氮化锰的微波合成

黄加伍, 李 俊, 彭 虎, 雷 春

(长沙隆泰科技有限公司, 长沙 410013)

摘 要: 以74μm锰粉为原料, 在氢气和氮气的混合气、 750℃以及保温2h的条件下于微波反应器中合成氮含量为7.75%(质量分数)的氮化锰。 研究了粉末粒度、 合成温度、 合成保温时间及合成气氛对合成产物氮含量的影响。 结果表明: 氮化气氛需要氢气和氮气的混合气体, 氮化气氛中少量的氢促进了原料氮化和除去杂质氧。 微波高温合成技术的合成温度和合成时间较传统工艺具有明显的优势。

关键词: 氮化锰; 铁合金; 微波合成; 传统合成 中图分类号: TF123.134

文献标识码: A

Microwave synthesis of manganese nitride

HUANG Jia-wu, LI Jun, PENG Hu, LEI Chun

(Changsha Longtech Co. LTD., Changsha 410013, China)

Abstract: The nitro-manganese with nitrogen content up to 7.75% was synthesed using 74μm manganese powder as materials under condition of H2 and N2mixture atmosphere, 750℃ and holding time 2h in microwave applicator. The effects of particle size, synthesis temperature, holding time and reaction atmosphere were studied. The results show that the nitration atmosphere is mixture of N2(95%) and H2(5%). The small amounts of hydrogen in the nitrification atmosphere accelerates the nitrification of materials and purifies the oxygen impurities. The microwave synthesis is superior to conventional nitration in peak temperature and holding time.

Key words: manganese nitride; ferro-alloy; microwave synthesis; conventional synthesis

锰在炼钢中起着脱氧、 脱硫和合金化等作用。 锰的存在能消除或减弱因硫引起的热脆性, 从而提高钢的热加工性能; 锰能与铁形成固熔体以提高钢中铁素体和奥氏体的硬度和强度。 锰也是碳化物形成元素进入渗碳体中取代一部分铁原子, 锰在钢中降低临界转变温度, 细化珠光体晶粒并提高珠光体钢的强度。 锰能扩大Fe-C平衡相图中的γ相区, 使钢形成和稳定奥氏体组织的能力仅次于镍, 同时也提高了钢的淬火性[1]。

在炼钢中常将氮和钢的脆性联系在一起, 但氮也是一种廉价的合金化元素。 在高氮钢中, 由于引入了元素氮, 氮与钢中的其他元素交互作用时能赋予该钢种许多优异的性能, 如强度、 韧性好, 蠕变抗力大及耐腐蚀性好等。 氮最初作为奥氏体元素代替镍而用于奥氏体中以节省元素镍而改善材料性能[2]。

基于上述锰、 氮的各种用途, 往往在冶炼某些有色金属及合金钢时, 需同时加入这两种元素, 但单独加入这两种元素时, 存在着一些不便的因素, 如氮的溶解度低、 比重小、 不易加入, 而氮化锰合金则不仅易于加入, 而且锰、 氮的利用率高, 因而能弥补这些不足[1]。

随着社会的发展, 国内外对氮化锰的需求越来与大。 而传统氮化锰的生产一般在真空电阻炉内进行, 所用原料为固态中低碳锰铁或金属锰, 经过球磨、 压块, 在1273~1373K氮气气氛中合成氮含量为4%~6%的合金[3]。 传统方法的不足主要为氮化时间长及氮含量低。

微波合成是利用微波加热来合成材料, 它与传统的加热方式不同。 传统的加热是依靠发热体将热能通过对流、 传导或辐射方式传递至被加热物质而达到某一温度, 热量从外向内传递, 合成时间长、 能耗高; 而微波合成则是利用微波独特的波段与材料的基本结构耦合而产生的材料介质损耗使其材料整体加热的一种加热方式, 因而具有合成温度低、 合成时间短及能耗低等一系列优势[4, 5]。

本文作者应用微波能高温合成技术有效地合成含氮量较高的氮化锰, 对合成工艺进行了系统地研究, 并与传统工艺进行对比分析。

1 实验

1.1 实验原料及设备

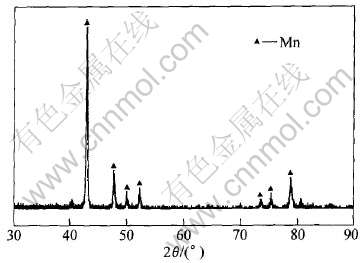

本研究所用电解金属锰片由湖南省冶金材料研究所提供, 其主要化学组成成分为99.71%Mn, 0.125%Fe, 0.014%Al, 0.085%Si, 0.025%C, 0.009%P, 0.032%S(质量分数)。 原料的X射线衍射谱如图1所示。

