩变形,发现随着变形温度升高,经多道次热压缩后试样的晶粒长宽比先减小然后增加,位错密度降低,亚晶尺寸增加,热压缩过程发生了动态再结晶。蔡一鸣等[7]对7039铝合金在300~500 ℃进行热压缩变形,发现在应变速率为10 s-1,变形温度大于300 ℃时,合金便发生了动态再结晶。李俊鹏等[8]研究了7075铝合金在300~400 ℃热压缩变形,发现在此温度区间内,其显微组织经历由无规则排布的位错演化成胞状组织、亚晶组织、而后发生亚晶长大,但仅发生动态回复,未发生动态再结晶。此外,Al-Zn-Mg-Cu合金属于可热处理强化变形铝合金,其最终使用状态通常为固溶时效态,所以变形后的合金在后续的固溶和时效热处理阶段,将发生不同程度的静态回复和静态再结晶[9]。Al-Zn-Mg-Cu合金回复与再结晶行为的差异无疑会导致其性能的差异,因此确定合适的变形温度是合金产品性能调控的关键。

在此,本文作者选择飞机结构材料用高性能Al-Zn-Mg-Cu系7A04铝合金为对象,研究了挤压温度对不同状态(挤压态、固溶时效态)铝合金再结晶组织、织构及力学性能的影响规律,并结合组织和织构检测结果进行机理分析,进而为通过调整挤压工艺而实现对产品性能的调控提供参考。

1 实验

本实验中所用7A04铝合金的主要化学成分(质量分数,%)为Zn 5.15,Mg 2.30,Cu 1.70,Cr 0.21,Fe 0.30,Si 0.09,Mn 0.23,Al 余量。切取d 40 mm×60 mm的圆柱坯料,将坯料置入SGM-M30/12型箱式电阻炉中进行均匀化处理,均匀化处理制度为460 ℃、24 h[10],均匀化后冷却方式为水淬,坯料的初始平均晶粒尺寸约为28 μm。将坯料在不同的挤压温度下挤压成d 8.4 mm的棒材,挤压温度范围为390~500 ℃,挤压比为23:1,挤压时采用在线水淬。挤压棒材的固溶时效处理制度为(475 ℃,1 h)+(120 ℃,24 h)[10]。

采用LEO-1450型扫描电镜的EBSP组件(EBSD)以及HKL-Channel软件分析挤压态试样的晶粒取向和动态再结晶程度。采用ZEISS Axiovert 200MAT金相显微镜(OM)观察7A04合金时效态试样的金相组织(观察位置均为挤压棒材的芯部位置),侵蚀剂为Graff Sargent 试剂(1 mL HF+16 mL HNO3+3 g CrO3+83 mL H2O)。采用透射电镜(TEM)观察挤压态试样的析出相和亚结构,TEM样品经机械减薄后,用30%硝酸+ 70%(体积分数)甲醇电解液在-35 ℃双喷减薄,电流50~60 mA。采用Brucker D8 Discovery 织构测试仪测试了每个试样的{111}、{200}、{220}、{113}4个不完全极图,然后运用球谐函数级数法展开法求出展开系数l=22的取向分布函数(ODF)[11],并采用织构分析法求出“真ODF”(l=23)以消除“鬼峰”的影响[12]。拉伸性能测试参照GB/T 228.1—2010标准,在Instron3369力学实验机上进行。

