文章编号:1004-0609(2013)12-3381-06

钪、锆和锶复合微合金化铸态镍铝青铜的显微组织与性能

许晓静,陈树东,楚满军,潘 励,魏 建,侍国防

(江苏大学 先进制造与现代装备技术工程研究院,镇江 212013)

摘 要:采用硬度测试、金相观察、扫描电镜、能谱分析及腐蚀和摩擦实验的方法,研究钪、锆和锶对铸态镍铝青铜的硬度、组织、耐腐蚀性能和摩擦磨损性能的影响。结果表明:与未微合金化铸态镍铝青铜(Cu-8.57Al- 5.3Fe-4.6Ni-1.07Mn-0.63Zn)相比,钪、锆和锶复合微合金化铸态镍铝青铜(Cu-9.97Al-5.4Fe-4.52Ni-1.05Mn-0.62Zn- 0.045Zr-0.029Sr-0.057Sc)的相组成没有显著变化,都由α相、β相(高温相)和κ相组成,且各相均显著细化,合金硬度从212.1HV提高到240.7HV;由于组织细化,合金内优先发生腐蚀的共析组织(α+κIII相),其腐蚀通道产生概率降低,从而在3.5%NaCl水溶液中的均匀腐蚀和电化学腐蚀速率分别降低了.2%和17.8%(微合金化后的腐蚀速率分别为0.023 mm/a和0.231 mm/a);摩擦因数降低了23.4%(微合金化后的摩擦因数为0.019 3)。

关键词:镍铝青铜;微合金化;显微组织;耐腐蚀性能;摩擦磨损性能

中图分类号:TG 27 文献标志码:A

Microstructures and properties of micro-alloyed nickel-aluminium bronze ingot by scandium, zirconium and strontium composite

XU Xiao-jing, CHEN Shu-dong, CHU Man-jun, PAN Li, WEI Jian, SHI Guo-fang

(Engineering Institute of Advanced Manufacturing and Modern Equipment Technology, Jiangsu University, Zhenjiang 212013, China)

Abstract: The effects of scandium, zirconium and strontium on the hardness, microstructures, corrosion resistance and friction-wear properties of nickel-aluminium bronze ingot were investigated by means of hardness measurement, optical microscopy (OM), scanning electron microscopy (SEM), energy spectrum analysis and corrosion and friction experiments. The results show that, compared with the un-micro-alloying nickel-aluminium bronze ingot (Cu-8.57Al- 5.3Fe-4.6Ni-1.07Mn-0.63Zn), the micro-alloying nickel-aluminium bronze ingot (Cu-9.97Al-5.4Fe-4.52Ni-1.05Mn- 0.62Zn-0.045Zr-0.03Sr- 0.057Sc) has no significant change in the phase composition, which is composed of α-phase, β-phase (high-temperature phase) and κ-phase, and each phase is remarkably refined. The alloy hardness increases from 212.1HV to 240.7HV. The corrosion occurs preferentially in eutectoid region (α-phase+κIII-phase), but the refinement of the eutectoid microstructure reduces the probability of generating the corrosion channel. So, in 3.5%NaCl water solution, the micro-alloying nickel-aluminium bronze ingot presents better corrosion and tribological properties, the uniform corrosion rate and the electrochemical corrosion rate decrease by 5.2% and 17.8%, the corrosion rates of micro-alloying nickel-aluminium bronze are 0.023 mm/a and 0.231 mm/a, and the friction coefficient decreases by 23.4% (friction coefficient is 0.019 3), respectively.

