文章编号:1004-0609(2013)07-1990-06

水对常压干燥制备块状TiO2气凝胶显微结构的影响

卢 斌,张丁日,宋 淼,卢孟磊

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:以钛酸丁酯(TTIP)为前驱体、乙酸为催化剂、甲酰胺为干燥控制化学添加剂,通过控制原料中TTIP与H2O的摩尔比以及老化液中H2O与乙醇(EtOH)的摩尔比,并结合常压干燥工艺,制备块状TiO2气凝胶。采用XRD、BET、SEM和FT-IR等对样品进行表征。结果表明,当原料中TTIP与H2O的摩尔比为1:4、老化液中H2O与EtOH的摩尔比为5:2时,TiO2气凝胶具有最小表观密度(0.15 g/cm3)、最大比表面积(573.4 m2/g)、孔径分布集中、块体体积约为16.0 cm3。

关键词:TiO2气凝胶;溶胶-凝胶法;常压干燥法

中图分类号:O648 文献标志码:A

Effect of H2O on microstructure of TiO2 aerogel with block size prepared by ambient pressure drying process

LU Bin, ZHANG Ding-ri, SONG Miao, LU Meng-lei

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: TiO2 aerogels with block size were prepared by ambient pressure drying process via sol-gel technology using tetrabutyl orthotitanate (TTIP) as precursor, acetic acid as catalyst, formamide as drying control chemical additive. The influencing factors of the molar ratio of TTIP to H2O, the molar ratio of H2O to EtOH in the aging liquid were analyzed. The structures of the samples were characterized by XRD, BET, SEM and FT-IR. The results indicate that when molar ratios of TTIP to H2O and H2O to EtOH are 1:4 and 5:2, respectively, the prepared TiO2 aerogels have the best performance of the least bulk density of 0.15 g/cm3, the largest specific surface area of 573.4 m2/g, and the block volume of about 16.0 cm3.

Key words: TiO2 aerogel; sol-gel method; ambient pressure drying

TiO2气凝胶作为一类新型纳米轻质多孔无机功能材料,具有比表面积大、孔隙率高以及化学稳定性好、对人体无毒害、催化活性和吸附性较高等优异性能[1],在空气净化、废水处理以及有机污染物的光催化降解等领域具有广泛应用[2-4],是一种很有发展前景的绿色环保型光催化材料。

TiO2气凝胶成块问题是制约其循环使用的关键。通常,块状TiO2气凝胶是以钛酸丁酯(TTIP)为前驱体,结合CO2超临界干燥工艺制得。YUSUKE等[5]以TTIP为前驱体、乙酸为催化剂,采用丙酮溶剂置换和CO2超临界干燥工艺,制得块状TiO2气凝胶;王鲜等[6]以TTIP为前驱体、HCl为催化剂,通过控制TTIP和H2O的摩尔比,采用CO2超临界干燥工艺,制备块状TiO2气凝胶;甘礼华等[7]以TTIP为前驱体、HNO3为催化剂,通过控制原料配比,采用CO2超临界干燥工艺,制得块状TiO2气凝胶。然而,超临界干燥工艺对设备要求高、制备周期长、不利于工业化生产[8],而常压干燥工艺被认为是TiO2气凝胶工业化生产的理想方法。目前,有关对常压干燥工艺制备块状TiO2气凝胶研究的报道很少。在常压干燥工艺中,水的用量对TiO2气凝胶成块性能至关重要[9],本文作者结合前期研究成果[10],较系统地研究原料中TTIP和H2O的摩尔比以及老化液中H2O与EtOH的摩尔比对TiO2气凝胶微观结构的影响,通过常压干燥工艺制备出性能优异的块状TiO2气凝胶。

