DOI: 10.11817/j.ysxb.1004.0609.2020-36502

白钨矿串联式酸浸槽内流场特性

唐忠阳,曹国祥,李江涛,赵中伟

(中南大学 冶金与环境学院,长沙 410083)

摘 要:利用计算流体力学(CFD)技术,对在使用框式搅拌桨条件下磷硫混酸浸出白钨矿串联方型搅拌槽内的固体颗粒流动行为进行了三维数值模拟及分析,探究进口流速、溢流板高度、相邻溢流板间距对串联搅拌浸出槽的串联分区效果的影响规律。以5槽串联的浸出槽(单槽尺寸为200 mm×200 mm×310 mm)为例,进行了槽内流场特性模拟和实验验证。结果表明:利用溢流板串联过后的连续搅拌酸浸槽内会因为在相邻的溢流板之间得不到有效搅拌作用而发生堆积现象;随着溢流板高度的增高、溢流板间距的减小,白钨矿连续酸浸槽内串联效果逐渐变好。实验结果表明:当进口流量为400 mL/min、溢流板高度为190 mm、溢流板间距为6 mm时,计算得到的虚拟槽数N接近实际串联的槽数5,无因次化方差为0.2108,多槽联接的串联效果良好。本研究为硫磷混酸连续浸出白钨矿浸出槽的工业优化设计提供了理论基础和优化方向。

关键词:浸出槽;流动行为;计算流体力学(CFD);停留时间分布(RTD);非理想流动模型

文章编号:1004-0609(2020)-10-2388-11 中图分类号:TF801 文献标志码:A

钨广泛应用于国民经济诸多领域,是重要的战略资源,欧盟将其列为20种关键性原材料清单,也是我国24种重要的战略性矿产之一[1]。钨业是我国的优势产业,我国钨资源储量,产量和出口量均居世界第一[2]。钨冶炼的主要原料为白钨矿(CaWO4)和黑钨矿((Fe、Mn)WO4)。随着优质黑钨资源的不断开发和消耗,冶炼企业处理的钨矿成分日益复杂、伴生元素综合利用难度加大。另外,由于国家环保政策的日趋严厉,传统的钨冶炼生产方式面临着更严峻的环保压力。针对上述的资源和技术现状,文献[3-4]提出了利用硫磷混酸协同浸出白钨矿的新工艺。新工艺的关键是获得粗大、均匀、稳定的二水硫酸钙分解渣,从而保障白钨矿的高效稳定分解和后续过滤洗涤操作。为了提供均一、稳定的二水硫酸钙的结晶环境,设计了专门的连续浸出设备[5]。连续浸出设备的结构和固体颗粒在槽内的混合特性很大程度上决定了硫酸钙水合物结晶的性质,因此研究白钨矿和其反应产物二水硫酸钙在连续浸出槽中的流动特性是十分有意义的。

由于硫磷混酸浸出白钨矿的搅拌浸出槽设备存在不透视、槽内温度较高、反应浸出剂属于强酸等原因,因此不便于通过物理实验来观察浸出槽内的流场分布特性。随着计算流体力学(CFD)技术以及其相关软件的不断发展,很多研究学者通过模拟搅拌槽内的流场分布特性来设计、优化搅拌浸出槽结构。例如,侯拴第等[6-9]利用CFD对不同搅拌桨型的搅拌槽进行三维数值模拟,得到不同条件下的流场运动特性,与开展的物理实验有较好的吻合度。也有研究人员[10-13]将计算流体力学(CFD)技术和数值模拟方法应用到冶金过程中。例如,逄启寿等[10]利用标准的 双方程模型对无机相(水)和有机相(P507)的混合液在搅拌槽中产生的流场进行数值模拟,计算了槽内的流体速度场和压力场,为搅拌槽的优化设计提供理论基础。停留时间分布(RTD)是浸出槽内物质微观混合的宏观表现,通过研究连续浸出槽内物质的停留时间分布可以确定反应器内流动特性和混合模型,再通过构建模型和定量计算指明实际反应器与理想反应器的偏离程度以及优化方向[14]。近年来,基于水模型的物理实验和计算流体动力学(CFD)模拟被广泛用于克服复杂冶金过程中测量的困难[15-16]。例如,李鹏等[17]对机械搅拌锌浸出槽内的固液两相流场进行了模拟,为锌浸出槽的优化设计提供了理论指导。

双方程模型对无机相(水)和有机相(P507)的混合液在搅拌槽中产生的流场进行数值模拟,计算了槽内的流体速度场和压力场,为搅拌槽的优化设计提供理论基础。停留时间分布(RTD)是浸出槽内物质微观混合的宏观表现,通过研究连续浸出槽内物质的停留时间分布可以确定反应器内流动特性和混合模型,再通过构建模型和定量计算指明实际反应器与理想反应器的偏离程度以及优化方向[14]。近年来,基于水模型的物理实验和计算流体动力学(CFD)模拟被广泛用于克服复杂冶金过程中测量的困难[15-16]。例如,李鹏等[17]对机械搅拌锌浸出槽内的固液两相流场进行了模拟,为锌浸出槽的优化设计提供了理论指导。

本研究将通过CFD技术来详细研究硫磷混酸浸出白钨矿过程中连续浸出搅拌槽内的流场流动特性,并结合冶金反应工程学中的知识点来表征物料在槽内的流动和停留时间分布,同时探究进口流量、溢流板高度、相邻溢流板间距对白钨矿连续搅拌浸出槽内的串联分区效果的影响规律,以期能为磷硫混酸浸出白钨矿搅拌槽的工业优化设计提供理论指导。