Key words: nickel-aluminium bronze; micro-alloying; microstructure; corrosion resistance; friction-wear properties

镍铝青铜具有优良的抗海水腐蚀性能[1-2],是制造海上舰船螺旋桨、海水泵的主体材料[3],同时,该合金还具有良好的摩擦学性能,在高速、高压、高温下工作的轴承衬套、涡轮以及机械模具等领域亦具有广泛的应用前景。国外已经对镍铝青铜进行了系统的研究,而国内对其研究甚少,这极大地限制了我国海洋事业的发展。随着现代舰船的大型化、深水化以及服役周期的延长和服役环境的进一步苛刻,迫切需要性能更优的镍铝青铜作为螺旋桨的加工材料。

众所周知,微合金化是提高合金性能的主要手段之一。铜-锆二元相图表明[4],过渡族金属锆在铜中的固溶度极小,965 ℃时仅为0.15%,且随着温度下降而急剧降低,并以金属间化合物形式析出;500 ℃时,锆在铜中的固溶度只有0.01%,因此,锆起到强化作用。在铜中加入锆可以制成具有高强高导电性能的铜锆合金。锶在铜中的固溶度也很低,亦起到强化作用[5]。钪既是过渡族金属,又是稀土金属。微量钪加入到镍铝青铜合金中,在合金凝固初期,有可能与Al形成A13Zr(熔点1 580 ℃)和Al3Sc(熔点1 320 ℃)等高熔点物相,对铜合金的后续凝固起到非均质形核作用,细化合金组织[6-7]。

本文作者研究一种钪、锆和锶复合微合金化铸态镍铝青铜的组织、硬度、耐腐蚀性能和摩擦磨损性能,以期为高性能镍铝青铜材料的制备提供科学依据。

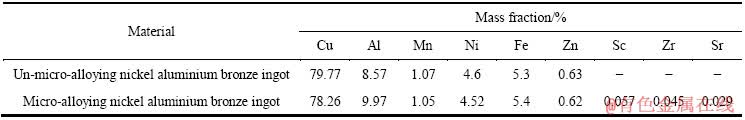

1 实验

钪、锆和锶复合微合金化铸态镍铝青铜的制备方法为:将镍铝青铜熔化后,加入Al-Sr中间合金、Al-Zr中间合金和纯Sc,待全部熔化后,加入清渣剂,接着通入高纯氮气精炼,倒入浇包,静置除渣后倒入砂模基尔铸型浇铸成锭。熔炼温度为1 280~1 300 ℃,浇铸温度为1 150 ℃。采用同样熔铸但未进行微合金化的铸态镍铝青铜进行对比。表1所列为所制备合金铸锭的成分。

采用HV-1000型显微硬度计测量硬度,加载载荷为2 N,加载持续时间为25 s。采用3 g FeCl3、2 mL盐酸和96 mL酒精配制金相腐蚀溶液。在含3.5% NaCl的水溶液中进行均匀腐蚀实验、电化学腐蚀实验和摩擦磨损实验。按JB/T 7901—1999(金属材料实验室均匀腐蚀全浸试验方法)标准[8]进行均匀腐蚀实验,溶液温度保持为20 ℃,浸泡168 h后取出试样,用V(HCl):V(H2O)=1:1溶液去除腐蚀产物,根据质量损失法计算腐蚀速率。采用CS350双单元电化学工作站进行电化学腐蚀实验[9],扫描电位范围为-1.0~2.5 V,扫描速率为20 mV/s。采用MGW-01型高频往复微动摩擦磨损试验机测试摩擦磨损性能,摩擦对偶件为直径4 mm的Si3N4球,载荷为1 N,时间为10 min,频率为20 Hz,冲程为1 mm。

采用Nikon EPIPHOH 300金相显微镜和带有X射线能谱仪(EDS)的JEOL JSM-7001F型场发射扫描电子显微镜(SEM)观察合金显微组织以及微观形貌。采用D/max-2500PC型X射线衍射仪进行物相分析,扫描速度为6 (°)/min,步宽为0.01°、Cu靶、管电流为200 mA,扫描角度为30°~80°。

