文章编号:1004-0609(2015)04-0924-07

淬火水温对ZL210A合金显微组织及力学性能的影响

马 雨1,徐志锋1,蔡长春1,张永才2

(1. 南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063;

2. 中国南方航空工业(集团)有限公司,株洲 412002)

摘 要:结合拉伸力学性能测试,采用光学显微镜(OM)、扫描电镜(SEM)、透射电镜(TEM)及能谱分析仪(EDS),研究淬火水温对ZL210A合金显微组织、拉伸断口形貌及力学性能的影响。结果表明:随淬火水温的升高,析出相不断聚集长大,晶粒内空白区域增大,无沉淀析出带变宽;合金的拉伸断口都存在明显的尺寸不等的韧窝,淬火水温为50 ℃的试样的拉伸断口韧窝尺寸较大且深,试样塑性较好;合金的抗拉强度、屈服强度、硬度和伸长率都随淬火水温的升高先增加后减少;当淬火水温为50 ℃时,合金的抗拉强度、屈服强度、硬度和伸长率达最大值分别为477 MPa、363 MPa、149 HV和3%。

关键词:ZL210A合金;淬火水温;显微组织;力学性能;断口形貌

中图分类号:TG156.1;TG166.3 文献标志码:A

Effect of quenching water temperature on microstructure and mechanical properties of ZL210A alloy

MA Yu1, XU Zhi-feng1, CAI Chang-chun1, ZHANG Yong-cai2

(1. National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology,

Nanchang Hangkong University, Nanchang 330063, China;

2. Southern China Aviation Industry (Group) Co., Ltd., Zhuzhou 412002, China)

Abstract: The effect of quenching water temperature on the microstructure,fracture morphology and mechanical properties of ZL210A alloy was studied by tensile tests, optical microscopy, scanning electron microscopy, transmission electron microscopy and energy spectrum analysis.The results show that, with increasing the quenching water temperature, the precipitate phase tends to grow up, and many blank areas in the grain expand, the precipitation free zones become wider. All the tensile fractures have some dimples with different sizes, when the quenching temperature is 50 ℃, the dimple size is large and deep. The samples have a good plasticity. The tensile strength, yield strength, hardness and elongation of samples increase first and then decrease as the quenching water temperature rises, when the quenching water temperature is 50 ℃, the peak values of tensile strength, yield strength, hardness and elongation are 477 MPa, 363 MPa, 149 HV and 3%, respectively.

Key words: ZL210A alloy; quenching water temperature; microstructure; mechanical property; fracture morphology

ZL210A铸造铝合金是我国铸造工作者在俄BA10合金的基础上成功研制出的一种适合我国国内生产应用的典型的可热处理强化的高强度铸造Al-Cu-Mn系铝合金,热处理对其力学性能有着决定性的影响[1]。ZL210A合金不含Ag和V等稀贵金属,对杂质限量也较ZL205A等合金宽,在保证合金性能的同时,降低了对金属原材料的要求,简化了生产工艺,具有很高的经济价值[2-4]。目前,ZL210A合金已实际用于生产飞机、导弹上的一些关键受力构件,如支架和壳体等。

贾泮江等[5-7]分别从固溶温度、时效温度及时效时间的角度对ZL210A合金进行了研究,优化了ZL210A合金的生产工艺参数,提高了ZL210A合金的性能。但ZL210A合金在实际生产中,在保证高强度的同时,其伸长率很低,甚至低于1%。Al-Cu-Mn合金淬火后得到的固溶体过饱和程度对时效强化效果具有决定性作用,故该系合金存在一定的淬火敏感性,淬火水温是影响其性能的一个重要因数[8-9]。淬火水温较低时,获得的固溶体的饱和度增大,合金的强度、硬度升高,而塑性则有所降低;淬火水温较高时,强度降低而塑性有所增加[10]。因此,进行ZL210A合金淬火敏感性方面的研究十分迫切,而国内外有关淬火水温对ZL210A合金组织和性能影响的相关研究还很少。