1 物理模型

1.1 几何模型

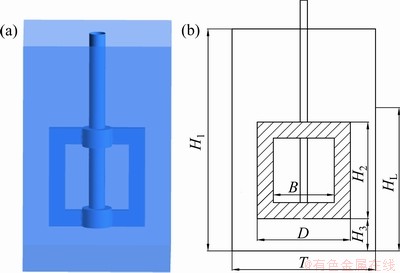

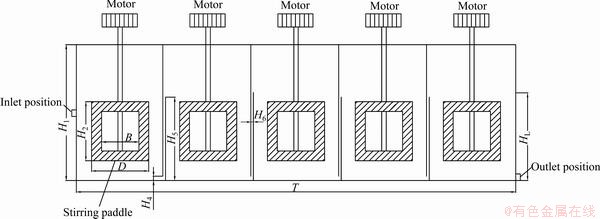

数值模拟中的模型是利用 ANSYS Workbench 中的软件 Geometry-Design Modeler建立的。由于在实际应用磷硫混酸浸出白钨矿的过程中采用了串联的搅拌浸出槽,同时考虑到方型单槽易于串联、使用管道少、串联后占地面积小等优点,因此本次模拟使用的是一个底面为正方型的方型槽。该方型槽如图1所示,由有机玻璃制成,底边长T=200 mm,高H1=310 mm,体积V=8 L,槽子中的液面高度HL=200 mm;用于搅拌的框式搅拌桨外直径D=130 mm,内直径B=85 mm,搅拌桨叶的高H2=135 mm,厚度A=10 mm,搅拌浆离槽底高度H3=35 mm。在前面描述的单个搅拌浸出方型槽基础上,将5个相同的方型槽进行串联操作,中间由溢流板阻隔,如图2所示。每个串联的搅拌槽前后侧均安装有挡板,其挡板宽度为10 mm。用于串联搅拌槽的上溢流板离槽底H4=10 mm,下溢流板高H5=190 mm,相邻两溢流板间距H6=6 mm。每个串联的搅拌浸出槽均采用上进下出的进出料方式。

图1 搅拌浸出槽结构示意图

Fig. 1 Structural diagram of stirred leaching tank

1.2 数学模型

稳定状态下,利用Eulerian-Eulerian多相流模型与标准 的湍流模型描述搅拌浸出槽内的多相流动过程:其连续方程[18-24]如式(1)和(2)所示:

的湍流模型描述搅拌浸出槽内的多相流动过程:其连续方程[18-24]如式(1)和(2)所示:

(1)

(1)

(2)

(2)

式中:下标l、s分别表示模拟中的液固两相; 表示体积分数;

表示体积分数; 表示密度;

表示密度; 表示速度;t表示时间。

表示速度;t表示时间。

液-固动量方程如式(3)和(4)所示:

(3)

(3)

(4)

(4)

式中:g表示重力加速度; 表示黏度;

表示黏度; 表示湍流黏度;p表示压力;F表示相间动量传递项。

表示湍流黏度;p表示压力;F表示相间动量传递项。

图2 多槽串联连续搅拌浸出槽示意图

Fig. 2 Schematic diagram of continuous stirred leaching tank

标准 湍流模型方程如式(5)~(7)所示:

湍流模型方程如式(5)~(7)所示:

(5)

(5)

(6)

(6)

式中:

(7)

(7)

上述方程式中 表示湍动能,

表示湍动能, 表示能量消耗率,

表示能量消耗率, 、

、 、

、 、

、 、

、 都是标准

都是标准 湍流模型当中的参数,这些参数的值有

湍流模型当中的参数,这些参数的值有 =1.45、

=1.45、 =1.9、

=1.9、 =0.09、

=0.09、 =1.0、

=1.0、 =1.3。

=1.3。

相间阻力及阻力系数方程如式(8)所示:

(8)

(8)

式中:CD表示阻力系数;dp表示颗粒直径。考虑到本文中的固相体积分数很小,CD可以从Wen-Yu模型中得到,如式(9)和(10)所示:

(9)

(9)

(10)

(10)

对于利用CFD技术模拟固相颗粒在白钨矿酸浸槽中的停留时间,需要在稳定流场的基础上加上非稳态质量组分方程,其可表示为式(11):

(11)

(11)

式中:Yi代表组分i质量分数;Ji表示组分的质量扩散通量,其具体表达是可以写为式(12):

(12)

(12)

式中:Di,k表示组分i在组分k中的扩散速率,SCi是施密特数,大小为0.7。

1.3 计算方法、边界条件及物性参数

1.3.1 计算方法

数值模拟过程中利用 ANSYS Workbench 中嵌入的软件Fluent 来进行计算方法的构建。采用Eulerian-Eulerian多相流模型、标准 的湍流模型对磷硫混酸浸出白钨矿方型搅拌槽内的多相流动过程进行了三维数值模拟,近壁区域的流动方式选用Standard Wall Functions。在固液两相流的相间阻力系数选用Wen-yu模型来进行描述,不考虑固体颗粒之间、固体颗粒与壁面之间的相互作用。使用多重参考系法(MRF)来解决运动流体域(旋转区域)和静止流体域间(静止区域)相互作用的问题,进行压力速度耦合时选用Coupled的伪瞬态算法,差分格式使用一阶迎风(First order upwind)。

的湍流模型对磷硫混酸浸出白钨矿方型搅拌槽内的多相流动过程进行了三维数值模拟,近壁区域的流动方式选用Standard Wall Functions。在固液两相流的相间阻力系数选用Wen-yu模型来进行描述,不考虑固体颗粒之间、固体颗粒与壁面之间的相互作用。使用多重参考系法(MRF)来解决运动流体域(旋转区域)和静止流体域间(静止区域)相互作用的问题,进行压力速度耦合时选用Coupled的伪瞬态算法,差分格式使用一阶迎风(First order upwind)。

