文章编号:1004-0609(2010)06-1021-11

镁合金纯净化研究新进展

吴国华1, 2, 3,孙 明1, 2, 3,王 玮1, 2, 3,丁文江1, 2, 3

(1. 上海交通大学 轻合金精密成型国家工程研究中心,上海 200240;

2. 上海交通大学 金属基复合材料国家重点实验室,上海 200240;

3. 上海交通大学 材料科学与工程学院,上海 200240)

摘 要:阐述镁合金中的夹杂物种类及其危害,镁合金含有MgO、Mg3N2、MgS、α-Fe、MnAl6、Fe2(Si,B)、Fe3(Al,Si)、(Fe,Mn)3Si和(Fe,Mn)5Si3等非金属夹杂物及Fe、Cu和Ni等有害金属元素。非金属夹杂物会严重降低合金的强度和韧性;Fe等有害元素会大幅度增加镁合金的腐蚀速率。重点阐述镁合金双活性加硼熔剂除铁技术及其除铁效果。针对稀土镁合金的净化难题,介绍稀土镁合金的专用净化熔剂、MgO泡沫陶瓷过滤器及旋转喷吹等镁合金非熔剂净化方法。综述复合净化对镁合金力学性能、流动性及热裂性的影响,并展望镁合金净化技术的未来发展。

关键词:镁合金;净化;夹杂;力学性能;流动性;热裂性

中图分类号:TG146 文献标志码:A

New research development on purification technology of magnesium alloys

WU Guo-hua1, 2, 3, SUN Ming1, 2, 3, WANG Wei1, 2, 3, DING Wen-jiang1, 2, 3

(1. National Engineering Research Center of Light Alloy Net Forming,Shanghai Jiao Tong University, Shanghai 200240, China;

2. Key State Laboratory of Metal Matrix Composite, Shanghai Jiao Tong University, Shanghai 200240, China;

3. School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: The kinds and hazard of inclusions in the magnesium alloys were clarified. The non-metallic inclusions, such as MgO, Mg3N2, MgS, α-Fe, MnAl6, Fe2(Si,B), Fe3(Al,Si), (Fe,Mn)3Si and (Fe,Mn)5Si3, and deleterious elements, such as Fe, Cu and Ni, always present in the magnesium alloys. The non-metallic inclusions severely decrease the strength and ductility, while Fe sharply increases the corrosion rate of the magnesium alloys. The Fe reduction technology as well as the reduction effectiveness of double-activity boron addition technique was emphasized. Aiming at the purification problem of Mg-RE alloys, the dedicated fluxes were introduced. Moreover, the non-flux purification methods including MgO ceramic foam filter (CFF) and gas bubbling technology were described. The effects of composite purification technology (CPT) on the mechanical properties, fluidity and hot cracking were reviewed. At last, the development prospect of purification technology of magnesium alloys was presented.

Key words: magnesium alloys; purification; inclusions; mechanical property; fluidity; hot cracking

我国是世界上镁矿资源最富有的国家,中国工程院在2005年《我国富有资源镁及镁合金发展战略研究报告书》中指出,金属镁以其本身特有的资源、性能、环境和价格优势成为21世纪我国材料工业持续发展的必然选择[1]。由于镁合金具有密度小、比强度和疲劳强度高、比弹性模量好以及优良的切削加工性能,使镁合金在一系列国防尖端领域及日常制造业中被广泛应用[2-6],譬如,汽车减重节能和环保的要求推动镁合金在汽车领域的大规模开发应用[7]。随着对镁合金研究的不断深入,人们发现镁合金较低纯净度已成为制约镁合金应用的关键瓶颈之一,尤其是氧化等夹杂成为破坏力学性能和腐蚀性能的发源地[8]。镁合金内较高的夹杂物含量不仅限制镁合金材料潜力的发挥,而且还大大降低镁合金材料的成型性能及耐蚀性[9]。因此,有必要采取净化措施来提高镁熔体的纯净度,提升镁合金的品质。这对于促进镁合金产业发展,具有重要意义。

1 镁合金中的夹杂物及危害

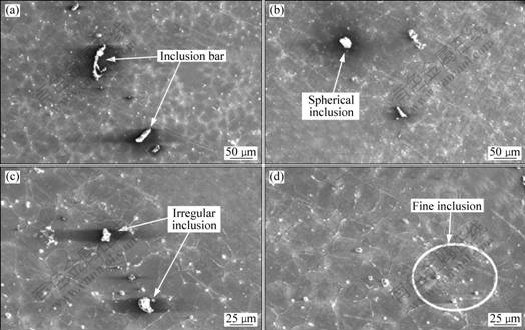

由于镁化学性质活泼,在原镁生产及合金熔炼过程中极易产生氧化夹杂,恶化铸件品质及力学性能。影响镁合金品质的夹杂物根据成分和结构不同主要分为非金属夹杂物和金属夹杂物,非金属夹杂物如[10]:MgO、Mg3N2、MgS、α-Fe、MnAl6、Fe2(Si,B)、Fe3(Al,Si)、(Fe,Mn)3Si和(Fe,Mn)5Si3等。图1所示为GW103K (Mg-10Gd-3Y-0.5Zr)合金中夹杂物的典型 形貌[11]。

图1 GW103K镁合金中夹杂物的典型形貌

Fig.1 Typical morphologies of nonmetallic inclusions in GW103K Mg alloy: (a) Inclusion bar; (b) Spherical inclusion; (c) Irregular inclusion; (d) Fine inclusion

