文章编号:1004-0609(2016)-03-0526-09

时效处理对挤压态Mg-Gd-Nd-Sr-Zn-Zr合金力学与腐蚀性能的影响

章晓波1, 2,殷 俏1, 2,马青龙1, 2,巴志新1, 2,王章忠1, 2,王 强3

(1. 南京工程学院 材料工程学院,南京 211167;

2. 江苏省先进结构材料与应用技术重点实验室,南京 211167;

3. 江苏康尚医疗器械有限公司,丹阳 212300)

摘 要:为提高生物镁合金的力学和腐蚀性能,对挤压态Mg-3Gd-1Nd-0.3Sr-0.2Zn-0.4Zr镁合金进行不同温度的时效处理,研究时效温度对合金显微组织、室温力学性能和在模拟体液中腐蚀性能的影响。结果表明:合金的析出相呈针状且富含Zr元素。时效处理后合金的显微硬度和屈服强度均比挤压态的高,且随时效温度的升高先升高后降低,当时效温度为185 ℃时,合金的显微硬度和屈服强度最高。腐蚀速率随着时效温度的升高先降低后升高,时效温度为230 ℃时,其质量损失腐蚀速率为挤压态的52%±7%。

关键词:时效处理;生物镁合金;力学性能;腐蚀性能

中图分类号:TG146.2 文献标志码:A

生物医用镁合金是近年来兴起的一种新型生物医用金属材料。与目前临床应用的不锈钢、钛合金、钴基合金等金属生物材料不同,镁合金的抗拉压强度、密度、弹性模量与人体自然骨更接近,具有更好的生物力学性能,可以有效降低应力遮挡效应[1-3],是理想的骨科固定材料。且镁是人体必需的微量元素,镁及镁合金在生物环境中可降解,形成镁离子参与生物体的新陈代谢并自然排出体外。研究表明[4-6],将镁合金植入人体后,自然降解产生的镁离子对组织细胞无毒性、无致敏性、无刺激性、无致癌性,在生物体中没有发生排斥和不良反应,即具有良好的生物相容性。然而,由于镁的标准电极电位很低,且在人体中产生的腐蚀产物膜都是易于溶解的化合物,导致镁合金腐蚀速率过快;此外,镁基体很容易与第二相或杂质元素等发生微电池腐蚀,造成严重的局部腐蚀现象[7]。腐蚀速率过快和局部腐蚀均可导致植入材料过早丧失力学完整性[1]。因此,降低腐蚀速率,促进均匀腐蚀是生物镁合金临床应用亟待解决的问题。

目前大多数研究集中在生物镁合金的表面处理上,但是表面处理只能短时间抑制基体腐蚀,一旦表面膜破裂,基体的腐蚀速率依旧很快,且表面处理不能解决基体局部腐蚀的问题[8-9]。有报道指出,ZX50镁合金进行微弧氧化后植入老鼠体内8周后几乎全部降解,而未微弧氧化的ZX50合金尚未完全降解[10],表明表面处理甚至可加快镁合金后期的腐蚀速率。因此,必须提高镁合金自身的耐腐蚀性能(包括腐蚀速率和腐蚀方式),以满足临床应用的要求。

合金化、细晶化可提高镁合金的腐蚀性能和力学性能[11-13]。时效处理可以提高镁合金的力学性能,但对于其腐蚀性能的研究结果差异较大。T6态GW103K[14]和GW73K[15]镁合金在NaCl溶液中的腐蚀速率远低于相应铸态合金的,但略高于T4态的。T6态Mg-3.08Nd-0.27Zn-0.43Zr在模拟体液中的耐蚀性能则优于铸态和T4态的[16]。T6态Mg-(4-x)Nd-xGd-Sr-Zn-Zr(x=0,1,2和3)系列镁合金的腐蚀速率除x=1外,其余T6态腐蚀速率低于铸态[17]。有报道表明对于挤压态细晶镁合金进行时效处理可进一步提高其耐蚀性能[18],但未阐明机理。因此,研究时效处理对生物镁合金腐蚀行为的影响,探讨其腐蚀机理具有重要意义。已有研究表明含有稀土元素Gd或Nd的Mg-Gd-Zn-Zr[19]和Mg-Nd-Zn-Zr[20]镁合金无细胞毒性。Sr是人体的必需营养元素,可促进成骨细胞生长[9,21]。本文作者以Gd、Nd为主要合金化元素,通过挤压细化晶粒,对挤压态Mg-3Gd-1Nd-0.3Sr-0.2Zn-0.4Zr生物镁合金进行不同温度的时效处理,研究合金的室温力学性能及在模拟体液中的腐蚀性能,阐明时效处理对合金腐蚀性能的作用机制,以期应用于骨科固定材料领域。