在此,本文作者就淬火水温对ZL210A合金微观组织及力学性能的影响进行研究,旨在丰富和完善该合金的生产工艺参数,弥补国内外有关ZL210A合金研究的空缺,提高其综合力学性能,为该合金的生产应用提供一定的理论指导和借鉴。

1 实验

合金采用纯度为99.99 %的高纯铝、Al-50Cu、Al-10Mn、Al-5Ti、Al-5Si、Al-5Mg、Al-5Zn、Al-5Zr中间合金和纯Cd配制而成,合金标准成分见表1。采用SG2-S-12型电阻坩埚炉熔炼合金,合金液用C2Cl6精炼处理,浇注温度为740 ℃。

采用砂型铸造浇注合金拉伸试棒,经机加工将试棒加工成标准国标单铸拉伸试样。固溶处理工艺如下:(540±3) ℃保温11 h,淬火水温分别为30、50、70和90 ℃;时效处理工艺如下:(180±3) ℃保温6 h,空冷。在WDW-5型微机控制电子万能试验机上进行拉伸试验,主要测量试样的抗拉强度(σb)、屈服强度(σ0.2)、伸长率(δ)和硬度(HV),在XSP-4XB型光学显微镜下观察合金显微组织并拍摄金相照片,采用D8ADVANCE型X射线衍射仪、Quanta2000型扫描电子显微镜和JEM-2100F型透射电镜微对合金的组织、元素成分以及相结构进行观察与分析。

2 实验结果

2.1 金相组织及断口形貌分析

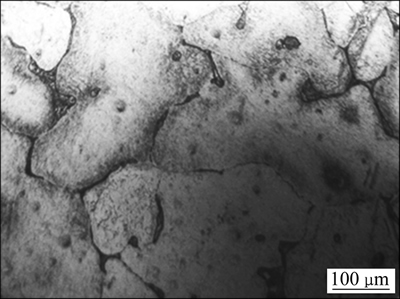

图1所示为740 ℃浇注的ZL210A合金铸态的金相组织。由图1可以看出,合金的铸态组织主要由晶内及晶界一些粗大析出相和断断续续的共晶网状组织构成。根据Al-Cu-Mn三元合金相图可知,在平衡条件下,合金结晶过程为:先结晶出α(Al),然后发生L→α(Al)+Al6Mn二元共晶,最后发生L+Al6Mn→ α(Al)+T(Al12CuMn2)包共晶反应。Cu溶入基体中不会出现θ相,所以在平衡结晶条件下铸态组织主要为α相和T相。但在实际情况下,合金发生不平衡结晶,Cu不能全部溶入基体中,在发生包共晶反应之后,仍然会有液相存在,并且液相中的Cu含量很高,会发生L→α(Al)+θ(Al2Cu)+T(Al12CuMn2)三元共晶反应。因此,实际情况下的铸态组织包含α(Al)、θ(A12Cu)和T(Al12CuMn2)相[11-12]。浇注温度为740 ℃时,铸态合金拉伸试样的抗拉强度(σb)、屈服强度(σ0.2)、硬度(HV)和伸长率(δ)分别为187 MPa、65 MPa、62 HV和6.5%。