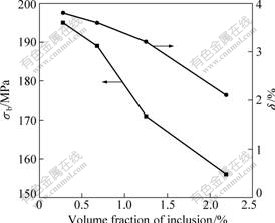

非金属夹杂物严重降低合金的强度、韧性和疲劳抗力。Fe、Cu和Ni等在镁合金中的固溶度很小,形成金属夹杂,降低镁的耐蚀性。另外,镁合金中的气体夹杂危害铸件气密性及力学性能。图2所示为夹杂物体积分数对AZ911D镁合金力学性能的影响。由图2可看出,随着合金中夹杂物含量的增加,镁合金的抗拉强度与伸长率明显下降[3]。图3所示为Fe含量对AZ91D镁合金腐蚀性能的影响。由图3可看出,当Fe含量达到一定程度后,会大幅度增加镁合金的腐蚀速率[12]。因此,生产中必须采取措施来去除镁熔体中的夹杂物,但镁熔体中的夹杂物密度与镁接近,与镁的分离性较差,通常悬浮于镁熔体中,难以上浮或下沉,因此,相对铝、钛等轻合金而言,镁熔体的净化难度更高。

图2 夹杂物体积分数对AZ91D镁合金力学性能的影响

Fig.2 Effects of volume fraction of inclusions on mechanical properties of AZ91D Mg alloy

图3 Fe含量对AZ91D镁合金腐蚀性能的影响

Fig.3 Effect of Fe content on corrosion resistance of AZ91D Mg alloy

2 镁合金净化方法

2.1 熔剂净化法

目前,熔剂净化由于成本低、操作简便、效果好而被广泛采用。其原理是利用熔剂润湿夹杂物,使夹杂物团聚并与熔剂结合形成沉淀,沉降至熔体底部[10]。所有夹杂物中,MgO含量(质量分数)高达80%,精炼处理主要是除去MgO。精炼熔剂中,MgCl2熔融后能很好地润湿镁液中的非金属夹杂物,部分氧化物(MgO和CaO)能和MgCl2形成稳定或不稳定的配合物:MgO(CaO)+MgCl2=MgCl2·MgO(CaO),5MgO+ MgCl2=MgCl2·5MgO。经过熔剂精练后,可使非金属夹杂物的尺寸降低到20 μm左右,同时含量降低。

最常用的熔剂主要是由MgCl2、KCl、CaF2和BaCl2等卤盐按比例混合组成。国内外熔剂种类繁多,如美国Dow230、220,德国ElrasalB、ElrasalC和英国MZ、Z系列。国内为含氯盐或氟盐的RJ系列。近几年来,国内出现了自主开发的精炼剂,比如上海交通大学研制的镁合金精炼剂[13]、中国铝业股份有限公司研制的耐热镁合金用熔剂[14]。另外,在精炼时添加Mn、Ti、Zr、Be或B等元素的单质或化合物可除铁,添加某些稀土化合物也能除杂[15]。吴国华等[16]发明的镁合金锆化合物除硅熔剂,其质量组分如下:30%~45%含水氯化镁、15%~25%氯化钾、5%~12%氯化钡、10%~17%氟化钙、10%~25%氟化镁、3%~8%氟化钠、2%~8%的四氯化锆和/或氟锆化钾,能有效降低镁合金中的含硅量,尤其对Mg2Si具有良好的去除作用。

当前,除了在镁熔体去除夹杂物净化熔剂方面开展大量研究工作之外,在镁合金除铁及稀土镁合金专用净化熔剂开发方面也取得了较大进展。Fe是镁合金中的主要金属夹杂之一,在材料的制备、处理、加工和运输过程中,不可避免地在镁及其合金中引入Fe杂质。由于Fe存在的形态及其与镁基体间巨大的电位差,使Fe成为降低镁合金抗腐蚀性能的主要因素之 一[17],同时有报道称Fe还会粗化镁合金晶粒[18]。因此,镁合金除铁便成为改善材料品质和提高镁合金性能所必需解决的课题。

传统的镁合金除铁技术研究主要集中在合金化方面,即以中间合金或其它形式加入Mn、Zr和Ti等合金元素,使之与Fe形成复杂化合物除去或改变铁的存在形态。Mn是镁合金常用的除铁元素,对此研究很多[19],然而由于Fe与Mn的比例难以控制,过多的Mn对合金性能不利,因此并未取得理想的效果。上海交通大学大力开展了熔剂化除铁技术研究[20-23],并深入系统地对熔剂除铁工艺及原理进行了探讨。研制了两种新型镁合金除铁复合净化熔剂JDFe-1和JDFe-2,发明了镁合金双活性加硼除铁技术。通过在熔剂中加入少量的B2O3和Na2B4O7达到了除铁除杂的双重目的。它克服了采用中间合金除铁手段的不足,又大大降低了成本,这对于镁旧料回收及提高原镁质量方面都有十分重要的意义。

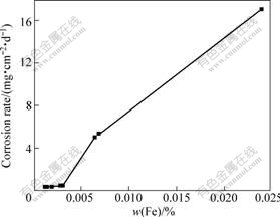

图4所示为在不同静置时间和处理温度下镁合金中铁含量w(Fe)与B2O3用量w(B2O3)的关系[12]。由图4可看出:在任一处理温度和静置时间下,铁含量都随w(B2O3)的增加而迅速下降;但当w(B2O3)超过0.7%时,铁含量变化不再显著;另外,在相同w(B2O3)的情况下,处理温度越高,除铁效果越明显。由于镁合金在高温下氧化严重,过高的处理温度会增加熔体的氧化夹杂。综合考虑除铁与净化的关系,认为735 ℃是最佳处理温度。静置时间越长,作用越充分,除铁效果就越好,但考虑到生产效率及能耗,认为40 min是恰当的静置时间。由于在净化处理过程中,镁熔体与熔剂之间发生复杂的物理化学反应,随着反应的进行,镁熔体中的反应物Fe不断减少,使反应在热力学上的趋势逐渐减弱,逐渐使反应达到动态平衡,此时Fe含量即达到极限值,之后再增加B2O3的用量,Fe含量变化不大。