1 实验

1.1 试剂和仪器

试剂:钛酸四丁酯(TTIP)为化学纯;无水乙醇(EtOH)、乙酸(HAc)、甲酰胺、正硅酸乙酯(TEOS)和正己烷均为分析纯;去离子水(H2O)为自制。

仪器:荷兰FEI公司生产的Sirion 200型场发射扫描电镜(SEM);美国Nicolet公司生产的AVATAR-360型傅里叶红外光谱仪;美国康塔公司生产的NOVA 2002e型比表面及孔径分析仪(300 ℃脱气处理3 h,77 K下吸附N2)。

1.2 块状TiO2气凝胶的制备

TiO2醇凝胶的制备:将钛酸四丁酯(TTIP)、无水乙醇和乙酸按一定比例混合均匀,记为溶液A;将一定量乙酸、去离子水及无水乙醇混合均匀,记为溶液B。将溶液B缓慢滴加入溶液A中,搅拌一定时间后,滴入适量甲酰胺并搅拌均匀,30 ℃下静置凝胶,得到TiO2醇凝胶。钛酸四丁酯、无水乙醇、乙酸、水、甲酰胺的摩尔比为1:20:1.2:(2~7):0.6。

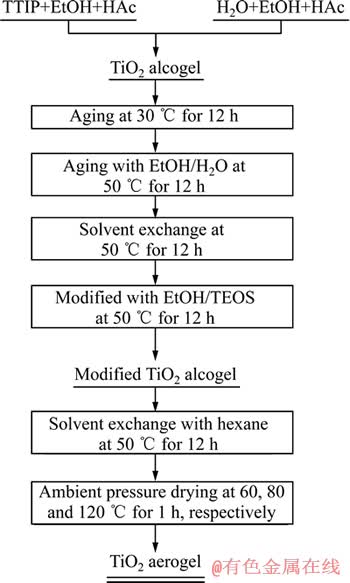

TiO2醇凝胶的老化及常压干燥:将制得的醇凝胶在30 ℃下自然老化12 h;在无水乙醇和去离子水混合溶液(H2O与EtOH摩尔比分别为0:1、5:6、5:2、15:2、1:0)中老化12 h;然后在乙醇中老化12 h;在一定比例的正硅酸乙酯和乙醇的混合溶液(体积比为1:1)中浸泡12 h;再在正己烷中进行溶剂置换;将处理后的凝胶放在干燥箱内进行梯度干燥,60、80和120 ℃分别恒温干燥1 h,得到块状TiO2气凝胶。常压干燥法制备块状TiO2气凝胶流程图如图1所示。

2 结果与讨论

2.1 原料中水用量对TiO2凝胶时间影响

表1所列为原料中TTIP与H2O的摩尔比对TiO2凝胶时间的影响。由表1中可知,TTIP与H2O的摩尔比为1:2时,TiO2溶胶7 d后仍未凝胶;当TTIP与H2O的摩尔比增加至1:3时,凝胶时间为48 h,凝胶较软,表明此时水用量偏少,导致TTIP水解速率慢,水解不充分。当水量较少时,TTIP中的4个丁氧基(—OC4H9)不能完全水解成羟基(—OH),进而阻碍水解产物之间的缩聚反应,导致Ti—O—Ti键桥数量少,凝胶时间长,凝胶较软。当TTIP与H2O的摩尔比增加至1:4时,凝胶时间缩短至2 h,此时TTIP水解速率和水解产物的缩聚速率均适中,有利于凝胶骨架交联均匀,提高骨架强度,进而更易制得块状TiO2气凝胶。当TTIP与H2O的摩尔比继续增加至1:5和1:6时,凝胶时间缩短到1 h内。由于水用量较多,TTIP水解速率和缩聚速率均很快,TTIP来不及完成水解和缩聚反应,导致凝胶骨架上含有较多未水解的丁氧基(—OC4H9),因此,凝胶骨架交联程度低。在后续EtOH-H2O溶液中老化时,由于继续发生水解和缩聚反应,且反应较剧烈,容易导致凝胶体发生开裂,影响其成块性。当TTIP与H2O的摩尔比继续增加至1:7时,水解速率过快,生成白色沉淀(Ti(OH)4),难以形成TiO2醇凝胶。实验表明,在本研究条件下,选取TTIP和H2O的摩尔比为1:4较为适宜。

