文章编号:1004-0609(2013)S1-s0159-08

Mo、V、Cr元素对β钛合金力学性能的影响

李 倩1,葛 鹏1,赵永庆1,王 敏2,周 伟1

(1. 西北有色金属研究院 钛合金研究所,西安 710016;

2. 西北工业大学 材料学院,西安710072)

摘 要:设计了3种三元系近β钛合金,并对合金的组织与性能进行了分析,研究了各元素对合金组织特征与力学性能的影响。结果表明:经400 ℃时效后,3种合金硬度由大到小依次为合金3、合金2、合金1;经500、600、700 ℃时效后,3种合金硬度由大到小依次为合金3、合金1、合金2;3种合金固溶时效处理后的强塑性匹配由高到低为合金1、合金2、合金3,在相同时效制度下,合金1的断裂韧性优于合金2的;添加Mo和V元素可以提高裂纹产生的抗力,从而提升合金的断裂韧性,并且Mo元素的效果比V元素的好。

关键词:β钛合金;时效;析出相;硬度;强塑性

中图分类号: 文献标志码:A

Effects of alloying elements Mo, V and Cr on mechanical properties of β titanium alloy

LI Qian1, GE Peng1, ZHAO Yong-Qing1, WANG Min2, ZHOU Wei1

(1. Titanium Alloy Research Center, Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China;

2. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Three new type metastable β titanium alloys were designed. The structure and properties of the ternary system titanium alloy were investigated systematically. The effects of alloy elements on the structures and mechanical properties of these ternary system titanium alloys were also studied. The results show the sequence from large to small of the hardness of alloy aged at 400 ℃ is alloy 3, alloy 2 and alloy 1. The sequence from large to small of hardness for the same alloy aged at 500, 600, and 700 ℃ is alloy 3, alloy 1 and alloy 2, respectively. The reasonable match between ductility and strength of these alloys after aging, from good to bad, is alloy 1, alloy 2 and alloy 3. With the same aging treatment, the fracture toughness of alloy 1 is better than that of alloy 2. Mo and V can enhance the cracks resistance, and then increase the fracture toughness, and the element Mo has better effect than V.

Key words: β titanium alloy; aging; precipitated phase; hardness; strength and toughness

随着近代航空和航天领域不断地发展,结构件用钛合金正在向高强度、冷成形的β和近β型合金方向发展。通过对现有比较成熟的高强钛合金如Ti-1023、VT-22、Ti-5553、VT-16、Ti-38644、Ti-1300[1]等的成分分析可以发现,Al、Mo、V、Cr、Fe是高强结构钛合金设计选用的主要元素。在新型高强韧钛合金设计时面临的问题是怎样合理地选择Mo、V、Cr 3种元素。本文作者从相对简单的三元合金体系入手,设计几种Ti-Al-Me(Mo、V、Cr)近β钛合金进行相关的组织与性能分析,总结各元素对于合金组织性能的影响。根据目前的研究现状,加入5%的Al比较合理,既可以提高强度又可以抑制ω相的形成。结合现有的合金的成分配比,由此设计3种近β钛合金,合金的成分为Ti-5Al-15Mo、Ti-5Al-22V和Ti-5Al-10Cr。根据文献[2-3]对β稳定元素临界浓度的研究结果,计算所设计的3种合金的β稳定系数值均为1.4左右。

1 实验

Ti-5Al-Me(Mo、V、Cr)均采用真空自耗熔炼。为表述方便,规定Ti-5Al-15Mo合金为合金1,Ti-5Al- 22V合金为合金2,Ti-5Al-10Cr合金为合金3。3种合金均在β相区开坯,两相区锻造成70 mm×70 mm方棒。用金相法测试3种合金相变点分别为(880±5)、(830±5)、(850±5) ℃。从合金棒材上取纵向拉伸试样、断裂韧性试样及硬度试样。采用热处理制度为900 ℃+30 min+WQ固溶处理后,分别在400、500、600、700 ℃进行15、30、60、120、240、480、960 min时效处理,时效后采用空冷。显微组织观察和金相照片在光学显微镜(Optical Microscope,OM)上完成。高倍显微组织观察在扫描电子显微镜(Scanning Electron microscope,SEM)上完成。XRD分析在D8 ADVANCE型XRD分析仪上完成。