图4 不同静置时间时镁合金中Fe含量与B2O3用量的关系

Fig.4 Relationships between Fe content in magnesium alloy and B2O3 content: (a) 10 min; (b) 40 min; (c) 70 min

含稀土镁合金的净化是一个很大的难题,这是因为熔剂中的主要组分MgCl2会与稀土元素反应RE+MgCl2→RECl3+Mg,导致昂贵稀土的大量损耗[24- 25]。因此,当前实际应用中,对于含稀土镁合金常常不采取熔剂净化,或采取不含或含少量MgCl2的熔剂净化,这样虽能使稀土损耗降低,但却导致净化效果不很理想,合金中夹杂物较多,品质较差。

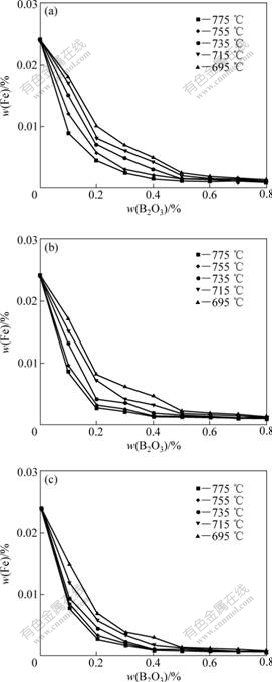

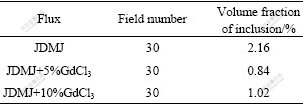

上海交通大学为解决这一难题开辟一条新的途 径[26-32],即在不减少MgCl2的前提下,在熔剂中添加稀土化合物,研制成功含稀土镁合金专用净化熔剂。结果表明:含7.5%CeCl3的稀土熔剂JDCe净化处理含Ce的AZCe合金后,合金中的稀土Ce损耗仅为5.3%,远远低于常用熔剂净化的稀土损耗,表明CeCl3具有抑制熔剂净化AZCe合金中Ce损耗的作用[12, 26-27];含7.5%LaCl3的稀土熔剂JDLa净化处理含La的AZLa合金后,合金中的稀土La损耗仅为5.6%,远远低于常用熔剂净化的稀土损耗,LaCl3具有抑制熔剂净化AZLa合金中La损耗的作用[28-29]。熔剂中添加GdCl3或YCl3,并未降低原熔剂JDMJ对Mg-Gd-Y-Zr稀土镁合金的精炼效果,如表1所列,同时通过热力学上抑制稀土Gd、Y与熔剂组元MgCl2的反应,从而降低稀土Gd和Y的损耗量[11, 30-32],如图5所示。

表1 GdCl3熔剂含量对GW103K稀土镁合金的净化除杂效果

Table 1 Statistical volume fraction of inclusions in GW103K alloys refined with different GdCl3 additions

图5 精炼剂中添加GdCl3或YCl3对GW103K合金稀土Gd或Y损耗的抑制作用

Fig.5 Effects of GdCl3 or YCl3 additions into flux on suppressing of mass loss of Gd or Y

2.2 非熔剂净化法

熔剂净化工艺因除杂效率高、成本低、操作方便而成为镁合金生产中普遍采用的净化方法,但是熔剂净化存在金属损耗增加、熔剂夹杂、不能去气等不足,尤其在熔炼稀土镁合金时,对熔剂成分要求严格。由于非熔剂净化工艺能弥补熔剂净化工艺的不足,从而得到深入研究,目前已开发出多种净化方式,如过滤净化、喷吹气体净化、真空处理及超声波处理等[33-35]。

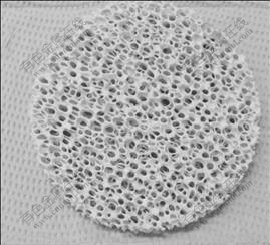

泡沫陶瓷过滤器(Ceramic foam filter)是一种高效除杂介质,它是由细密的陶瓷枝干骨架构成的三维连续网状结构。泡沫陶瓷过滤器的过滤机理比较复杂,通常认为,泡沫陶瓷过滤片对夹杂物的捕捉有以下作用[36-37]:过滤作用,在过滤片的各个孔洞口处阻挡夹杂物颗粒;沉淀作用,金属熔体通过过滤片时,一些很细小夹杂物颗粒即沉淀于过滤片内部的一些角落而去除;吸附作用,泡沫陶瓷过滤器内壁对固态微细夹杂或液态夹杂可吸附去除。这些机制的综合作用,可使泡沫陶瓷过滤达到极好的效果,不但可以滤掉合金熔体中小至10~20 ?m的微细夹杂物颗粒,而且能滤掉用一般过滤介质难以滤除的液态熔剂夹杂。图6所示为镁熔体过滤专用的MgO泡沫陶瓷过滤器。

图6 MgO泡沫陶瓷过滤器形状

Fig.6 Shape of MgO ceramic foam filter

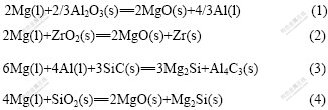

常用的泡沫陶瓷过滤器的材质为SiC、Al2O3、ZrO2及MgO材质。由于MgO的生成自由能很低,易与生成自由能较高的氧化物发生式(1)~(3)的反应,容易在浇铸过程中造成过滤器破损和带入夹杂。式(4)说明高温条件下,熔融镁液会与过滤器中的SiO2发生反应生成粗大汉字状Mg2Si相,严重损害合金的力学性能,因此要求过滤器中不能含有过多的SiO2[38]。

在这些材质的过滤器中,因为MgO过滤器不与镁熔体反应,不会对镁熔体产生污染,而且由于MgO与镁合金液中的液态熔剂润湿角很小,MgO泡沫陶瓷过滤片极易吸附镁合金中的熔剂液滴,从而使镁合金铸件免除了熔剂夹杂缺陷,从而十分适用于镁液的净化,在实际应用中也得到较好的验证。