利用CFD技术模拟固相颗粒在白钨矿酸浸槽中的停留时间的求解策略是在基于上述求解方法得到的稳态流场情况下,再加上一组非稳态质量组分运输方程。具体做法就是在得到稳态流场之后,打开非稳态质量组分运输方程,在白钨矿酸浸槽进口处加入一种跟槽内固相颗粒性质相近的示踪剂(本研究选用氢氧化镁作为示踪剂),持续时间1 s,之后在酸浸槽出口检测示踪剂浓度。根据测得的示踪剂浓度随时间的变化曲线,得到待分析的固相颗粒在白钨矿酸浸槽中的停留时间分布曲线[25]。

1.3.2 边界条件

1) 入口边界条件:在处理有入口时的情况采用速度入口边界Velocity-inlet。

2) 出口边界条件:在处理有出口时的情况采用压力出口边界Pressure-inlet。

3) 使用多重参考系法(MRF)来解决运动流体域(旋转区域)和静止流体域间(静止区域)相互作用的问题,将运动区域与静止区域相互接触的面设置为Interface。

4) 搅拌槽的固体壁面设置为No Slip 壁面边界。

1.3.3 物性参数

搅拌槽内的液固两相工作介质分别为磷硫混酸浸出液和二水硫酸钙,测得的液相密度为1200 kg/m3,黏度为3 mPa·s[26];固相密度为2320 kg/m3,平均粒径为2×10-5 m,固相体积分数为8.75%。利用黏度数据可以计算得到雷诺数Re,从而确定槽内的流动处于湍流状态。

2 多槽串联连续浸出槽数值模拟流场分析

2.1 多槽串联连续浸出槽扩大模拟流场分析

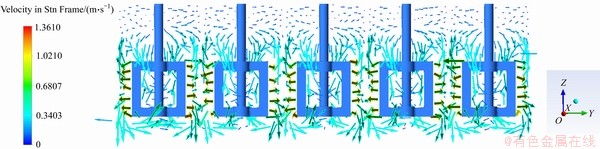

模拟了在转速为200 r/min、框式搅拌桨离底间距为35 mm、在每个串联的方型搅拌槽前后两侧有挡板情况下的白钨矿连续浸出槽内的三维流场。图3所示为数值模拟得到的连续搅拌浸出槽在YZ截面上的速度矢量图。从图3中可以看出,槽内流体在框式搅拌桨的搅拌作用下会形成6个流动区域,即位于搅拌桨上下位置的两对旋涡区、容易发生堆积的锥形区域、由于离心力作用而产生的内、外射流区和相邻溢流板间的相对静止区域。流体由于离心力作用由搅拌桨内外两个边框处甩出,在搅拌槽中部形成向内和向外运动的射流区。在向外射流区内,流体运动至槽壁处,射流区上部流体向上运动,在搅拌桨上部形成旋涡区。而当射流区下部流体运动至槽壁处后沿着槽壁向下运动,接着触碰到槽底向上运动,在搅拌桨下部形成一对明显的旋涡区。同时,在搅拌轴的正下方由于受到搅拌桨的作用力较小形成一个锥形区域。在这个区域内的流体运动速度较周围其他区域的流体运动速度慢,因此在搅拌桨转速较慢的情况下,固体产物硫酸钙会更容易在这个区域发生堆积,造成槽内死区。而在相邻溢流板间的区域由于得不到搅拌而会形成流体流动速度很小、相对静止的区域。

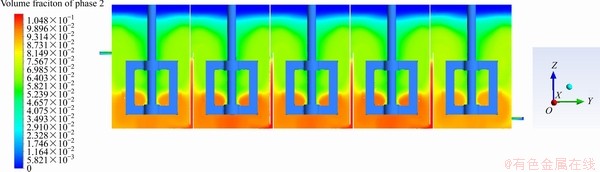

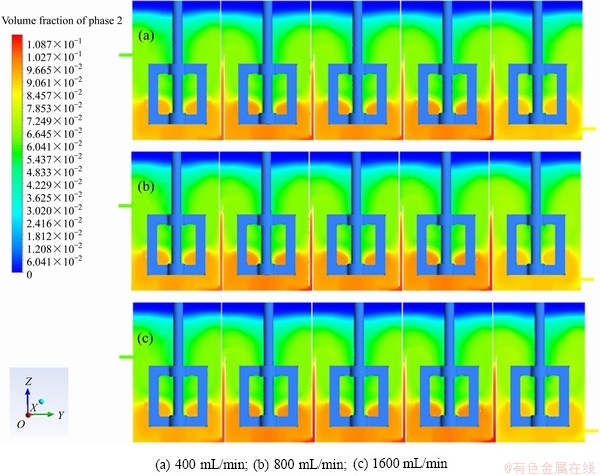

图4所示为数值模拟得到的连续搅拌浸出槽在YZ截面上的固相浓度分布图。从图4来看,搅拌槽内固体颗粒沿轴向出现明显的分层分布,上层固相浓度较小,下层固相浓度较大。利用溢流板串联过后的槽内会因为在相邻的溢流板之间得不到搅拌作用而易发生堆积现象,而且该区域的固相浓度要明显高于槽内其他区域的固相浓度,甚至高于槽底的固相浓度。

2.2 进口流量对固体颗粒流动特性的影响

在进行单槽研究时,主要追求每个槽中的返混程度达到最大,即考虑无因次化方差越大越好,死区体积分数越小越好,但是在讨论多槽串联的白钨矿连续酸浸槽时要考虑到分区作用。在分析白钨矿连续酸浸槽内固相颗粒的流动特性和多槽串联效果时,考量标准是平均停留时间分布曲线的峰值是否接近θ=1,实际平均停留时间是否更接近理想平均停留时间,并且还引进非理想流动模型来进行讨论分析。