1 实验

对挤压态Mg-3Gd-1Nd-0.3Sr-0.2Zn-0.4Zr(质量分数,%)合金进行不同温度的时效处理,加热温度分别为160、170、185、200、215、230和245 ℃,保温 12 h。采用显微硬度计测量各种状态下合金的硬度,硬度测量载荷为1 N,加载时间15 s,每个试样测10个点,然后取平均值。根据硬度测试结果选取挤压态与时效处理态(时效温度分别为160、185、230、245 ℃)的试样进行组织观察、室温拉伸测试和生物腐蚀性能研究。

根据GB/T 228-2002沿挤压方向制备拉伸样品。采用拉伸试验机测试合金的室温力学性能,拉伸速率为1 mm/min,每组测2个平行试样,数据取平均值。试样先后经粗磨、细磨后,用氧化铝抛光粉溶液抛光至镜面,然后用醋酸硝酸乙二醇水溶液(20 mL醋酸+1 mL硝酸+60 mL乙二醇+19 mL水)进行侵蚀,利用扫描电子显微镜(SEM)观察合金的显微组织,利用能谱仪(EDS)分析合金微区的化学成分。

采用失重法和Tafel极化法测试不同状态合金在 37 ℃ 模拟体液(SBF)中的腐蚀性能,每组 4个平行试样,数据取平均值。模拟体液成分及配比为NaCl(8.0 g/L)、 KCl(0.4 g/L)、NaHCO3 (0.35 g/L)、 glucose(1.0 g/L)、MgSO4·7H2O(0.06 g/L)、CaCl2(0.14 g/L)、Na2HPO4·2H2O(0.06 g/L)、KH2PO4(0.06 g/L)、MgCl2·6H2O(0.1 g/L)。实验参照ASTM G31-72标准进行。将试样上下表面和侧面均打磨抛光成镜面,称量浸泡前试样的质量,溶液体积与浸泡试样的表面积之比为45 mL/cm2,24 h更换一次溶液,共浸泡120 h。在浸泡实验结束后,取出试样,用去离子水冲洗后吹干。采用SEM观察腐蚀形貌,利用EDS分析腐蚀产物。然后置于沸腾的铬酸硝酸银水溶液(200 g/L CrO3+10 g/L AgNO3)中清洗5 min以洗去表面腐蚀产物,用去离子水冲洗后滴无水乙醇吹干、称取质量,计算合金的腐蚀速率。采用数码相机拍摄清除腐蚀产物后腐蚀样品的表面宏观形貌。以饱和甘汞电极作为参考电极,铂电极作为辅助电极,试样为工作电极,在37 ℃ 的SBF中进行极化曲线测试,扫描速率为1 mV/s。

2 结果与分析

2.1 显微组织

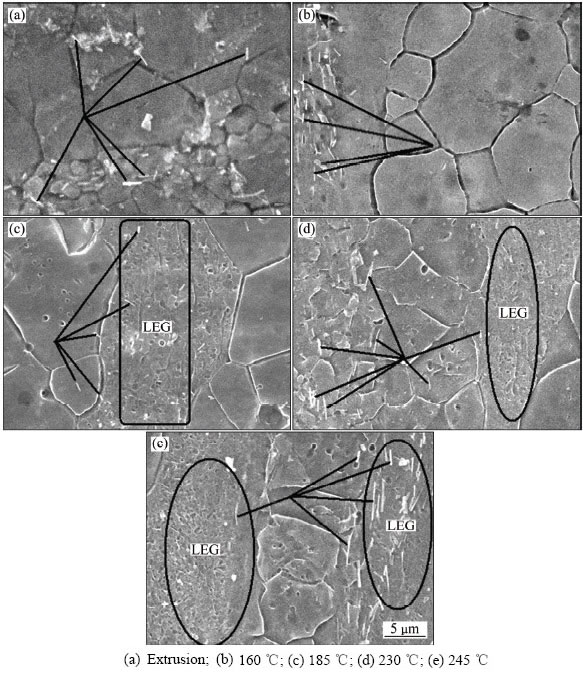

图1所示为镁合金在不同温度时效后的SEM像。由图1可以观察到粗大的被拉长的晶粒(long elongated grains,如图1(c)~(e)中标注的LEG,挤压态和160 ℃处理的样品组织中均有这种结构),这是由于挤压比较小或挤压温度较低导致合金部分区域没有足够的变形储能来触发动态再结晶[22],在挤压过程中未发生动态再结晶的晶粒沿挤压方向被拉长,呈现变形组织特征。晶粒内部和晶界上有针状和球状析出相析出,随时效温度的提高,晶粒大小没有发生显著变化,晶内析出相数量增多,且尺寸有所增大。