在镁合金的非熔剂净化工艺中,旋转喷吹净化法因其去气效率高,兼有一定的去杂功能而备受关注。旋转喷吹法的基本原理是借助吹头向合金中通入气体,利用吹头的快速旋转作用在熔体深处形成快速运动的气液涡流,使通入熔体的气体被破碎成细小的气泡群,分布都很均匀(几乎充满坩埚内熔体的各个部位),从而显著改善浮游精炼的效果。在镁熔体中,由于气泡中氢的分压为零( ),借助于镁液和气泡中氢分压之差,氢便会不断扩散进入气泡浮出液面被去除,气泡表面所吸附的夹杂物也随之上浮而排除。

),借助于镁液和气泡中氢分压之差,氢便会不断扩散进入气泡浮出液面被去除,气泡表面所吸附的夹杂物也随之上浮而排除。

影响镁合金旋转喷吹净化的效果取决于3个方面因素[39]:1) 气泡的大小和气泡在熔体中的分散程度;2) 气体的性质和纯度。镁合金液常用的气体介质为Ar等惰性气体、C2Cl6和N2等。其中以Ar等惰性气体最为常见,C2Cl6去气的同时兼有一定的变质作用,但污染严重,由于氮气可与镁反应生成Mg2N3夹杂,因此多用于大型熔化炉预除气;3) 喷吹工艺参数。如喷头转速、吹气时间、气体流量和处理温度等。张承甫等[39]以ZM-5合金为例,研究除气效果与处理温度和静置时间的关系,认为750 ℃时除气效果比670 ℃时要差;随静置时间延长,除气效果提高,但一定时间后,气体含量不再降低。

由于镁合金的非熔剂净化工艺针对性强,无法同时达到既高效去杂、又除气的目的,因此促进了对复合净化工艺的研究,如熔剂净化与非熔剂净化工艺的结合以及多种非熔剂净化工艺的结合等。其中比较常见的如熔剂净化结合泡沫陶瓷过滤、熔剂净化结合气体旋转喷吹、泡沫陶瓷过滤结合气体旋转喷吹等净化工艺,以达到既除气又去夹杂的目的,尽可能提高镁合金的质量[40-41],复合净化工艺目前已显示出良好的应用前景。卢晨等[40]提供的由熔剂净化、吹气净化和过滤净化组成的复合净化新工艺,首先用JDMJ或RJ2熔剂精炼,之后用99.9%~99.999%的氩气吹气净化,再用孔隙率为70%~95%的氧化镁泡沫陶瓷过滤器过滤净化,可使再生镁合金的力学性能接近于新料性能。

3 净化对镁合金力学性能的影响

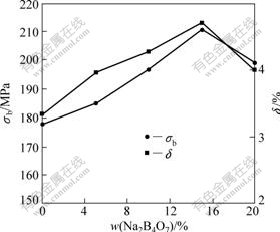

高洪涛等[42]使用含Na2B4O7除铁熔剂对AZ91D镁合金废料进行净化后,试样力学性能得到很大提高,结果如图7所示。

图7 Na2B4O7熔剂含量对AZ91D镁合金力学性能的影响

Fig.7 Effect of Na2B4O7 content on mechanical properties of AZ91D Mg alloy

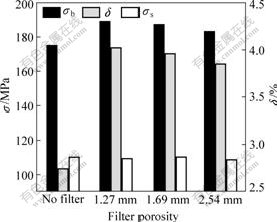

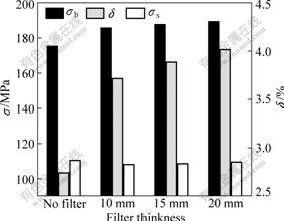

WU等[43]采用MgO泡沫陶瓷过滤器对AZ91废料的净化结果表明,合金的抗拉强度σb和伸长率δ分别从169.5 MPa、2.6%提高至180.9 MPa、4.35%,分别提高了6.7%和67.3%。黄伯杰等[44]介绍经1.69~1.95 mmMgO泡沫陶瓷过滤净化后,由于去除表面熔剂及大量夹杂,使得浇铸的飞机发动件外壳铸件合格率由零提高到70%。王薇薇等[38]采用MgO泡沫陶瓷过滤ZM-5合金。试验结果表明,净化后合金的抗拉强度提高了25.2%,伸长率提高82%。吴国华等[10]研究了不同孔径及不同厚度泡沫陶瓷过滤净化对AZ91合金力学性能的影响(见图7和8)。由图8可看出,经厚度为20 mm MgO泡沫陶瓷过滤净化后,随着过滤器孔隙率增加,合金抗拉强度σb和伸长率δ增加,且以δ增加最为明显。其中,1.27 mm孔径的过滤器可使合金σb和δ提高 7.9%和6.7%。图9所示为不同厚度泡沫陶瓷过滤对合金力学性能的影响。由图9可看出,采用10 mm厚泡沫陶瓷过滤器,σb和δ分别从175.3 MPa和2.74%增加到185.6 MPa和3.72%,分别增加了5.9%和35.8%;当过滤器厚度增加到20 mm,σb和δ分别增加到189.3 MPa和4.02%。