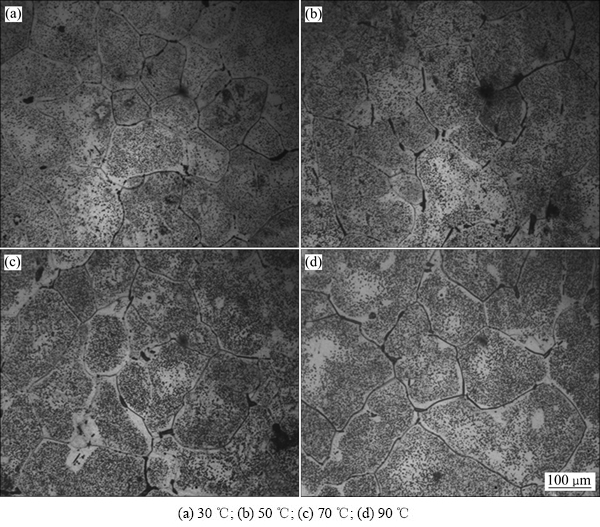

图2所示分别为经30、50、70和90 ℃淬火后试样时效态金相组织。由图2(a)可知,30 ℃淬火后试样时效态晶粒大小较为均匀、晶界较为清晰,晶内及晶界处分布大量细小、均匀、弥散的点状析出相。呈黑色树枝状分布在晶界上的为T(Al12CuMn2)相[13-14],时效温度较低或时效时间较短时,T相呈弥散点状分布。当时效温度较高或时效时间较长时,T相呈条状偏聚于晶界处,如果T相偏聚严重,会导致晶粒内部出现空白区域和PFZ区域变宽,使时效析出强化效果降低,且T相在晶界处呈条状分布对基体产生了割裂作用,会使合金的塑性也迅速降低。由图2(b)可以看出,与30 ℃淬火后试样的时效态组织相比,50 ℃淬火后试样的时效态组织中析出相的分布更加均匀、弥散,晶界更为清晰,但晶界处仍有T相偏聚并粗化。由图2(c)可知,70 ℃淬火后试样的时效态晶粒比30和50 ℃淬火后试样的晶粒较为粗大,同时T相在晶界处的偏聚现象加剧,导致固溶体中溶质原子数量降低,晶内出现了更多的空白区域,减少了最终时效处理强化相的析出量,削弱了ZL210A合金的时效强化作用,T相的偏聚和粗化也降低了对位错的阻碍作用,所以,合金的强度和硬度降低[15],T相在晶界的偏聚和粗化导致合金的塑性更低。由图2(d)可知,90 ℃淬火后试样的时效态组织中晶粒变得更为粗大,晶界变得模糊,在晶界处仍有T相偏聚的现象,晶内出现了很多的空白区域。

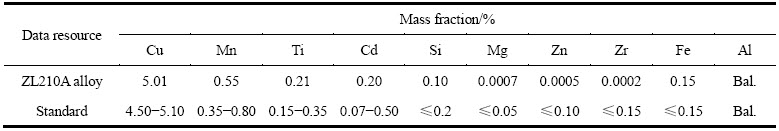

表1 ZL210A合金的化学成分

Table 1 Chemical composition of ZL210A alloy

图1 740 ℃浇注ZL210A合金的铸态金相组织

Fig. 1 As-cast microstructure of ZL210A alloy at 740 ℃

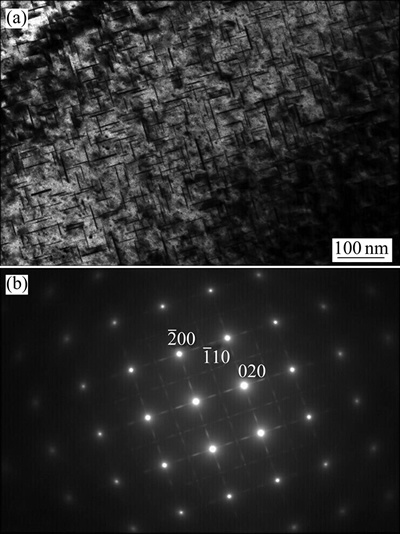

图3所示分别为70 ℃淬火处理试样的明场相图和和对应选区的SAED谱。由图3(a)可以看出,合金基体中析出了大量长条状的呈方向性垂直排列的析出相,因为θ′相是与基体α(Al)相呈(100)θ′//(100)α,[100]θ′//[100]α垂直排列的取向关系,所以70 ℃淬火处理试样的组织中析出的大量的呈方向性垂直分布的析出相是θ′相。另外,从图3(a)还可以看出,合金基体中除了析出大量的θ′相之外,组织中还包含有许多弥散分布的小黑点,这些小黑点可能是时效过程中析出的GPⅠ区和GPⅡ区(θ″相)。图3(b)所示为图3(a)对应的SAED谱,由图3(b)可以看出,图中的衍射斑点附近有断断续续的条纹特征,这是θ′相SAED谱的典型特征。经标定,图3(b)中较亮的衍射斑点为α(Al)在 (001)面的衍射斑点,较暗的衍射斑点为θ相在 面的衍射斑点。