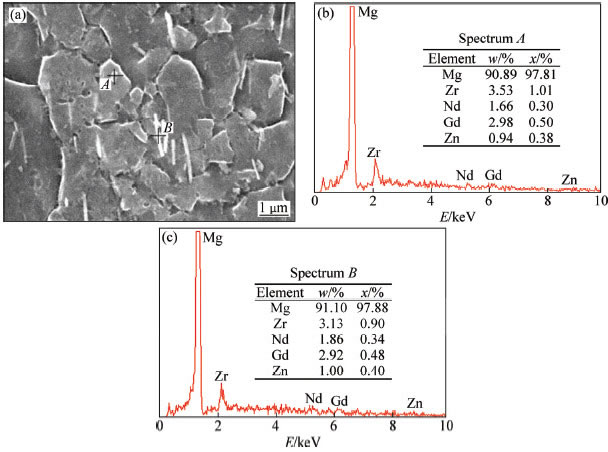

为更清楚地分析析出相形貌及其成分,对时效温度为230 ℃的合金组织进行高倍SEM观察,如图2(a)所示,并对析出相微区进行EDS分析,如图2(b)和(c)所示。由图2可知,球状和针状白色析出相成分基本一致,除镁元素外,还含有少量的Zr、Nd、Gd、Zn元素,其中Zr元素含量最多,为3.1%~3.5%,表明球状与针状物为富Zr化合物。之所以呈现不同的形态,是由于富Zr析出物的位向不同,垂直于观察平面分布的析出相呈球状,而平行于观察平面分布的析出相呈针状。

2.2 力学性能

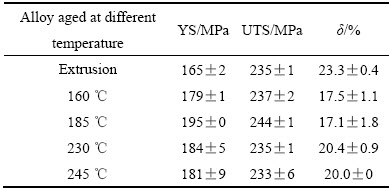

图3所示为镁合金在不同温度时效后的显微硬度。由图3可看出随时效温度升高,硬度值先增大后减小,温度为185 ℃时硬度达峰值(硬度提高13%),时效后的显微硬度均高于挤压态的。根据显微硬度结果,选取挤压态、时效温度分别为160、185、230、245 ℃的试样进行拉伸试验和腐蚀性能研究。表1所列为不同状态下合金的室温拉伸性能。时效后合金的屈服强度(YS)随温度升高先增大后减小,在185 ℃时屈服强度达195 MPa,比挤压态提高18%±2%。而合金的抗拉强度(UTS)则未有明显变化,表明时效处理后合金的屈强比有所增大,加工硬化稍有降低。时效处理后合金的伸长率(δ)较挤压态有所下降,但仍保持在17%以上。

在时效处理过程中,时效温度相对较低时,溶质原子的扩散系数较小,容易形成细小弥散的强化相。随着时效温度不断升高,溶质原子扩散系数增大,析出相的析出进程加快,且呈长大趋势[23]。因此,时效温度相对较低时,合金的硬度不断增大;然而,时效温度较高时达到完全脱溶的状态所需的时间比低温时的要短,即峰值出现的时间相对要早,一旦达到峰值后,合金中的析出相完全析出,随后析出相开始粗化,出现过时效,因而硬度不断降低。

图1 不同时效温度下镁合金的SEM像

Fig. 1 SEM images of Mg alloys aged at different temperatures

图2 230 ℃时时效态镁合金SEM像及微区EDS分析结果

Fig. 2 SEM image (a) and EDS spectra ((b), (c)) of Mg alloys aged at 230 ℃

图3 不同时效温度下镁合金的显微硬度

Fig. 3 Microhardness of Mg alloys aged at different temperatures

表1 镁合金室温拉伸性能

Table 1 Tensile properties of Mg alloys tested at room temperature

时效处理后,合金屈服强度提高的主要原因在于析出相与位错的交互作用。当位错运动遇到析出相时,可通过绕过方式在析出相周围生成位错环或以切过方式通过析出相[24]。由于挤压态合金组织不均匀,存在粗大的被拉长晶粒,随着时效温度的升高,合金发生明显的回复(可认为是静态回复),位错密度降低,在一定程度上弱化合金挤压后加工硬化的效果[25]。因此,随着时效温度的升高,在析出相和静态回复的作用下,合金屈服强度先升高后降低。时效处理后析出相对位错的阻碍作用加强,导致位错在析出相周围大量塞积,较大的应力集中容易萌生微裂纹,从而降低合金的塑性。