2 结果与分析

2.1 添加元素对合金固溶组织的影响

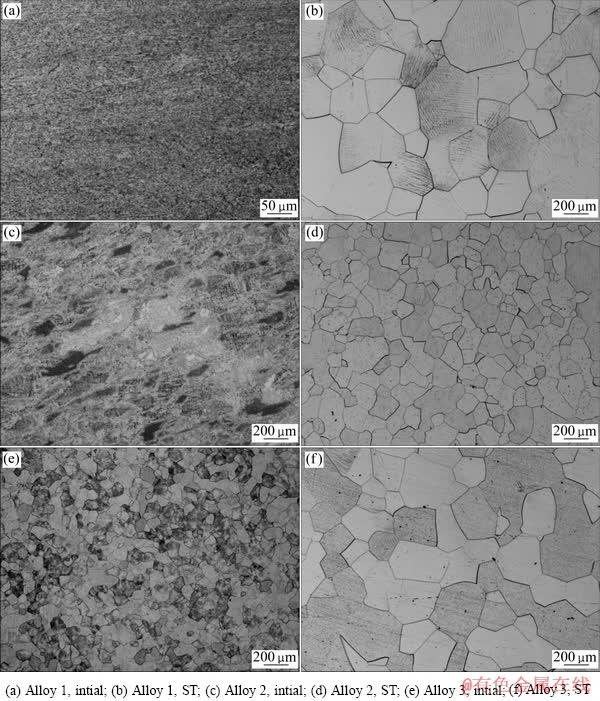

图1所示为3种合金固溶(ST)处理前后的组织形貌。

由图1可知,在Al含量相同的条件下,分别添加了V、Cr、Mo元素的3种合金在晶粒尺寸上有明显的不同。首先,从3种合金的锻态组织金相照片可以看出合金均为等轴组织,并包含有一定晶团尺寸且晶界被破碎的片层组织。同时可以得出原始晶粒的尺寸,合金1和3的原始晶粒尺寸均非常细小,仅为几微米,合金2的原始晶粒尺寸虽然也比较小,但是比其他2个合金的要大一些。然而在经过了固溶处理之后,反而是合金2的平均晶粒尺寸最小,约为112 μm,其次是合金1的,约为213 μm,平均晶粒尺寸最大的是合金3,约为288 μm。研究表明[4],计算得到的3种合金的长大激活能分别为85.1、92 l和83.7 kJ/mol。这与大多数钛合金的β晶粒长大激活能相比要小一些,与Ti-6Al-4V合金的97 kJ/mol相当。结合图1的组织分析可以看出,合金1与3的晶粒长大所需要的能量小,晶粒长大相对容易。这可能与这两种合金较低的相变点及较高的热处理温度有关。这说明对于三元系β钛合金来说,V元素对于抑制晶粒生长有一定的作用,效果优于Mo和Cr元素。

图1 合金的显微组织

Fig. 1 Optical microstructures of alloys

2.2 添加元素对合金硬度的影响

实践证明,金属材料的各种硬度之间,硬度与强度之间具有近似的相应关系。影响材料硬度的主要因素有成分、相组成、显微组织和冷变形等。对于本文中的3种合金来说,每种合金取样的化学成分和热加工工艺相同,因此,硬度差异应归结为不同温度热处理引起合金的析出相组成、形貌和尺寸的差别。图2所示为不同热处理制度后3种合金的硬度值比较。由图2可以看出,不管时效温度高低, 3种合金中合金3的硬度最高。400 ℃时效时,合金2的硬度高于合金1的,而在其他温度时效时,情况相反,合金1的硬度又高于合金2的,除了合金元素本身的物理参数差异所带来的不同之外,还可能与合金的析出相有关。400 ℃时效后,3种合金硬度由大到小排列为合金3、合金2、合金1;经500、600、700 ℃时效后的3种合金硬度由大到小依次为合金3、合金1、合金2。合金元素的强化效应主要考虑合金元素与Ti元素之间存在着原子直径、弹性模量以及化合价等方面的差异。这些因素综合考虑才能比较完整地体现出合金元素加入后引起的总弹性能量的变化。总弹性能量变化越大,强化效果越明显。V元素化合价(n=5)与Ti化合价(n=4)之差为1,Cr元素化合价(n=6)与Ti化合价之差为2,Mo元素化合价(n=6)与Ti化合价之差为2。因此V元素与Ti的化合价之差最小,其它两个元素相同。V元素弹性模量与Ti的弹性模量之差为5 670 MPa,Cr元素与Ti的弹性模量之差为18 900 MPa,Mo元素与Ti的弹性模量之差为22 050 MPa。因此,虽然Mo的原子直径之差与Ti直径之差的百分比(RMo-RTi)/RTi= 2.09%明显小于V的原子直径与Ti直径之差的百分比(RV-RTi)/RTi= 4.3%,但是Mo的强化效果高于V的[5]。而Cr的原子直径之差与Ti的原子直径之差的百分比(RCr-RTi)/RTi=4.68%。从上述硬度试验的硬化效果来看,Cr元素的强化效果高于Mo元素,但到底这两个元素的强化能力哪个更强,可能还与含量等条件有一定的关系。

