结晶助剂在铝酸钠溶液种分过程中的作用机理

刘战伟1, 2,陈文汨1,李旺兴1, 2

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 中国铝业股份有限公司 郑州研究院,河南 郑州,450041)

摘 要:为了了解结晶助剂(CGM)在铝酸钠溶液种分过程中的作用机理,研究CGM对二次成核和附聚过程的影响。通过对粒度分布及扫描电镜(SEM)照片的对比,探讨CGM对分解过程的影响。研究结果表明:在二次成核过程中,添加微量CGM的溶液中一开始会形成大量的二次成核,但是,这些二次成核细粒子会被立即吸附到晶种表面或者快速附聚而形成大孔隙的聚合体,从而使得二次成核的细粒子数量减少;在附聚过程中,添加微量CGM有助于提高附聚阶段的黏结过程,形成结实的块状六角几何形状的附聚体;添加CGM可以有效地减少磨损时颗粒的破裂,从而形成完全黏结的附聚物。

关键词:结晶助剂;铝酸钠溶液;种分;二次成核;附聚

中图分类号:TF111 文献标志码:A 文章编号:1672-7207(2010)05-1709-05

Mechanism of crystal growth modifier in bayer seeded precipitation process of sodium aluminate solution

LIU Zhan-wei1, 2, CHEN Wen-mi1, LI Wang-xing1, 2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Zhengzhou Research Institute of Aluminum Corporation of China Limited, Zhengzhou 450041, China)

Abstract: In order to understand the mechanism of crystal growth modifier (CGM) in Bayer seeded precipitation process of sodium aluminate solution better, the effects of CGM on the secondary nucleation and agglomeration process were studied. The effects of CGM on seeded precipitation process were researched by the analysis of particle size distribution and scanning electron microscope (SEM). The results show that in the process of secondary nucleation, a large number of secondary nuclei form initially when the CGM is added into sodium aluminate solution, and these nuclei immediately are either adsorbed back on the seed surface or rapidly agglomerated with each other to form aggregates with a high porosity, so the number of secondary nuclei decreases. In the process of agglomeration, the action of the CGM additive aids the cementation process during agglomeration, and in terms of attrition the additive appears to successfully reduce the breakdown of particles, and form a fully cemented agglomerate.

Key words: crystal growth modifier; sodium aluminate solution; seeded precipitation; secondary nucleation; agglomeration

对铝酸钠溶液强化分解进行研究一直是铝酸钠溶液种分过程研究的热点方向之一[1-3]。添加剂强化铝酸钠溶液分解具有操作简单、成本低等优点,是一种值得深入研究、具有工业应用前景的强化方法。国外生产砂状氧化铝的厂家很流行采用结晶助剂(CGM),使得超细颗粒减少,颗粒强度增加[4-5],但是,由于我国的铝土矿多为一水硬铝石型铝土矿,与国外铝土矿不同,这些CGM对强化我国铝酸钠溶液分解效果不是那么明显。国内有些研究者[6-12]也开发出一些添加剂来强化铝酸钠溶液,但这些添加剂主要侧重于提高溶液分解率,而且添加量也较大。要研究适合自己生产工艺的CGM,首先要了解CGM在分解过程中的作用机理。铝酸钠溶液的分解过程不同于其他无机盐的结晶过程,它包括氢氧化铝晶体的生长、氢氧化铝晶种的附聚、次生晶核的生成以及晶粒的破裂和磨损等物理化学变化[13]。采用不同的种分条件,如过饱和度、添加的种子量和种子粒度、反应时间以及温度等,可以消除或减弱成核、附聚和长大之间的影响,把它们区别开来加以研究[14-15]。一般认为:高温、中等过饱和度、低种子比和细晶种有利于附聚;中等温度、低过饱和度、高种子比和粗晶种有利于晶种长大;低温、高过饱和度、高种子比和粗晶种有利于成核。在此,本文作者通过研究CGM对二次成核与附聚过程的影响,解释添加剂在分解反应中的作用原理。