2 结果与讨论

2.1 挤压温度对7A04铝合金棒材组织的影响

2.1.1 挤压温度对挤压组织的影响

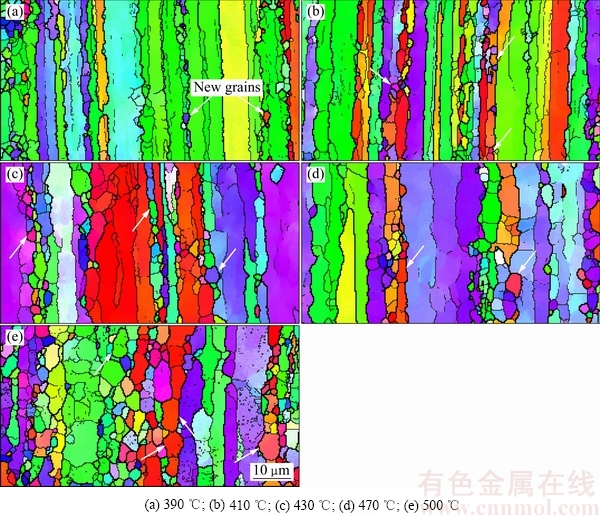

图1 7A04铝合金经不同温度挤压后的EBSD组织

Fig. 1 EBSD images of 7A04 aluminum alloy extruded at different temperatures

图1所示为7A04铝合金经不同温度下挤压后的挤压态组织(ESBD取向成像图)。由图1可知,当挤压温度为390 ℃时,合金中呈现大量变形后纤维组织,并且局部区域发生动态再结晶(见图1(a)中箭头所指),形成细小的且晶粒取向不同于变形基体的新晶粒,其所占体积分数约为2.4%;随着挤压温度的升高,原始晶界附近出现的新晶粒逐渐增多,则说明动态再结晶的程度进一步增大。当挤压温度升高至410、430、470 ℃时,对应的动态再结晶的体积分数分别增至为8.2%、12.5%和21.4%,且动态再结晶的晶粒尺寸也逐渐变大,但仍然以变形纤维组织为主。当挤压温度升至500 ℃时,动态再结晶程度继续增大,其体积分数增至41.3%,且部分动态再结晶晶粒合并长大,形成等轴晶组织,纤维组织基本消失。

上述结果表明,当挤压温度在390~500 ℃范围内时,随着挤压温度的升高,棒材发生动态再结晶程度逐渐增大,动态再结晶的体积分数由2.4%增大至41.3%,且动态再结晶晶粒尺寸也逐渐变大。

进一步采用TEM观察挤压态试样的微观特征,结果如图2所示。在390 ℃挤压时,合金内部大部分晶界周围存在较多的位错堆积和明显的位错缠结(见图2(a));在430 ℃挤压时,在原始晶界处出现了细小的动态再结晶晶粒,晶粒内部部分区域位错发生湮没,位错密度较低(见图2(b));当挤压温度升至470 ℃时,晶界附近出现较多的再结晶晶粒,合金的位错密度显著减少,晶界取向差加大,晶界更加明晰且锋锐。

图2 7A04铝合金经不同温度挤压后的TEM像

Fig. 2 TEM images of 7A04 aluminum alloy extruded at different temperatures

由图2可知,当低温挤压时(即挤压温度为390 ℃),动态再结晶程度较低,主要是发生较强的动态回复;随着挤压温度升高,动态再结晶程度逐渐增大,动态再结晶晶粒数量逐渐增多,且动态再结晶粒逐渐增大。

在较低温度(390 ℃)挤压时,由于变形温度较低,刃型位错没有足够的能量,不足以发生攀移和交滑移,则多边化过程困难,即形成亚晶困难,进而动态再结晶形核困难,主要以动态回复为主,动态再结晶程度很小。因此,较低温度挤压棒材中具有较高的位错密度,即积累较多变形储能,为后续热处理过程中的静态再结晶提供驱动力。当挤压温度升高至430 ℃时,增强了原子的热激活能力,原子间的结合力减弱,位错滑移阻力减小,位错间的相互抵消和重组作用加强,多边化充分进行形成更多小角度亚晶界(LAGB),在应力和热激活作用下,小角度亚晶界不断吸收新的位错从而转化为大角度晶界(HAGB),形成动态再结晶晶 粒[13]。随着挤压温度继续升高,即温度为470 ℃时,原子热激活能更大,则动态再结晶的形核率增大,形成较多的动态再结晶晶粒,进而位错密度显著降低,变形储能显著减少。