图8 过滤器孔隙率对合金力学性能的影响

Fig.8 Effects of filter porosity on mechanical properties of alloy

图9 过滤器厚度对合金力学性能的影响

Fig.9 Effects of filter thickness on mechanical properties of alloy

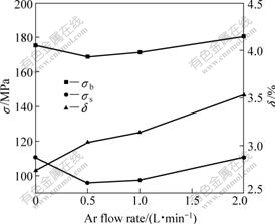

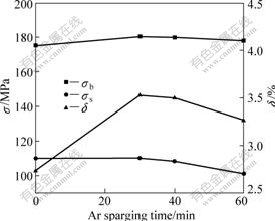

丁文江[10]采用旋转喷吹装置对AZ91镁熔体进行了吹氩处理,吹头孔径为0.2 mm,吹头旋转速度为120 r/min,所采用工艺为730 ℃时吹气处理30 min。研究表明,高Ar气流量有利于提高合金的力学性能,而较低的Ar气流量处理会降低合金抗拉强度。图10所示为Ar流量对合金力学性能的影响。由图10可见,采用0.5 L/min的低Ar气流量处理,将使合金的σb和σs分别从175.3 MPa和110.3 MPa降到168.8 MPa和96 MPa;而增大气体流量至2.0 L/min,合金的σb和σs分别增加至180.6 MPa和110.5 MPa。图11所示为730 ℃时采用2.0 L/min的Ar气流量进行吹Ar处理条件下,吹Ar时间对合金力学性能的影响。由图11可见,吹气30 min使σb和δ分别从175.3 MPa和2.74%增加到180.6 MPa和3.53%,但进一步增加吹气时间对合金性能反而不利。

图10 Ar气流量对合金力学性能的影响

Fig.10 Effects of Ar gas flow rate on mechanical properties of alloy

图11 吹Ar时间对合金力学性能的影响

Fig.11 Effects of Ar sparging time on mechanical properties of alloy

WU等[41]研究表明,AZ31镁合金在730 ℃经旋转喷吹氩气30 min并结合不同孔径MgO和Al2O3泡沫陶瓷过滤后,合金的抗拉强度和伸长率明显提高,如图12所示。由图12可看出,当结合1.27 mm孔径MgO泡沫陶瓷过滤器净化后,合金的σb和δ分别从144.6 MPa和5.21%提高至 180.8 MPa和9.06%,分别提高了25%和73.9%。

图12 旋转喷吹结合过滤净化对AZ31合金抗拉强度和伸长率的影响

Fig.12 Effects of gas bubbling incorporating filtration on ultimate tensile strength (a) and elongation (b) of AZ31 alloy

4 净化对镁合金流动性和热裂行为的影响

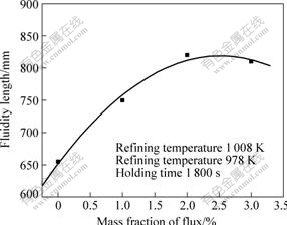

高洪涛[12]的研究表明:不使用精炼剂净化时,镁合金的流动长度只有655 mm;当使用2% 除杂精炼剂净化处理后,镁合金的流动长度达到820 mm;而当继续增加精炼剂用量,镁合金的流动性稍有降低,结果如图13所示。这是因为未净化的合金液内部存在许多非金属夹杂,降低合金的流动性;净化后合金中的夹杂物大幅度减少,从而提高流动性;而过量的精炼剂往往会引入精炼剂夹杂,降低流动性。

图13 精炼剂用量对镁合金铸造流动性能的影响

Fig.13 Effect of flux addition on fluidity of magnesium alloy

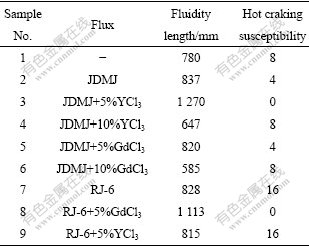

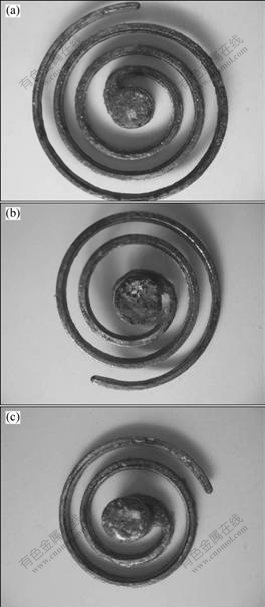

黄玉光等[45-46]研究净化对Mg-10Gd-3Y-Zr合金热裂和流动性的影响。表2所列为加入不同精炼剂后,Mg-10Gd-3Y-Zr合金流动性试样的长度和热裂倾向性因子,流动性模具预热温度400 ℃, 热裂模具预热温度150 ℃,试样浇注温度750 ℃。比较4个流动性试样(试样1、2、3、4),未经过精炼处理的流动性试样长度仅为780 mm,经过JDMJ精炼后试样长度增至837 mm,加入5%YCl3精炼剂后,试样长度进一步增加到1 270 mm;熔剂中YCl3的加入量超过5%后,流动性试样长度反而有所下降,如图14所示[47]。

表2 不同精炼剂对Mg-10Gd-3Y-Zr合金流动性和热裂倾向性的影响

Table 2 Effects of different refiners on fluidity of Mg-10Gd-3Y-Zr magnesium alloy

图13 JDMJ+x%YCl3精炼后流动性试样长度

Fig.13 Length of fluidity samples after refined by JDMJ (a), JDMJ+5%YCl3 (b) and JDMJ+10%YCl3 (c)

同样,未精炼的Mg-10Gd-3Y-Zr合金热裂倾向性因子(Hot cracking susceptibility, HCS)达到8,经过JDMJ精炼后,热裂倾向性因子降至4,经过JDMJ+5%YCl3后,热裂倾向性因子进一步降至0,但当熔剂中的YCl3的加入量超过5%后,热裂倾向性因子反而上升至8。