在实际的非理想流动过程中,往往会构造或者选择一个能够描述实际非理想流动的模型,来导出表征该非理想流动反应器有关变量间函数关系的数学表达,其中的槽列模型比较常用。它是假想用N个全等的理想全混槽串联起来的非理想反应器模型,这种非理想模型的量化参数用虚拟的串联槽数N来表示,如式(13)所示[27]:

(13)

(13)

本研究利用槽列模型来分别讨论在实验过程中多槽串联连续浸出槽内固相颗粒的实际流动特性。参数N可以用来表征流动和分区效果的好坏,表征实验过程中讨论的无因次化方差。本文所研究的是5槽串联,那么利用非理想模型计算出来的N值越接近5,无因次化方差越接近0.2,就表明串联效果最好。

图3 多槽串联连续搅拌浸出槽YZ截面上的速度矢量图

Fig. 3 Velocity vectors profile on YZ plane of continuous stirred leaching tank

图4 多槽串联连续搅拌浸出槽YZ截面上的固相浓度分布图

Fig. 4 Contour plots of solid concentration on YZ plane of continuous stirred leaching tank

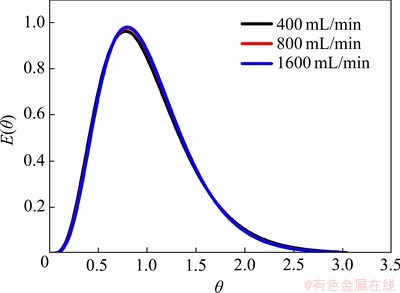

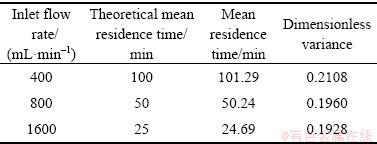

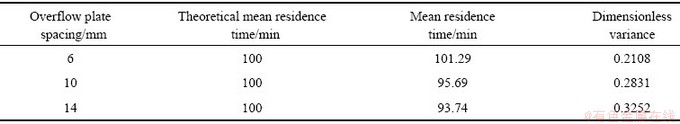

图5所示为不同进口流量对多槽串联连续搅拌浸出槽中固体颗粒RTD曲线的影响对比图。从图5中可以看出,随着进口流量的减小,RTD曲线有着微小向前移动的趋势,RTD曲线峰值随之稍稍偏离θ=1,这对通过溢流板连接的多槽串联分区是不利的,但总体上来说影响不大。表1所示为RTD参数在不同入口流量条件下的变化情况。从表1中可以看出,平均停留时间将随着进口流量的增大成反比例地减少;当进口流量在400 mL/min时,固相颗粒在槽内的平均停留时间为101.29 min;而当进口流量在1600 mL/min时,固相颗粒在槽内的平均停留时间仅为24.69 min。这说明过大流量对本文研究系统不利,不能保证固相颗粒在槽内停留足够的时间,不利于槽内反应物的浸出和反应产物的结晶操作。

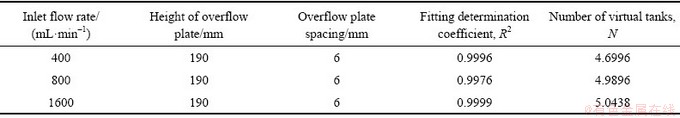

利用Matlab软件对停留时间分布曲线的实验值和按照非理想流动模型的计算值做非线性回归拟合(见表2)。表2展示的是不同操作条件下实验测定值和模型计算值拟合的相关度,它利用了一个确定系数R2来表征,并根据实验结果计算得到了虚拟槽数N。从表2可以看出,拟合相关度还是比较好的,最差拟合情况下的确定系数也有0.99以上。从虚拟槽数上看,进口流量越大越接近理想虚拟槽数5,但是从实际生产中考虑的话,不可能将进口流量调到那么高,这样会导致固相颗粒在槽内的平均停留时间偏低。

图5 不同进口流量对多槽串联连续搅拌浸出槽中固体颗粒RTD曲线的影响

Fig. 5 Influence of inlet rate on RTD curves of solid particles of continuous stirred leaching tank

表1 不同进口流量条件下RTD参数比较表

Table 1 Comparison of RTD parameters at different flow rates

从槽内整体的固相浓度分布来看,增加进口流量也存在着一定的缺点。图6所示为数值模拟得到的不同进口流量条件下多槽串联连续搅拌浸出槽在X=0轴截面上的固相浓度分布对比图。

从图6中可以看出,在研究范围内,进口流量的大小并不能在宏观上改变槽内流场流动特性。随着进口流量的增加,多槽串联连续搅拌浸出槽在X=0轴截面上的固相颗粒最大体积分数呈现增加趋势,但增加的趋势不明显。当进口流量在400 mL/min时,X=0轴截面上的最大固相体积分数为10.95%,而当进口流量增加到1600 mL/min时,最大固相体积分数增加到11.29%。