2.1.2 挤压温度对时效态组织的影响

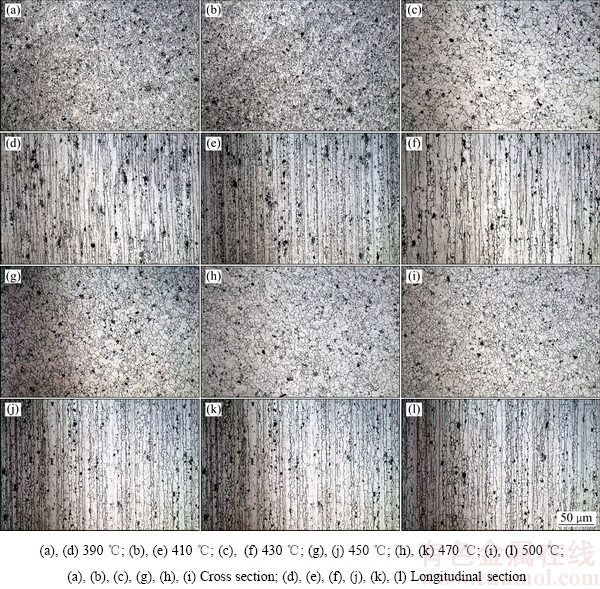

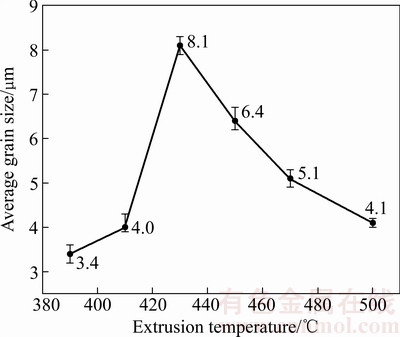

将在不同温度下挤压的棒材进行固溶时效热处理,棒材发生了明显的静态再结晶及晶粒的长大现象,其时效态的金相组织如图3所示。采用Image J软件对每个试样横截面10个视场的晶粒尺寸统计如4所示。由文献[14-15]可知,Graff Sargent试剂腐蚀试样后,在显微镜下用较低倍数观察,合金中非再结晶区域由于含有大量细小亚晶组织而呈黑色,而再结晶区域由于亚晶合并长大使该区域亚晶界减少而呈亮白色。在较高倍数下观察,可观察到非再结晶区域为大量的细小亚晶,再结晶区域为粗大条形的晶粒。

由图3和4可以看出,在挤压温度为390~500 ℃范围内,挤压棒材固溶时效态组织随着挤压温度的升高,其横截面平均晶粒尺寸先增大后减小。其中,挤压温度为390 ℃的挤压棒材固溶时效后的横截面平均晶粒尺寸约为3.4 μm;当挤压温度为410 ℃时,其时效态的试样再结晶程度增大(见图3(e)),且横截面平均晶粒尺寸约为4.0 μm;随着挤压温度继续升高至430 ℃时,再结晶程度达到最大(见图3(f)),但仍然是部分再结晶,此时其横截面平均晶粒尺寸达到最大,约为8.1 μm;继续提高挤压温度至450、470和500 ℃时,则时效态试样的再结晶程度反而逐渐减小(见图3(j)、(k)和(l)),而且试样的横截面平均晶粒尺寸也逐渐减小,分别减小至6.4、5.1和4.1 μm。