2 结果与分析

2.1 显微组织、XRD分析及硬度

镍铝青铜的合金元素较多,Cu、Al、Ni、Fe、Mn可以生成很多种化合物,组织十分复杂,通常由α相(一种面心立方的富铜固溶体)、β相(一种高温相,室温时为β′相)和κ相(金属间化合物)组成。相关资料[10-11]显示,κ相又可以分为很多种。κI相呈球状或玫瑰花状,是一种富铁相(基于Fe3Al的金属间化合物)。κII相表现为树枝状的玫瑰花形,其不规则地分布在α/β边界上,比κI相的玫瑰花结小。κIII相是以一种层片状的形式出现,有时会以棒状或球状的(退化层状的)形式出现。它通常生长在α/β边界上,也会在粗大的κI相边界处形成,并且被描述成富镍相(AlNi)。κIV相是一种存在于α相内很细的沉淀物,多被认为是富铁相。其中,高温β相缓慢冷却时,会转变为α相,并伴随着在晶粒边界上呈层片状分布的κIII相和球状κII相的生成。在常规空冷条件下,冷却速度并不会足够慢,并且铸件厚薄不均,冷却速度也不尽相同。因此,部分高温β相会转变成α相以及κIII相和κII相,还有部分没有时间冷却的β相,因其具有马氏体组织,也被称作β′相。

表1 合金的化学组成

Table 1 Chemical composition of alloy

图1所示为未微合金化和微合金化铸态镍铝青铜的XRD谱。图2所示为未微合金化和微合金化铸态镍铝青铜的显微组织。从图1可以看出,微合金化前后镍铝青铜相的成分并没有发生显著变化,这也与图2中所看到的组织相符合,只是α相、κIII相以及κIV相明显变少了。图中只标出了单一的α相,且出现了右偏峰,这是α相是固溶体的缘故。其他相含量很低,XRD未能检测出。

相比之下可以看出,微合金化镍铝青铜组织中的β相、κI相和κII相没有明显变化;α相显著细化,面积只为原来的几分之一;棒状κIII相的长度大大缩短,但数目却增加许多;α相内κIV相也明显变少,在图中以灰白点的形式出现,而非原来点状的凹坑,这些都说明了微合金化元素起到了细化组织的作用。

硬度测量显示,未微合金化铸态镍铝青铜硬度为212.1HV,微合金化铸态镍铝青铜硬度为240.7HV,硬度提高了约13.4%,这主要是硬质点κ相变小,数目增多,分布均匀的缘故。

2.2 均匀腐蚀性能

表2所列为未微合金化和微合金化铸态镍铝青铜的均匀腐蚀速率。相比之下,可以看出二者在常温下的均匀腐蚀速率都很低,都处在腐蚀四级标准[12]中的优良级。但微合金化后的镍铝青铜具有更好的耐均匀腐蚀性能,其均匀腐蚀速率比未微合金化铸态镍铝青铜的均匀腐蚀速率降低了约5.2%。

图1 未微合金化和微合金化铸态镍铝青铜的XRD谱

Fig. 1 XRD patterns of un-micro-alloying (a) and micro- alloying (b) nickel-aluminium bronze ingot

图3所示为未微合金化和微合金化铸态镍铝青铜合金经均匀腐蚀后的SEM像。由图3可以看出,微合金化铸态镍铝青铜的表面腐蚀损坏面积比未微合金化铸态镍铝青铜的要小。合金表面亮白色点状物质是腐蚀沉淀物,其主要成分是铜和铝。图3(a)中明显突出合金表面的玫瑰花结是κI相,这说明κI相腐蚀程度较轻,基本没有受到腐蚀;κII相和α相内的κIV相在图中看不清楚,但可以很明显的辨别出其腐蚀很轻;而腐蚀严重的区域有明显的凹坑,且凹坑面积较大、坑内凹凸不平犹如沟壑一般,这是镍铝青铜的共析组织优先受到腐蚀[13-14]所致。腐蚀开始时,共析组织(如图中箭头所示)内的α相优先受到攻击,但是腐蚀速率较低。这是共析区域内大量阴极κIII相的出现以及共析区域内阳极和阴极相互毗邻的缘故。腐蚀开始时,富铜α相相对于κIII相来说是阳极,优先以很低的速率腐蚀。但是,随着时间的延长,最先受到保护的κIII相相对于α相来说会成为阳极,而连续分布的κIII相会加快合金的腐蚀,形成巨大的凹坑。微合金化后的铸态镍铝青铜由于α相的细化,棒状κIII相的长度缩短且分布更加弥散,其形成贯通腐蚀通道的能力就会降低,因此,耐腐蚀性能大大提高。