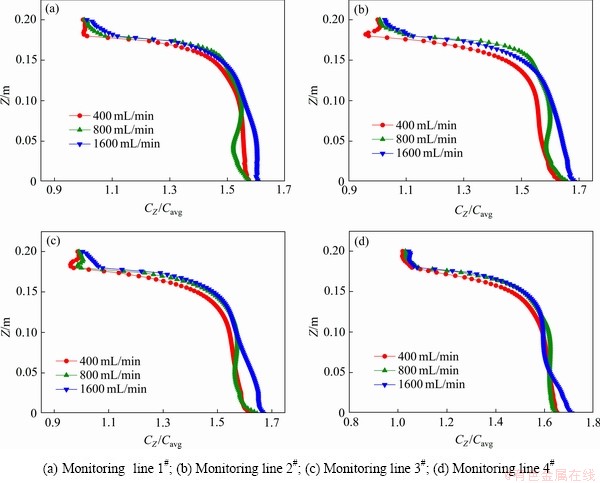

为了比较不同进口流量条件下白钨矿颗粒在溢流板间的悬浮状况,特选择4组溢流板间的轴向线作为监测线,其4条监测线的端点坐标如表3所标注。图7所示为不同进口流量对固相颗粒在槽内4条监测线上的固相浓度分布影响。由图7可知,随着进口流量的减小,每组溢流板间的固相体积分数均呈减小趋势,在进口流量为400 mL/min时,每组溢流板间的固相体积分数最小。

表2 不同操作条件下拟合计算确定系数R2与虚拟槽数N

Table 2 Fitting calculations for R2 and N under different operating conditions

图6 在不同进口流量条件下YZ截面上的固相浓度分布对比

Fig. 6 Comparison of solid concentration distribution on YZ plane at different inlet flow rates

图7 进口流量对固相颗粒在槽内4条监测线上的固相浓度分布影响

Fig. 7 Influence of inlet flow rate on local axial solid concentration profiles on four detection lines in stirred tank

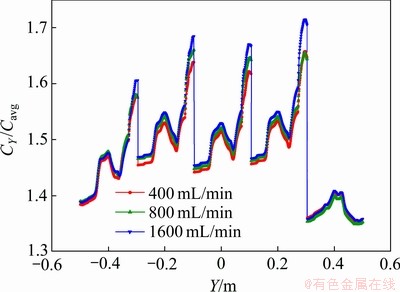

图8所示为不同进口流量条件下槽底X=0径向方向上固相浓度分布。从图8中可得到与上述结论一致的规律。随着进口流量的增加,槽底X=0径向方向上固体颗粒的浓度也随之增大。因为随着进口流量的增加,单位时间内引入系统的固相颗粒会在槽内累积,在各槽串联的过程中,每组溢流板之间还会有一定的阻隔作用,从而导致固相颗粒在系统中累积得越来越多。从固相颗粒在槽内的停留时间分布、悬浮特性以及反应浸出、结晶等方面综合考虑,选择进口流量为400 mL/min最为合适。

2.3 溢流板高度对固体颗粒流动特性的影响

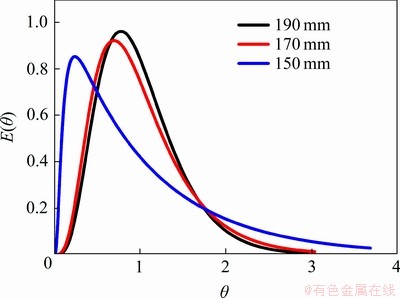

图9所示为溢流板高度对多槽串联连续搅拌浸出槽中固体颗粒RTD曲线的影响。从图9中可以看出,随着溢流板高度的升高,RTD曲线明显向后移动,峰值朝着θ=1逼近;当溢流板高度为150 mm时的RTD曲线有着明显的拖尾现象,导致固相颗粒离开系统的时间分散,白钨矿的浸出时间和二水硫酸钙的结晶成长时间长短不一,无法获得均匀、粗大的二水硫酸钙晶体。

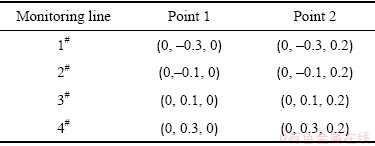

表3 轴向方向上的监测线示意表

Table 3 Schematic table of monitoring lines in axial direction

图8 不同进口流量条件下槽底X=0径向方向上固相浓度分布

Fig. 8 Distribution of solid phase concentration at bottom along radical direction X=0 under condition of different inlet flow rates

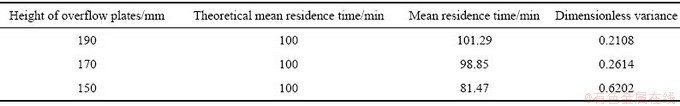

表4所列为不同溢流板高度条件下RTD参数比较表。从表4中可以看出,随着溢流板高度的减小,槽内的无因次化方差随之偏离0.2;当溢流板高度为150 mm时,无因次化方差达到最大值为0.6202,固相颗粒在槽内的平均停留时间较理论平均停留时间缩短了将近20 min。表5所示为不同溢流板高度条件下实验测定值与模型计算值拟合的相关度和计算得到的虚拟槽数N。从表5中可以看出,随着溢流板高度从190 mm降低到150 mm,虚拟槽数N从4.6996减小到1.5153,这说明如果将溢流板高度从190 mm降低到150 mm,多槽串联效果就会从5槽串联减少到相当于2槽串联,不利于分区结晶。

2.4 溢流板间距对固体颗粒流动特性的影响

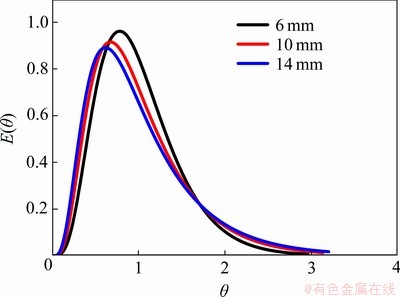

图10所示为溢流板间距对多槽串联连续搅拌浸出槽中固体颗粒RTD曲线的影响。由图10可看出,随着相邻溢流板间距的增大,RTD曲线向前偏移,逐渐偏离θ=1,而且越是增大溢流板间距,RTD曲线拖尾现象越是严重,这说明随着溢流板间距的增大,槽内的固相颗粒离开系统的时间更加分散。

