文章编号: 1004-0609(2006)05-0914-05

银锰矿中银的回收新工艺

张小云, 田学达, 刘小玲, 张东方

(湘潭大学 化工学院, 湘潭 411105)

摘 要: 采用“浮选—磁选—还原浸出—重选脱泥”工艺处理银含量为3.15×10-4的某银锰矿。 银的独立矿物用浮选回收; 以类质同象分布于锰矿物中的银用磁选富集; 将浮选精矿和银锰磁选精矿合并, 用焙烧黄铁矿产生的SO2和纤维素还原剂进行还原浸出, 锰溶于液相中, 银在浸出渣中富集; 将浸出渣进行重选脱泥, 可得Ag含量为59.6×10-4的银精矿, Ag的总回收率大于90.68%。

关键词: 银; 银锰矿; 浮选; 磁选; 还原浸出; 脱泥 中图分类号: TF111.3; TF832

文献标识码: A

A novel technique for silver recovery from silver-manganese ore

ZHANG Xiao-yun, TIAN Xue-da, LIU Xiao-ling, ZHANG Dong-fang

(Chemical Engineering College, Xiangtan University, Xiangtan 411105, China)

Abstract: The silver in some oxidized silver-manganese ore with a grade of 3.15×10-4 Ag was concentrated with a novel technique including flotation, magnetic separation, reducing leaching and gravity desliming. Around 8.50% silver minerals were separated by flotation, and 91.50% silver contained in manganese ore through isomorphism was concentrated by magnetic separation. The manganese in the concentrate of both flotation and magnetic separation was dissolved in a reducing leaching, in which pyrite and some cellulose reductant were used. A silver concentrate with a grade of 59.6×10-4 and a recovery of 90.68% were obtained by a gravity desliming process.

Key words: silver; silver-manganese ore; flotation; magnetic separation; reducing leaching; desliming

额仁陶勒盖银矿位于内蒙古呼伦贝尔盟境内, 是一个以银为主、 伴生锰、 金、 铜铅锌的大型矿床[1]。 该矿分4种工业类型, 即石英脉硅化类型, 蚀变硫化物型, 锰硅型和铅锌石英脉型, 其中锰硅型矿石银的平均品位为41.22 ×10-4, 占矿石储量的8.00%。 在锰硅型矿石中, 银主要以两种形式存在: 1) 以独立的银矿物产出; 2) 以类质同象形式分布于硬锰矿中。 分析表明, 银的独立矿物仅占8.00%左右, 主要为自然银、 硒银矿、 角银矿、 碘银矿和硫锑铜银矿, 而86.45%的银分布在硬锰矿中, Mn与Ag为正消长关系。

银的回收通常分为两种方法[2, 3]。 对于银的独立矿物, 可用浮选法回收, 由于银矿物可浮性好, 一般以硫化钠作调整剂, 丁黄药和丁铵黑药作捕收剂即可获得良好效果[4, 5]。 对于锰矿物中银, 只能先得到银锰磁选粗精矿后再进行银锰分离[6]。 银锰分离的方法主要有还原焙烧法[7]、 还原剂还原法[8-10]、 细菌堆浸法和氯化焙烧法等[11-14]。 这些方法均能有效改变银锰矿中MnO2的物质结构和组成, 使银暴露后再回收。

根据额仁陶勒盖银矿的矿石性质, 结合矿山硫酸供应困难但矿区周边有大量黄铁矿的实际情况, 本文采用“浮选—磁选—还原浸出—重选脱泥”新工艺, 较好地实现了独立银矿的回收和银锰回收与分离。 本文的研究重点是银锰分离, 因为这是实现银回收的根本前提, 银独立矿物浮选与银锰磁选只是为银锰分离创造必要条件。

1 实验

1.1 矿石

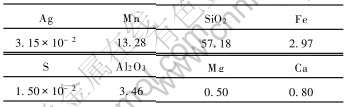

矿石取自内蒙古额仁陶勒盖银矿, 由内蒙古金山矿业有限公司提供。 矿物成分较简单, 金属矿物主要有硬锰矿、 软锰矿、 碘银矿、 褐铁矿, 非金属矿物以石英为主。 矿石经破碎、 磨粉制成不同粒级的试样。 试样多元素分析见表1。

表1 银锰矿试样的元素分析

Table 1 Element analysis of silver-manganese ore (mass fraction, %)