图1 原料的X射线衍射谱

Fig.1 XRD pattern of raw material

本研究所用的气体为瓶装纯氮和瓶装氢气与氮气的混合气体, 纯氮按GB/T8980—1996执行, 混合气体参照GB/T8980—1996和GB/T3634—1995执行。 混合气体中的氢气含量为5%, 余量为氮气。 所用的设备为MW-L0316V隆泰微波炉, 其结构如图2所示。 微波频率为2.45 GHz, 功率为3kW高精度程控微波源, 微波炉内为可调转速的承载系统, 在炉内可形成大空间高能量密度和高均匀分布相统一的微波场。 测温采用Raytek高精度红外测温仪测温。

图2 Longtech微波炉照片

Fig.2 Photo of longtech microwave oven

1.2 制备方法及实验方案

制备过程为: 机械破碎→过筛→成型→排胶→加料入炉→抽真空→充氮气→升温进行氮化操作→降温→出炉取样→质检。

具体实验方案如下。

1) 渗氮方法 采用固态粉末气态渗氮, 选择纯氮和氢、 氮混合气体。

2) 渗氮温度 根据Mn-N相图[6, 7]和前人的研究工作[1, 3], 温度为700℃~850℃。

3) 渗氮时间 根据前人的研究工作[8, 9]结合微波合成的特点[10], 合成时间选择为0.5~3h。

4) 渗氮的试样 选择机械球磨破碎, 选取不同的粒度进行实验。

1.3 样品检测

X射线衍射采用Cu靶, 日本理学D/max-rA衍射仪。 化学滴定法检测N含量, 采用凯氏定氮法测定, 样品与硫酸和催化剂一同加热硝化。 生成的氨与硫酸结合生成硫酸铵, 然后加碱蒸馏使氨气逸出, 用过量的硼酸吸收后, 以酸滴定测出氮含量。 根据消耗掉盐酸标准溶液的体积, 按公式w(N)={[(V2-V1)×c(HCl)×0.014]/m}×100 计算氮含量。 其中w(N)为样品的总氮含量, %; V1为空白滴定时消耗盐酸标准溶液的体积, mL; V2为试样滴定时消耗盐酸标准溶液的体积, mL; c(HCl)为盐酸标准溶液的浓度, mol/L; m为试样的质量, g; 0.014为与1mL盐酸标准溶液(c(HCl)=1mol/L)相当的、 以克表示的氮质量。 氮含量的测量精度: 测定总氮平行实验测定值之差小于0.3%[11]。

2 结果与讨论

2.1 X射线衍射分析

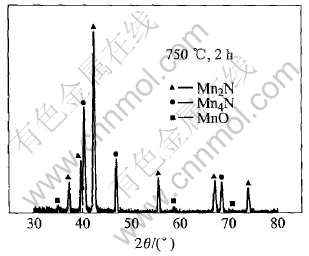

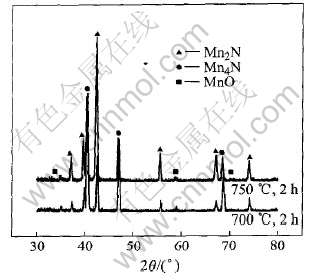

图3所示为产物的X射线衍射谱。 由图3中可看出, 原料中单质Mn的衍射峰已不能看到; 所有强衍射峰均由Mn4N、 Mn2N产生, 说明单质Mn已被氮化; 除了强衍射峰之外, 还有弱的衍射峰存在, 主要为MnO。

