文章编号:1004-0609(2014)02-0325-10

铸锻复合一体化成形6061铝合金的组织和力学性能

彭 勇1, 2,王顺成1,郑开宏1,戚文军1,周海涛2

(1. 广东省工业技术研究院(广州有色金属研究院) 金属加工与成型技术研究所,广州 510650;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用铸锻复合一体化成形6061铝合金,研究启锻时间对6061铝合金的凝固、补缩、显微组织和力学性能的影响。结果表明:靠近锻压冲头面6061铝合金为流线变形组织,中间部位晶粒则被压扁压实,靠近下模部分的合金晶粒在模具激冷作用下得到细化。当启锻时间为3~4 s时,锻压作用能够对合金进行强制性补缩和压实组织,并产生塑性变形,避免了缩孔、裂纹和组织疏松等缺陷出现。随着启锻时间的延长,热处理前后铸锻件的抗拉强度和伸长率先增大再趋于平缓和减小,当启锻时间为4 s时,6061铝合金铸锻件的拉伸力学性能达到最高,未热处理的抗拉强度和伸长率分别为211.1 MPa和17.6%,热处理后的抗拉强度和伸长率分别为368.9 MPa和11.5%。

关键词:6061变形铝合金;铸锻复合一体化成形;启锻时间;强制补缩

中图分类号:TG146.2 文献标志码:A

Microstructure and mechanical properties of 6061 aluminum alloy prepared by casting-forging integrated technology

PENG Yong1, 2, WANG Shun-cheng1, ZHENG Kai-hong1, QI Wen-jun1, ZHOU Hai-tao2

(1. Institute of Materials Processing and forming technology, Guangdong General Research Institute of Industrial Technology (Guangzhou Research Institute of Non-ferrous Metals), Guangzhou 510650, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China.)

Abstract: The casting-forging integrated technology was adopted to prepare 6061 aluminum alloy. The effects of forging start-up time on solidification, feeding, microstructure and mechanical properties of 6061 aluminum alloy were investigated. The results show that the microstructure of 6061 aluminum alloy closed to forging punch surface is deformation microstructure. The grains of 6061 aluminum alloy in the middle part are crushed and compacted. The grains of 6061 aluminum alloy closed to the lower mold are refined due to the chilling effect by the mold. When the forging start-up time is 3-4 s, the shrinkage, cracks and loose tissue can be avoided, because the forging force can effectively carry out pressure feeding, and make structure compacted through the forced feeding and plastic deformation. With the increase of forging start-up time, the tensile strength and elongation of 6061 aluminum alloy with and without T6 heat treatment first increase and then decrease. The maximal mechanical properties of the 6061 aluminum alloy parts can be obtained when the forging start-up time is 4 s. The tensile strength and elongation of 6061 aluminum alloy without T6 heat treatment is 211.1 MPa and 17.6%, respectively. The tensile strength and elongation of 6061 aluminum alloy with T6 heat treatment is 368.9 MPa and 11.5%, respectively.

Key words: 6061 wrought aluminum alloy; casting-forging integrated technology; forging start-up time; forced feeding

6061铝合金是一种典型的可热处理强化铝合金,属于Al-Mg-Si系合金,其具有良好的塑性、耐蚀性、可焊性、较低的淬火敏感系数和较好的成型性能,较为适宜锻造成形,其锻件主要应用于汽车、摩托车和游艇上,然而,对于一些结构复杂的零件,锻造加工工艺比较繁琐,成本高昂,很难发挥其优势,因而制件形状受到较大限制[1-2]。6061铝合金属于变形铝合金,铸造性能较差,一般情况下是很难用金属型铸造、低压铸造和高压铸造等这些传统的铸造工艺进行生产,主要是由于其往往存在晶粒粗大、组织不均匀和成分偏析等缺陷[3-4]。