图2 未微合金化和微合金化铸态镍铝青铜的显微组织

Fig. 2 Microstructures of un-micro-alloying ((a), (c)) and micro-alloying ((b), (d)) nickel-aluminium bronze ingot

表2 未微合金化和微合金化铸态镍铝青铜的均匀腐蚀实验结果

Table 2 Testing results of uniform corrosion of un-micro-alloying and micro-alloying nickel-aluminium bronze ingot

图3 未微合金化和微合金化铸态镍铝青铜均匀腐蚀的SEM像

Fig. 3 SEM images of uniform corrosion of un-micro- alloying (a) and micro-alloying (b) nickel-aluminium bronze ingot

2.3 电化学腐蚀性能

图4所示为未微合金化和微合金化铸态镍铝青铜的动电位极化曲线。表3所列为其自腐蚀电位(φ0)、腐蚀电流密度(J0)和腐蚀速率(v)。可以看出,二者几乎同时发生了明显的钝化,但是微合金化铸态镍铝青铜自腐蚀电位较高,腐蚀电流密度较低,腐蚀速率明显下降(比前者降低了17.8%),说明微合金化铸态镍铝青铜具有更好的抗电化学腐蚀性能。

图4 未微合金化和微合金化铸态镍铝青铜的动电位极化曲线

Fig. 4 Potentiodynamic polarization curves of un-micro- alloying and micro-alloying nickel-aluminium bronze ingot

表3 未微合金化和微合金化铸态镍铝青铜电化学腐蚀参数

Table 3 Electrochemical corrosion parameters of un-micro- alloying (a) and micro-alloying (b) nickel-aluminium bronze ingots

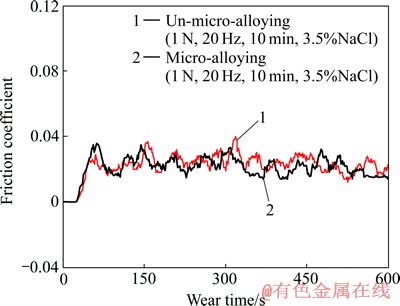

2.4 摩擦磨损性能

图5所示为未微合金化和微合金化铸态镍铝青铜摩擦因数随磨损时间变化的曲线。可以看出,微合金化铸态镍铝青铜具有较低的平均摩擦因数,其平均值分别约为0.025 2和0.019 3。该曲线表明,摩擦在初始跑合阶段,摩擦因数随时间增加而急剧上升,达到最高点后迅速下降,然后趋于上下波动的稳定阶段。尽管在跑合阶段,微合金化铸态镍铝青铜的摩擦因数更高,但是在后续的摩擦过程中,微合金化铸态镍铝青铜基本上保持较低的摩擦因数且更加稳定。

图5 未微合金化和微合金化铸态镍铝青铜摩擦因数随磨损时间变化的曲线

Fig. 5 Changing curves of friction coefficient of un-micro- alloying and micro-alloying nickel-aluminium bronze ingot with wear time