比较表2中4个流动性试样(试样1、2、5、6)可看出,JDMJ+x%GdCl3系列精炼剂对合金流动性和热裂倾向性的影响,经过JDMJ精炼后,试样长度由780 mm增加达到837 mm,但向JDMJ中GdCl3的加入量超过5%后,流动性试样长度开始下降;合金的热裂倾向性因子也呈现出同样的规律,当JDMJ中GdCl3的加入量超过5%后,合金热裂倾向性因子反而上升。比较试样1、7、8、9可看出,RJ-6精炼剂和RJ-6+5%YCl3的加入能提高Mg-10Gd-3Y-0.5Zr合金的流动性,特别是经过RJ-6+5%GdCl3精炼后,试样长度由780 mm增加至 1 113 mm,而热裂倾向性因子大幅下降,由16下降至0。从表1中可看出,合金的流动性与合金的热裂倾向具有相同的变化趋势,可能都与合金中的夹杂物含量变化趋势有关[47]。

5 展望

21世纪的能源与绿色制造问题日益突出,镁合金材料是绿色工程金属材料,但我国的镁合金品质还不高,镁合金中的夹杂及气体严重降低了镁合金品质,已成为限制镁合金广泛应用的瓶颈。目前,钢铁、铝合金材料中夹杂物研究已比较成熟,这对镁合金夹杂物的研究很有借鉴意义。

影响镁合金品质的因素主要有非金属夹杂物和金属夹杂物,净化镁合金熔体以除去其内的夹杂是提高镁合金品质的主要途径,采用熔剂法净化,成本低、操作简便、效果好而被广泛采用。而目前的熔剂大都是单一的去除非金属夹杂物,且都以MgCl2为主要成分,存在较多缺点。此外,熔剂与镁熔体在精炼过程中会发生复杂的物理化学反应和冶金作用,而当前关于熔剂-熔体系统中结构、界面、物质传输等研究颇为不足,严重制约了镁合金熔剂净化技术的发展和净化理论的建立。今后应加强对熔剂物化性质及熔剂与镁熔体之间交互作用过程的研究,大幅度提高熔剂的净化效率;开发出新型高效的绿色镁合金净化熔剂,减少环境污染;发展镁熔体夹杂物形成与去除的物理化学原理。

非熔剂净化工艺已被证实是提高镁合金品质的重要途径之一,尤其是泡沫陶瓷过滤和旋转喷吹气体净化以及在此基础上发展起来的复合净化工艺,具有除杂、去气效率高的特点,正日渐成为研究热点。但是对过滤及吹气净化等非熔剂净化的机理及相关工艺参数的研究并不深入,尚待深入探索。

我国虽然是镁资源和原镁生产大国,也是镁初级产品出口大国,但高品质、高附加值镁合金材料的开发及应用技术还十分落后,而镁合金纯净化工艺水平的落后正是其中的主要制约因素之一。因此,深入开展镁合金净化理论与工艺的研究,并应用于高品质镁合金的生产,不断拓展镁合金的应用领域,对我国镁合金产业的发展具有重要意义。

REFERENCES

[1] 左铁镛. 我国富有资源镁及镁合金发展战略研究报告书[R]. 北京: 中国工程院, 2005.

ZUO Tie-yong. Strategic research and China rich magnesium resource and magnesium alloys development[R]. Beijing: Chinese Academy of Engineering, 2005.

[2] 陈振华, 刘俊伟, 陈 鼎, 严红革. 镁合金超塑性的变形机 理﹑研究现状及发展趋势[J]. 中国有色金属学报, 2008, 18(2): 193-202.

CHEN Zhen-hua, LIU Jun-wei, CHEN Ding, YAN Hong-ge. Deformation mechanisms, current status and development direction of superplastic magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 193-202.

[3] YANG Ming-bo, MA Yan-long, PAN Fu-sheng. Effects of little Ce addition on as-cast microstructure and creep properties of Mg-3Sn-2Ca magnesium alloy[J].Trans Nonferrous Met Soc China, 2009, 19(5): 1087-1092.

[4] CHENG Ying-liang, QIN Ting-wei, WANG Hui-min, ZHANG Zhao. Comparison of corrosion behaviors of AZ31, AZ91, AM60 and ZK60 magnesium alloys[J].Trans Nonferrous Met Soc China, 2009, 19(3): 517-524.

[5] SUN M, WU G H, WANG W, DING W J. Effect of Zr on the microstructure, mechanical properties and corrosion resistance of Mg-10Gd-3Y magnesium alloy[J]. Mater Sci Eng A, 2009, 523(1/2): 145-151.

[6] YANG Z, LI J P, ZHANG J X, LORIMER G W, ROBSON J. Review on research and development of magnesium alloys[J]. Acta Metallurgica Sinica (English Letters), 2008, 21(5): 313-328.

[7] 郑伟超, 李双寿, 汤 彬, 曾大本. 稀土对AZ31B变形镁合金组织和力学性能的影响[J].中国有色金属学报, 2006, 16(2): 194-204.

ZHENG Wei-chao, LI Shuang-shou, TANG Bin, ZENG Da-ben. Effects of rare earth on microstructure and mechanical properties of AZ31B wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 194-204.

[8] TARTAGLIA J M, SWARTZ R E, BENTZ R L, HOWARD J H. Magnesium alloy ingots: Chemical and metallographic analyses[J]. JOM, 2001, 53(11): 16-19.

[9] KOJIMA Y, AIZAWA T, HIGASHI K, KAMADO S. Issues that influence magnesium’s use in the automotive industry[J]. Materials Science Forum, 2003, 419/422: 43-50.

[10] 丁文江. 镁合金科学与技术[M]. 北京: 科学出版社, 2007.

DING Wen-jiang. Magnesium alloy science and technology[M]. Beijing: Science Press, 2007.

[11] WANG W, WU G H, WANG Q D, HUANG Y G, DING W J, DING W J. Gd contents, mechanical and corrosion properties of Mg-10Gd-3Y-0.5Zr alloy purified by fluxes containing GdCl3 additions[J]. Mater Sci Eng A, 2009, 507(1/2): 207-214.