图3 合成氮化锰产物的X射线衍线谱

Fig.3 XRD pattern of synthesized manganese nitride

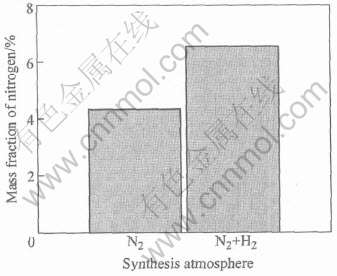

2.2 采用不同的渗氮气氛合成样品氮含量效果对比

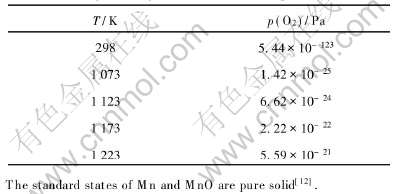

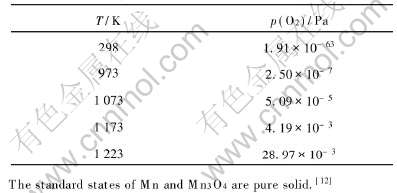

采用不同的渗氮气氛合成效果对比如图4所示。 由图4中可看出, 在相同的温度、 相同的合成时、 不同气氛合成样品的氮含量相差很大, 从出炉的颜色也可以看出渗氮气氛对样品氮含量的影响非常明显: 采用氢气与氮气的混合气体合成样品时, 样品表面呈绿色, 厚度很薄, 主体颜色呈灰色; 采用纯氮合成样品时, 样品呈棕褐色, 氮含量较低。 造成纯氮合成样品氮含量较低的主要原因是由于合成体系中含有一定的O-2, 在整个升温和保温过程中只要体系中存在O-2, 即使在极低的氧分压条件下也会生成MnO或者Mn3O4(从表1和2中可看出氧化的氧分压条件), 体系中一旦形成MnO和Mn3O4, 将会抑制Mn的氮化。 本研究采用氢气和氮气的混合气体微波合成有效地实现抑制Mn和MnO的氧化, 实现了Mn的氮化, 其相结构图如图3和5所示。

图4 微波合成气氛对氮含量的影响

Fig.4 Effect of synthesis atmosphere on nitrogen content of products

表1 不同温度下生成MnO的平衡氧分压

Table 1 Oxygen equilibrium pressures of MnO growing at different temperatures

表2 不同温度时由MnO生成Mn3O4的平衡氧分压

Table 2 Oxygen equilibrium pressures of Mn3O4 produced by MnO at different temperatures

图5所示为样品分别在700℃和750℃下微波合成2h氮化锰产物的X射线衍射谱。 从图5中可明显看出, 700℃时合成的Mn2N比750℃时合成的Mn2N的衍射峰小, 检测氮含量也相对较少。

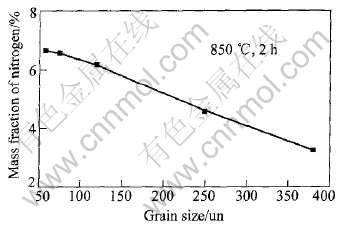

2.3 采用不同粒度锰粉合成对氮含量的影响

微波合成样品粒度对合成产物氮含量的影响如图6所示(850℃, 2h)。 从图6可看出, 随着试样粒度的细化, 产物氮含量逐步提高, 但细化到74μm后, 氮含量增加变得越来越不明显。 这是由于对给定质量的金属锰试样, 其粒度愈小, 比表面积愈大, 发生气固作用的界面和表面原子内扩散面积

图5 合成氮化锰产物的X射线衍射谱

Fig.5 XRD patterns of synthesized manganese nitride

图6 样品的粒度对合成产物氮含量的影响

Fig.6 Effect of grain size on nitrogen content of synthesized products

均显著增大, 明显有利于原子的扩散和大幅度提高试样的渗氮速度。 另一方面, 在上述相同渗氮条件下, 试样表面的氮原子浓度相等, 显然, 试样粒度愈大, 扩散距离相应增加, 产生扩散推动力的浓度梯度相应降低, 明显不利于原子的扩散及渗氮速度的提高。 此外, 根据扩散和扩散控制有关理论, 锰原子的扩散速度远小于氮原子的扩散速度。 结合本研究结果, 可认为渗氮过程的主要控制环节为[N]在Mn-N系的各种生成物的扩散速度及其在金属锰中的扩散速度。 当粒度细化到一定程度(74μm), 在微波合成温度和合成时间条件下, 氮原子能较充分地扩散并能达到扩散地路程, 再细化粉体后氮含量增加变得不明显。

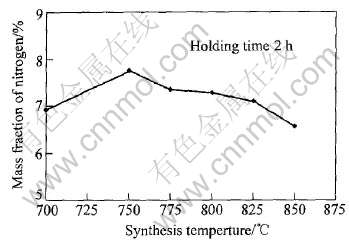

2.4 反应合成温度对氮含量的影响

合成温度对反应产物氮含量的影响如图7所示(粒度小于74μm, 保温2h)。 从图7中可以看出,各样品在同样其他微波合成条件下, 当温度小于750℃时, 随着温度的增加, 样品氮含量随之增加; 超过750℃后, 随着温度的增高, 样品的氮含量逐渐减少, 主要原因是由于生成的Mn2N不稳定, 发生了Mn2N[FY]Mn4N+N2 反应。 微波合成温度明显于常规合成温度(850℃), 主要的原因是由于微波与材料(锰原子与氮原子)相互作用, 产生的热效应与非热效应(特别是非热效应)增强了原子的活性, 降低了生成氮化锰的活化能, 促进了合成反应, 使合成能在较低的温度下较快地完成[13]。