铸锻联合(或复合)是将铸造和锻造相结合的一种成形工艺,其具体实现形式也较多。最基本的过程是先用铸造方法铸出毛坯,清理后将毛坯重新加热,再放入锻模中进行锻造[5-6]。随后又出现了挤压铸造中的局部补压技术、双重挤压铸造技术等[7]。姜巨福等[8]将压铸和锻造相结合提出了液态压铸锻造双控成形技术,并在普通压铸机上增加锻造装置,设计制造了镁合金铸锻双控成形机,进行了镁合金摩托车发动机外壳和轮毂的铸锻成形实验。本课题组根据现有技术存在的问题,提出了低速充型高压铸造与大面积大变形量锻造相结合的铸锻复合一体化成形技术[9]。该技术将铸造和锻造合二为一,即先采用压力铸造的方法将金属液缓慢挤入铸锻模内,有效避免了充型过程的卷气裹气,保证了复杂形状零件的预成型,然后在同一套模具内立即对凝固金属进行大面积大变形量的闭模锻造,使其发生强制补缩和组织压实,提高了整个铸锻件的组织致密度和力学性能,从而为一些高强度、高致密度和形状复杂的受力结构件和耐磨耐压的气密性零部件的成形提供了途径。其中,启锻时间是铸锻复合一体化成形过程中影响后续锻造补缩的重要因素,本文作者在此研究启锻时间对铸锻复合一体化成形6061变形铝合金组织与力学性能的影响。

1 实验

1.1 实验材料

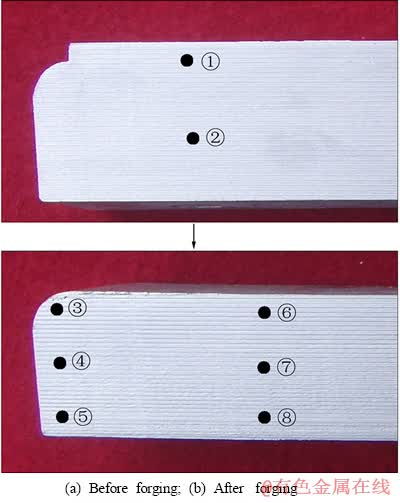

将合金料在100 kg中频感应炉中进行熔炼,加料前将炉温升至300~400 ℃时,加入工业纯铝(99.7%,质量分数,下同);炉温升至720 ℃时加入Al-50%Cu(质量分数)中间合金和速溶硅(99.2%),730 ℃时加入Al-5%Ti-1%B,然后搅拌均匀;待炉料全部熔化后,精炼除气,静置,除渣,加入少量覆盖剂后,再加入用纯铝箔包覆的纯镁锭(99.85%),搅拌均匀,静置除渣,用料勺取少量合金液进行化学成分测定(SPECTRO-MAXx直读光谱仪),分析结果如表1所列;随后在750 ℃时进行铸锻复合成形试验。

表1 实验6061铝合金的化学成分

Table 1 Chemical compositions of 6061 alloy (mass fraction, %)

1.2 试验过程与方法

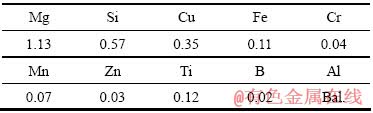

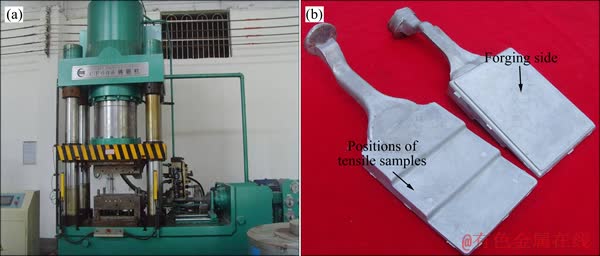

采用自主研发的6 000 kN铸锻复合一体化成形机(设备如图1所示)进行试验,其试验模具是在压力铸造模具的基础上增加了具有锻造功能的锻芯[10],试验之前将模具通过电热管预热至250 ℃左右。铸锻复合一体化的工艺流程[10]主要包括浇注、压力铸造、模锻、开模顶出几部分(见图2),其主要通过控制浇注温度、模具温度、充型速度、充型压力、启锻时间、保压时间和锻压力等工艺参数来实现对制件性能的控制。试验是在充型速度和锻压力大小合适的情况下进行的,即冲头压射速度为55 mm/s,锻压力大小为120 MPa,用PLC调节启锻时间,启锻时间分别为0、1.0、2.0、3.0、4.0和5.0 s。其他主要工艺参数如下:充型压力为140 MPa,浇注温度为750 ℃,保压时间为20 s直至铸锻件完全复合成形。