[12] 高洪涛. 镁合金熔剂净化行为及理论研究[D]. 上海: 上海交通大学, 2006.

GAO Hong-tao. Flux purification behavior and theory for magnesium alloy[D]. Shanghai: Shanghai Jiao Tong University, 2006.

[13] 吴国华, 丁文江. 镁合金精炼剂及生产方法[P]. CN01142611.X, 2002-08-14.

WU Guo-hua, DING Wen-jiang. Flux of magnesium alloy and its production method[P]. CN01142611.X, 2002-08-14.

[14] 姚素娟, 褚丙武, 周远富, 梁 冬, 赵 群. 一种耐热镁合金用熔剂[P]. CN200610109367.2, 2007-01-31.

YAO Su-juan, CHU Bing-wu, ZHOU Yuan-fu, LIANG Fu, ZHAO Qun. Flux for heat resistant magnesium alloys[P]. CN200610109367.2, 2007-01-31.

[15] 孙 明, 吴国华, 王 玮, 丁文江. 镁合金纯净化研究现状与展望[J]. 材料导报, 2008, 22(4): 88-92.

SUN Ming, WU Guo-hua, WANG Wei, DING Wen-jiang. Current state and prospect of research on purification technology of magnesium alloys[J]. Materials Review, 2008, 22(4): 88-92.

[16] 吴国华, 丁文江, 曾小勤, 刘六法. 镁合金锆化合物除硅熔剂及其生产方法[P]. CN03141550.4, 2004-02-25.

WU Guo-hua, DING Wen-jiang, ZENG Xiao-qin, LIU Liu-fa. Flux containg zirconium compound for silicon reducation of magnesium alloy[P]. CN03141550.4, 2004-02-25.

[17] INOUE M, IWAI M, MATUZAWA K, KAMADO S, KOJIMA Y. Effect of impurities on corrosion behavior of pure magnesium in salt water environment[J]. Journal of Japan Institute of Light Metals, 1998, 48(6): 257-262.

[18] TAMURA Y, MOTEGI T, KONO N, SATO E. Effect of minor elements on grain size of Mg-9%Al alloy[J]. Materials Science Forum, 2000, 350/351: 199-204.

[19] LUNDER O, TERJE K A, NISANCIOGLU K. Effect of Mn additions on the corrosion behavior of mould-cast magnesium ASTM AZ91[J]. Corrosion, 1987, 43(5): 291-295.

[20] WU G H, GAO H T, DING W J, ZHU Y P. Study on mechanism of iron reduction in magnesium alloy melt[J]. Journal of Materials Science, 2005, 40(23): 6175-6180.

[21] GAO H T, WU G H, DING W J, ZHU Y P. Study on Fe reduction in AZ91 melt by B2O3[J]. Mater Sci Eng A, 2004, 368(1/2): 311-317.

[22] GAO H T, WU G H, DING W J, ZHU Y P. Effects of purification fluxes containing boride on AZ91 alloy[J]. Materials Science Forum, 2005, 488/489: 25-30.

[23] GAO H T, WU G H, DING W J, ZHU Y P. Recycling of magnesium Alloy AZ91 scrap by a B2O3 containing fluxes[J]. Journal of Materials Science, 2004, 39(21): 6449-6456.

[24] NAIR K S, MITTAL M C. Rare earths in magnesium alloys[J]. Materials Science Forum, 1986, 30: 89-104.

[25] FRIEDRICH H E, MORDIKE B L. Magnesium technology: metallurgy, design data, applications[M]. Berlin: Springer-Verlag, 2006: 140.

[26] DING W J, WU G H, BONG S Y, CHANG D Y. Effects of CeCl3-containing flux on the microstructure and mechanical properties of magnesium alloy containing rare earth[J]. Materials Science Forum, 2007, 546/549: 563-566.

[27] 高洪涛, 吴国华, 樊 昱, 丁文江, 朱燕萍. CeCl3对含Ce镁合金精炼过程中Ce损耗量的影响[J]. 中国有色金属学报, 2005, 15(12): 2003-2008.

GAO Hong-tao, WU Guo-hua, FAN Yu, DING Wen-jiang, ZHU Yan-ping. Effect of CeCl3 on loss of Ce in magnesium alloy during refining[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 2003-2008.

[28] 吴国华, 高洪涛, 朱燕萍, 丁文江. 熔剂中添加LaCl3对Mg合金显微组织与性能的影响[J].金属学报, 2004, 40(7): 694-698.

WU Guo-hua, GAO Hong-tao, ZHU Yan-ping, DING Wen-jiang. Effect of LaCl3 Addition in flux on the microstructure and properties of magnesium alloys[J]. Acta Metallrugica Sinica, 2004, 40(7): 694-698.

[29] WU G H, GAO H T, ZENG X Q, DING W J. Effect of LaCl3 on the structure and properties of magnesium alloys[J]. Materials Science Forum, 2005, 488/489: 111-114.

[30] WANG W, HUANG Y G, WU G H, WANG Q D, SUN M, DING W J. Influence of flux containing YCl3 additions on purifying effectiveness and properties of Mg-10Gd-3Y-0.5Zr alloy[J]. Journal of Alloys and Compounds, 2009, 480(2): 386-391.

[31] WANG W, WU G H, SUN M, HUANG Y G, WANG Q D, DING W J. Effects of flux containing YCl3 on the yttrium loss, mechanical and corrosion properties of Mg-10Gd-3Y-0.5Zr alloy[J]. Mater Sci Eng A, 2009, in Press.

[32] WANG W, WU G H, WANG Q D, HUANG Y G, SUN M, DING W J. Investigation of flux containing GdCl3 on recycling Mg-Gd-Y-Zr scraps[J]. Trans Nonferrous Met Soc China, 2008, 18(S1): s292-s298.