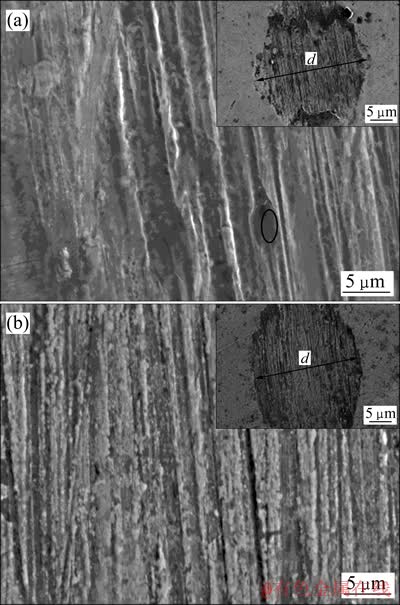

图6所示为未微合金化和微合金化铸态镍铝青铜磨痕的SEM像和宽度。其中嵌入图为低倍磨痕宽度图。可以看出,摩擦后的表面特征[15]主要有以下4点:1) 沿活动方向上存在明显的犁沟和犁皱,图6(a)中的犁沟深且宽;2) 存在痘状凹坑(见图中红圈处),这些凹坑是硬质点脱落形成的;3) 犁沟旁边存在光滑的承载面,说明该区域在摩擦力的作用下发生塑性变形,但在该区域没有发现裂纹的存在,说明无脆性断裂现象;4) 从图6(a)的磨痕宽度图可以看出,其磨痕的起始和终止段剥落较为严重,发生严重的剥层脱落现象,而图6(b)中没有发现剥层现象。

从图6分析可知,微合金化后的铸态镍铝青铜磨痕宽度稍小,耐磨性能更好。在摩擦过程中,部分剥落的硬质颗粒κ相(主要是富铁相)会被压入合金的表面,并在摩擦力的作用下沿着沿摩擦力方向产生运动。运动的磨粒会对基体产生犁沟或微切削作用形成剥落物,磨粒会把材料推向两边或前后边缘形成犁皱,犁皱在继续摩擦过程中会再次变形,形成塑性变形区。该区域在法相载荷的作用下被压平,经过反复的塑性变形造成该区域产生加工硬化,最后形成光滑的支撑面。磨粒的大小、形状各异,所以产生的犁沟大小、沟形也不尽相同。微合金化后的铸态镍铝青铜中α相内部的硬质点κIV相(富铁相)更细,分布更加均匀,在发生磨粒磨损时,硬质点κIV相对基体产生的犁沟会更窄更浅,而且共析组织内呈层片状分布的棒状κIII相(软体相,AlNi)更短,分布也更均匀,既可阻碍基体的块状剥落,也可降低产生微切削的概率,因此,其耐磨性能更佳。

图6 未微合金化和微合金化铸态镍铝青铜磨痕的SEM像和宽度

Fig. 6 SEM images and width of wear scar of un-micro- alloying (a) and micro-alloying (b) nickel-aluminium bronze ingot

3 结论

1) 在镍铝青铜中加入微量Sc、Zr和Sr,可以显著细化合金组织,使组织分布更加弥散,大幅提高合金硬度及其腐蚀和摩擦学性能。

2) 镍铝青铜的腐蚀优先发生在共析组织(α+κIII)中,而细化后的共析组织降低腐蚀通道产生的概率,在一定程度上使得合金表面的腐蚀面积减小了。

3) 镍铝青铜磨损主要是由于硬质点κ相剥落而产生的磨粒磨损,大量细小的κIV相(富铁相)和κIII相(软体相)增加了合金的耐磨性和韧性,提高合金的耐磨性。

4) 通过合理的铸造,成功制备一种含0.045%Zr、0.057%Sc和0.029%Sr的镍铝青铜合金,其硬度为240.7HV,均匀腐蚀速率、电化学腐蚀速率和摩擦因数分别降低了5.2%、17.8%和23.4%。

REFERENCES

[1] Barik R C, Wharton J A, Wood R J K, Tan K S, Stokes K R. Erosion and erosion-corrosion performance of cast and thermally sprayed nickel-aluminium bronze[J]. Wear, 2005, 259: 230-242.

[2] NI D R, XIAO B L, MA Z Y, QIAO Y X, ZHENG Y G. Corrosion properties of friction-stir processed cast NiAl bronze[J]. Corrosion Science, 2010, 52: 1610-1617.

[3] 宋德军, 孙现龙, 许 磊, 叶景涛, 胡伟民. 变形镍铝青铜合金的组织研究[J]. 稀有金属, 2008, 32(4): 420-424.

SONG De-jun, SUN Xian-long, XU Lei, YE Jing-tao, HU Wei-min. Research on microstructure of deforming nickel-aluminium braze alloy[J]. Chinese Journal of Rare Metals, 2008, 32(4): 420-424.

