文章编号:1004-0609(2009)09-1594-07

Al含量对B4C-AlB12-Al复合材料性能的影响

薛向欣1, 2, 3,王东山1, 2, 3,张 莹1, 2, 3

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 东北大学 辽宁省高校硼资源生态化综合利用技术与硼材料重点试验室,沈阳 110004;

3. 东北大学 辽宁省硼资源综合开发利用工程技术研究中心,沈阳 110004)

摘 要:以B粉、Al粉和B4C粉为原料,采用粉末冶金法在1 200 ℃、高纯氩气保护条件下,烧结制备了B4C-AlB12-Al复合材料。利用XRD和SEM对其相组成和显微结构进行了表征,研究了初始原料中Al含量对材料中AlB12的晶形转变、力学性能和常温导电性能的影响。结果表明:烧结产物由B4C、AlB12、Al及Al3BC和少量Al2O3组成,随Al含量的增加,材料中AlB12的存在形式由α相向β相转变;Al含量大于31.99%时,AlB12完全为β-AlB12相;当原料中Al含量为39.71%时,试样的硬度最高为661 MPa;当Al含量为45.85%时,试样的抗弯强度最高达64 MPa;当Al含量为45.85%左右时,Al的加入量是决定材料能否形成导电网络的最低加入量,此时材料的电阻率为9.82×10-2 ?·cm。

关键词:B4C;AlB12;力学性能;导电性能

中图分类号:TB 331 文献标识码:A

Effect of Al content on properties of B4C-AlB12-Al composites

XUE Xiang-xin1, 2, 3, WANG Dong-shan1, 2, 3, ZHANG Ying1, 2, 3

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. Liaoning Key Laboratory for Ecologically Comprehensive Utilization of Boron, Northeastern University,

Shenyang 110004, China;

3. Resources and Materials, Engineering and Technology Research Center for Boron Resource Comprehensive Development and Application of Liaoning Province, Northeastern University, Shenyang 110004, China)

Abstract: B4C-AlB12-Al composites were sintered by powder metallurgy method under high pure argon shield at 1 200 ℃ using boron powder, aluminium powder and boron carbide powder as raw materials. The phase composition and microstructures were characterized using XRD and SEM. The effect of Al content in materials on crystal transfer, mechanical properties and room-temperature electrical conductivity were studied. The results show that the main phase of the reduction product are B4C, AlB12, Al, Al3BC and small amount of Al2O3. With the increase of Al content, α-AlB12 is converted into β-AlB12. When the Al content reach 39.71% and 45.85%, the maximum hardness and bending strength are 661 MPa and 64 MPa, respectively. Al content is about 45.85%, which is the minimum adding amount can determine if the prepared materials can form the conductive network. The minimum adding amount of Al content is 45.85%, and the resistance rate is 9.82×10-2 ?·cm.

Key words: B4C; AlB12; mechanical properties; electrical conductivity

B4C由于具有低密度、高硬度和良好的中子吸收能力而备受关注[1-2]。为了改善B4C韧性低、难烧结的弱点[3],B4C/Al、Cu和Mg等金属陶瓷复合材料的研究成为近年来的热点[4-6]。以B4C/Al复合材料为例,虽然采用渗透法和搅拌法可以得到力学性能较好的B4C-Al复合材料[7-8],但由于无法控制铝的加入量,从而只能得到性能单一的导电材料。粉末冶金工艺的优点在于可根据需要调整原材料的配比,得到不同性能的材料。南策文和陈新政[9]通过调整Ti的含量得到绝缘材料、可变导电材料和导电材料等不同导电性能的材料,适用于不同导电需求的领域,具有广泛的应用前景。原位反应制备复相材料是近年来才出现的具有突破性的工艺方法。由于它的增强相是在合成过程中形成,因此,具有比常规方法更优越的性能。艾桃桃等[10]通过原位反应合成的Al2O3,由于颗粒细小,弥散分布在基体晶界处是所制材料的主要增韧机制。李桂荣等[11]通过原位反应合成颗粒来增强Al基复合材料。结果表明:内生增强相颗粒为ZrAl3、ZrB2和Al2O3,弥散分布在基体中,可明显提高复合材料的抗拉强度和屈服强度。