[33] HANKO G, MACHER G. Technologies for efficient Mg-scrap recycling[C]//KAPLAN H I. Magnesium technology 2003. San Diego: TMS, 2003: 29-32.

[34] BELL S, DAVIS B, JAVAID A, ESSADIQI E. Final report on refining technologies of magnesium[R]. Ottawa: Government of Canada, 2006.

[35] HAN J W, KIM D J, YOU B D, BYUN J Y, SHIM J D. Effect of gas bubbling and impeller agitation on degassing kinetics during magnesium alloy (AZ91D) melt recycling-water model approach[J]. Materials Science Forum, 2003, 439: 192-199.

[36] CHEN F, HUANG X, WANG Y, ZHANG Y, HU Z. Investigation on foam ceramic filter to remove inclusions in revert alloy[J]. Material Letters, 1998: 372-376.

[37] 王薇薇, 张绍兴. 泡沫陶瓷过滤片的正确选择和使用[J]. 铸造技术, 1996, 4: 7-10.

WANG Wei-wei, ZHANG Shao-xing. Selection and application of ceramic foam filters[J]. Foundry Technology, 1996, 4: 7-10.

[38] 王薇薇, 徐介文, 曹达富. 用纯氧化镁泡沫陶瓷过滤器过滤铸造镁合金的研究[J]. 铸造技术. 1991, 6: 15-18.

WANG Wei-wei, XU Jie-wen, CAO Da-fu. Filtration of Mg alloy with pure magnesia ceramic foam filter[J]. Foundry Technology, 1991, 6: 15-18.

[39] 张承甫, 龚建森, 黄杏蓉, 王凯歌. 液态金属的净化与变质[M]. 上海: 上海科学技术出版社, 1989.

ZHANG Cheng-fu, GONG Jian-lin, HUANG Xing-rong, WANG Kai-ge. Purification and modification of liquid metal[M]. Shanghai: Shanghai Scientific and Technical Publishers, 1989.

[40] 卢 晨, 吴国华, 蔡 超, 曾 克, 丁文江. 镁合金净化技术研究[J]. 金属成形工艺, 2002, 20(5): 5-7.

LU Chen, WU Guo-hua, CAI Chao, ZENG Ke, DING Wen-jiang. Study on the purification technology of magnesium alloy[J]. Metal Forming Technology, 2002, 20(5): 5-7.

[41] WU G H, SEUNG H K, BONG S Y. Effects of non-flux purification on the microstructure and mechanical properties of AZ31+xCa Mg alloy[J]. Material Science Forum, 2007, 546/549: 217-220.

[42] 高洪涛, 吴国华, 丁文江, 朱燕萍. Na2B4O7对镁合金旧料组织和性能的影响[J]. 特种铸造及有色合金, 2005, 25(2): 65-67.

GAO Hong-tao, WU Guo-hua, DING Wen-jiang, ZHU Yan-ping. Effects of Na2B4O7 on the microstructure and properties of magnesium alloy wastes[J]. Special casting and nonferrous alloys, 2005, 25 (2): 65-67.

[43] WU G H, XIE M, ZHAI C Q. Purification technology of AZ91 magnesium alloy wastes[J]. Trans Nonferrous Met Soc China, 2003, 13(6): 1260-1264.

[44] 黄伯杰, 王耀臣, 聂邦盛, 李毓辉, 王薇薇, 曹达富. 泡沫陶瓷过滤技术在高标准镁合金铸件生产中的应用研究[J]. 特种铸造及有色合金, 1995, 2: 19-21.

HUANG Bo-jie, WANG Yao-chen, NIE Bang-sheng, LI Yu-hui, WANG Wei-wei, CAO Da-fu. Implication of ceramic foam filtration technology in production of stringent specification magnesium alloy castings[J]. Special Casting and Nonferrous alloys, 1995, 2: 19-21.

[45] 黄玉光, 吴国华, 王 玮, 侯正全, 陈 斌, 丁文江. 熔剂净化对Mg-Gd-Y-Zr合金流动性的影响[J]. 铸造, 2009, 58(2): 104-107.

HUANG Yu-guang, WU Guo-hua, WANG Wei, HOU Zheng-quan, CHEN Bin, DING Wen-jiang. Efect of flux purification on fluidity of Mg-Gd-Y-Zr magnesium alloy[J]. Foundry, 2009, 58(2): 104-107.

[46] 黄玉光, 吴国华, 王 玮, 侯正全, 陈 斌, 丁文江. 浇注及净化工艺因素对Mg-Gd-Y-Zr合金流动性的影响[J]. 材料导报,2009, 23(2): 95-97, 101.

HUANG Yu-guang, WU Guo-hua, WANG Wei, HOU Zheng-quan, CHEN Bin, DING Wen-jiang. Effects of purification and casting technological parameters on fluidity of Mg-Gd-Y-Zr magnesium alloy[J]. Materials Review, 2009, 23(2): 95-97, 101.

[47] 黄玉光. Mg-Gd-Y-Zr合金的热裂和流动性研究[D]. 上海: 上海交通大学, 2009.

HUANG Yu-guang. Study on the fluidity and hot tearing behavior of Mg-Gd-Y-Zr alloys[D]. Shanghai: Shanghai Jiao Tong University, 2009.

__________________________________

基金项目:国家重点基础研究发展计划资助项目(2007CB613701);国家高技术研究发展计划资助项目(2009AA033501);上海市优秀学科带头人计划资助项目(08XD14020)

收稿日期:2009-11-15;修订日期:2010-01-06

通信作者:吴国华,教授,博士;电话:021-54742630;传真:021-34202794;E-mail:ghwu@sjtu.edu.cn

(编辑 李艳红)