图1 TiO2气凝胶制备流程图

Fig. 1 Flowchart of experimental procedure for preparation of TiO2 aerogel

表1 水用量对TiO2凝胶时间的影响

Table 1 Effect of water consumption on gel time of TiO2

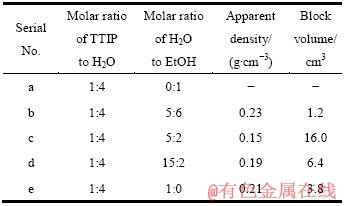

2.2 老化液中水用量对凝胶表观密度和块体尺寸的影响

将实验制备的TiO2气凝胶切成矩形,分别用游标卡尺测定其长度、宽度和高度,用分析天平称量质量,然后计算气凝胶的表观密度。

表2所列为老化液中水用量对TiO2气凝胶表观密度和成块性能影响,相应条件下样品实物照片见图2。由表2可知,当老化液中H2O与EtOH的摩尔比为5:2时,样品的块体最大,表观密度最低。当仅使用无水乙醇作为老化液时,常压干燥样品出现致密化现象,表明此TiO2醇凝胶骨架上仍存在丁氧基(—OC4H9)和未反应的羟基(—OH),丁氧基(—OC4H9)具有位阻效应,羟基(—OH)不能完全发生缩合反应,导致骨架交联程度低。此外,TiO2醇凝胶骨架上残余未反应的丁氧基(—OC4H9),导致凝胶骨架交联程度低,干燥后骨架坍塌,样品出现致密化现象,样品实物照片见图2(a)。当仅使用水作为老化液时,由于水用量大,TiO2醇凝胶在老化过程中水解缩聚反应剧烈,TiO2醇凝胶在老化过程易发生开裂,致使气凝胶样品块体较小,样品实物照片见图2(e)。上述实验表明,当老化液中存在适量的水时,TiO2醇凝胶在老化过程中继续发生水解缩聚反应,且反应速率适中时,可在不破坏凝胶骨架的前提下增加Ti—O—Ti键桥数量,提高骨架强度,样品实物照片见图2(c)。

表2 老化液中水用量对TiO2气凝胶表观密度和成块性能的影响

Table 2 Effect of water consumption of aging fluid on apparent density and block size of TiO2 aerogels

图2 含不同H2O与EtOH摩尔比(n)老化液制备的TiO2气凝胶的实物照片

Fig. 2 Physical pictures of TiO2 aerogel at different molar ratios of H2O to EtOH(n)

2.3 TiO2气凝胶比表面积和孔结构分析

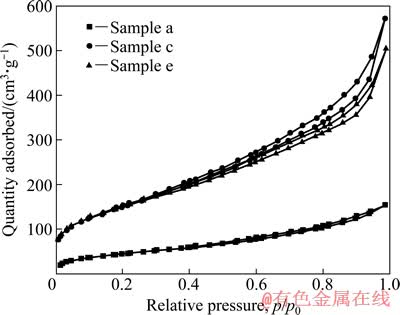

图3所示为典型TiO2气凝胶样品a、c和e的N2吸附—脱附曲线。由图3可知,样品a的吸附—脱附曲线没有明显的滞后回线,并且其N2最大吸附量为160 cm3/g,明显小于样品c和e的,说明样品a不存在气凝胶的多孔疏松结构,孔容和比表面积均很小,这与图2中样品a发生致密化现象相吻合。样品c和e中吸附等温线均属于第Ⅳ类型,为典型介孔吸附等温线,说明样品存在多分子层吸附和毛细管凝结现象。样品c和e的吸附—脱附曲线均具有明显的滞后回线现象,按照Bore理论[11]分类,此吸附—脱附等温线属于E型滞后回线,其孔洞由细颈、广体的“墨水瓶”孔组成,符合气凝胶的结构特征[12]。相对压力(p/p0)接近1时,样品c和e的等温吸附线斜率很大,说明样品c和e中大孔数量较多[13]。与样品e相比,样品c的最大吸附量较大,说明样品c的比表面积和孔容均较大,这与通过多点BET法和BJH法计算的比表面积和孔容(见表3)结果一致。