图7 合成温度对产物氮含量的影响

Fig.7 Effect of sythesis temperature on nitrogen content of products

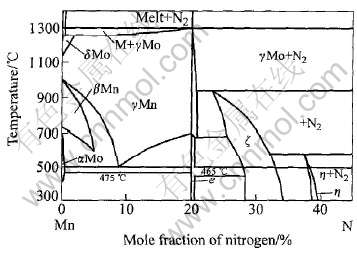

图8所示为Mn-N二元相图。 从图8中可以看出, 当氮含量为18%~20%(摩尔分数), 主要的相结构为Mn4N。 为了达到合成出氮含量为20%~30%(摩尔分数)的效果, 从Mn-N相图分析来看, 合成温度必须在930℃以下, 高于930℃, 合成的Mn2N是不稳定的, 合成过程中过量的氮气有利于氮化锰的合成; 当氮含量大于20%(摩尔分数)时,出现相结构Mn2N, 本研究显示的最佳微波合成温度为750℃。

图8 Mn-N二元相图[7]

Fig.8 Mn-N binary phase diagram

2.5 反应合成时间对氮含量的影响

合成保温时间对氮含量的影响如图9所示。 由图9可看出, 当合成保温时间为30~60min时, 随着时间延长, 氮含量增加较快; 当合成保温时间为60~120min时, 氮含量增加较慢; 当合成保温大于120min时, 氮含量增加较少。 主要是由于金属锰渗氮过程的主要环节为氮原子在Mn-N系各种生成物中的扩散及其在金属锰粉中的扩散, 因此, 合成过程需要一定的保温时间。 但由于同时微波穿透介质样品, 使整体样品的颗粒表面和晶粒界面的原子在微波能的驱动下扩散速度增强[14], 加快了氮原子在介质中的扩散[15], 从而使氮化时间较传统工艺有明显的缩短。 因此, 在保温时间为120min时, 氮化过程基本完成。

图9 合成保温时间对产物氮含量的影响

Fig.9 Effect of holding time on nitrogen content of products

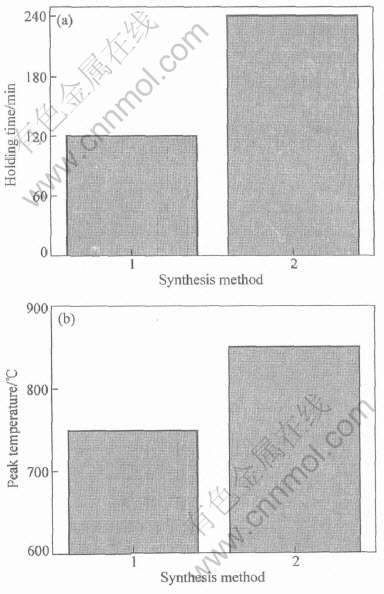

2.6 微波合成与传统合成工艺对比

在微波合成效果(氮含量)达到或超过传统真空电阻炉合成工艺条件时, 微波工艺与传统工艺对比如图10所示。 从图10中可以明显看出, 氮化锰采用微波设备合成具有很明显的优势, 该技术填补了我国合成氮化锰技术的一项空白。 合成温度比传统的合成温度至少低100℃, 合成保温时间仅为传统工艺合成保温时间的1/2, 甚至更短, 充分发挥了微波合成的高效、 省时、 节能的特点, 有着广阔的工业应用前景。

3 结论

1) 由金属锰采用微波氮化合成氮化锰工艺技术, 填补了国内生产氮化锰技术的一项空白, 合成温度和合成时间较传统工艺有明显的优势, 具有广阔的工业应用前景。

图10 微波合成(2.45GHz)与传统合成工艺对比

Fig.10 Comparison of microwave(1) and conventional(2) synthesis processing of nitro-manganese

2) 以74μm锰粉为原料, 在750℃, 保温2h的条件下合成氮含量7.75%的氮化锰。

3) 氮化气氛宜采用氢气和氮气的混合气体, 否则易出现氧含量过高, 从而抑制氮化过程的进行。

REFERENCES

[1]蒋汉祥, 刘廷军, 戴清香. 制取氮化锰工艺和技术[J]. 重庆大学学报(自然科学板), 2001, 24(4): 102-105.