本文作者采用B粉、Al粉和B4C粉末为原料,在氩气保护条件下,采用粉末冶金法通过原位反应制备了B4C-AlB12-Al复合材料,并研究初始原料中Al含量对材料中AlB12的存在形式、力学性能和常温导电性能的影响。

1 实验

实验所用B4C粉的平均粒径为3.0 μm,B4C质量分数为90.23%,无定形B粉(粒径小于1.0 μm)中B质量分数为96.1%,Al粉平均粒径2.84 μm,Al质量分数为97.3%。将上述粉末按照一定质量比混合均匀,称取适量坯料放入钢模中,用769YP-15A压力机于260 MPa压力下单轴向机压制成5.7 mm×5.7 mm×40 mm的条形试块。将试样条装入石墨坩埚中,适量埋粉,在真空碳管炉、高纯氩气保护条件下升温烧结。真空碳管炉在充氩气前,炉内保持真空度为2×10-2 Pa,炉内氩气充至40 kPa。试验中各试样配料组成及试样编号如表1所列。

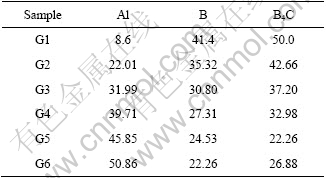

表1 配料组成

Table 1 Initial composition of raw materials (mass fraction, %)

采用日本理学D/MAX-RB型X射线衍射仪测定合成产物的相组成,测试条件为Cu靶Kα辐射,工作电压为40 kV。采用日本岛津公司SSX-550型扫描电镜(SEM)观察断口的显微形貌。采用401MVDTM数显显微维氏硬度计测定抛光试样的显微硬度,荷载 0.98 N,加载时间5 s。在CMT5105型电子万能试验机上采用三点弯曲法测定材料的抗弯强度,试样尺寸4 mm×5 mm×35 mm,跨距30 mm,加压速度0.05 mm/min。采用四点法测定材料的常温电阻率。

2 结果与分析

2.1 材料的XRD表征分析

图1所示为经1 200 ℃恒温烧结1.5 h后试样的XRD谱。由图1可见,复合材料中主要存在AlB12、B4C、Al3BC、Al和Al2O3等物相。当Al含量为8.6%(G1) 时,材料主要由α-AlB12,B4C和Al2O3组成,没有发现单质Al和Al3BC的衍射峰,说明此时B和Al间发生了固-液反应,且系统中有氧参与反应;当Al含量增加到22.01%(G2),α-AlB12和Al2O3衍射峰明显降低,产物中开始出现Al3BC相,但生成的Al3BC很少;随Al含量进一步增加(G3~G6),Al衍射峰逐渐增高,Al2O3含量则逐渐降低,甚至消失,说明此时试样氧化程度不断降低。硼铝化合物主要以β-AlB12形式存在,α-AlB12的衍射峰完全消失,Al3BC相出现先增高后降低的变化,Al含量39.71%(G4)时,衍射峰强度最高。

图1 经1 200 ℃烧结1.5 h后试样的XRD谱

Fig.1 XRD patterns of samples synthesized at 1 200 ℃ for 1.5 h

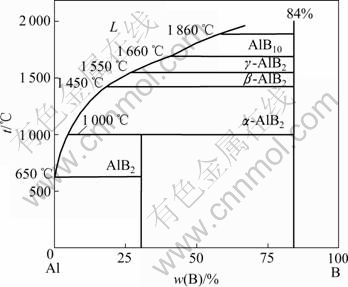

由B-Al相图(见图2)[12]可以看出,B-Al在1 000 ℃左右反应形成α-AlB12,在1 450 ℃左右发生晶形转变形成β-AlB12。MATKOVICH等[13]指出AlB12的两种同素异形体为低温四方相α-AlB12和高温正交相β-AlB12两种同素异形体间的转变温度为1 550 ℃,体积变化率为1.7%。本试验的烧结温度仅为1 200 ℃,远低于β-AlB12正交相形成温度,但XRD谱却显示,Al含量对AlB12的存在形式产生显著影响,当试样中Al含量超过31.99%(G3)时,产物中AlB12以高温正交相β-AlB12形式存在。DU和WATANABE[14]在研究中发现,α相的AlB12粒子分散到Al基中能够在950 ℃的低温下发生相变,产生β-AlB12相,同时,Al基冷却时产生的热收缩会导致压应力的产生,β-AlB12由于这种压应力的作用而存在。本试验中XRD谱显示G3~G6的产物中存在明显的单质铝,构成产生压应力的客观要素。因此,在1 200 ℃时出现了正交相,而G1和G2中并不具备这样的压力条件,因此,AlB12以α相的形式存在。