面的衍射斑点。

图2 不同淬火水温时效态试样的金相组织

Fig. 2 Aging metallographs of aging samples water-quenched at different temperatures

图3 70 ℃水温淬火时效态试样的明场相和SAED谱

Fig. 3 BF image(a) of aging water-quenched at 70 ℃ and SAED image(b)

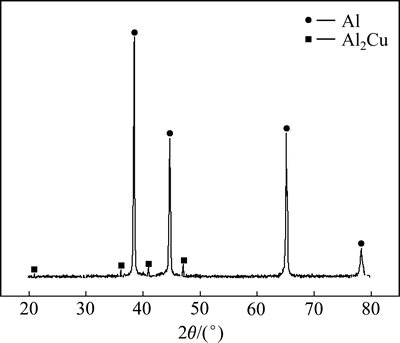

图4所示为经过30 ℃水温淬火试样时效态的XRD谱。由图4可知,30 ℃水温淬火后的试样组织中含有α(Al)相和θ(Al2Cu)相,由于合金中Mn元素含量较少,因此,并未检测出T(Al12CuMn2)相。

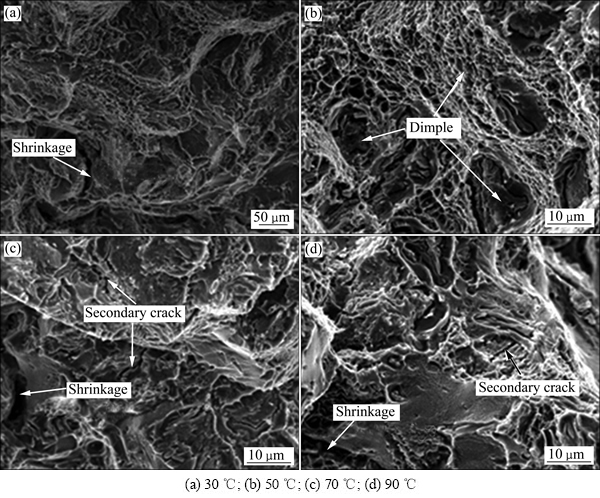

图5所示分别为经30、50、70和90 ℃淬火后试样时效态的断口形貌图。由图5(a)可知,30 ℃淬火后,试样时效态断口形貌中存在尺寸大小交错分布的韧窝,其中小韧窝较多、深度较浅,大韧窝较少,试样主要以韧窝型断裂为主,从断口形貌中可以看出,试样组织中存在缩孔缺陷。由图5(b)可知,与30 ℃淬火后试样时效态断口形貌相比,50 ℃淬火后试样时效态断口也有很多大小交叉分布的韧窝,且大韧窝尺寸更大更深。由图5(c)可知,70 ℃淬火后,试样的时效态拉伸断口形貌高低不平,断口形貌中韧窝数量较少,且韧窝较小较浅,同时,存在二次裂纹和缩孔缺陷。由图5(d)可以看出,90 ℃淬火后试样的时效态拉伸断口形貌中韧窝更少,断口表现出一定的脆性断裂特征,试样中也存在二次裂纹和缩孔缺陷。