黄铁矿取自某铅锌选矿厂尾矿, 80%的矿物粒度小于0.074mm, 含S 31.28%。

1.2 试剂

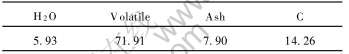

浮选用丁铵黑药、 丁黄药和硫化钠均为工业品; 实验所用纤维素还原剂由某工业加工副产品经生化改性制得, 富含纤维素和半纤维素, 外观呈颗粒状, 浅黄色。 这种还原剂源广价廉、 无毒无污染。 纤维素还原剂组分分析结果见表2。

表2 纤维素还原剂组分分析

Table 2 Analysis of main components in cellulose reductant (mass fraction, %)

1.3 实验方法与仪器

将矿石湿磨至粒度为80%小于0.074mm, 在槽容积为1L的FXD单槽浮选机中浮选银的独立矿物, 得到浮选精矿; 浮选尾矿用强磁选机分选, 磁性产品为银锰磁选精矿, 非磁性产品为尾矿; 用黄铁矿焙烧产生的SO2和纤维素还原剂还原锰矿物, 实现银锰分离。 黄铁矿焙烧在自行设计的d40mm×900mm的管式反应器内进行, 用d42mm×650mm管式电炉加热, DRZ-6型温度控制器调控反应温度, 银锰磁选精矿调配成一定浓度的矿浆吸收液, 置于主吸收槽中, 浮选精矿调配成一定浓度的矿浆吸收液, 置于副吸收槽中, 黄铁矿焙烧产生的烟气首先进入主吸收槽, 烟气中SO2与银锰磁选精矿中的锰矿物反应生成MnSO4, SO3被矿浆吸收转化为H2SO4; 主吸收槽尾气进入副吸收槽, 未被主吸收槽吸附的SO2和SO3与副吸收槽中浮选精矿中锰矿物反应或被矿浆吸收。 矿浆吸收液固体浓度约35%, 搅拌速度约400r/min。

2 结果与讨论

2.1 浮选与磁选

试样中银的独立矿物占8.50%, 其余91.50%的银以类质同象形式分布在锰矿中。 银的独立矿物可浮选性良好。 条件实验表明, 取试样500g, 磨至合格细度, 矿浆pH为7.6左右, 浮选药剂用量分别为每吨矿硫化钠500g、 丁黄药8g、 丁铵黑药10g, 浮选时间12min, 银的回收率可达11.50%以上, 银的独立矿物几乎全部回收, 且银锰矿也少量夹杂上浮, 所得浮选精矿产率2.65%, 含Ag 13.67×10-4, 含Mn 10.63%。

本研究中, 磁选的目的在于确保银锰回收率的前提下尽可能提高银锰磁选精矿中Ag的含量。 在磁场强度955 kA/m的条件下对浮选尾矿进行磁选, 磁性产品中Ag含量为7.43×10-4, Ag的回收率为75.45%; 锰含量38.60%, Mn的回收率93.48%。

浮选和磁选后, Ag的总回收率为86.95%, Mn的回收率大于93.48%。

2.2 银锰磁选精矿的银锰分离

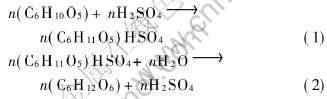

磁选所得银锰精矿的脱锰方法很多。 考虑到矿产地的资源、 地理位置及交通情况, 本实验确定以黄铁矿作为原料, 焙烧产生SO2气体, 用银锰磁选精矿矿浆吸收, 通过SO2将MnO2还原成Mn2+而进入溶液。 探索了黄铁矿与银锰磁选精矿共焙烧, 结果表明共焙烧法无论是还原效果、 废气处理、 还原后渣中Ag含量和浸出液中银含量等指标均比黄铁矿单独焙烧所得指标差, 因此初步认为共焙烧法不适合本试样。 实验还发现, 仅以黄铁矿焙烧产生SO2还原MnO2, 达不到理想的还原效果, 原因是本实验中黄铁矿焙烧时必须通入适量空气, SO2易与O2产生SO3, SO3与矿浆接触生成H2SO4, 而H2SO4不具备溶解MnO2的能力。 文献[15, 16]的研究表明, 有一种纤维素是MnO2的良好还原剂。 该纤维素在H2SO4溶液中水解产生的多糖是主要的还原成分, 其反应式可表示为