图2 B-Al二元相图

Fig.2 Binary phase diagram of B-Al

试验过程中不可能完全杜绝氧的存在,尽管真空炉内起始氧分压只有4×10-3 Pa,但仍然远高于1 200 ℃时Al2O3的平衡氧分压(2.95×10-29 Pa),因此必须有Al2O3生成。试样中Al2O3的生成量随着铝含量的增加而减少(见图1),这与反应过程中铝的蒸汽压pAl有关,在627~1 327 ℃的温度范围内,Al的饱和蒸汽压随温度的变化关系为[15]

由式(1)计算得到1 200 ℃时饱和蒸汽压pAl=1.42 Pa。由于此时Al的饱和蒸汽压较高,气态Al弥散在坩埚内,和氧发生气相反应起到了赶排坩埚内氧气,深度脱氧的作用[16],在坩埚内形成无氧环境,保证了试样不被进一步氧化。

2.2 初始原料中Al含量对复合材料力学性能的影响

在陶瓷-金属复合材料中,非金属成分使陶瓷-金属复合材料具有所要求的硬度、热强性和耐磨性,而金属相把陶瓷-金属复合材料中的固体微粒组合在均一的物料中,使材料具有必要的强度和可塑性。因此,陶瓷-金属复合材料的性能取决于金属的性能、陶瓷的性能、两者的体积分数以及相界面的结合强度。

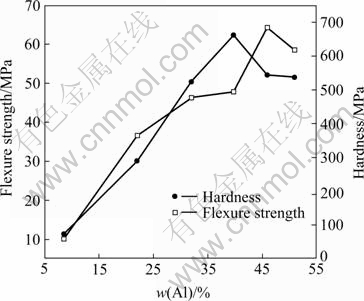

图3所示为经1 200 ℃烧结1.5 h后B4C-AlB12-Al复合材料的硬度、抗弯强度与原料中Al含量的关系。由图3可知,随初始原料中Al含量的增加,材料硬度先增加后降低,当Al含量为8.6%~39.71%时,硬度增加较快。这是因为随着Al含量的增加,B和B4C颗粒和Al接触机会增多,陶瓷相AlB12和Al3BC会随之增加,并且二者均为高硬度相(AlB12显微硬度为24.5~ 25.6 GPa),因此材料的硬度明显提高。试样的XRD图谱显示AlB12和Al3BC含量并不随Al含量持续增加而增加,而是在出现峰值后趋于下降(Al3BC衍射峰在G4处最高),只有单质Al随原料中Al量的增加不断增大。单质Al的硬度一般较小,大量单质Al的存在会明显降低材料的硬度。因此,原料中Al含量为39.71%时,最适宜提高试样的硬度,此时材料的硬度为661 MPa。

图3 经1 200 ℃烧结1.5 h后试样硬度和抗弯强度与初始原料中Al加入量的关系

Fig.3 Relationships between micro-hardness and bend strength and Al content in initial materials synthesized at 1 200 ℃ for 1.5 h

由图3还可看出,随初始原料中Al含量的增加,B4C-AlB12-Al复合材料的抗弯强度亦先增加后降低。强度是由陶瓷-金属复合材料体内对裂纹扩展的抵抗能力决定的。在断裂应力的作用下,裂纹主要是通过晶界传播,即发生晶间断裂。李青等[8]的研究表明,经1 200 ℃烧结0.5 h时,Al金属侵蚀B4C陶瓷形成富铝中间产物,该产物沿B4C颗粒的边缘生长,产物层较薄,增强了B4C和Al的界面结合,使得裂纹沿晶界传播过程中的阻力增大或在扩展过程中发生偏转,耗散裂尖部分能量起到强化晶界的作用。但Al金属的这种增强作用受其在材料中含量的限制。当Al含量较低时,呈现随机、孤立和不连续分布状态,不能完全包裹B4C颗粒,产生的晶界相较少,如Al含量8.6%(G1)时(见图1),没有产生Al3BC相,且在实验温度下,材料没有烧结,因此强度较低。但当其含量过高时,又会使晶界相过多,界面层增厚,从而产生新的缺陷,导致材料的抗弯强度下降。本实验中Al含量为45.85%时,材料抗弯强度最高,达到64 MPa。