2.3 腐蚀性能

图4所示为合金在SBF中的极化曲线图。表2所列为根据合金极化曲线拟合的腐蚀电流密度和腐蚀电位。由表2可以看出,合金的腐蚀电位变化较为混乱。从腐蚀热力学角度来说,腐蚀电位越低,腐蚀倾向性越明显,但其与腐蚀速率无直接关系,腐蚀速率主要由腐蚀电流密度决定。随着时效温度的升高,腐蚀电流密度先减慢后加快,且均小于挤压态的。其中时效温度为185 ℃时腐蚀电流密度最小,比挤压态的低一个数量级,表明时效处理后合金的耐蚀性能显著提高。

图5所示为不同状态下合金在SBF中浸泡120 h后的腐蚀速率。由图5可以看出,腐蚀速率随时效温度升高先降低后升高,其中,时效温度为230 ℃时腐蚀速率最慢,约为挤压态的1/2,这与极化曲线测试的结果差距较大。这是由于失重法获得的是浸泡平均腐蚀率;而电化学法给出的是瞬时腐蚀速率,无法反应随着浸泡时间延长合金的腐蚀速率的变化情况[26]。

图4 镁合金的极化曲线图

Fig. 4 Polarization curves of Mg alloys

表2 镁合金极化曲线实验数据

Table 2 Polarization curves data of Mg alloys

图5 镁合金在SBF中浸泡120 h后的腐蚀速率

Fig. 5 Corrosion rates of Mg alloys immersed in SBF for 120 h

本实验中,析出相与静态回复是影响合金腐蚀性能的主要因素。挤压态合金组织不均匀,且具有一定的残余应力,时效过程中,合金发生了静态回复,空位数量、位错密度降低,残余应力得以释放,有利于合金耐蚀性能的提高[27]。析出相对合金耐蚀性能具有两面性:一方面,时效温度较低时,析出相主要从未发生动态再结晶的被拉长晶粒中析出,等轴晶为过饱和固溶体,两者的电位差相差较小,因而电偶腐蚀驱动力较小;而当时效温度为245 ℃时,等轴晶内析出相明显增多,尺寸略有增大,析出相与基体间的电位差增大,电偶腐蚀驱动力增强。另一方面,富Zr析出相的存在可在试样表面形成氧化物保护层[28],阻碍合金的腐蚀。因此,时效处理态合金的腐蚀速率随温度升高先逐渐降低后又升高,这是静态回复和析出相综合作用的结果。