上述过程为水解糖化过程, 生成的强还原性多糖与MnO2作用, 使得MnO2被还原成Mn2+。 反应式为

因此, 本研究确定以SO2作为气体还原剂, 以这种纤维素为固体还原剂实现Ag与Mn的分离。

2.2.1 SO2气体还原对银锰分离的影响

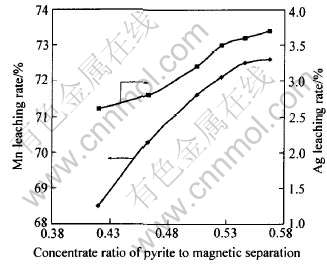

每次实验取经强磁选得到的银锰磁选精矿500g, 根据磁选精矿中Mn含量及所用黄铁矿中S含量, 假定黄铁矿在焙烧炉中完全分解, 银锰矿中Mn全部以MnO2形式存在(事实上主要以硬锰矿形式存在), 则可确定黄铁矿的理论用量为210g, 即理论上黄铁矿与银锰磁选精矿的用量比值为0.42。 以此理论用量为基础逐渐增加黄铁矿用量, 焙烧温度670℃, 焙烧和还原浸出时间3h, 考查Mn、 Ag浸出率, 实验结果见图1。

图1 黄铁矿用量与Ag和Mn浸出率的关系

Fig.1 Effect of pyrite dosage on silver and manganese leaching rate

由图1可知, 即使在较大的黄铁矿用量下, Mn的浸出率也不高; 继续增大黄铁矿用量, Mn的浸出率增加缓慢, 浸出后溶液pH值逐渐降低, 这些现象说明焙烧产生的SO2气体并未100%与MnO2反应, 而是有一部分SO2首先与焙烧炉中通入的空气中的O2反应生成了SO3, SO3与矿浆撞触后产生H2SO4。 由于H2SO4的存在, 导致Ag的少量溶解。 实验中测定了黄铁矿焙烧渣中硫含量小于2.00%, 测定了吸收尾气中SO2瞬间排放浓度不超过600mg/m3, 说明黄铁矿分解较完全, SO2吸收也较完全。 锰浸出率不高的原因在于银锰矿中锰矿物是以硬锰矿为主, 硬锰矿中MnO2成分未被较好还原。

继续增大黄铁矿用量, 不能显著提高锰的浸出率, 因此考虑在矿浆中加入纤维素还原剂, 以提高Mn的浸出率, 有效实现银锰分离。

2.2.2 纤维素还原剂对银锰分离的影响

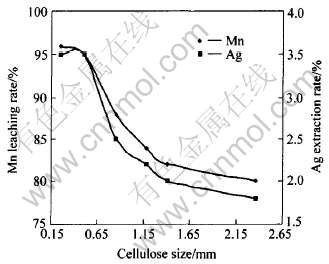

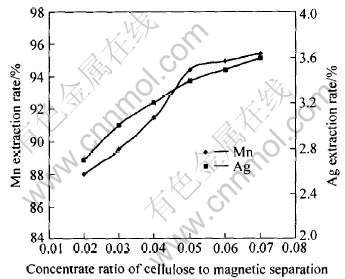

取银锰磁选精矿500g, 黄铁矿250g, 纤维素还原剂与银锰磁选精矿混合均匀后置于主吸收槽中, 其他条件同2.2.1, 分别考查纤维素还原剂细度和用量对银锰分离的影响。 图2所示为是纤维素用量为25g(即纤维素与银锰磁选精矿的质量比为1∶20)时, 纤维素粒度对还原效果的影响。 图3所示是纤维素粒度小于0.5mm时, 纤维素用量与银锰磁选精矿用量的比值对还原效果的影响。

图2 纤维素粒度对还原效果的影响

Fig.2 Effect of cellulose fineness on extraction of Mn and Ag

图3 纤维素用量对还原效果的影响

Fig.3 Effect of cellulose dosage on extraction of Mn and Ag

图2表明, 在一定的还原浸出时间内, 纤维素细度对还原效果有一定影响。 纤维素越细, 还原效果越好。 但若纤维素太细, 在生产实践中不容易实现, 因此取细度为0.5mm为宜。

由图3可知, 纤维素与银锰磁选精矿的质量比直接影响还原效果。 在实验条件下, 纤维素质量与银锰磁选精矿质量比值为0.05时, 锰矿物的还原已进行得相当充分, 反应物料中Mn的浸出率达94.00%, 比单独使用SO2作为还原剂时增加20.00%以上。 继续增大纤维素用量, 还原效果略有增加。 在增加使用纤维素时, 银的浸出率不超过3.60%, 与单独使用SO2作为还原剂时相当, 说明使用纤维素不会增加银在液相中的溶解。