图2 热处理温度对3种合金硬度的影响

Fig. 2 Effect of heat treatment temperature on hardness of three alloys

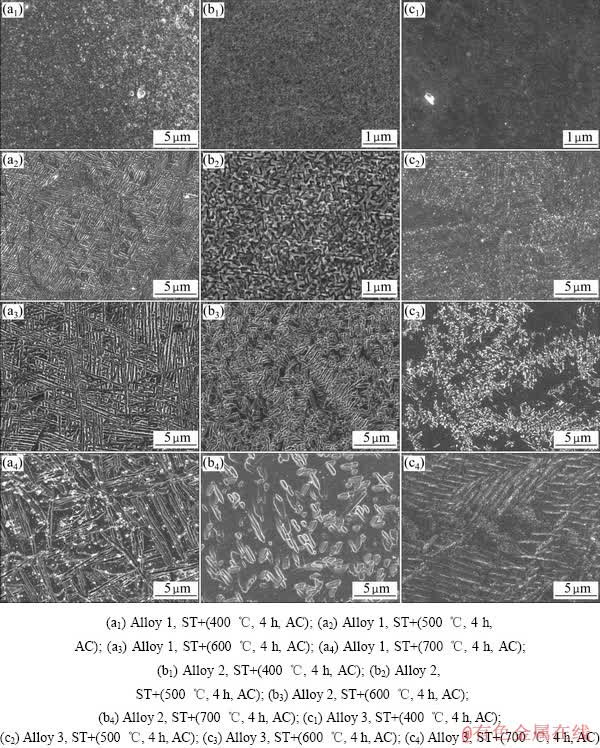

图3所示为3种合金时效后的SEM像。由图3可知,时效温度的升高导致合金析出相的组成和形貌发生了变化,而这种变化引起了合金硬度的差异。

对于合金2来说,时效时间相同的条件下,提高时效温度,硬度值不断下降。这与α相尺寸有关,尺寸越大,硬度值越小。到700 ℃时,时效硬度与淬火硬度基本相当。而对于合金1,在400 ℃时效时,可能因为时效温度比较低,还没有析出α相,这时存在一些过渡相,有可能是β′相,而众所周知的是β′相对于合金的强度没有明显改善作用。因此,400 ℃时效后,合金的硬度与淬火态的硬度差不多,没有明显提高。在500、600、700 ℃时效时,情况与合金2的差不多,同样也是因为析出了片层状的α相不断长大引起硬度值的下降。

图3 合金不同热处理后的SEM像

Fig. 3 SEM images of alloys with different heat treatments

研究表明[6],Ti-10Cr合金在固溶处理后,析出相主要为亚稳β相和淬火ω相,但是在合金3中,XRD观察没有发现有ω相的存在。这是因为合金中加入了Al元素。Al有3个电子参与合金化,少于Ti的价电子数,因此,钛合金中添加Al元素可以降低合金的电子浓度,起到抑制ω相形成的作用。ω相虽然能增加合金的硬度但是会降低其塑性,这在很多近β钛合金的研究中都得到了证实[7]。对于合金3,因为有了TiCr2析出相,情况略微复杂一些。合金在500 ℃时效时,虽然析出了α相,但是没有出现明显的硬度值变化,而是基本维持在HV490。时效16 h后,析出了能提高合金硬度的TiCr2相,但是含量很少,因此对硬度的贡献不大。温度升高到600 ℃,时效4 h以后,通过对合金TEM观察,发现了TiCr2相(图4),尺寸约为100 nm。然而短时时效并没有析出TiCr2相,这与时效时间有关,时间过短,合金没有足够的反应时间。因为TiCr2相的增多,合金的硬度较500 ℃时效后的硬度有所增加,但是当时效时间大于8 h之后,因为TiCr2的长大,合金硬度再次下降,这是由于随着TiCr2相长大带来的对强度贡献的降低造成的。700 ℃时效则因为析出的α相过于粗大,因此时效后的硬度与淬火硬度基本处于同一水平。