图1 6 000 kN铸锻复合一体化成形机及试样件

Fig. 1 Casting-forging integrated forming technology machine with 6 000 kN(a) and test pieces(b)

图2 铸锻复合一体化成形示意图

Fig. 2 Schematic diagram of casting-forging integrated technology

铸锻复合一体化成形实验后,将部分铸件毛坯进行T6热处理,具体工艺如下[11]:530 ℃固溶3 h,随后水淬,接着180 ℃人工时效6 h,最后空冷,热处理炉选用箱式空气循环电阻炉。

1.3 试样分析检测

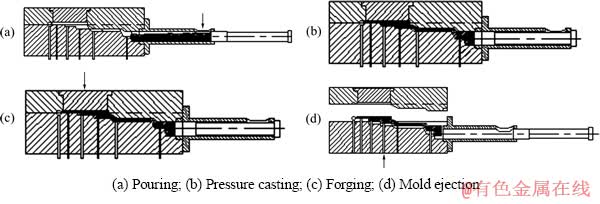

按照图1所示取样位置(铸锻件中间厚度处)将铸锻件线切割取出圆柱形试样,然后机械加工成如图3所示的圆棒拉伸试样(GB/T228—2002),在DNS200电子拉伸试验机上进行力学性能测试,拉伸变形速率为2 mm/min,试验结果为5个实验值的平均值;显微组织取样位置选取铸锻件锻压前后的截面部分,如图4所示,分别选取了锻压前后的①~⑧不同位置。试样经过磨制抛光和用低浓度的混合酸(2 mL HF、3 mL HCl、5 mL HNO3和250 mL H2O)腐蚀后,采用LeicaDMI3000M型金相显微镜进行微观组织观察;在JoelJSM-820扫描电子显微镜上进行拉伸断口形貌观察。

图3 拉伸试样尺寸

Fig. 3 Dimension of tensile specimen (Unit: mm)

图4 铸锻复合一体化成形取样件

Fig. 4 Sampling pieces of 6061 alloy prepared by casting- forging integrated technology

2 结果与讨论

2.1 启锻时间对宏观组织的影响

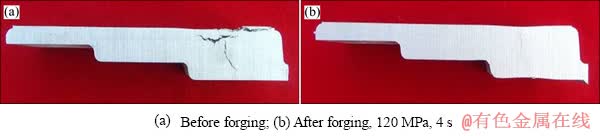

图5(a)和(b)所示分别为铸锻复合一体化成形锻压前后的试样宏观形貌。由图5可以看出,未施加锻压力时制件的厚壁处仍存在较大的裂纹,施加锻压力后,裂纹得到愈合。这主要是由于6061铝合金(变形铝合金)的结晶间隔宽,其在结晶过程中首先形成粗大的α(Al)树枝晶骨架(且此树枝晶骨架体积比相对较大),而具有充填补缩功能的共晶成分的液态金属体积比相对较少,而且受枝晶阻挡难以流动充填。在这种补缩不好的条件下,加上金属模具不可退让性,铸坯的厚壁部分很容易形成缩孔和裂纹[12]。施加锻压力后,铸坯在随后的凝固过程中受到较大压力,部分已经凝固的枝晶组织被打碎重新再形核长大,尚未凝固的液态金属穿过粗大的枝晶,在压力作用下补充到即将缩裂的部位中去,以达到“压力补缩”的效果[13]。