在挤压温度390~430 ℃范围内,随着温度的升高再结晶程度逐渐增大,平均晶粒尺寸也逐渐变大。随着挤压温度的升高,热激活的作用增强,亚晶界的可动性增强,亚晶长大加剧,从而动态再结晶程度逐渐增大(见图1(a)、(b)和(c));同时,虽然挤压温度的升高在一定程度上降低了变形储能,但仍足以在固溶热处理时诱发再结晶。因此,挤压棒材经过相同的固溶时效处理后,挤压温度越高,棒材时效态的再结晶程度和平均晶粒尺寸均越大。但是,当挤压温度超过430 ℃后,继续升高挤压温度,由于挤压温度较高,动态再结晶程度显著增大(见图1(d)和(e)),较大程度动态再结晶的发生消耗了大量的形变储能(见图2(c)),而形变储能又是后续热处理过程发生再结晶和晶粒长大的驱动力,因此,当挤压温度为450、470和500 ℃时,时效态试样的再结晶程度逐渐减小,且平均晶粒尺寸也逐渐减小。

图3 7A04铝合金经不同温度挤压后时效态显微组织

Fig. 3 Aging microstructures of 7A04 aluminum alloy bars extruded at different temperatures

图4 7A04铝合金经不同温度挤压后时效态的横截面平均晶粒尺寸

Fig. 4 Effect of extrusion temperature on average grain size of cross section of 7A04 aluminum alloy bars after aging

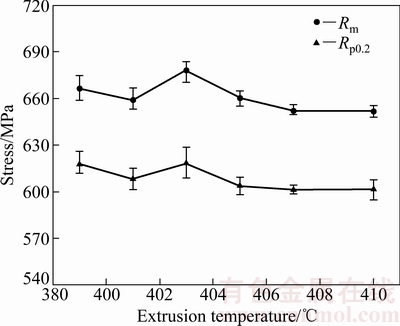

2.2 挤压温度对7A04铝合金棒材力学性能的影响

7A04铝合金经不同温度挤压的棒材固溶时效处理后的强度与挤压温度的关系如图5所示。当挤压温度为390 ℃时,时效态7A04铝合金挤压棒材的抗拉强度(Rm)为666.4 MPa,屈服强度(Rp0.2)为618.0 MPa。经410 ℃挤压变形的时效态合金棒材相比经390 ℃挤压变形的时效态合金棒材的抗拉强度和屈服强度略微有所下降,即减小到659.0和608.4 MPa。而经430 ℃挤压变形时效态合金棒材相比经390和410 ℃挤压变形时效态合金棒材的抗拉强度明显提高,为678.1 MPa,屈服强度略微升高,为618.3 MPa。随着挤压温度的继续升高,则时效态7A04铝合金挤压棒材的强度呈下降趋势,经470 ℃挤压变形时效态合金棒材的抗拉强度和屈服强度,分别下降至652.0和601.2 MPa。经500 ℃挤压变形时效态合金挤压棒材的抗拉强度、屈服强度基本不变,分别为651.7和601.6 MPa。综上所述可知,随着挤压温度的升高,时效态合金棒材的强度先增大后减小。

图5 时效态7A04铝合金棒材的强度与挤压温度的关系

Fig. 5 Relationship between strength of aged 7A04 aluminum alloy extrusion bars and extrusion temperature

图6 7A04铝合金经不同温度挤压后时效态的取向分布函数(ODF)图

Fig. 6 Orientation distribution function (ODF) of aged 7A04 aluminum alloy extruded at different temperatures

值得注意的是,430 ℃挤压棒材时效态的强度最高,而且晶粒尺寸也最大(见图4),该现象并不符合Hall-Perch公式。而当挤压温度越高时,挤压态棒材的难溶相越粗大,棒材固溶处理后固溶原子过饱和度越小,则时效后析出强化作用将减小,所以理论上时效态430 ℃挤压棒材的强度要低于时效态390 ℃挤压棒材的强度。