图4 30 ℃水温淬火时效态试样的XRD谱

Fig. 4 XRD pattern of aging sample water-quenched at 30 ℃

图5 不同淬火水温试样的断口形貌

Fig. 5 Fracture morphologies of samples water-quenched at different temperatures

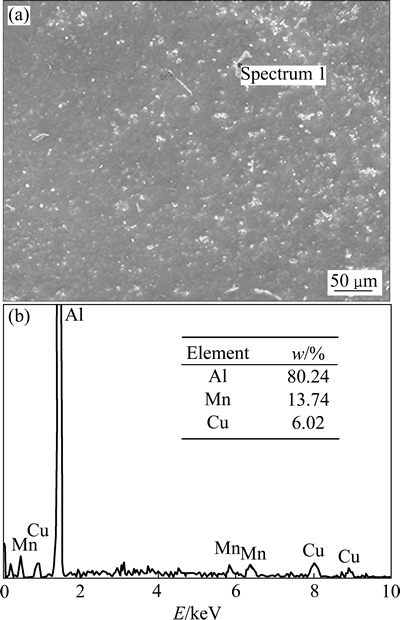

图6所示为经30 ℃水温淬火后时效态试样的SEM像及EDS分析结果。由EDS分析可知,图6(a)中打点处的元素成分为Al、Mn和Cu,其摩尔分数分别为80.24%、13.74%和6.02%,结合扫描电镜中相的形貌及EDS分析可知,图中打点处的成分确定为T(Al12CuMn2)相。

图6 30 ℃水温淬火后时效态试样的SEM像及EDS分析结果

图6 30 ℃水温淬火后时效态试样的SEM像及EDS分析结果

Fig. 6 SEM image(a) and EDS analysis results(b) of aging samples after water-quenched at 30 ℃

2.2 力学性能分析

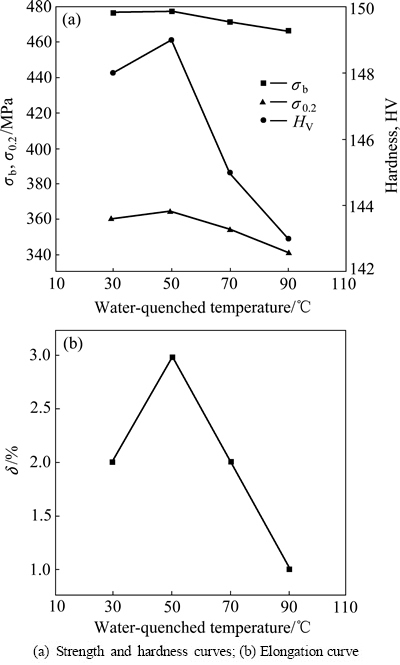

图7(a)所示为淬火水温对ZL210A合金拉伸试样强度和硬度影响的曲线图,图7(b)所示为淬火水温对ZL210A合金拉伸试样伸长率影响的曲线图。由图7(a)可以看出,随淬火水温的升高,合金试样的抗拉强度和屈服强度都先增加后减少,但变化幅度不大,ZL210A合金试样在30、50、70和90 ℃时的抗拉强度分别为476、477、471和466 MPa,屈服强度值分别为360、363、354和347 MPa;当淬火水温为50 ℃时,合金试样的抗拉强度和屈服强度达到最大值,分别为477和363 MPa。ZL210A合金拉伸试样的硬度值也随淬火水温的升高而先增加后减少,变化幅度也很小,合金试样在30、50、70和90 ℃时的硬度值分别为148、149、145和143 HV,当淬火水温为50 ℃时,硬度达到最大值149 HV。由图7(b)可以看出,ZL210A合金试样的伸长率随淬火水温的升高而先增加后减少,当淬火水温为30和70 ℃时,合金试样的伸长率为2%;当淬火水温为50 ℃时,合金试样的伸长率达最大值3%;当淬火水温继续升高至90 ℃时,合金试样的伸长率降低,仅为1%。

图7 淬火水温对时效态ZL210A合金力学性能的影响

Fig. 7 Effect of water-quenched temperature on mechanical properties of aging ZL210A alloy