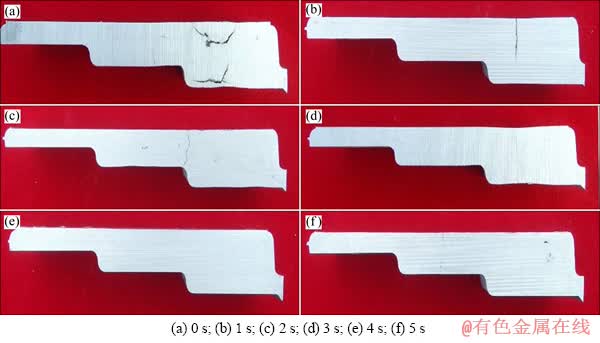

图6所示分别为不同启锻时间下铸锻复合一体化成形件的宏观形貌。由图6可以看出,当启锻时间为0~2 s时,铸锻件皆有不同程度的裂纹存在,且随着启锻时间的增长,裂纹逐渐变小直至消失;当启锻时间为5 s时,铸锻件又出现裂纹。铸锻复合一体化成形过程中,启锻时间过短,铸坯固相分数太低,此时的锻压过程相当于“液态模锻”,制件的外形得到较好的控制,锻压过程也较容易完成,然而,锻压后铸坯再凝固收缩,仍会出现缩孔、裂纹和组织疏松;随着启锻时间的延长,即铸坯固相分数的升高,金属在凝固过程中枝晶骨架逐渐形成,此时施加锻压力,把难以流动的具有充填补缩功能的共晶成分“强制性”的压入枝晶骨架间隙中,从而有效地遏制了随后凝固收缩产生的收缩裂纹。当启锻时间过长时,铸坯固相体积分数太高或者已经完全凝固,已凝固的粗大枝晶组织相互间连成一体,此时施加的锻压力几乎完全作用在固相骨架上,使组织破碎形成微小裂纹;在没有液相补充的情况下,且此时的精密锻造锻压变形量又很有限,使得裂纹永久地保存下来[14]。因此,铸锻复合一体化成形中应根据制件的形状、大小和壁厚等选择合适的启锻时间,此时的锻压过程不仅能进行强制补缩,密实组织,还能使制件产生进一步的塑性变形,提高其综合力学性能。

2.2 启锻时间对显微组织的影响

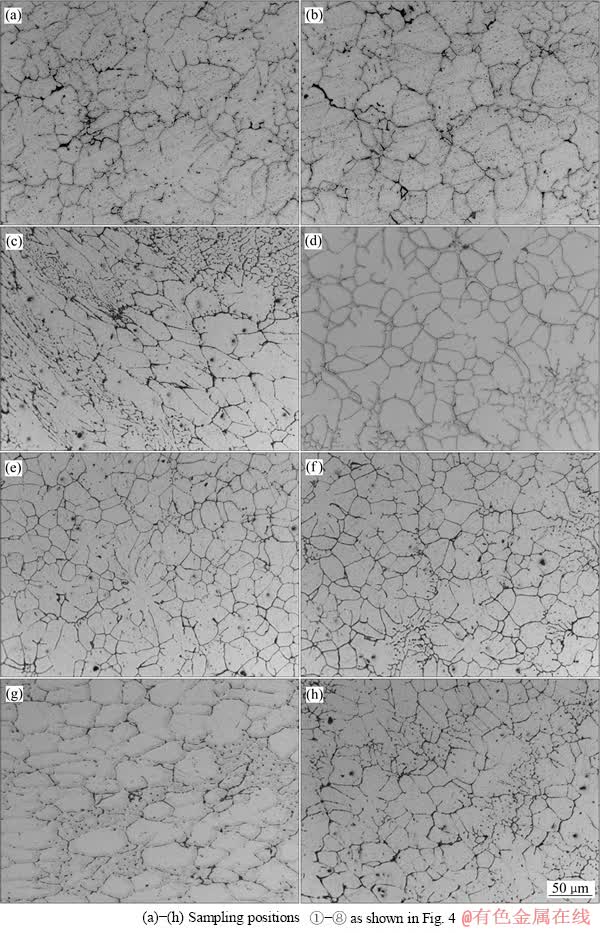

铸锻复合一体化成形微观组织试样取自铸锻件中间厚度部分的截面部分,如图4所示。由图4可以看出,锻压后,制件上面的凸台基本锻平。由于试样变形时受到模具上下施压面与锻件端面制件摩擦力的影响,试样各部位受力条件和变形量不同,试样内部变形也不均匀,为了分析合金铸锻后的显微组织,分别选取了如图4所示的①~⑧不同位置进行分析,其结果如图7中所示。