银锰磁选精矿还原浸出后, 银主要富集在浸出渣中, 浸出液中含有少量银。 浸出液中银的回收方法需根据浸出液中锰的加工处理工艺确定。 当浸出液中锰用于制取硫酸锰时, 银可在硫酸锰液净化除杂的渣中回收。 若硫酸锰液用于生产碳酸锰, 则可首先加入适量盐酸得到 AgCl沉淀, 浸出液中银99.00%以上可回收。

2.2.3 还原浸出渣的脱泥与工艺流程的确定

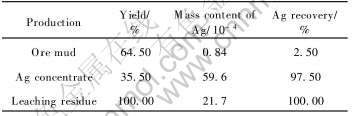

取矿石试样500g, 磨至合适粒度后浮选, 得到13.3g浮选精矿, 其中Ag含量为13.67×10-4, Mn含量10.63%; 浮选尾矿经强磁选, 得到160.0g银锰磁选精矿, 其中Ag含量7.43×10-4, Mn含量38.60%。 考虑到浮选精矿中Mn含量也较高, 因此将银锰磁选精矿与8g纤维素混合调浆后置于主吸收槽, 浮选精矿置于副吸收槽, 用200g黄铁矿焙烧产生的SO2对主副吸收槽中锰矿物进行还原浸出, 得到67.5g浸出渣, 渣中Ag含量为2.17×10-3, Ag回收率93.00%。 将此浸出渣细磨至小于0.045mm后, 用重选法脱泥, 实验结果列于表3。

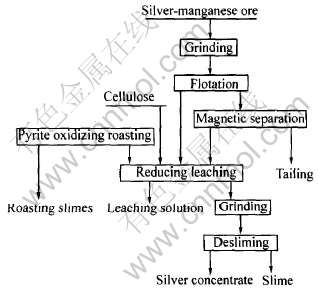

浸出渣经重选脱泥, 可得到银含量为5.96×10-3的Ag精矿, Ag总回收率为97.5%×93%=90.68%。 通过实验, 确定处理该银锰矿的原则流程如图4所示。

表3 浸出渣脱泥实验结果

Table 3 Desliming result of leaching residue

图4 银锰矿中银的回收原则流程图

Fig.4 Flowsheet of silver recovery from silver-manganese ore

3 结论

1) 含银3.15×10-4的银锰矿中, 少量的银独立矿物可用浮选回收, 以类质同象分布于锰矿物中的银用强磁选富集。

2) 用焙烧黄铁矿产生的SO2和纤维素还原剂对浮选精矿与银锰磁选精矿进行还原浸出, Mn溶于液相中, Ag富集于渣中, 可有效地实现银锰分离。

3) 浸出渣细磨后脱泥, 可得到银含量5.96×10-4的银精矿, 银回收率大于90.68%。

REFERENCES

[1]吕志成, 张培萍, 段国正, 等. 内蒙古额仁陶勒盖银矿床锰矿物的矿物学初步研究[J]. 矿物岩石, 2002, 22(3): 1-3.

LU Zhi-cheng, ZHANG Pei-ping, DUAN Guo-zheng, et al. Study on manganese minerals of Erentaolegai silver deposit[J]. Mineral Petrol, 2002, 22(3): 1-3.

[2]孙敬峰. 从某银锰矿回收银[J]. 湿法冶金, 2001, 21(1): 25-27.

SUN Jing-feng. Recovery of silver from silver-manganite[J]. Hydrometallergy of China, 2002, 21(1): 25-27.

[3]岳铁兵, 李迎国, 魏德州, 等. 某低品位银锰矿选矿工艺研究[J]. 中国锰业, 2004, 22(3): 4-7.

YUE Tie-bing, LI Ying-guo, WEI De-zhou, et al. A technical research on concentrating silver and manganese ores of one lower grade[J]. Chinas Manganese Industry, 2004, 22(3): 4-7.

[4]李维天. 锰银氧化矿选冶工艺的研究现状及进展[J]. 广西地质, 2001, 12(3): 63-66.

LI Wei-tian. Review for recovery technique of silver-manganese oxide ores[J]. Guangxi Geology, 2001, 12(3): 63-66.

[5]吴文伟. 采用选冶联合工艺富集氧化型银锰矿中的银[J]. 有色金属(选矿部分), 2003, 55(5): 22-24.

WU Wen-wei. The concentration of silver from oxidative silver-manganese ore with united technologies of beneficiation and metallurgy[J]. Nonferrous Metals(Mineral Processing), 2003, 55(5): 22-24.