3 分析与讨论

Al-Cu合金淬火的目的是获得过饱和的固溶体,以便在后续的时效过程中获得更多的细小弥散分布的析出相。淬火水温是影响Al-Cu合金固溶处理效果的一个重要因素,因此,对合金的最终力学性能起到决定性的影响。淬火水温较低时,合金的冷却速率提高,获得的固溶体过饱和度较大,合金强度较高;淬火水温较高时,析出相的尺寸变大,且析出相偏聚现象加重,淬火水温较高还可能导致第二相的提前析出,降低合金的过饱和程度,相当于时效处理前已进行了一次短暂的时效处理,同时,预先析出的第二相能够吸附附近的溶质原子而继续长大,造成附近溶质贫乏加剧,使合金的强度和硬度降低。合金试样在30 ℃较低温度淬火时,晶界及晶内析出较多的细小弥散的析出相,使合金得到强化。淬火水温较高为50 ℃时,析出相分布更加均匀、弥散,晶界也更为清晰,合金强度和塑性得到进一步提高。淬火水温70 ℃时,析出相在晶界处偏聚并粗化,晶内出现较多空白区域,PFZ区域也变宽,合金的强度、硬度和塑性降低。淬火水温为90 ℃时,晶界更为模糊,晶内空白区域增大,PFZ区域宽度增加,导致合金的强度和硬度进一步降低,另一方面,由于析出相不断在晶界聚集和长大,对基体合金的割裂作用加强,合金的塑性进一步降低。

4 结论

1) 随淬火水温的升高,ZL210A合金晶内空白区域增大,PFZ区域变宽,T相不断偏聚并粗化。

2) 不同淬火水温试样的拉伸断口都有大小不等的韧窝存在,由拉伸断口还可以看出,试样还存在缩孔和二次裂纹缺陷。淬火水温为50 ℃的试样拉伸断口 韧窝尺寸较大且深,塑性最好。

3) 合金拉伸试样的抗拉强度、屈服强度和硬度都随淬火水温的升高先增加后减小,当淬火水温为50 ℃时,合金试样的抗拉强度、屈服强度、硬度和伸长率达到最大值,分别为477 MPa、363 MPa、149 HV和3%,ZL210A合金适宜的淬火水温为50 ℃。

REFERENCES

[1] 张晓敏, 毛 健, 车 云. 淬火水温对Al-Cu-Mn高强铸造合金性能的影响[J]. 热加工工艺, 2011, 40(20): 147-149.

ZHANG Xiao-ming, MAO Jian, CHE Yun. Influence of quenching water temperature on mechanical property of high strength cast Al-Cu-Mn alloy[J]. Hot Working Technology, 2011, 40(20): 147-149.

[2] 耿浩然, 马家骥, 黄重伯, 荣福荣. ZL210A高强度铸造铝合金的研制[J]. 中国有色金属学报, 1995, 5(3): 85-89.

GEN Hao-ran, MA Jia-ji, HUANG Zhong-bo, RONG Fu-rong. Development of ZL210A casting high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 1995, 5(3): 85-89.

[3] 周永江, 熊艳才, 洪润洲, 姚惟斌. 一种新型高强度铸造铝合金ZL210A[J]. 特种铸造及有色合金, 2007, 27(4): 322-324.

ZHOU Yong-jiang, XIONG Yan-cai, HONG Run-zhou, YAO Wei-bin. A new type of high-strength ZL210A casting aluminum alloy[J]. Special Casting & Nonferrous Alloys. 2007, 27(4): 322-324.

[4] 陈子勇, 舒 群, 陈玉勇. 高强度铸造铝铜合金显微组织与力学性能的研究[J]. 材料科学与工艺, 2007, 15(5): 718-722.

CHEN Zi-yong, SHU Qun, CHEN Yu-yong. The study of microstructure and mechanical properties of high strength and toughness casting Al-Cu alloy[J]. Materials Science and Technology, 2007, 15(5): 718-722.

[5] 贾泮江, 陈邦峰, 刘国利. 固溶温度对ZL210A铸造铝合金砂型试样力学性能和微观组织的影响[J]. 金属热处理, 2008, 33(4): 24-26.

JIA Pan-jiang, CHEN Bang-feng, LIU Guo-li. Effect of solid solution temperatures on the mechanical properties and microstructure of sand-cast samples of ZL210A cast aluminum alloy[J]. Heat Treatment of Metals, 2008, 33(4): 24-26.

[6] 贾泮江, 陈邦峰. 时效温度对ZL210A铸造铝合金力学性能和微观组织的影响[J]. 轻合金加工技术, 2008, 36(10): 31-41.