图5 铸锻复合一体化成形试样件锻压前后的宏观形貌

Fig. 5 Macro-morphologies of 6061 alloy under different forging pressure prepared by casting-forging integrated technology

图6 不同启锻时间下铸锻复合一体化成形6061铝合金的宏观形貌

Fig. 6 Macro-morphologies of 6061 alloy test pieces prepared by casting-forging integrated technology under different forging start-up times

图7 铸锻复合一体化成形件不同位置的显微组织

Fig. 7 Microstructures of part of different positions prepared by casting-forging integrated technology

图7所示为铸锻复合一体化成形锻压前后不同位置的显微组织。由图7可以看出,锻压前后铸锻件的显微组织发生明显变化,锻压后不同位置的显微组织也有着较大差别。图7(a)和(b)所示为铸锻复合一体化成形未锻压试样的显微组织,可以看出,未锻压时合金晶粒比较粗大,且有明显的凝固铸造缺陷存在。图7(c)~(h)所示为锻压力为120 MPa、启锻时间为4 s时铸锻件不同部位的金相组织,可以看出,对同一个试样分析,不同部位不同区域的显微组织具有各自的显微组织特征。区域③处于凸台与制件基体最直接接触的位置(见图7(c)),施加锻压力后,凸台上的金属沿着基体往下流动,此时,基体铸态组织开始变形,基体中晶粒沿金属流动的方向拉长生长,呈现出较为明显的变形组织;区域④和⑤受到锻压力的影响较小,变形量也非常小(见图7(d)和(e)),且区域⑤相对于区域④来说晶粒稍细小,这主要是由于区域⑤与铸锻模具的下模直接接触并受到其激冷作用;区域⑥和⑧的显微组织比较均匀,几乎全部为细小的等轴晶粒(见图7(f)和(h)),且晶粒受到锻压力的作用而明显细化,而区域⑦的晶粒明显被压扁(见图7(g))。这主要是由于制件上下部分受到模具的激冷等作用先凝固,而中间部分则最后凝固,且区域⑥和⑧的温降也比区域⑦的快,这也就导致中间晶粒比上下部分晶粒稍显粗大;施加模锻压力后,区域⑦由于变形温度较区域⑥和⑧的都高,变形抗力也较小,因而在变形力的作用下也较容易产生塑性变形。

由此可见,区域③和区域⑦的显微组织变化较为明显,基本能反映铸锻复合一体化成形过程中显微组织的演变过程,因此,可直接选择变化较为明显的区域③和区域⑦来研究不同启锻时间对铸锻件显微组织的影响。