图9 溢流板高度对多槽串联连续搅拌浸出槽中固体颗粒RTD曲线的影响

Fig. 9 Influence of overflow plate height on RTD curves of solid particles of continuous stirred leaching tank

表4 不同溢流板高度条件下RTD参数比较表

Table 4 Comparison of RTD parameters at different overflow plate heights

图10 溢流板间距对多槽串联连续搅拌浸出槽中固体颗粒RTD曲线的影响

Fig. 10 Influence of overflow plate spacing on RTD curves of solid particles of continuous stirred leaching tank

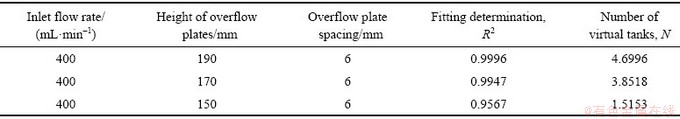

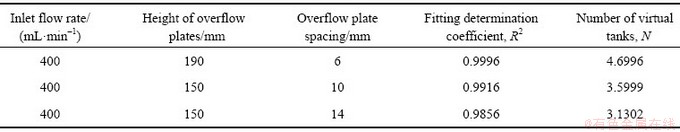

表6所列为不同溢流板间距条件下RTD参数比较表。从表6中可以看出,随着溢流板间距的增大,槽内固相颗粒的停留时间逐渐偏离理论的平均停留时间。从无因次化方差上看,随着溢流板间距的增大,无因次化方差逐渐偏离0.2;当溢流板间距为6 mm时,无因次化方差为0.2108;当溢流板间距增大到14 mm时,无因次化方差增大至0.3252。

表7所列为不同溢流板高度条件下实验测定值与模型计算值拟合的相关度和计算得到的虚拟槽数N。从表7中可以看出,随着溢流板间距从6 mm增大到14 mm,虚拟槽数N从4.6996减小到3.1302,这就说明将溢流板间距从6 mm增大到14 mm时,多槽串联效果从5槽串联减少到相当于3槽串联,这样不利于分区结晶。

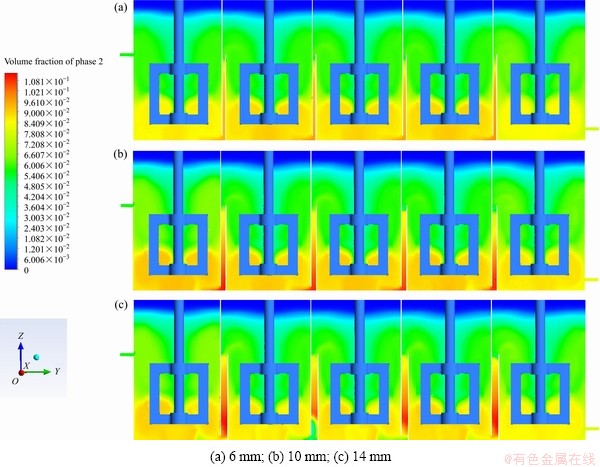

图11所示为数值模拟得到的不同溢流板间距条件下多槽串联连续搅拌浸出槽在YZ截面上的固相浓度分布对比图。从图11来看,随着溢流板间距的增大,在YZ截面上的固相体积分数也会随之增大;当溢流板间距为6 mm时,槽内在YZ截面上的硫酸钙颗粒的最大体积分数值最小为10.96%。而作为对比,当溢流板间距为14 mm时,在YZ截面上的固相最大体积分数值增大至12.43%。这是因为溢流板之间的区域得不到搅拌,增加这部分区域,减小搅动区域,导致槽内的搅拌效果就会变差。因此,增大相邻溢流板间距对固相颗粒在槽内的悬浮特性和串联分区效果都是不利的。

表5 不同操作条件下拟合计算确定系数R2与虚拟槽数N

Table 5 Fitting calculations for R2 and N under different operating conditions

表6 不同溢流板间距条件下RTD参数比较

Table 6 Comparison of RTD parameters at different overflow plate spacings

表7 不同操作条件下拟合计算确定系数R2与虚拟槽数N

Table 7 Fitting calculations for R2 and N under different operating conditions

图11 在不同溢流板间距条件下YZ截面上的固相浓度分布对比

Fig. 11 Comparison of solid phase concentration distribution of YZ plane under condition of different overflow plate spaces

3 结论

1) 串联之后的每个方型槽内会形成6个流动区域,容易发生堆积的锥形区域和相邻溢流板间的流动速度较小。搅拌槽内固体颗粒沿轴向出现明显的分层分布,利用溢流板串联过后的连续搅拌酸浸槽内会因为在相邻的溢流板之间得不到搅拌作用而会在此区域发生堆积现象,而且该区域的固相浓度要明显高于槽内其他区域,甚至是槽底的固相浓度。

2) 利用非理想流动模型来表征实验过程中的停留时间分布,模型拟合的停留时间曲线与实验测量的曲线吻合程度良好。进口流量、溢流板高度、相邻溢流板间距的设计影响了连续酸浸槽内串联效果:在保证较好的进口流量情况下,随着溢流板高度的增高、溢流板间距的减小,白钨矿连续酸浸槽内串联效果逐渐变好。

REFERENCES

[1] 袁 博, 李钟山, 刘良先, 柳群义, 孙立楠, 赵 敏. 我国钨资源储备规划形势分析[J]. 中国矿业, 2016, 25(1): 15-18.