图4 合金中的TiCr2相

Fig. 4 TiCr2 phase of Ti-5Al-10Cr

2.3 添加元素与合金强塑性的关系

2.3.1 硬度与拉伸性能的关系

根据3种合金的时效硬化表现,即均在时效4 h时基本达到最大值,所以选取时效时间为4 h。而考虑到400 ℃时效处理时合金的硬度值较高,塑性会比较差,因此在拉伸性能测试制度的选择上暂不考虑400 ℃低温时效。由于对合金3进行了700、600 ℃时效后发现合金塑性较差,因此没有对该合金进行500 ℃时效后 的室温拉伸测试。表1中列出了3种合金固溶时效处 理后的拉伸性能。STA-1、STA-2、STA-3分别代表的热处理制度为((900 ℃,30 min,WQ) + (500 ℃, 4 h,AC))、((900 ℃,30 min,WQ) + (600 ℃,4 h,AC))和((900 ℃,30 min,WQ)+(700 ℃, 4 h,AC))。由表1可以看出,降低时效温度有利于强化,但对塑性的影响则相反。700 ℃时效后,合金3的强度最高,但是其塑性很差,小于5%。合金1的强度和塑性均比合金2的好。600 ℃时效后,合金3的强度略微有些降低,没有测出伸长率。该温度时效后合金1的强度仍然高于合金2的,两个合金的塑性基本相当;600 ℃时效后合金的强度高于700 ℃时效后的,但是塑性有所下降。合金1和2经500 ℃时效后的拉伸性能相比较,两个合金的强度有较大程度的提高,但是塑性下降也比较大。时效后两个合金的强度与塑性基本相当,合金1的略高。在3种时效制度下,合金1的性能优于合金2的,强塑性匹配较好。合金3的塑性差,无法得到有效数据。

表1 合金在不同温度时效处理后的性能

Table 1 Mechanical properties of three alloys aged at different temperatures

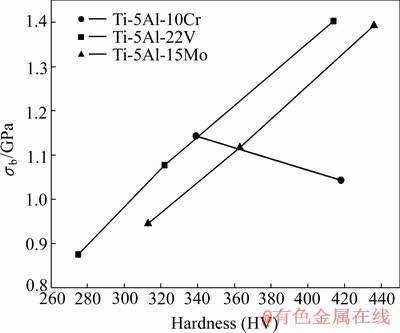

图5所示为3种合金的拉伸强度和硬度的关系。 将相关数据进行拟合,获得3种合金拉伸强度和硬度(Hv)的定量关系式。

Ti-5Al-22V:σb=-149.916 52+3.763 35Hv (1)

Ti-5Al-10Cr:σb=1 572.113 92-1.265 82Hv (2)

Ti-5Al-15Mo:σb=-202.159 51+ 3.652 41Hv (3)