[6]郭秀平, 吴艳秋, 李朝辉, 等. 某低品位锰银矿强磁选工艺研究[J]. 矿产综合利用, 2004, 24(1): 7-9.

GUO Xiu-ping, WU Yan-qiu, LI Zhao-hui, et al. High intensity magnetic separation of a low grade manganese-silver ore[J]. Multipurpose Utilization of Mineral Resources, 2004, 24(1): 7-9.

[7]吴文伟. 银锰精矿焙烧-硫酸浸出提银新工艺[J]. 有色金属, 2004, 56(1): 48-50.

WU Wen-wei. Silver extraction from silver-manganese concentrate by roasting-leaching with sulfuric acid[J]. Nonferrous Metals, 2004, 56(1): 48-50.

[8]余丽秀, 杨卉蓬, 王秋霞, 等. 有机还原剂处理银锰矿新工艺研究[J]. 矿产保护与利用, 2002, 21(2): 38-40.

YU Li-xiu, YANG Hui-peng, WANG Qiu-xia, et al. Study on new technique of reduction processing Ag-Mn ore with organic reducing agent[J]. Conservation and Utilization of Mineral Resources, 2002, (2): 38-40.

[9]张斌, 姜涛, 陈启元, 等. 银锰矿一步法浸出动力学探讨[J]. 矿产保护与利用, 2001, 20(2): 43-46.

ZHANG Bin, JIANG Tao,CHEN Qin-yuan, et al. Dynamics on simultaneous leaching of manganese and silver[J]. Conservation and Utilization of Mineral Resources, 2001, (2): 43-46.

[10]孙亚光, 余丽秋. 碳氢化合物湿法处理银锰矿应用研究[J]. 中国锰业, 2004, 22(1): 1-4.

SUN Yan-guang, YU Li-qiu. Study on technique and application of reduction of Mn-Ag ore with organic compound[J]. Chinas Manganese Industry, 2004, 22(1): 1-4.

[11]JIANG Tao, YANG Yong-bin. Simultaneous leaching of manganese and silver from manganese-silver ores at room temperature[J]. Hydrometallurgy, 2003, 69(1-3): 177-186.

[12]张斌, 陈启元, 姜涛, 等. 锰银矿同步浸出锰、 银新工艺试验研究[J]. 黄金, 2001, 22(7): 26-29.

ZHANG Bin, CHEN Qi-yuan, JIANG Tao, et al. A new technological research for simultaneous leaching of manganese and silver from a manganese-silver associated ore[J]. Gold, 2001, 22(7): 26-29.

[13]袁明亮, 邱冠周, 王淀佐. 细粒嵌布锰银矿浸出中的超声强化作用[J]. 过程工程学报, 2002, 2(1): 21-25.

YUAN Ming-liang, QIU Guan-zhou, WANG Dian-zuo. Effect of ultrasonic wave on leaching manganese-containing silver ore with the binary ore leaching process[J]. The Chinese Journal of Process Engineering, 2002, 2(1): 21-25.

[14]周元敏, 梅光贵. 由Ag-Mn矿浸锰液制取碳酸锰或硫酸锰的研究[J]. 中国锰业, 2003, 21(1): 10-13.

ZHOU Yuan-min, MEI Guang-gui. Study on the preparation manganese carbonate or manganese sulphate from leaching silver-manganese ore solution[J]. Chinas Manganese Industry, 2003, 21(1): 10-13.

[15]张小云, 田学达, 刘树根, 等. 铁锰多金属矿综合利用新工艺研究[J]. 中国有色金属学报, 2005, 15(4): 650-654.

ZHANG Xiao-yun, TIAN Xue-da, LIU Shu-gen, et al. Utilization technique of ferromanganese ore[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 650-654.

[16]张小云, 田学达. 纤维素还原低含量软锰矿制备硫酸锰[J]. 精细化工, 2006, 23(2): 195-197.

ZHANG Xiao-yun, TIAN Xue-da. Preparation of manganese sulfate from pyrolusite with cellulose as reductant[J]. Fine Chemicals, 2006, 23(2): 195-197.

基金项目: 湖南省教育厅资助项目(04C645); 湖南省科技厅科技计划重点资助项目(03SSY1011)

收稿日期: 2005-10-20; 修订日期: 2006-04-03

通讯作者: 张小云; 电话: 0732-8292246; E-mail: snowy@xtu.edu.cn

(编辑龙怀中)