图3 样品a、c和e的N2吸附—脱附等温曲线

Fig. 3 Nitrogen adsorption—desorption isotherm curves of samples a, c and e

图4所示为典型TiO2气凝胶样品a、c和e的BJH孔径分布曲线。由图4可知,样品a的孔径分布曲线较平坦,表明样品a孔径分布不均匀。样品c和e孔径分布较集中,主要分布在5 nm处。样品c的孔径分布在5 nm处峰值最高,说明样品c孔径分布最集中,在干燥过程中毛细管力差值较小,对样品c结构的破坏较小[14],宏观表现为块体较大,与图2中样品c实物照片相吻合。

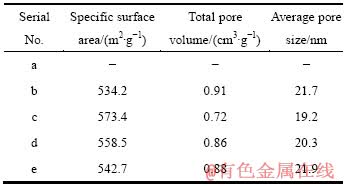

表3 老化液中用水量对TiO2气凝胶比表面积、孔容和孔径影响

Table 3 Effect of water consumption of aging fluid on specific surface area, total pore volume and average pore size of TiO2 aerogels

图4 样品a、c和e的孔径分布曲线

Fig. 4 Pore size distribution curves of samples a, c and e

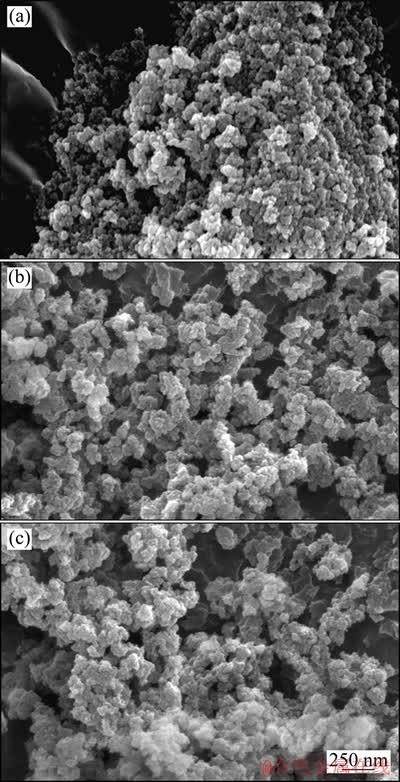

2.4 TiO2气凝胶的微观形貌

图5所示为典型TiO2气凝胶样品a、c和e的SEM像。由图5可知,样品a有明显致密化现象,与其实物照片相一致;样品c和e网络骨架由许多球状颗粒无序排列构成,颗粒尺寸在20 nm左右,说明样品c和e具有典型的三维网络多孔结构。

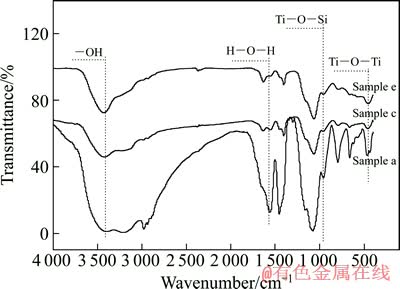

2.5 TiO2气凝胶的红外光谱分析

图6所示为典型TiO2气凝胶样品a、c和e的FT-IR谱。由图6可知,TiO2气凝胶各样品在3 450 cm-1附近为表面羟基(—OH)吸收峰,其中,样品a在此处的吸收峰最强,说明表面残留羟基基团最多,也进一步说明样品a水解产物的缩聚反应较不完全,易导致凝胶样品干燥后收缩加大。1 650 cm-1处为物理吸附水的H—O—H弯曲振动峰,样品a的吸收峰最强,说明样品a表面的羟基(—OH)最多。460 cm-1处为Ti—O—Ti键伸缩振动吸收峰,表明样品a、c和e骨架主要由Ti—O—Ti键构成。1 400~1 550 cm-1范围内的峰与样品中残留有机物有关。而960 cm-1处吸收峰是Ti—O—Si键的吸收峰,表明正硅酸乙酯在TiO2的表面发生了反应[15]。