从图5可以看到,3种合金的强度关系直线性偏差都不大,拟合较好。

图5 3种合金的HV与σb的关系

Fig. 5 Relationship between HV and σb for three alloys

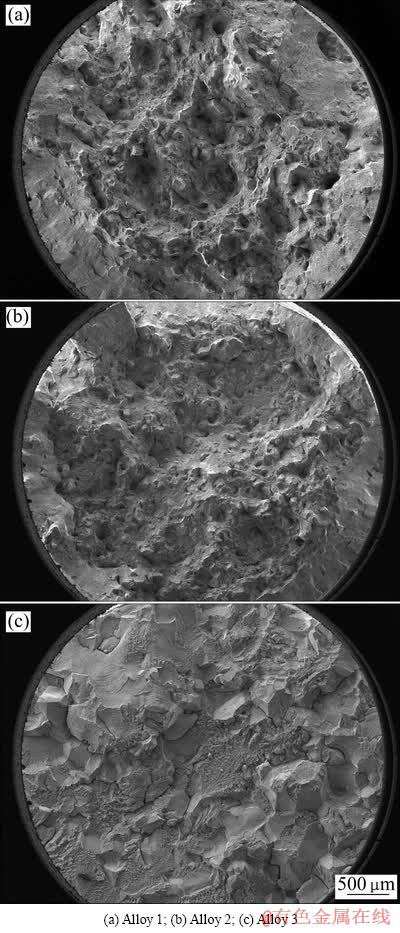

图6 合金热处理后的拉伸断口SEM宏观照片

Fig. 6 SEM fractographs of three tensile specimens with heat treatments

图6和7所示为3种合金600 ℃、4 h时效后的拉伸断口形貌。一般来说,塑性较好材料的光滑圆柱试样的拉伸断口呈杯锥状,由纤维区、放射区及剪切唇3部分组成,宏观断口3个区域的形貌、大小及微观特征在一定程度上反映了材料的塑性性能和组织特征。从图6可以看出,合金1和2宏观上纤维区和剪切唇明显较小,有的甚至没有,其心部断口形貌为韧性断裂的韧窝开裂和局部地方形成的准解理断裂的混合型断裂,断口呈纤维状,灰暗色。这种混合型断裂一般从试样的中心部位开始的,也就是裂纹的萌生区位于试样的截面中心,因为单轴拉伸时,试样截面中心处于三向应力状态易产生变形。这表明此状态下的合金塑性较好。而合金3的断口平齐而光亮,断口形貌均呈结晶状,为脆性断裂。3种合金经固溶时效处理后拉伸断口高倍SEM像如图7所示。

图7 合金热处理后的拉伸断口SEM像

Fig. 7 SEM fractographs of three tensile specimens with heat treatments

从图7中可以看到,合金的拉伸断口为韧窝+解理断裂特征(包括局部的沿晶断裂),表面有较大的起伏,随着时效温度的升高,韧窝的深度有所增加。合金3为脆性断裂,与合金的低塑性相对应,同时还有沿晶裂纹出现。

2.3.2 合金强塑性

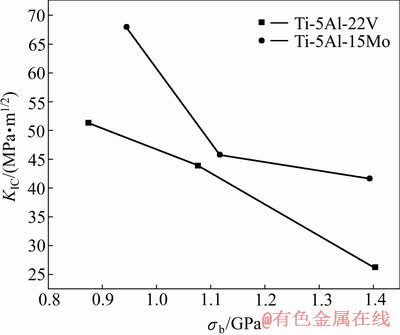

对钛合金来说,影响钛合金断裂韧性的主要因素是合金成分和显微组织形貌。合金成分决定了合金类型和合金中β相的数量。随着间隙元素含量的增加,材料的韧性会降低,β钛合金中的β稳定元素也会降低材料的韧性。在考察了合金典型时效制度下的拉伸性能之后,合金3在700 ℃时效后的塑性也比较差,因此在断裂韧性的测试时没有考虑该合金,而是选取了合金1与2进行了断裂韧性测试。在试样热处理制度的制定上,一方面考虑到β钛合金延长时效时间会显著降低合金的断裂韧性[8-11],另一方面前期的力学性能测试也侧重于不同时效温度之间强度和塑性的比较,因此,断裂韧性试样的热处理制度与拉伸性能制度相同(见表1)。从表1可以看出,合金1和2的变化规律相同。随着时效温度的升高,合金的强度降低,塑性升高,断裂韧性升高。这3个性能呈现出随时效温度的升高而单调增加的趋势。对于α+β型及近β型钛合金,在β区退火往往可以得到高疲劳裂纹扩展抗力及高断裂韧性,而后随炉缓慢冷却可获得组织各向异性小、晶粒尺寸均匀的魏氏组织特征。这种状态的合金一般具有较高的断裂韧性,但由于其强化效应弱且对塑性不利,在现有的商业高强结构钛合金中尚未得到应用。本文中的3种合金具有较高含量的β稳定元素,具备了退火后时效硬化的成分基础,在合适的热处理制度下,可以得到良好的断裂韧性。

将表1中的数据绘入图8,数据拟合后,得到合金时效后强度和断裂韧性的定量关系式。

Ti-5Al-22V:

KIC=53.697 63+0.025 2σb-3.193×10-5 (4)

(4)

KIC=458.980 38-0.654 76σb+2.549 44×10-4 (5)

(5)

图8 合金强度和断裂韧性的关系

Fig. 8 Relationship between Rm and K1C of alloys

由式(4)和(5)可以得到,合金的断裂韧性随强度的增加单调递减。由此可见,加入了β稳定元素,虽然能提高强度但也能降低韧性。Mo元素提高强度的作用高于V元素,这一点在两种合金的强度上显而易见,但是合金1的断裂韧性却明显好于合金2的,这是由于加入Mo元素阻止了亚临界裂纹的产生,效果优于V元素。因此,在两种合金固溶时效后塑性基本相同的情况下,合金1的断裂韧性明显优于合金2的。