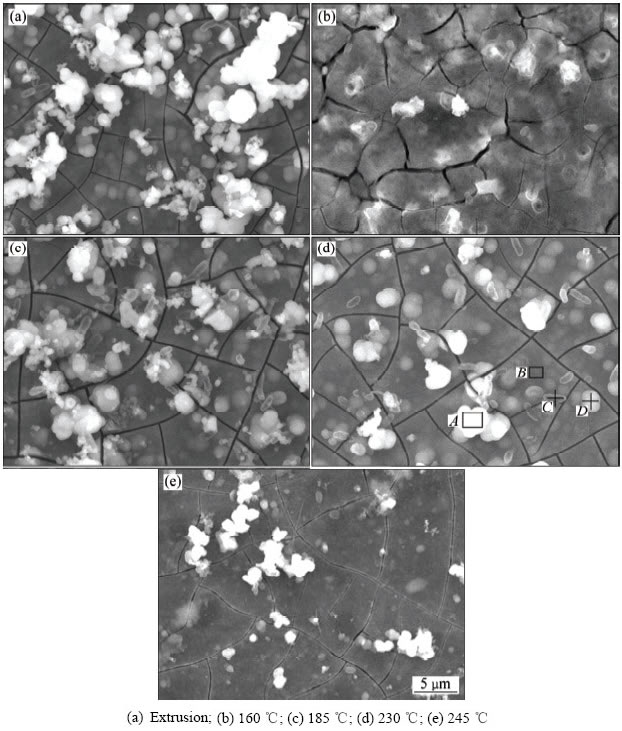

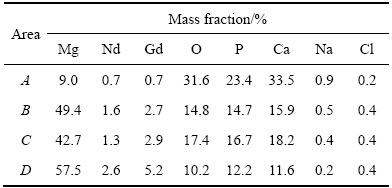

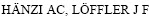

图6所示为合金在SBF中浸泡120 h后的腐蚀表面SEM像。从SEM像可观察到浸泡试样表面一层致密的腐蚀产物层,在吹干过程中,由于脱水导致腐蚀产物层产生裂纹。此外,在腐蚀表面观察到白色颗粒团聚、球状颗粒及蠕虫状颗粒。对图6(d)中标记微区进行EDS成分分析,结果如表3所列。白色颗粒团聚区域(A处)主要富含Ca、O和P元素,镁含量仅有9%,表明白色颗粒是SBF中Ca、O、P等主要溶质沉积在试样表面形成团聚颗粒,而非合金的主要腐蚀产物。腐蚀产物层(B处)与蠕虫状颗粒(C处)主要含有Mg、Ca、O、P及少量的Gd和Nd,且两者各元素含量较为接近。而球状颗粒(D处)Mg、Nd、Gd含量明显增多,且Gd和Nd含量高于合金中Gd和Nd的添加量,而O、Ca、P含量相应减少,说明此处为合金析出相所在位置。

图6 镁合金在SBF中浸泡120 h后的表面微观形貌

Fig. 6 Surface morphologies of Mg alloys immersed in SBF for 120 h

表3 图6(d)中不同区域的化学成分

Table 3 Chemical compositions of different areas marked in Fig. 6(d)

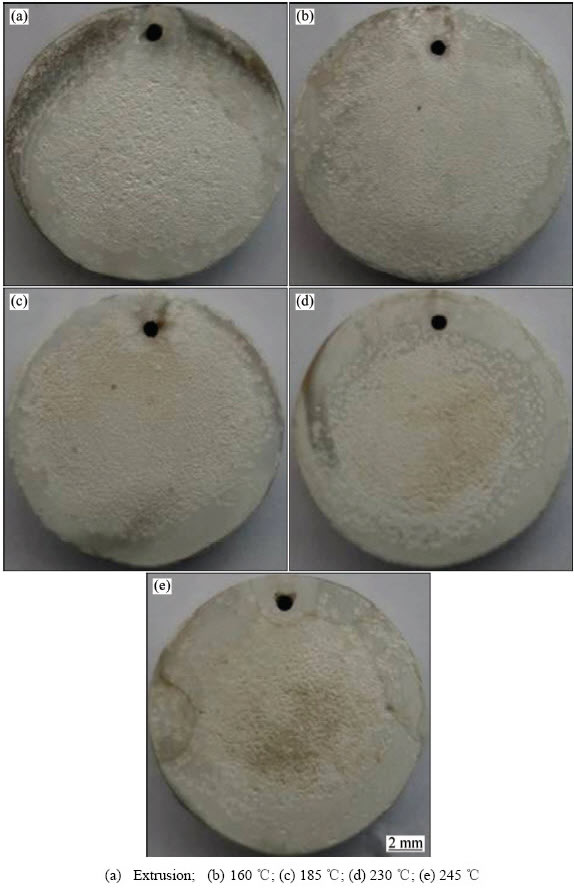

图7所示为试样在SBF中浸泡120 h后的宏观腐蚀照片。图7显示腐蚀试样表面有一些小坑点,但整体较为平滑,表现为宏观均匀腐蚀形貌。这是由于合金中主要合金化元素为Gd和Nd,它们与Mg形成的化合物与基体的腐蚀电位差很小[29],而析出的富Zr化合物因是纳米级且总体数量有限,其作为耐蚀阴极所形成的微电偶效应较弱,因此,电偶腐蚀导致的局部腐蚀倾向性相应较小,合金表现为生物可降解材料所需的均匀腐蚀方式。

图7 镁合金在SBF中浸泡120 h洗去腐蚀产物后的宏观腐蚀照片

Fig. 7 Macro images of Mg alloys immersed in SBF for 120 h and removed corrosion products

理想的可降解植入材料应该满足力学完整性与降解性的良好结合[30]。以骨科固定物为例,在植入初期植入材料能够提供足够的支撑力;在植入中期随着不断降解,其力学完整性逐渐下降,而新生骨可逐渐承受一定的力;植入后期骨愈合,植入材料完全降解,失去支撑功能。纯镁的体外力学性能研究表明,其屈服强度、抗拉强度和伸长率随着浸泡时间的延长呈缓慢下降趋势[31]。最近有报道指出高纯镁植入动物体内呈均匀降解,植入4周后,其弯曲力是植入前的60.8%,仍能提供较高的力(177.3 N)[32]。因此,均匀降解能达到材料植入前期提供足够的支撑力,植入中期保持一定支撑力的效果,是可降解材料理想的降解方式。