1 实验

1.1 实验原料

1.1.1 铝酸钠溶液的配制

实验用铝酸钠溶液是采用工业氢氧化铝和分析纯的氢氧化钠煮制而成的。将原料按计算值称取,放在不锈钢锅中加热溶解,配制成所需物质的量比的浓溶液。待溶液冷却后,进行真空抽滤以去除不溶杂质,然后,存放于耐碱的容器中待用。使用时,加蒸馏水稀释至所需浓度。

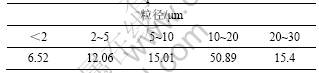

1.1.2 附聚实验晶种的制备

用超细氢氧化铝来制备粒度均匀的细氢氧化铝晶种,使用25 μm的筛子进行湿筛,得到粒径<30 μm的晶体。对这些晶体进行超声波处理,然后经过洗涤、干燥进行粒度分析,其粒度分布如表1所示,晶体的比表面积为0.481 2 m2/g。

表1 附聚实验用晶种的粒度分布

Table 1 Particle size distribution of seed for agglomeration experiment %

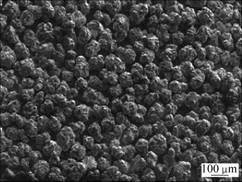

1.1.3 二次成核实验晶种的制备

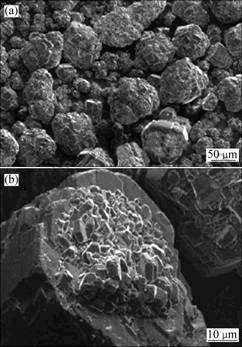

用高纯Al(OH)3来制备粒度均匀的粗氢氧化铝晶种,使用25 μm和106 μm的筛子进行湿筛,得到粒度为30~104 μm的晶体。对这些晶体进行超声波处 理,然后,通过沉降法将细粒子去除。所得到的产品经过洗涤、干燥进行扫描电镜分析,结果如图1所示。由图1可见:这些晶体是由附聚的假六角形晶体组成,粒度为30~100 μm,具有相当光滑的表面,相应的比表面积为0.164 5 m2/g。

图1 二次成核实验中晶种晶体的SEM照片

Fig.1 SEM photomicrograph of gibbsite seed crystals for secondary nucleation experiments

1.1.4 结晶助剂

结晶助剂为Nalco公司提供的7837-1,这是 Nalco公司根据中国氧化铝厂的实际情况专门研究的一种新型结晶助剂。

1.2 实验方法

在分解开始前,用微量加样器将CGM注入分解槽,随后把铝酸钠溶液移入分解槽后开始搅拌,混合10 min后把氢氧化铝晶种加入分解槽开始计时,分解一段时间后取样进行固液分离,取固体氢氧化铝充分洗涤、烘干后用Mastersizer 2000激光粒度分析仪分析氢氧化铝的粒度,采用日本JEOL JSM-5600LV型扫描电镜分析产品的显微结构。

2 结果与分析

2.1 二次成核实验

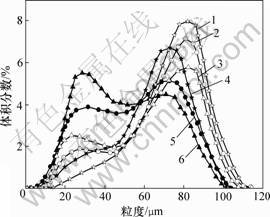

为了研究二次成核过程,采用高过饱和度αk(氧化钠与氧化铝的物质的量比)为1.45的铝酸钠溶液在 60 ℃加粗晶种进行恒温12 h的分解实验。CGM的添加量为30 μL/L。在2,6和12 h时用取样器取样,经过过滤、洗涤和烘干后,进行粒度测定和SEM分析,结果如图2~4所示。