4 结论

1) 经400 ℃时效后的3种合金硬度由大到小依次为合金3、合金2、合金1;经500、600、700℃时效后,3种合金硬度由大到小依次为合金3、合金1、合金2。

2) 3种合金固溶时效处理后的强塑性匹配由高到低依次为合金1、合金2、合金3;相同时效制度下,Ti-5Al-15Mo合金的断裂韧性优于Ti-5Al-22V合金的。

3) 添加β稳定元素可以提高合金强度,但在一定程度上会降低韧性。添加Mo和V元素可以提高裂纹产生的抗力,从而提升合金的断裂韧性,并且Mo元素的效果比V元素的好。

REFERENCES

[1] 葛 鹏, 周 伟, 赵永庆. 热处理制度对Ti-1300合金组织和力学性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s1068-s1072.

GE Peng, ZHOU Wei, ZHAO Yong-qing. Influence of heat treatment on microstructure and mechanical properties of Ti-1300 alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s1068-s1072.

[2] FROES F H, BOMBERGER H B. The beta-titanium alloys [J]. Metals, 1985, 37(7): 28-37.

[3] ZHOU L, EYLON D,  G, OUCHI C. The structure diagram of titanium alloys in coordinates molybdenum equivalent-aluminium equivalent [C]// Titanium’98 Proceedings of Xi’an International Titanium Conference. Beijing: International Academic Publishers, 1999: 402-409.

G, OUCHI C. The structure diagram of titanium alloys in coordinates molybdenum equivalent-aluminium equivalent [C]// Titanium’98 Proceedings of Xi’an International Titanium Conference. Beijing: International Academic Publishers, 1999: 402-409.

[4] 李 倩, 王 敏, 赵永庆, 葛 鹏, 周 伟. Ti-5Al-10Cr与Ti-5Al-15Mo合金β晶粒长大动力学研究[J]. 热加工工艺, 2012, 41(10): 89-91.

LI Qian, WANG Min, ZHAO Yong-qing, GE Peng, ZHOU Wei. Kinetic analysis of β-Grain growth in Ti-5Al-10Cr and Ti-5Al-15Mo alloy [J]. Hot Working Technology, 2012, 41(10): 89-91.

[5] NIKOUSLULA N. Complex alloying of titanium alloys [J]. KHOREV A I. Metallovedenie I Termieheskaya Obrabotka Metallov, 1975, 8: 58-63.

[6] 冯 亮, 葛 鹏, 杨 义, 周 伟. Ti-10Cr合金析出相对硬度的影响[J]. 中国有色金属学报, 2010, 20(S1): s1-s5.

FENG Liang, GE Peng, YANG Yi, ZHOU Wei. Influence of precipitated phase on hardness of Ti-10Cr alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s1-s5.

[7] 李世凯, 余 魏, 廖志谦, 闫飞昊, 王美娇. ω相对Ti10V2Fe3Al合金性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s387-s392.

LI Shi-kai, YU Wei, LIAO Zhi-qian, YAN Fei-hao, WANG Mei-jiao. Effects of ω phase on properties of Ti10V2Fe3Al alloy [J]. The Chinese Journal of Nonferrous Metals. 2010, 20(S1): s387-s392.

[8] BUTTINELLI D, FELLI F, FESTA G D, QUERALES A J. Effect of heat treatments on the fatigue behavior of the beta-c titanium alloy [C]// Titanium’92. Warrendale, PA, USA: Science and Technology: 1993: 505-515.

[9] TERLINDE G T, RATHJEN H J, SCHWALBE K H. Microstructure and fracture toughness of the aged β-Ti alloy Ti10V-2Fe-3Al [J]. Met Trans, 1988(19): 1037-1043.

[10] BOYER R R, HALL J A. Microstructure/property relationships in Ti-15V-3Cr-3Al-3Sn high strength castings, in microstructure/ property relationships in Ti-aluminides and alloys [C]// Light Metals 1991. Warrendale, PA, USA: TMS, 1991: 511-525.

[11] NIWA N, TAKATORI H. Effect of step aging on the fracture toughness of Ti-15V-3Cr-3Sn-3Al alloy [C]// Beta Titanium Alloys in the 1990’s. Warrendale, PA, USA: TMS, 1993: 237- 245.

(编辑 李向群)

基金项目:陕西省重点科技创新团队(2012KCT-23)

收稿日期:2013-07-31;修订日期:2013-10-04

通信作者:李 倩,工程师;电话:029-86231078;传真:029-86360416;E-mail: leeqian0426@hotmail.com