YUAN Bo, LI Zhong-shan, LIU Liang-xian, LIU Qun-yi, SUN Li-nan, ZHAO Min. Analysis of the tungsten resources reserve plan in China[J]. China Mining Magazine, 2016, 25(1): 15-18.

[2] 中国钨业协会. 中国钨工业发展规划(2016—2020年)[J]. 中国钨业, 2017, 32(1): 9-15.

China Tungsten Industry Association. China tungsten industry development plan (2016—2020)[J]. China Tungsten Industry, 2017, 32(1): 9-15.

[3] 赵中伟, 李江涛, 陈星宇, 刘旭恒. 我国白钨矿钨冶炼技术现状与发展[J]. 有色金属科学与工程, 2013, 4(5): 11-14.

ZHAO Zhong-wei, LI Jiang-tao, CHEN Xing-yu, LIU Xu-heng. Technology status and development of scheelite metallurgy in China[J]. Nonferrous Metals Science and Engineering, 2013, 4(5): 11-14.

[4] LI Jiang-tao, ZHAO Zhong-wei. Kinetics of scheelite concentrate digestion with sulfuric acid in the presence of phosphoric acid[J]. Hydrometallurgy, 2016, 163: 55-60.

[5] 赵中伟, 李江涛. 一种连续浸出白钨矿的方法: 中国, ZL201410704909.5[P]. 2016-04-27.

ZHAO Zhong-wei, LI Jiang-tao. The invention relates to a continuous leaching method for scheelite ore: China, ZL201410704909.5[P]. 2016-04-27.

[6] 侯拴第, 王英琛, 施力田. 螺旋桨搅拌槽内湍流运动测量及数据处理[J]. 高校化学工程学报, 1996, 10(2): 196-201.

HOU Shuan-di, WANG Ying-tan, SHI Li-tian. Measurement of turbulence parameters and date processing in stirred tank with an axial impeller[J]. Journal of Chemical Engineering of Chinese Universities, 1996, 10(2): 196-201.

[7] 侯拴弟. 搅拌槽内三维流场的实验研究及数值模拟[D]. 北京: 北京化工大学, 1997: 20-80.

HOU Shuan-di. Experimental and numerical modeling study on fluid dynamic sin stirred tanks[D]. Beijing: Beijing University of Chemical Technology, 1997: 20-80.

[8] 侯拴第, 钟孝湘, 王英琛, 施力田, 张 政. 斜叶涡轮搅拌槽流动场数值研究[J]. 北京化工大学学报, 1999, 26(4): 1-4.

HOU Shuan-di, ZHONG Xiao-xiang, WANG Ying-tan, SHI Li-tian, ZHANG Zheng. A computational study of flow patterns in stirred tank agitated by pitched blade turbines[J]. Journal of Beijing University of Chemical Technology, 1999, 26(4): 1-4.

[9] 侯拴第, 张 政, 王英琛, 施力田. 轴流桨搅拌槽三维流场数值模拟[J]. 化工学报, 2000, 51(1): 70-76.

HOU Shuan-di, ZHANG Zheng, WANG Ying-chen, SHI Li-tian. Numerical simulation of turbulent flow in stirred tank agitated by axial impeller[J]. Journal of Chemical Industry and Engineering, 2000, 51(1): 70-76.

[10] 逄启寿, 邓华军. 双三层桨搅拌槽内三维流场的数值模 拟[J]. 有色金属(冶炼部分), 2012(7): 40-43.

PANG Qi-shou, DENG Hua-jun. Numerical simulation of three-dimensional flow fields generated by three-layer blades in agitation tank[J]. Non-ferrous Metals (Smelting Part), 2012(7): 40-43.

[11] KHAMAR L, SAMRANE K. The use of the CFD for the hydrodynamic flow diagnostic and study in a phosphoric acid reactor[J]. Procedia Engineering, 2016, 138: 369-377.

[12] 陶保林. 磷酸陈化槽内固-液两相混合搅拌过程模拟计算研究[D]. 武汉: 武汉工程大学, 2013: 7-65.

TAO Bao-lin. Simulation the process of solid-liquid two-phase mixing in the phosphate aging tank[D]. Wuhan: Wuhan Institute of Technology, 2013: 7-65.

[13] 陈 卓, 周 萍, 李 鹏, 肖功明, 闫红杰, 魏文武. 机械搅拌式锌浸出槽内固液两相流的数值模拟与结构优化[J]. 中国有色金属学报, 2012, 22(6): 1835-1841.

CHEN Zhuo, ZHOU Ping, LI Peng, XIAO Gong-ming, YAN Hong-jie, WEI Wen-wu. Numerical simulation and structure optimization of solid-liquid two-phase flow field in mechanical stirred zinc leach tank[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1835-1841.

[14] 金 丹, 付海玲, 吴剑华, 孙 丹. 混合器停留时间分布的研究进展[J]. 化工进展, 2011, 30(7): 1399-1405.

JIN Dan, FU Hai-ling, WU Jian-hua, SUN Dan. Advance in research on residence time distribution in mixers[J]. Chemical Industry and Engineering and Engineering Process, 2011, 30(7): 1399-1405.

[15] LUDWIG A, WU M, KHARICHA A. Simulation in metallurgical processing: Recent developments and future perspectives[J]. JOM, 2016, 160(8): 1-7.

[16] ZHAO Hong-liang, LIU Yan, ZHANG Ting-an, GU Song-qing, ZHANG Chao. Computational fluid dynamics (CFD) simulations on multiphase flow in mechanically agitated seed precipitation tank[J]. JOM, 2014, 66(7): 1218-1226.