由文献[16-17]可知,7000系铝合金的强度除了与晶粒尺寸和析出相有关,织构组分也是重要作用因素。为此,取上述3个典型的试样(即挤压温度分别为390、430和470 ℃的试样)进行宏观织构分析。图6所示为试样的取向分布函数(ODF)图。由图6可知,当挤压温度为390 ℃时,棒材含有织构取向密度值约为21.0的Cube织构({100}<001>)和A型织构({110}<111>),织构取向密度值约为13.0的Goss织构({110}<100>),织构取向密度值约为17.0的Copper织构({112}<111>)和织构取向密度值约为9.0的S型织构({123}<634>);挤压温度为430 ℃时,其织构组分与挤压温度为390 ℃试样的相似,但其相应的织构强度均有增强,其中Cube织构的取向密度值增加至25.0,A型织构的增加至29.0,Goss、Copper和A型织构的增加至17.0;当挤压温度为470 ℃时,除Cube织构外,A型、Goss、Copper、S型织构的强度均有所降低,分别为13.0、9.0、9.0、13.0。由文献[18-20]可知,Copper、A型、S型织构所对应的晶粒取向属于硬取向,对材料强度的贡献较大,而Goss、Cube织构是软取向,对材料强度的贡献相对较小。挤压温度为430℃的试样,虽然其晶粒尺寸最大(见图4),但是试样中的硬取向含量高于挤压温度为390 ℃和470 ℃的试样,这可能是图5中试样的强度随挤压温度升高呈先增大后减小的原因。此外,对于挤压温度较高(如470 ℃)的试样,再结晶程度较高(见图1)也是导致其强度下降的原因之一。

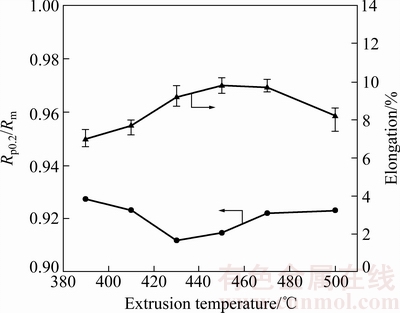

图7所示为不同挤压温度的挤压棒材时效处理后的屈强比和伸长率与挤压温度的关系图。当挤压温度为390 ℃时,伸长率约为7.0;挤压温度410 ℃时,伸长率约为7.7;当挤压温度升高至430 ℃时,伸长率增大至9.2;当挤压温度继续升高到450 ℃和470 ℃,伸长率也较大,分别为9.8,9.7;而挤压温度为500 ℃时,伸长率降至8.2。综上所述可知,随着挤压温度的升高,棒材的伸长率呈先增大后减小的变化趋势。

图7 时效态7A04铝合金棒材的屈强比、伸长率与挤压温度的关系

Fig. 7 Effect of extrusion temperature on yield ratio (Rp0.2/Rm) and elongation of 7A04 aluminum alloy bars after aging

3 结论

1) 当挤压温度在390~500 ℃范围内时,随着挤压温度的升高,棒材发生动态再结晶程度逐渐增大,动态再结晶的体积分数由2.4%增大至41.3%,且动态再结晶晶粒尺寸也逐渐增大。

2) 不同温度挤压棒材经固溶时效处理后,晶粒尺寸随着挤压温度的升高呈先增大后减小的趋势,其中挤压温度为390 ℃时,横截面平均晶粒尺寸最小,约为3.4 μm;而挤压温度为430 ℃时,横截面平均晶粒尺寸达到最大,约为8.1 μm。

3) 随着挤压温度的升高,挤压棒材固溶时效后的强度和伸长率均呈先增大后减小的趋势,其中挤压温度430 ℃时的抗拉和屈服强度均最高、伸长率也较高,分别为678.1 MPa、618.3 MPa和9.2%。

4) 在本实验条件下,晶粒尺寸较大的时效态挤压棒材相比晶粒尺寸较小的棒材具有更高的强度,并不单纯遵守Hall-Perch公式,其原因是由于大晶粒棒材中存在较多的硬取向Copper织构({112}<111>)和S型织构({123}<634>)。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小峰, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] WIILLIAMS J C, EDGAR A, SRAKE J R. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[3] 谢建新, 刘静安. 金属挤压理论与技术[M]. 第2版. 北京: 冶金工业出版社, 2012: 106-109.