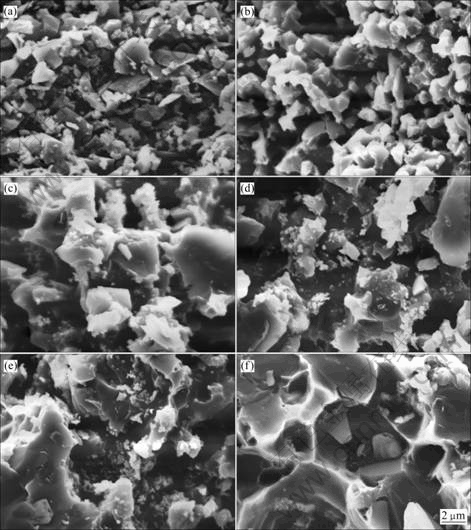

图4所示为经1 200 ℃烧结1.5 h后试样G1~G6断口的SEM像。由图4可见,试样G1晶粒松散堆积,完全没有烧结;试样G2晶粒之间已经开始有了黏结迹象,但断口还是比较粗糙,主要表现为沿晶断裂;试样G3和G4的断口开始表现为穿晶断裂和沿晶断裂混合的一种断裂模式,且试样G4穿晶断裂多于沿晶断裂,显示出材料具有较高的强度;试样G5断口显示存在大量光滑晶粒断面,断裂以穿晶断裂为主,并能发现少量的B4C颗粒从Al基中拔出留下的界面和韧窝;试样G6断面显示出大量晶粒拔出时留下的不规则形状的韧窝和少量平滑的晶粒断面。从界面上萌生的裂纹在基体中增殖,最终形成B4C和AlB12颗粒的这种拔出机制。断面平滑晶粒一般比较粗大,这是因为通常大颗粒B4C存在缺陷的可能性更高,断裂强度低,同时大颗粒的长径比大、尖角更尖锐,这容易引起颗粒尖角处高应力集中,造成大颗粒在较低应力下断裂。

图4 经1 200 ℃烧结1.5 h后试样G1~G6断口的SEM像

Fig.4 SEM images of fractures of samples G1~G6 synthesized at 1 200 ℃ for 1.5 h: (a) G1; (b) G2; (c) G3; (d) G4; (e) G5; (f) G6