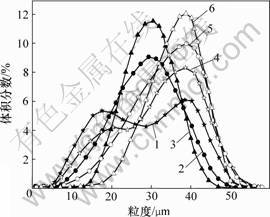

由图2可知,在铝酸钠溶液中未添加CGM时,粗晶种加入溶液后,开始成核较慢,生成的细粒子较少,随着时间的延长,细粒子数不断增加,从而导致粗粒子的体积分数下降,此时的分解过程以二次成核为主。但是在铝酸钠溶液中添加了CGM后,二次成核的细粒子减少,且随着时间的延长,细粒子数量明显地减少。这说明CGM的添加可以抑制分解过程中的二次成核。

1—添加CGM分解2 h;2—添加CGM分解6 h;3—添加CGM分解12 h;4—未加CGM分解2 h;5—未加CGM分解6 h;6—未加CGM分解12 h

图2 二次成核过程的粒度分布

Fig.2 Particle size distribution of secondary nucleation process

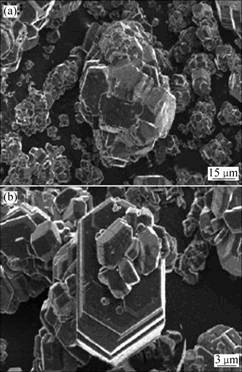

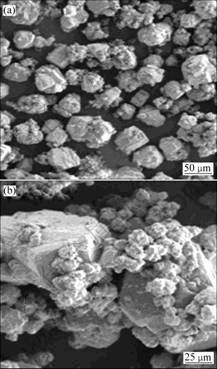

从图3可以看出:在温度为60 ℃时,初晶为准六角板状,经过附聚和长大,形成粒度为10~30 μm的二次晶体;二次成核和附聚体混合,并且二次晶核很少在母体晶种表面附着和长大。

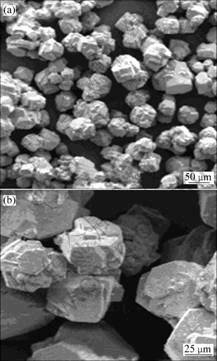

从添加CGM的样品的SEM照片(图4)可知:在温度为60 ℃时,初晶主要表现为准六角板状,并产生一些拉长的六角状晶体。这些初晶的粒度为0.5~10 μm,也就是说,只要晶核一形成就会立即附着在晶种表面。二次成核和附聚体混合,但是,二次成核没有与母体晶种分离。母体晶种表面部分或全部覆盖有二次成核细粒子。这些细小的颗粒沿着准六角板状在晶种表面长成棒状或针状形貌。在添加CGM的情况下,大多数细颗粒黏附于晶种表面并逐渐长大,剩余细颗粒在溶液中形成聚合体,其中有些再次附着到母体晶种表面。

从图4还可以看出,在添加CGM的情况下,会产生大量的细颗粒,似乎与图2中所显示的CGM的添加可以使二次成核的细粒子减少相矛盾。这是由于在添加CGM的溶液中一开始会形成大量的二次成核,但是这些二次成核细粒子会被立即吸附到晶种表面或者快速附聚而形成大孔隙的聚合体,从而使得二次成核的细粒子数量减少。

(a) 放大倍数为1 500;(b) 放大倍数为6 000

图3 分解6 h后未添加CGM样品的SEM照片

Fig.3 SEM images of secondary nucleation experiment for 6 h without CGM

(a) 放大倍数为500;(b) 放大倍数为3 500

图4 分解6 h后添加CGM样品的SEM照片

Fig.4 SEM images of secondary nucleation experiment for 6 h with CGM

2.2 附聚实验

为了研究附聚过程,采用过饱和度αk为1.55的铝酸钠溶液在78 ℃加细晶种进行8 h的附聚实验,CGM的添加量为30 μL/L。在1,4和8 h时用取样器取样,经过过滤、洗涤和烘干后,进行粒度测定和SEM分析,结果如图5~7所示。