XIE Jian-xin, LIU Jing-an. Theory and technology for metal extrusion[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2012: 106-109.

[4] 肖亚庆. 铝加工技术实用手册[M]. 北京: 冶金工业出版社, 2004: 584-615.

XIAO Ya-qing. Handbook of aluminum processing technology[M]. Beijing: Metallurgical Industry Press, 2004: 584-615.

[5] 陈学海, 陈康华, 董鹏轩, 彭国胜, 陈送义. 7085 铝合金的热变形组织演变及动态再结晶模型[J]. 中国有色金属学报, 2013, 23(1): 44-50.

CHEN Xue-hai, CHEN Kang-hua, DONG Peng-xuan, PENG Guo-sheng, CHEN Song-yi. Microstructure evolution and dynamic recrystallization model of 7085 aluminum alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 44-50.

[6] YAN Liang-ming, SHEN Jian, LI Zhou-bing, LI Jun-peng. Effect of deformation temperature on microstructure and mechanical properties of 7055 aluminum alloy after heat treatment[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 625-630.

[7] 蔡一鸣, 李慧中, 梁霄鹏, 汤国建. 7039铝合金高温的热变形行为[J]. 中国有色金属学报, 2008, 18(10): 1775-1780.

CAI Yi-ming, LI Hui-zhong, LIANG Xiao-peng, TANG Guo-jian. Thermal deformation behavior for 7039 aluminum alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1775-1780.

[8] 李俊鹏, 沈 健, 闫晓东, 毛柏平, 闫亮明. 温度对7075铝合金热变形显微组织演化的影响[J]. 中国有色金属学报, 2008, 18(11): 1951-1957.

LI Jun-peng, SHEN Jian, YAN Xiao-dong, MAO Bai-ping, YAN Liang-ming. Effect of temperature on microstructure evolution of 7075 alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1951-1957.

[9] HIRSTR J. Virtual fabrication of aluminum products- microstructure modeling in industrial aluminum production[M]. Weinheim: Wiley-VCH, 2007: 83-110.

[10] XU Xiao-feng, ZHAO Yu-guang, WANG Xu-dong, ZHANG Yang-yang, NING Yu-heng. Effect of rapid solid-solution induced by electropulsing on the microstructure and mechanical properties in 7075 Al alloy[J]. Materials Science and Engineering A, 2016, 654: 278-281.

[11] BUNGE H J. Texture analysis in materials Science[M]. London: Butterworths, 1982: 88-106.

[12] LUCKE K, POSPIECH J, VIMICH K H, JURA J. On the problem of the reproduction of the true orientation distribution from pole figures[J]. Acta Metallurgica, 1981, 29(1): 167-185.

[13] 刘文胜, 刘东亮, 马运柱, 王 娟, 杨波平. 变形温度对2A14铝合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2015, 25(2): 308-314.

LIU Wen-sheng, LIU Dong-liang, MA Yun-zhu, WANG Juan, YANG Bo-ping. Effects of deformation temperature on microstructure and mechanical properties of 2A14 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 308-314.

[14] 熊创贤, 邓运来, 万 里, 张新明. 7050铝合金板在固溶过程中微结构与织构的演变[J]. 中国有色金属学报, 2010, 20(3): 427-434.

XIONG Chuang-xian, DENG Yun-lai, WAN Li, ZHANG Xin-ming. Evolutions of microstructures and textures of 7050 Al alloy plate during solution heat treatment[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 427-434.

[15] 陈学海, 陈康华, 梁 信, 陈送义, 彭国胜. 热变形温度对7085铝合金组织和性能的影响[J]. 中国有色金属学报, 2011, 21(1): 88-94.