3 结论

1) 对合金进行时效处理后析出相为富Zr化合物,且随时效温度升高,晶内析出相数量增多,尺寸略有增大。当时效工艺为185 ℃时,合金的显微硬度和屈服强度达到最大值。

2) 时效处理后,合金的腐蚀速率较挤压态降低。质量损失测试结果表明230 ℃时腐蚀速率最慢,为挤压态的52%±7%;而极化法结果显示时效温度为185 ℃时合金的腐蚀速率最慢,约比挤压态低一个数量级。对比两种测试方法,质量损失法获得的合金腐蚀速率更可靠。

3) 静态回复有利于合金耐蚀性能的提高,而析出相对耐蚀性能具有双重作用。时效后,腐蚀速率先降低后有所升高受静态回复和析出相共同影响。

REFERENCES

[1] ZHENG Y, GU X, WITTE F. Biodegradable metals[J]. Materials Science and Engineering R, 2014, 77: 1-34.

[2] 袁广银, 章晓波, 牛佳林, 陶海荣, 陈道运, 何耀华, 蒋 垚, 丁文江. 新型可降解生物医用镁合金 JDBM的研究进展[J]. 中国有色金属学报, 2011, 21(10): 2476-2488.

YUAN Guang-yin, ZHANG Xiao-bo, NIU Jia-lin, TAO Hai-rong, CHEN Dao-yun, HE Yao-hua, JIANG Yao, DING Wen-jiang. Research progress of new type of degradable biomedical magnesium alloys JDBM[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2476-2488.

[3] KIRKLAND N. Magnesium biomaterials: Past, present and future[J]. Corrosion Engineering, Science and Technology, 2012, 47(5): 322-328.

[4] WINDHAGEN H, RADTKE K, WEIZBAUER A, DIEKMANN J, NOLL Y, KREIMEYER U, SCHAVAN R, STUKENBORG- COLSMAN C, WAIZY H. Biodegradable magnesium-based screw clinically equivalent to titanium screw in hallux valgus surgery: Short term results of the first prospective, randomized, controlled clinical pilot study[J]. Biomedical Engineering Online, 2013, 12: 62.

[5] ZHEN Z, LIU X, HUANG T, XI T, ZHENG Y. Hemolysis and cytotoxicity mechanisms of biodegradable magnesium and its alloys[J]. Materials Science and Engineering C, 2015, 46: 202-206.

[6] MAO L, SHEN L, NIU J, ZHANG J, DING W, WU Y, FAN R, YUAN G. Nanophasic biodegradation enhances the durability and biocompatibility of magnesium alloys for the next-generation vascular stents[J]. Nanoscale, 2013, 5(20): 9517-9522.

[7] ATRENS A, SONG G, LIU M, SHI Z, CAO F, DARGUSCH M S. Review of recent developments in the field of magnesium corrosion[J]. Advanced Engineering Materials, 2015, 17(4): 400-453.

[8] YANG J, JIAO Y, CUI F, LEE I S, YIN Q, ZHANG Y. Modification of degradation behavior of magnesium alloy by IBAD coating of calcium phosphate[J]. Surface and Coating Technology, 2008, 202(22/23): 5733-5736.

[9] GU X, XIE X, LI N, ZHENG Y, QIN L. In vitro and in vivo studies on a Mg-Sr binary alloy system developed as a new kind of biodegradable metal[J]. Acta Biomaterialia, 2012, 8(6): 2360-2374.

[10] FISCHERAUER S F, KRAUS T, WU X, TANGL S, SORANTIN E,  , UGGOWITZER P J, WEINBERG A M. In vivo degradation performance of micro-arc-oxidized magnesium implants: A micro–CT study in rats[J]. Acta Biomaterialia, 2013, 9(2): 5411-5420.

, UGGOWITZER P J, WEINBERG A M. In vivo degradation performance of micro-arc-oxidized magnesium implants: A micro–CT study in rats[J]. Acta Biomaterialia, 2013, 9(2): 5411-5420.

[11] BORNAPOUR M, CELIKIN M, CERRUTI M, PEKGULERYUZ M. Magnesium implant alloy with low levels of strontium and calcium: The third element effect and phase selection improve bio-corrosion resistance and mechanical performance[J]. Materials Science and Engineering C, 2014, 35: 267-282.

[12] ZHANG X, BA Z, WANG Z, XUE Y, WANG Q. Microstructure and biocorrosion behaviors of solution treated and as-extruded Mg-2.2Nd-xSr-0.3Zr alloys[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(12): 3797-3803.