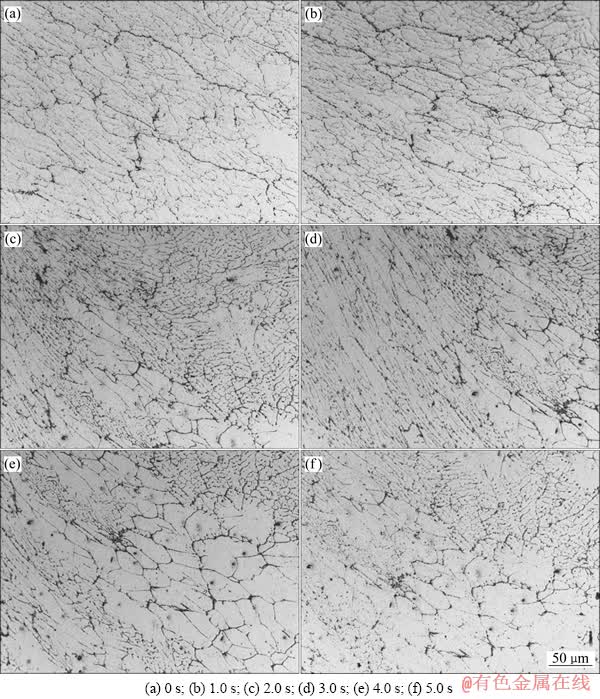

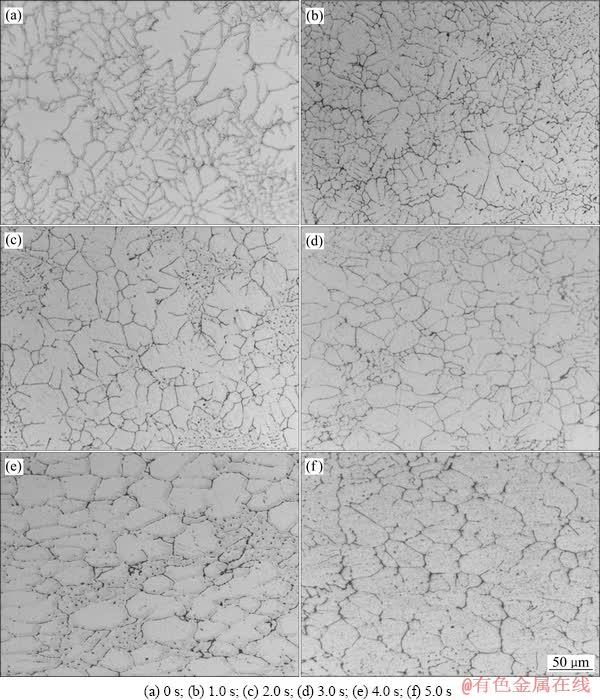

图8和9所示分别为锻压力为120 MPa、不同启锻时间下区域③和区域⑦的显微组织变化。由图8和9可以看出,不同始锻时间下铸锻件区域③的显微组织中晶粒皆被拉长,呈现明显的流线变形组织,区域⑦晶粒较区域③明显增大,在锻压力的作用下,铸锻件的组织得到较好的密实。当启锻时间为0~1s时,液态金属充型完毕后立即施加锻压力,金属液在较大的锻压力作用下发生动态凝固,与模具直接接触的区域③处晶粒得到较大程度的细化且先凝固形成硬壳层,后续的锻压力使得其产生塑性变形[15],同时,锻压力对尚未凝固的液-固区(区域⑦)产生挤压作用,使得其存在较强的枝晶流动[16],合金元素较高的共晶成分容易汇集于最后凝固的区域⑦。随着启锻时间的延长,金属的固相率逐渐升高,合金中已凝固的区域③的晶粒在锻压力的作用下沿着变形的方向被拉长,而未凝固的液态金属也在锻压力的作用下被强制挤压到起骨架作用的固相分子间隙中,形成明显的变形组织,合金的晶粒也随着启锻时间的延长而增大。在锻压的过程中,区域⑦的显微组织被压扁且得到很好的压实。当始锻时间过长时,由于铸坯固相体积分数太高或者已完全凝固,不管是铸锻件的区域③还是区域⑦时,合金的晶粒皆较大。在大锻压力的作用下,铸锻件的区域③产生少量塑性变形,晶粒沿着金属的流动方向被拉长,而铸锻件的区域⑦处于闭式模锻内,晶粒比较粗大,且由于间隔时间较长使得金属的温度降低较快,因而此时施加的锻压力很难使合金产生较大塑性变形。