[4] 刘 平, 任凤章, 贾淑果. 铜合金及其应用[M]. 北京: 化学工业出版社, 2007: 102-108.

LIU Ping, REN Feng-zhang, JIA Shu-guo. Copper alloy and its application[M]. Beijing: Chemical Industry Press, 2007: 102-108.

[5] 郭青蔚, 王桂生, 郭庚辰. 常用有色金属二元合金相图集[M]. 北京: 化学工业出版社, 2009: 68.

GUO Qing-wei, WANG Gui-sheng, GUO Geng-chen. Commonly used nonferrous metal atlas of binary alloy phase[M]. Beijing: Chemical Industry Press, 2009: 68.

[6] 尹登峰, 郑子樵, 余志明. Sc对Al-Li-Cu-Mg-Ag-Zr合金组织和性能的影响[J]. 稀有金属材料与工程, 2003, 32(9): 736-739.

YIN Deng-feng, ZHENG Zi-qiao, YU Zhi-ming. Effect of Sc on microstructure and properties of Al-Li-Cu-Mg-Ag-Zr alloy[J]. Rare Metal Materials and Engineering, 2003, 32(9): 736-739.

[7] 毛建伟, 金头男, 徐国富. 含钪Al-Cu合金的显微组织[J]. 中国有色金属学报, 2005, 15(6): 923-928.

MAO Jian-wei, JIN Tou-nan, XU Guo-fu. Microstructure of Al-Cu alloy containing scandium[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(16): 923-928.

[8] JB/T 7901—1999. 金属材料实验室均匀腐蚀全浸试验方法[S].

JB/T 7901—1999. Mental materials-uniform corrosion-methods of laboratory immersion testing[S].

[9] KEAR G, BARKER B D, STOKES K, WALSH F C. Flow influenced electrochemical corrosion of nickel aluminium bronze[J]. Journal of Applied Electrochemistry, 2004, 34: 1241-1248.

[10] WHARTON J A, BARIK R C, KEAR G, WOOD R J K, STOKES K R, WALSH F C. The corrosion of nickel aluminium bronze in seawater[J]. Corrosion Science, 2005, 47: 3336-3367.

[11] Wharton J A, Stokes K R. The influence of nickel–aluminium bronze microstructure and crevice solution on the initiation of crevice corrosion[J]. Electrochimica Acta, 2008, 53: 2463-2473.

[12] 张文奇, 石声泰, 肖纪美. 金属腐蚀手册[M]. 上海: 上海科学技术出版社, 1987: 114-127.

ZHANG Wen-qi, SHI Sheng-tai, XIAO Ji-mei. Metal corrosion manual[M]. Shanghai: Shanghai Science and Technology Press, 1987: 114-127.

[13] Al-HASHEM A, RIAD W. The role of microstructure of nickel-aluminium-bronze alloy on its cavitation corrosion behavior in natural seawater[J]. Materials Characterization, 2002, 48: 37-41.

[14] FONLUPT S, BAYLE B, DELAFOSSE D, HEUZE J L. Role of second phases in the stress corrosion cracking of a nickel- aluminium bronze in saline water[J]. Corrosion Science, 2005, 47: 2792-2806.

[15] 徐建林, 陈 超, 喇培淸, 王智平, 李海兰, 刘明朗, 朱小武. 新型铸造铝青铜的润滑摩擦性能[J]. 中国有色金属学报, 2004, 14(6): 917-921.

XU Jian-lin, CHEN Chao, LA Pei-qing, WANG Zhi-ping, LI Hai-lan, LIU Ming-lang, ZHU Xiao-wu. Lubrication friction performance of new as-cast aluminum bronze[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 917-921.

(编辑 李艳红)

基金项目:江苏大学优秀学术青年骨干培养对象基金资助项目(1211110001);校企产学研合作项目(1801110288)

收稿日期:2012-12-27;修订日期:2013-07-24

通信作者:许晓静,教授,博士;电话:0511-88792058;E-mail: xjxu67@ujs.edu.cn