[13] WILLBOLD E, GU X, ALBERT D, KALLA K, BOBE K, BRAUNEIS M, JANNING C, NELLESEN J, CZAYKA W, TILLMANN W, ZHENG Y, WITTE F. Effect of the addition of low rare earth elements (Lanthanum, neodymium, cerium) on the biodegradation and biocompatibility of magnesium[J]. Acta Biomaterialia, 2015, 11: 554-562.

[14] PENG L, CHANG J, GUO X, ATRENS A, DING W, PENG Y. Influence of heat treatment and microstructure on the corrosion of magnesium alloy Mg-10Gd-3Y-0.4Zr[J]. Journal of Applied Electrochemistry, 2009, 39(6): 913-920.

[15] LIANG S, GUAN D, TAN X. The relation between heat treatment and corrosion behaviour of Mg-Gd-Y-Zr alloy[J]. Materials and Design, 2011, 32(3): 1194-1199.

[16] 章晓波, 袁广银, 王章忠. 铸造镁合金Mg-Nd-Zn-Zr的生物腐蚀性能[J]. 中国有色金属学报, 2013, 23(4): 905-911.

ZHANG Xiao-bo, YUAN Guang-yin, WANG Zhang-zhong. Biocorrosion properties of as-cast Mg-Nd-Zn-Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 905-911.

[17] 章晓波, 薛亚军, 王章忠, 贺显聪, 王 强. Mg-(4-x)Nd-xGd-Sr-Zn-Zr生物镁合金的组织、力学和腐蚀性能[J]. 金属学报, 2014, 50(8): 979-988.

ZHANG Xiao-bo, XUE Ya-jun, WANG Zhang-zhong, HE Xian-cong, WANG Qiang. Microstructure, mechanical and corrosion properties of Mg-(4-x)Nd-xGd-Sr-Zn-Zr bio- magnesium alloys[J]. Acta Metallurgica Sinica, 2014, 50(8): 979-988.

[18] ZHANG X, YUAN G, MAO L, NIU J, FU P, DING W. Effects of extrusion and heat treatment on the mechanical properties and biocorrosion behaviors of a Mg-Nd-Zn-Zr alloy[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2012, 7: 77-86.

[19] ZHANG X, WU Y, XUE Y, WANG Z, YANG L. Biocorrosion behavior and cytotoxicity of a Mg-Gd-Zn-Zr alloy with long period stacking ordered structure[J]. Materials Letters, 2012, 86: 42-45.

[20] QIN H, ZHAO Y, AN Z, CHENG M, WANG Q, CHENG T, WANG Q, WANG J, JIANG Y, ZHANG X, YUAN G. Enhanced antibacterial properties, biocompatibility, and corrosion resistance of degradable Mg-Nd-Zn-Zr alloy[J]. Biomaterials, 2015, 53: 211-220.

[21] BORNAPOUR M, MUJA N, SHUM-TIM D, CERRUTI M, PEKGULERYUZ M. Biocompatibility and biodegradability of Mg-Sr alloys: The formation of Sr-substituted hydroxyapatite[J]. Acta Biomaterialia, 2013, 9(2): 5319-5330.

[22] AZEEM M A, TEWARI A, MISHRA S, GOLLAPUDI S, RAMAMURTY U. Development of novel grain morphology during hot extrusion of magnesium AZ21 alloy[J]. Acta Materialia, 2010, 58(5): 1495-1502.

[23] 郭全英, 刘 正, 孙 晶, 毛萍莉. 时效温度对挤压态Mg-13Gd-4Y-0.4Zr合金组织与性能的影响[J]. 铸造, 2009, 58(11): 1150-1153.

GUO Quan-ying, LIU Zheng, SUN Jing, MAO Ping-li. Effects of aging temperature on microstructure and mechanical properties of as-extruded Mg-13Gd-4Y-0.4Zr alloys[J]. Foundary, 2009, 58(11): 1150-1153.

[24] 宋 波, 辛仁龙, 刘 庆. 析出相对镁合金变形机理影响的研究进展[J]. 中国有色金属学报, 2011, 21(11): 2719-2731.

SONG Bo, XIN Ren-long, LIU Qing. Research progress on effect of precipitation on deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2719-2731.

[25] 张 浩, 杜志惠, 阴中炜, 张绪虎. 形变热处理对Mg-6Zn-1Zr-1.5Y合金组织与性能的影响[J]. 稀有金属材料与工程, 2013, 42(1): 84-88.

ZHANG Hao, DU Zhi-hui, YIN Zhong-wei, ZHANG Xu-hu. Effect of hot extrusion and aging treatment on microstructure and mechanical properties of Mg-6Zn-1Zr-1.5Y alloy[J]. Rare Metal Materials and Engineering, 2013, 42(1): 84-88.