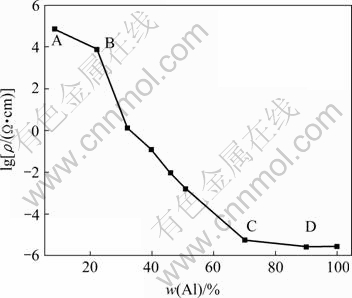

2.3 初始原料中Al含量对复合材料常温导电性能的影响

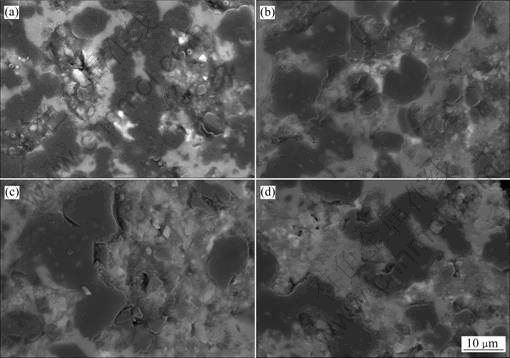

表2所列为经1 200 ℃保温1.5 h后试样G1~G9的常温电阻率。图5所示为试样常温电阻率对数值与初始原料中Al加入量的关系。由图5可见,复合材料的常温电阻率在很大范围内变化,且随材料中Al加入量的变化呈现一种非线性关系,与文献[9]中金属陶瓷电导率随金属相含量变化的曲线非常相似,表现为渗流现象,即随着Al加入量的增加,材料电阻率开始时缓慢降低,在到达某一临界值时急剧降低,随后又缓慢下降,说明Al的分布发生了由分散状态向网络状态的转变。整个变化过程可分为3个阶段:AB段(G1和G2)材料中Al含量较少为8.6%~22.01%,难以形成导电网络,呈随机、孤立和不连续的分散分布,材料的电性能由陶瓷基质决定,故材料的电阻率较高接近B4C陶瓷相的电阻率;BC段(G2~G7)材料的电阻率发生突变,说明随材料中Al含量的增加,基体内开始逐渐形成Al导电网络。BC段实际上是分散分布与网络分布共存的过渡阶段;在CD段(G7和G8),电阻率随材料中Al含量的增加缓慢降低,逐渐趋于纯Al(G9)的电阻率值。此时,Al已经基本形成了相互联结的导电网络,再增加Al含量对材料的电阻率影响不大。根据渗流理论,当导电粒子渗入绝缘基体内,复合材料电阻率变化存在一个临界值,在此值附近,电阻率将发生突变;大于此值时,复合材料中导电相彼此联结而形成导电网络。图6所示为试样G3~G6抛光表面的SEM像。图中深灰色部分为陶瓷基质,浅灰色部分为金属Al。由图6可见,随Al加入量的增加,Al逐渐由被分割的孤立状态转变为联通的网络分布,并提供了良好的导电通道。结合表2和图6可以认为,在本实验条件下,初始原料中45.85%左右的Al加入量是决定材料能否形成导电网络的最低加入量,此时材料的电阻率为9.82×10-2 ?·cm。

表2 经1 200 ℃烧结1.5 h试样的常温电阻率

Table 2 Room-temperature electric resistivity of samples fabricated at 1 200 ℃ for 1.5 h

图5 烧结试样常温电阻率与初始原料中Al加入量的关系

Fig.5 Relationship between electric resistivity of sintered samples at room temperature and Al content in initial raw materials

图6 试样G3~G6抛光表面的SEM像

Fig.6 SEM images of polished surface of samples: (a) G3; (b) G4; (c) G5; (d) G6

3 结论

1) 烧结试样中除含有B4C、AlB12和Al外,还含有界面相Al3BC和少量Al2O3。

2) 初始原料中Al含量对AlB12的存在形式产生显著影响。随Al含量的增加,材料中AlB12的存在形式由α相向β相转变,当Al含量大于31.99%时,完全为β-AlB12相。

3) 随初始原料中Al含量的增加,材料的硬度和抗弯强度呈现出相同的变化规律,都是先增加后降低,当原料中Al含量为39.71%时,试样的硬度最高为661 MPa;当Al含量为45.85%,试样的抗弯强度最高达64 MPa。

4) 材料的常温电阻率随Al含量的变化呈非线性变化,表现为渗流现象,可分为3个阶段,分别对应分散分布、过渡状态和网络分布。初始原料中Al含量约为45.85%时,材料的电阻率为9.82×10-2 ?·cm,决定材料能否形成导电网络的最低加入量。

REFERENCES

[1] 王永兰, 金志浩, 金生武, 高积强, 杨建峰, 李光新. 核反应堆控制材料B4C的研究[J]. 西安交通大学学报, 1991, 25(4): 25-30.

WANG Yong-lan, JIN Zhi-hao, JIN Sheng-wu, GAO Ji-qiang, YANG Jian-feng, LI Guang-xin. Study of reactor control material B4C[J]. Journal of Xi’an Jiaotong University, 1991, 25(4): 25-30.

[2] 李世波, 温广武, 葛 勇, 张宝生. 碳硼化合物的晶体结构[J]. 哈尔滨建筑大学学报, 1998, 31(4): 61-66.

LI Shi-bo, WEN Guang-wu, GE Yong, ZHANG Bao-sheng. The crystal structure of boron carbide[J]. Journal of Harbin University of Civil Engineering and Architecture, 1998, 31(4): 61-66.

[3] 白克武, 王永兰, 杨建锋, 高积强, 李光新, 李 平, 金志浩, 王笑天. 热压工艺对碳化硼显微结构和力学性能的影响[J]. 西安交通大学学报, 1994, 28(7): 73-78.

BAI Ke-wu, WANG Yong-lan, YANG Jian-feng, GAO Ji-qiang, LI Guang-xin, LI Ping, JIN Zhi-hao, WANG Xiao-tian. The influence of hot pressing parameters on the microstructures and mechanical properties of boron carbide[J]. Journal of Xi’an Jiaotong University, 1994, 28(7): 73-78.