CHEN Xue-hai, CHEN Kang-hua, LIANG Xin, CHEN Song-yi, PENG Guo-sheng. Effects of hot deformation temperature on microstructure and properties of 7085 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 88-94.

[16] 陈军洲, 甄 良, 戴圣龙, 邵文柱, 张宝友. 晶粒形貌及织构对AA7055铝合金板材不同厚度层屈服强度的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1966-1969.

CHEN Jun-zhou, ZHEN Liang, DAI sheng-long, SHAO Wen-zhu, ZHANG Bao-you. Effects of grain shape and texture on the through-thickness yield strength of AA 7055 aluminum alloy plate[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1966-1969.

[17] 顾 伟, 李静媛, 王一德. 晶粒尺寸及Taylor 因子对过时效态7050铝合金挤压型材横向力学性能的影响[J]. 金属学报, 2016, 52(1): 51-59.

GU Wei, LI Jing-yuan, WANG Yi-de. Effect of grain size and taylor factor on the transverse mechanical properties of 7050 aliminium alloy extrusion profile after over-aging[J]. Acta Metallurgica Sinica, 2016, 52(1): 51-59.

[18] STARINK M J, WANG S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51(17): 5131-5150.

[19] HUMPHREYS F J, HATHERLY M. Recrystallization and Related Annealing Phenomena[J]. 2nd ed. Oxford, London: Pergamon Press, 2004: 86-105.

[20] 张云崖, 邓运来, 万 里, 张新明. 形变热处理对Al-Zn-Mg-Cu合金板材组织与硬度的影响[J]. 金属学报, 2011, 47(10): 1270-1276.

ZHANG Yun-ya, DENG Yun-lai, WAN Li, ZHANG Xin-ming. Effects of thermal mechanical treatment on the microstructures and hardness of an Al-Zn-Mg-Cu alloy plate[J]. Acta Metallurgica Sinica, 2011, 47(10): 1270-1276.

Effects of extrusion temperature on dynamic recrystallization, aging microstructure and mechanical properties of Al-Zn-Mg-Cu alloy

XUE Jie, WANG You-wei, ZHANG Zhi-hao, XIE Jian-xin

(Key Laboratory for Advanced Materials Processing, Ministry of Education, Institute for Advanced Materials and Technology, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The effects of extrusion temperature on the microstructure, texture and mechanical properties of Al-Zn-Mg-Cu alloy were investigated. The results show that, when extrusion temperature increases from 390 ℃ to 500 ℃, the extent of dynamic recrystallization of the extruded bar increases from 2.4% to 41.3%, and the dynamically recrystallized grain size also increases gradually. After solid solution and aging treatments, the grain size of the extruded bars increases initially and then decreases with the increase of extrusion temperature, and the grain size reaches the maximum at 430 ℃. Meanwhile, the strength and elongation of the aged bars also increase firstly and then decrease. The tensile strength, yield strength and elongation of the aged bar extruded at 430 ℃ are relatively high of about 678.1 MPa、618.3 MPa and 9.2%, respectively. The aged bar with larger grain size has higher strength than the one with smaller grain size, which is ascribed to existence of both the stronger Copper textures ({112}<111>) and S type textures ({123}<634>) in the bars with larger grain size.

Key words: Al-Zn-Mg-Cu alloy; extrusion temperature; grain size; mechanical property; texture

Foundation item: Project(2016YFB0300901) supported by the National Key Research and Development Program of China

Received date: 2016-08-15; Accepted date: 2017-06-09

Corresponding author: ZHANG Zhi-hao; Tel: +86-10-62332253; E-mail: ntxxh279@163.com

(编辑 龙怀中)

基金项目:国家重点研发计划资助项目(2016YFB0300901)

收稿日期:2016-08-15;修订日期:2017-06-09

通信作者:张志豪,副教授,博士;电话:010-62332253;E-mail:ntzzh2279@163.com