[26] KIRKLAND N T, BIRBILIS N, STAIGER M P. Assessing the corrosion of biodegradable magnesium implants: A critical review of current methodologies and their limitations[J]. Acta Biomaterialia, 2012, 8(3): 925-936.

[27] 吴志林, 吴多祥, 袁人枢, 赵 磊, 赵言宝. 热处理对静液挤压AZ80镁合金管材腐蚀行为的影响[J]. 中国有色金属学报, 2015, 25(2): 301-307.

WU Zhi-lin, WU Duo-xiang, YUAN Ren-shu, ZHAO Lei, ZHAO Yan-bao. Effect of heat treatment on corrosion behavior of hydrostatic extruded AZ80 magnesium alloy tube[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 301-307.

[28] NEIL W C, FORSYTH M, HOWLETT P C, HUTCHINSON C R, HINTON B R W. Corrosion of heat treated magnesium alloy ZE41[J]. Corrosion Science, 2011, 53(10): 3299-3308.

[29] COY A E, VIEJO F, SKELDON P, THOMPSON G E. Susceptibility of rare-earth-magnesium alloys to micro-galvanic corrosion[J]. Corrosion Science, 2010, 52(12): 3896-3906.

[30] HERMAWAN H,  , MANTOVANI D. Developments in metallic biodegradable stents[J]. Acta Biomaterialia, 2010, 6(5): 1693-1693.

, MANTOVANI D. Developments in metallic biodegradable stents[J]. Acta Biomaterialia, 2010, 6(5): 1693-1693.

[31] BOWEN P K, DRELICH J, GOLDMAN J. A new in vitro-in vivo correlation for bioabsorbable magnesium stents from mechanical behavior[J]. Materials Science and Engineering C, 2013, 33(8): 5064-5070.

[32] HAN P, CHENG P, ZHANG S, ZHAO C, NI J, ZHANG Y, ZHONG W, HOU P, ZHANG X, ZHENG Y, CHAI Y. In vitro and in vivo studies on the degradation of high-purity Mg (99.99wt.%) screw femoral intracondylar fractured rabbit model[J]. Biomaterials, 2015, 64: 57-69.

Effect of aging treatment on mechanical and corrosion properties of as-extruded Mg-Gd-Nd-Sr-Zn-Zr alloy

ZHANG Xiao-bo1, 2, YIN Qiao1, 2, MA Qing-long1, 2, BA Zhi-xin1, 2, WANG Zhang-zhong1, 2, WANG Qiang3

(1. School of Materials Science and Engineering, Nanjing Institute of Technology, Nanjing 211167, China;

2. Jiangsu Key Laboratory of Advanced Structural Materials and Application Technology, Nanjing 211167, China;

3. Jiangsu Konsung Equipment Co., Ltd, Danyang 212300, China)

Abstract: In order to improve the mechanical and corrosion properties of biomagnesium alloy, the aging treatments at different temperatures were conducted on the as-extruded Mg-3Gd-1Nd-0.3Sr-0.2Zn-0.4Zr alloy. The effects of the aging temperature on microstructure, room-temperature mechanical properties and corrosion properties in simulated body fluid of the alloy were studied. The results show that the Zr-rich needle-like precipitate is observed. The microhardness and yield strength of the alloy after aging treatment are higher than those of the as-extruded alloy, and they first increase and then decline with increasing aging temperature. The highest microhardness and yield strength are obtained at the aging temperature of 185 ℃. The corrosion rate of the alloy first decreases and then increases with increasing aging temperature, and the lowest corrosion rate of the alloy is acquired aged at 230 ℃, which is only 52%±7% compared to that of the as-extruded alloy obtained by mass loss test.

Key words: aging treatment; biomagnesium alloy; mechanical property; corrosion property

Foundation item: Project (51301089) supported by the National Natural Science Foundation of China; Project (BK20130745) supported by the Natural Science Foundation of Jiangsu Province, China; Project supported by the Qing Lan Project of Jiangsu Province, China

Received date: 2015-05-06; Accepted date: 2015-10-20

Corresponding author: ZHANG Xiao-bo; Tel: +86-15951722675; E-mail: xbxbzhang2003@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51301089);江苏省自然科学基金资助项目(BK20130745);江苏省“青蓝工程”资助项目

收稿日期:2015-05-06;修订日期:2015-10-20

通信作者:章晓波,副教授,博士;电话:15951722675;E-mail:xbxbzhang2003@163.com