从图5可以看出,在没有添加CGM的情况下,细粒子随着时间的延长逐渐减少,相应地使得粗粒子的体积分数增加,此时的分解过程以附聚为主。当铝酸钠溶液中添加了CGM后,细粒子数更加明显地减少,相对于未添加CGM的情况,粒度分布图的主峰位置向右有所偏移,平均粒径有所增加,即粒度粗化,这说明CGM的添加可以促进分解过程中的附聚作用。

1—未加CGM附聚1 h;2—未加CGM附聚4 h;3—未加CGM附聚8 h;4—添加CGM附聚1 h;5—添加CGM附聚4 h;6—添加CGM附聚8 h

图5 附聚过程的粒度分布

Fig.5 Particle size distribution of agglomeration process

从图6可以看出:未添加CGM的附聚实验中有大量的细粒子,需要完全结合到母体晶种的晶体结构中。由图7可知:添加CGM的实验中经过4 h的附聚后,减少了细粒子的数量,并形成了结实的块状六角几何形状的附聚体,可以有效地减少颗粒的破裂。

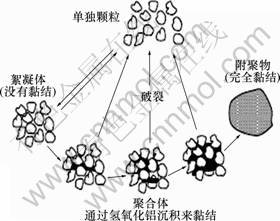

根据Low所提出的附聚机理[16]及实验结果,可以说明CGM添加剂是一种表面活性剂,使颗粒具有足够的能量以越过颗粒相互作用的能垒而相互接触,形成聚合体,它还迫使聚合体中的颗粒紧密排列,使聚合体结构致密。也就是说,CGM添加剂的作用有助于附聚阶段的黏结过程。添加CGM可以有效地减少磨损时颗粒的破裂,从而形成完全黏结的附聚物。

(a) 放大倍数为300;(b) 放大倍数为800

图6 附聚4 h后未添加CGM样品的SEM照片

Fig.6 SEM images of agglomeration experiment for 4 h without CGM

(a) 放大倍数为300;(b) 放大倍数为800

图7 附聚4 h后添加CGM样品的SEM照片

Fig.7 SEM images of agglomeration experiment for 4 h with CGM

图8 附聚机理

Fig.8 Mechanism of agglomeration

3 结论

(1) 在二次成核过程中,添加微量CGM的溶液中一开始会形成大量的二次成核,但是,这些二次成核细粒子会被立即吸附到晶种表面或快速附聚而形成大孔隙的聚合体,从而使得二次成核的细粒子数量减少。

(2) 在附聚过程中,添加微量CGM会有助于提高附聚阶段的黏结过程,形成结实的块状六角几何形状的附聚体。添加CGM可以有效地减少磨损时颗粒的破裂,从而形成完全黏结的附聚物。

(3) 在铝酸钠溶液种分过程中,加入微量CGM可以明显地增强颗粒的附聚和粗化,从而有效地抑制二次成核,使其在强化铝酸钠溶液的晶种分解、提高氢氧化铝产品的质量方面具有广阔的应用前景,为获得粒度均匀且粗大的砂状氧化铝奠定基础。

参考文献:

[1] 杨毅宏, 毕诗文, 谢雁丽. 表面活性剂对铝酸钠溶液分解的影响[J]. 东北大学学报: 自然科学版, 2002, 23(11): 1076-1078.

YANG Yi-hong, BI Shi-wen, XIE Yan-li. Effects of surfactant additives on the seeded precipitation in sodium aluminate solution[J]. Journal of Northeastern University: Natural Science, 2002, 23(11): 1076-1078.

[2] Helen W, Joanne L, Helen G. Gibbsite crystallization on inhibition (1): Effects of sodium gluconate on nucleation, agglomeration and growth[J]. Hydrometallurgy, 2000, 55(3): 275-288.

[3] 赵继华, 陈启元, 张平民, 等. 强化过饱和铝酸钠溶液种分过程的研究进展[J]. 轻金属, 2000(4): 29-31.