[4] OLOWOLAFE J O, SOLOMON J S, MITCHEL W, LAMPERT W V. Thermal and electrical properties of Au/B4C、Ni/B4C and Ta/Si contacts to silicon carbide[J]. Thin Solid Films, 2005, 479(1/2): 59-63.

[5] FROUMIN N, FRAGE N, AIZENSHTEIN M, DARIEL M P. Ceramic-metal interaction and wetting phenomena in the Cu/B4C system[J]. Journal of the European Ceramic Society, 2003, 23(15): 2821-2828.

[6] PYZIK A J, BEAMAN D R. Al-B-C phase development and effects on mechanical properties of B4C/Al derived composites[J]. Journal of American Ceramic Society, 1995, 78: 305-310.

[7] FU Xue-ying, ZHANG Hong, XI Hui-zhi, YI Xiao-su. Study on processing conditions of aluminum matrix composites reinforced with boron carbide particles[J]. Journal of The Rare Earth, 2004, 8: 215-223.

[8] 李 青, 华文君, 崔 岩, 张少卿. 无压浸渗法制备B4C/Al复合材料研究[J]. 材料工程, 2003, 17(4): 17-20.

LI Qing, HUA Wen-jun, CUI Yan, ZHANG Shao-qing. Fabricating aluminum toughed boron carbide composites by pressureless infiltration technology[J]. Journal of Materials Engineering, 2003, 17(4): 17-20.

[9] 南策文, 陈新政. Ti- Al2O3金属陶瓷的渗流模型[J]. 物理学报, 1987, 36(4): 511-513.

NAN Ce-wen, CHEN Xin-zheng. Percolation model of Ti- Al2O3 cermet[J]. Acta Physica Sinica, 1987, 36(4): 511-513.

[10] 艾桃桃, 王 芬, 冯小明, 郭从盛. 原位合成Al2O3颗粒增强双相TiAl基复合材料的组织与性能[J]. 中国有色金属学报, 2007, 17(11): 1849-1854.

AI Tao-tao, WANG Fen, FENG Xiao-ming, GUO Cong-sheng. Microstructure and mechanical properties of in situ Al2O3 particles reinforced two-phase TiAl-based composites[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1849-1854.

[11] 李桂荣, 戴起勋, 赵玉涛, 王宏明, 朱延山. Al-Zr-O-B体系原位合成颗粒增强铝基复合材料及其性能[J]. 中国有色金属学报, 2005, 15(4): 572-577.

LI Gui-rong, DAI Qi-xun, ZHAO Yu-tao, WANG Hong-ming, ZHU Yan-shan. Fabrication and properties of particles reinforced aluminum matrix composites in-situ synthesized in Al-Zr-O-B system[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 572-577.

[12] MOTA J M, MARTINEZ M A, VELASCO F. Preparation of aluminium boride by powder technology[J]. Ceramics International, 2004, 38(30): 301-306.

[13] MATKOVICH V I, ECONOMY J, GIESE R F. Presence of carbon in aluminium borides[J]. Journal of American Chemistry Society, 1964, 86(3): 2337-2340.

[14] DU W F, WATANABE T. High-toughness B4C-AlB12 composites prepared by Al infiltration[J]. Journal of the European Ceramic Society, 1997, 124(17): 879-884.

[15] 梁英教, 车荫昌. 无机物热力学手册[M]. 沈阳: 东北大学出版社, 1993: 450.

LIANG Ying-jiao, CHE Yin-chang. Thermodynamic data manual of inorganic matters[M]. Shenyang: Northeastern University Press, 1993: 450.

[16] 张 忻, 李亚伟, 金胜利, 李 楠, 张久兴. 无压渗透工艺制备MgO/AlN复相材料[J]. 硅酸盐学报, 2004, 32(9): 1078-1081.

ZHANG Xin, LI Ya-wei, JIN Sheng-li, LI Nan, ZHANG Jiu-xing. Preparation of MgO/AlN composite materials by melt infiltration process[J]. Journal of The Chinese Ceramic Society, 2004, 32(9): 1078-1081.

收稿日期:2008-04-05;修订日期:2009-03-18

通信作者:薛向欣,教授,博士;电话:024-83687371;E-mail: xuexx@mail.neu.edu.cn

(编辑 李艳红)