图5 样品a、c和e的SEM像

Fig. 5 SEM images of samples a (a), c (b) and e (c)

图6 样品a、c和e的FT-IR谱

Fig. 6 FT-IR patterns of samples a, c and e

2.6 块状TiO2气凝胶制备机理

钛酸丁酯(TTIP)的水解反应速率和缩聚反应速率直接影响TiO2 气凝胶的三维网络骨架结构。水既是TTIP水解反应的反应物,又是缩聚反应的生成物。当含水量较低时,TTIP中丁氧基(—OC4H9)水解不完全,水解产物主要发生线性缩聚反应,难以形成三维网络结构。当水量适当时,TTIP水解缩聚反应较充分,反应速率适中,形成的凝胶网络骨架强度高,且孔径均匀。当水量过多时,一方面,水解反应过快,凝胶时缩聚反应并不完全,易导致形成不均匀的三维网络结构;另一方面,残留在凝胶骨架中过量的水在后期溶剂置换过程中不容易被置换出来,由于水表面张力较大,水的存在使得凝胶中混合溶剂的表面张力增加,干燥时溶剂产生的毛细管力较高,易导致凝胶体发生开裂,块体减小。

TTIP水解反应和缩聚反应同时进行,其反应速率很难控制,导致所得凝胶骨架上仍存在大量未能反应的丁氧基(—OC4H9)和羟基(—OH),在其后的老化过程中继续发生水解和缩聚反应,通过控制老化液中水的含量来控制凝胶的水解缩聚反应,不断完善凝胶骨架交联度。当老化液中水量较少时,凝胶骨架上残余、未反应的丁氧基(—OC4H9)仍不能完全水解,凝胶骨架中Ti—O—Ti键数量并未明显提高,凝胶强度较低,很难抵抗干燥时溶剂产生的毛细管力,导致样品严重收缩,块体较小(图2(a))。当老化液中水量适当时,老化过程中凝胶继续发生水解缩聚反应,反应速率适当,得到的凝胶骨架交联度高、强度高,干燥后得到的样品比表面积和块体体积大(图2(c))。当老化液中水量 较多时,凝胶骨架上未反应的丁氧基(—OC4H9)和羟基(—OH)水解缩聚反应剧烈,导致凝胶在老化阶段就已发生开裂,尽管得到的样品比表面积较大,但块体体积较小(图2(e))。

3 结论

1) 以TTIP为前驱体、乙酸为催化剂、甲酰胺为干燥控制化学添加剂,当原料中TTIP与H2O的摩尔比为1:4、老化液中H2O与EtOH的摩尔比为5:2时,制得TiO2气凝胶表观密度为0.15 g/cm3,比表面积为573.4 m2/g,块体体积约为16.0 cm3。

2) 水对TTIP水解缩聚反应影响很大,在老化液中添加水,促进凝胶在老化过程中继续进行水解缩聚反应,提高凝胶骨架强度,抵抗干燥过程中的毛细管力。

REFERENCES

[1] FUJISHIMA A, ZHANG X T, TRYK D A. TiO2 photocatalysis and related surface phenomena[J]. Surface Science Reports, 2008, 63(12): 515-582.

[2] PAJONK G M. Catalytic aerogels[J]. Catalysis Today, 1997, 35(3): 319-337.

[3] DILGER S, HINTZE C, KRUMM M, LIZANDARAPUEYO C, DEEB S, PROCH S, POLARZ S. Gas phase synthesis of titania with aerogel character and its application as a support in oxidation catalysis[J]. Journal of Materials Chemistry, 2010, 20(44): 10032-10040.