[17] 李 鹏, 肖功明, 周 萍, 魏文武, 闫红杰. 机械式搅拌锌浸出槽内流场和停留时间的数值模拟[J]. 热科学与技术, 2012, 11(1): 53-58.

LI Peng, XIAO Gong-ming, ZHOU Ping, WEI Wen-wu, YAN Hong-jie. Numerical simulation of flow field and residence time in mechanical stirred zinc leach tank[J]. Journal of Thermal Science and Technology, 2012, 11(1): 53-58.

[18] 唐家鹏. FLUENT 14.0 超级学习手册[M]. 北京: 人民邮电出版社, 2013: 42-102.

TANG Jia-peng. Super study manual of FLUENT 14.0[M]. Beijing: People’s Posts and Telecommunications Press, 2013: 42-102.

[19] ZHAO Hong-liang, ZHANG Zi-mu, ZHANG Ting-an, LIU Yan, GU Song-qing, ZHANG Chao. Experimental and CFD studies of solid–liquid slurry tank stirred with an improved intermig impeller[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2650-2659.

[20] TAMBURINI A, CIPOLLINA A, MICALE G, CIOFALO M, BRUCATO A. Dense solid–liquid off-bottom suspension dynamics: Simulation and experiment[J]. Chemical Engineering Research & Design, 2009, 87(4): 587-597.

[21] BASAVARAJAPPA M, DRAPER T, TOTH P, TERRY A R, SANJA M. Numerical and experimental investigation of single phase flow characteristics in stirred tanks using Rushton turbine and flotation impeller[J]. Minerals Engineering, 2015, 83(1): 156-167.

[22] WADNERKAR D, UTIKAR R P, TADE M O, VISHNU K P. CFD simulation of solid–liquid stirred tanks[J]. Advanced Powder Technology, 2012, 23(4): 445-453.

[23] GU De-yin, LIU Zuo-hua, XIE Zhao-ming, LI Jun, TAO Chang-yuan, WANG Yun-dong. Numerical simulation of solid-liquid suspension in a stirred tank with a dual punched rigid-flexible impeller[J]. Advanced Powder Technology, 2017.

[24] SPIDLA M, SINEVIC V, JAHODA M, MACHON V. Solid particle distribution of moderately concentrated suspensions in a pilot plant stirred vessel[J]. Chemical Engineering Journal, 2005, 113: 73-82.

[25] 曹国祥, 唐忠阳, 李江涛, 李永立, 赵中伟, 伏 虎. 白钨矿连续酸浸槽内固体颗粒的流动特性实验及模型研究[J]. 化工进展, 2018, 37(7): 4565-4671.

CAO Guo-xiang, TANG Zhong-yang, LI Jiang-tao, LI Yong-li, ZHAO Zhong-wei, FU Hu. Experimental and modelling studies on flow characteristics of solid particles in a continuous tank for leaching scheelite[J]. Chemical Industry and Engineering Progress, 2018, 37(7): 4565-4671.

[26] 曹国祥. 白钨矿连续酸浸槽内流场特性及模拟计算研究[D]. 长沙: 中南大学, 2019: 18-19.

CAO Guo-xiang. Simulation study on the characteristics of flow field in a continuous stirred tank for leaching scheelite with sulfuric-phosphoric mixed acid[D]. Changsha: Central South University, 2019: 18-19.

[27] 肖兴国, 谢蕴国. 冶金反应工程学基础[M]. 北京: 冶金工业出版社, 2010: 160.

XIAO Xing-guo, XIE Yun-guo. Fundamentals of metallurgical reaction engineering[M]. Beijing: Metallurgical Industry Press, 2010: 160.

Flow field characteristic research in tanks reactor for leaching scheelite

TANG Zhong-yang, CAO Guo-xiang, LI Jiang-tao, ZHAO Zhong-wei

( School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: The application of computational fluid dynamic technology (CFD) using three-dimensional numerical simulation method on the analysis of gypsum particle flow behavior in the tanks reactor for scheelite leaching was investigated. The influences of inlet flow rate, height and spacing of overflow plates on the partition effect of tanks reactor was studied. A set of five stirred tanks reactor(size of single tank: 200 mm×200 mm×310 mm) was used as an example to simulate the flow field characteristics in the vessel. The results show that the particles gradually accumulated in between adjacent overflow plates due to non-effective mixing. With inlet flow rate and the height of overflow plate increasing and overflow plate spacing decreasing, the continuity and uniformity of fluid flow are improve significantly. Under the experiment conditions of inlet feed rate 400 mL/min, height of the overflow plate 190 mm, spacing between overflow plates 6 mm, the calculated virtual cell number N of is close to the actual tanks number 5, the dimensionless variance is 0.2108, and the tanks reactor has better performance with idealized partitioning effect. This research can provide theoretical basis and guidance for the optimization design and enlargement test of the stirred tank for scheelite leaching in sulfuric-phosphorous mixed acid.

Key words: tanks reactor; particle suspension; computational fluid dynamics (CFD); residence time distribution (RTD); non-ideal flow mode

Foundation item: Project(2018JJ3673) supported by the Natural Science Foundation of Hunan Province; Project (kq1802030) supported by the Changsha Outstanding Youth Program, China

Received date: 2019-11-04; Accepted date: 2020-08-31

Corresponding author: LI Jiang-tao; Tel: +86-731-88830476; E-mail: jiangtao-lee@csu.edu.cn

(编辑 李艳红)

基金项目:湖南省自然科学基金资助项目(2018JJ3673);长沙市杰出创新青年培养计划资助项目(kq1802030)

收稿日期:2019-11-04;修订日期:2020-08-31

通信作者:李江涛,副教授,博士;电话:0731-88830476;E-mail:jiangtao-lee@csu.edu.cn