JIANG Han-xiang, LIU Ting-un, DAI Qing-xiang. Nitration process and technology research on MnN[J]. Journal of Chongqing University(Natural Science Edition), 2001, 24(4): 102-105.

[2]梁连科. 氮化铁合金的研制及其有关问题[J]. 铁合金, 1998(4): 15-17.

LIANG Lian-ke. Manufacture of nitrogen-containing ferro-alloys[J]. Ferro-alloys, 1998(4): 15-17.

[3]崔先云. 回转法可控气氛生产氮化锰铁的实践[J]. 铁合金, 2001(1): 12-16.

CUI Xian-yun. Practice for smelting nitrided ferromanganese in controlled atmosphere with rotary kiln process[J]. Ferro-alloys, 2001(1): 12-16.

[4]周健, 程吉平, 袁润章, 等. 微波烧结WC-Co 细晶粒硬质合金的工艺与性能[J]. 中国有色金属学报, 1999, 9(3): 465-468.

ZHOU Jian, CHENG Ji-pin, YUAN Run-zhang, et al. Property and technology of WC-Co fine grain cemented carbide in microwave sintering[J]. The Chinese Journal of Nonferrous Metals 1999, 9(3): 465-468.

[5]瞿秀静, 符岩, 王云霞, 等. 微波合成锂离子电池正极材料LiCoO2[J]. 东北大学学报(自然科学版), 2003, 24(12): 1192-1194.

ZHAI Xiu-jing, FU Yan, WANG Yun-xia, et al. Microwave synthesized LiCoO2 as cathode material for lithium ion Battery[J]. Journal of Northeastern University (Natural Science), 2003, 24(12): 1192-1194.

[6]Hansen M, Anderko K. Constitution of Binary Alloys[M]. New York: McGraw Hill, 1958.

[7]Qiu C, Guillermet A F. Predicative approach to the entropy of manganese nitrides and calculation of the Mn-N phase diagram[J]. Metallkd Z, 1993, 84(1): 11-22.

[8]Гаснкwriter М И. 铁合金生产的理论和工艺[M]. 张烽, 译. 北京: 冶金工业出版社, 1994.

Гаснкwriter М И. Theory and techniques of production in ferro-alloys[M]. ZHANG Feng, transl. Beijing: Metallurgical Industry Press, 1994.

[9]Poulalion A, Botte R. Nitrogen addition in steelmaking using nitriding ferr-oalloys[A]. Foct J, Hendry A. International Conference on High Nitrogen steels-HNS88[C]. London: Carlton House Terrace, 1989. 49-52.

[10]李俊, 罗柳娟, 彭虎. 微波碳热还原制备氮化钒的研究和实践[J]. 铁合金, 2005, 36(3): 23-25.

LI Ju, LUO Liu-juan, PENG Hu. Study and practice of synthesis of vanadium nitride by microwave carbothermal reduction[J]. Ferro-alloys, 2005, 36(3): 23-25.

[11]中华人民共和国黑色冶金行业标准YB/T. 氮化锰[S].

Peoples Republic of China YB/T. Nitro-manganese[S].

[12]张金柱. 锰铁渗氮的热力学和动力学研究[D]. 重庆: 重庆大学, 2004.

ZHANG Jin-zhu. Studies on thermodynamics and kinetics of ferromanganese nitriding[D]. Chongqing: Chongqing University, 2004.

[13]Jung K S, Kwon J H, Sonb S M, et al Characteristics of the copper phthalocyanines synthesized at various conditions under the classical and microwave processes[J]. Synthetic Metals, 2004, 141(3): 259-264.

[14]Miyake S, Matsumoto T, Niinou A, et al. Application of Mirror-confinement-type ECR Plasma Sputtering and Microwave Radiation to the Low Temperature Synthesis of Crystallized HIGH-K Material Thin Films[M]. Oho: Microwave and Radio Frequency Applications, 2004. 138-146.

[15]徐庆, 陈文, 张枫, 等. Fe2O3-MnO2-CuO-Co2O3体系红外辐射材料的微波合成与表征[J]. 中国有色金属学报, 2001, 11(2): 127-130.

XU Qing, CHEN Wen, ZHANG Feng, et al. Microwave synthesis and characterization of Fe2O3-MnO2-CuO-Co2O3[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 127-130.

(编辑李艳红)

收稿日期: 2005-09-07; 修订日期: 2006-01-13

通讯作者: 黄加伍,电话: 0731-8803318; E-mail: hjw@longtech.cn