[4] DAGAN G, TOMKIEICZ M. Preparation and characterization of TiO2 aerogels for use as photocatalysts[J]. Non-Crystalline Solids, 1994, 175: 294-302.

[5] SHIMOYAMA Y, OGATA Y, ISHIBASHI R, IWAI Y. Drying processes for preparation of titania aerogel using supercritical carbon dioxide[J]. Chemical Engineering Research and Design, 2010, 88: 1427-1431.

[6] 王 鲜, 毕于铁, 任洪波, 张 林. 块状TiO2气凝胶的溶胶-凝胶过程及结构[J]. 强激光与粒子束, 2010, 22(10): 2349-2352.

WANG Xian, BI Yu-tie, REN Hong-bo, ZHANG Lin. Structure and sol-gel process of monolithic TiO2 aerogels[J]. High Power Laser and Particle Beams, 2010, 22(10): 2349-2352.

[7] 甘礼华, 陈龙武, 徐子颉. 块状TiO2气凝胶的形成过程及其对品质的影响[J]. 无机材料学报, 2001, 16(5): 846-852.

GAN Li-hua, CHEN Long-wu, XU Zi-jie. Formation process of monolithic TiO2 aerogels and its effect on aerogel’s properties[J]. Journal of Inorganic Materials, 2001, 16(5): 846-852.

[8] ARAVIND P R, SHAJESH P, MUKUNDAN P, WARRIER K G K. Silica-titania aerogel monoliths with large pore volume and surface area by ambient pressure drying[J]. Journal of Sol-Gel Sci Technol, 2009, 52(3): 328-344.

[9] 宋 淼. 常压干燥法制备TiO2气凝胶[D]. 长沙: 中南大学, 2012.

SONG Miao. TiO2 aerogel prepared by ambient pressure drying[D]. Changsha: Central South University, 2012.

[10] 卢 斌, 宋 淼, 卢 辉, 周 强, 魏琪青. 常压干燥法制备TiO2气凝胶[J]. 复合材料学报, 2012, 29(3): 127-133.

LU Bin, SONG Miao, LU Hui, ZHOU Qiang, WEI Qi-qing. TiO2 aerogel prepared by ambient pressure drying[J]. Acta Materiae Compositae Sinica, 2012, 29(3): 127-133.

[11] de BORE J H, EVERETT O H, STONE F S. The structure and properties of porous materials[M]. London: Butterworth, 1958: 68.

[12] DUTOIT D C M, SCHNEIDER M, BAIKER A. Titania-silica mixed oxides: I. Influence of sol-gel and drying conditions on structural properties[J]. Journal of Catalysis, 1995, 153(1): 165-176.

[13] 辛 勤, 罗孟飞. 现代催化研究方法[M]. 北京: 科学出版社, 2009: 10-16.

XIN Qin, LUO Meng-fei. Modern catalysis research methods[M]. Beijing: Science Press, 2009: 10-16.

[14] 秦国彤, 李文翠, 郭树才. 气凝胶结构控制[J]. 功能材料, 2000, 31(1): 26-29.

QIN Guo-tong, LI Wen-cui, GUO Shu-cai. Control of structure of aerogel[J]. Journal of Functional Materials, 2000, 31(1): 26-29.

[15] 胡久刚, 陈启元, 李 洁, 卢 斌, 李鹏举. 常压干燥法制备TiO2气凝胶光催化剂[J]. 无机材料学报, 2009, 24(4): 685-689.

HU Jiu-gang, CHEN Qi-yuan, LI Jie, LU Bin, LI Peng-ju. Preparation of TiO2 aerogel photocatalyst by ambient pressure drying[J]. Journal of Inorganic Materials, 2009, 24(4): 685-689.

(编辑 陈卫萍)

基金项目:湖南省科技计划重点项目(06GK2022)

收稿日期:2012-09-12;修订日期:2013-03-11

通信作者:卢 斌,副教授,博士;电话:0731-88836319;E-mail:luoffice@mail.csu.edu.cn