JIA Pan-jiang, CHEN Bang-hui. Effect of aging temperature on mechanical properties and microstructures of ZL210A casting aluminum alloy[J]. Light Alloy Fabrication Technology, 2008, 36(10): 31-41.

[7] 贾泮江, 陈邦峰. 时效时间对ZL210A铸造铝合金力学性能和微观组织的影响[J]. 航空材料学报, 2009, 29(1): 47-50.

JIA Pan-jiang, CHEN Bang-hui. Effect of aging time on mechanical properties and microstructure of ZL210A casting aluminum alloy[J]. Journal of Aeronautical Materials, 2009, 29(1): 47-50.

[8] 刘胜胆, 张新明, 黄胜宝. 淬火速率对 7055 铝合金组织和力学性能的影响[J]. 材料科学与工艺, 2008, 16(5): 650-653.

LIU Sheng-dan, ZHANG Xin-ming, HUANG Sheng-bao. Effects of quenching rates on microstructure and mechanical properties of 7055 aluminum alloy[J]. Transactions of Metal and Heat Treatment, 2008, 16(5): 650-653.

[9] 李敬民, 周丹晨, 李昌安, 黄姝珂. 淬火温度对液体淬火介质冷却能力的影响[J]. 材料热处理学报, 2011, 32(Supple): 30-32.

LI Jing-min, ZHOU Dan-chen, LI Chang-an, HUANG Shu-ke. Influence of quenching temperature on the cooling capacity of quenchant[J]. Transactions of Metal and Heat Treatment, 2011, 32(Supple): 30-32.

[10] 赵光伟, 李新中, 徐达鸣, 郭景杰, 傅恒志, 贺跃辉, 杜 勇. 热处理对不同冷速Al合金共晶相形貌及含量的影响[J]. 中国有色金属学报, 2012, 22(2): 343-349.

ZHAO Guang-wei, LI Xin-zhong, XU Da-ming, GUO Jing-jie, FU Heng-zhi, HE Yue-hui, DU Yong. Influence of heat treatment on morphology and quantity of eutectic phases of Al alloys with different cooling rates[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 343-349.

[11] 范云强, 陈志国, 郑子樵, 李艳芬. 分级时效对Al-Cu-Li-Mg-Mn-Zr合金微观组织与性能的影响[J]. 中国有色金属学报, 2005, 15(4): 590-595.

FAN Yun-qiang, CHEN Zhi-guo, ZHENG Zi-qiao, LI Yan-feng. Effects of multi stage ageing treatments on microstructure and mechanical properties of Al-Cu-Li-Mg-Mn-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 590-595.

[12] JANG J H, NAM D G, PARK Y H, PARK I M. Effect of solution treatment and artificial aging on microstructure and mechanical properties of Al-Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 631-635.

[13] 崔忠祈, 覃耀春. 金属学与热处理[M]. 2版. 北京: 机械工业出版社, 2011: 176.

CUI Zhong-qi, QIN Yao-chun. Metal science and heat treatment[M]. 2nd ed. Beijing: China Machine Press, 2011: 176.

[14] MAAMAR S, BONNEAUX J, HARMELIN M. On the peritectoid transition of the quasi-crystalline and crystalline T2 phases in rapidly solidified Al-Cu-Mn alloys[J]. Thermochimica Acta, 1993, 217(4): 231-239.

[15] 梁文杰, 潘青林, 何运斌. 含钪Al-Cu-Li-Zr合金的热处理制度[J]. 材料热处理学报, 2011, 32(9): 72-77.

LIANG Wen-jie, PAN Qin-lin, HE Yun-bing. Heat treatment of Al-Cu-Li-Zr alloy containing Sc[J]. Transactions of Metal and Heat Treatment, 2011, 32(9): 72-77.

(编辑 龙怀中)

基金项目:航空科学基金资助项目(2011ZE56007);江西省高等学校科技落地计划资助项目(DB201303014);江西省科技攻关项目(20133BBE50025)

收稿日期:2014-09-23;修订日期:2014-11-14

通信作者:徐志锋,教授;电话/传真:0791-86453167;E-mail: xu_zhf@163.com