ZHAO Ji-hua, CHEN Qi-yuan, ZHANG Ping-min, et al. Progress in study of intensifying seeded precipitation process of supersaturated sodium aluminate solution[J]. Light Metals, 2000(4): 29-31.

[4] Liu J J, Kouznetsov D, Counter J, et al. Performance of new crystal growth modifiers in bayer liquor[J]. Light Metals, 2007(1): 139-143.

[5] Kouznetsov D, Liu J J, O'Brien K, et al. New crystal growth modifiers for the bayer process[J]. Light Metals, 2008(1): 121-125.

[6] 张斌, 周科朝, 陈启元, 等. 添加剂强化拜耳法种分分解的工艺条件实验[J]. 中南大学学报: 自然科学版, 2006, 37(3): 522-525.

ZHANG Bin, ZHOU Ke-chao, CHEN Qi-yuan, et al. Experiment of process parameters on bayer seeded precipitation from caustic aluminate solutions added additives[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 522-525.

[7] Xie Y L, Bi S W, Wu J Q, et al. Study on the application and mechanism of cationic surfactant on the precipitation of sodium aluminate liquor[J]. Light Metals, 2001(1): 135-137.

[8] Xie Y L, Zhao Q, Bi S W, et al. Research on the application and mechanism of crystal growth modifier on the precipitation process in sodium aluminate liquors[J]. Light Metals, 2002(1): 157-160.

[9] 陈锋, 张宝砚, 毕诗文, 等. 添加剂对铝酸钠溶液晶种分解产生Al(OH)3和Al2O3的影响[J]. 中国有色金属学报, 2005, 15(12): 2054-2059.

CHEN Feng, ZHANG Bao-yan, BI Shi-wen, et al. Effect of additive on Al(OH)3 and Al2O3 made by seeded precipitation from sodium aluminate solution[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 2054-2059.

[10] 毕诗文, 于海燕. 氧化铝生产工艺[M]. 北京: 化学工业出版社, 2005: 5-20.

BI Shi-wen, YU Hai-yan. The study of alumina production techniques[M]. Beijing: Chemical Industry Press, 2005: 5-20.

[11] Lü B L, Chen Q Y, Yin Z L, et al. Effect of α-alanine on the seeded precipitation of sodium aluminate solution[J]. Light Metals, 2009(1): 183-187.

[12] Yin J G, Li W X, Chen Q Y, et al. Effect of cationic polyacrylamide on the seeded agglomeration process of sodium aluminate liquors[J]. Light Metals, 2009(1): 201-206.

[13] 杨重愚. 氧化铝生产工艺[M]. 北京: 冶金工业出版社, 1993: 1-15.

YANG Chong-yu. The study of alumina production techniques[M]. Beijing: Metallurgy Industry Press, 1993: 1-15.

[14] 陈文汨, 杨征会, 张利, 等. 结晶添加剂强化铝酸钠溶液种分过程的研究[J]. 湖南有色金属, 2002, 16(8): 23-26.

CHEN Wen-mi, YANG Zheng-hui, ZHANG Li, et al. Study on intensifying seeded precipitation process of sodium aluminate solution by crystallization additive[J]. Hunan Nonferrous Metals, 2002, 16(8): 23-26.

[15] Li J, PrestidgeC A, Addai M J. Secondary nucleation of gibbsite crystals from synthetic bayer liquors: Effect of alkali metal ions[J]. Journal of Crystal Growth, 2000, 219(4): 451-464.

[16] Low G C. Agglomeration effects in aluminium trihydroxide precipitation[D]. Brisbane: University of Queensland, 1975: 76-78.

(编辑 赵俊)

收稿日期:2010-01-03;修回日期:2010-04-15

基金项目:国家科技支撑计划(“十一五”计划)重大项目(ZY2007CABB14)

通信作者:刘战伟(1978-),女,山西忻州人,工程师,博士研究生,从事铝冶炼工艺技术的研究;电话0371-68918597;E-mail: zyy_lzw@rilm.com.cn