图8 不同启锻时间下铸锻件区域③的显微组织

Fig. 8 Microstructures of position ③ at different forging start-up times

图9 不同启锻时间下铸锻件区域⑦的显微组织

Fig. 9 Microstructures of position ⑦ at different forging start-up times

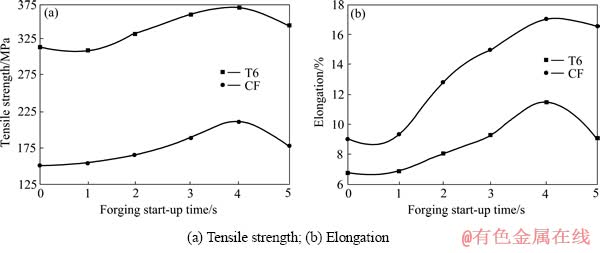

2.3 启锻时间对力学性能的影响

图10所示分别为不同启锻时间对铸锻复合一体化6061铝合金的抗拉强度σb和伸长率δ的影响。由图10可见,热处理前后6061铝合金的抗拉强度和伸长率皆随着启锻时间的延长先增大然后再缓慢减小,其中当启锻时间为4 s时,合金的力学性能达到最高,热处理前后的抗拉强度分别达到211.1和368.9 MPa,伸长率则分别达到17.6%和11.5%。

图10 不同启锻时间下合金的力学性能

Fig. 10 Mechanical properties of alloy under different forging start-up times

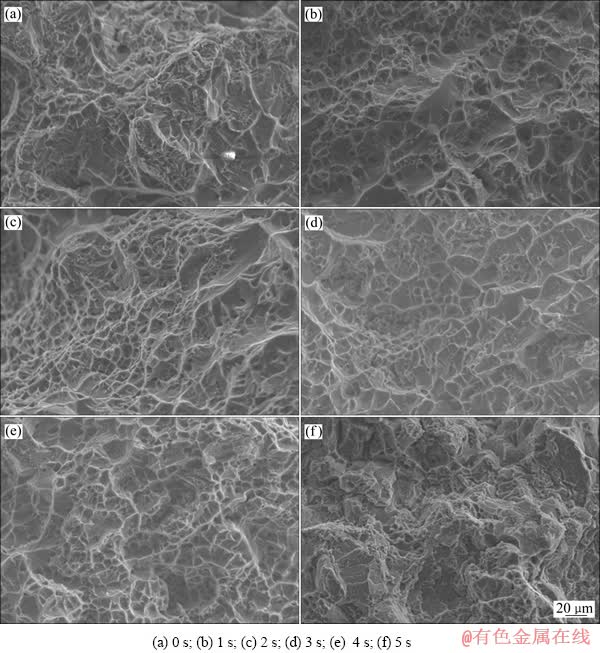

图11 不同启锻时间下合金的拉伸断口形貌

Fig. 11 SEM images of fracture morphologies of 6061 alloy under different forging start-up times

当启锻时间为0 s,即液态金属充型完毕后立即施加锻压力,此时铸锻件的力学性能最低,热处理前的抗拉强度为151.1 MPa,伸长率为9.1%。T6热处理后的抗拉强度为314.9 MPa,伸长率为6.8%,此时金属铸坯固相体积分数太低,液相中的固相枝晶组织细小,游离于液相之中,相互之间并没有接触;施加的锻压力并没有使枝晶组织充分破碎,而是加速了液态金属中枝晶和共晶等的流动,随后铸坯再凝固收缩,内部组织疏松和缩孔仍然存在,导致铸锻件力学性能的不高;随着启锻时间的延长(1~2 s),铸锻件的力学性能稍有上升,此时铸坯的固相体积分数较之前的稍高,施加锻压力后合金的变形主要以未凝固的液相成分包裹固相颗粒流动为主,固相颗粒难以发生塑性变形[17-18]。当启锻时间为3~4 s时,铸锻件的力学性能比较好,其中当启锻时间为4 s时,合金的力学性能达到最高;此时金属液在充型压力作用下已慢慢凝固,枝晶骨架已基本形成且连接成一整体,施加的锻压力几乎完全作用在固相骨架上,使得组织被压扁压实,产生较大塑性变形;同时,锻压力又能及时把金属中尚未凝固的共晶成分强制挤入骨架间隙中进行压力补缩,从而避免了疏松裂纹等出现。当启锻时间为5 s时,此时铸坯固相体积分数太高或者已完全凝固,且此时的金属温度下降得较快,合金的变形抗力较大,塑性变形困难,制件的力学性能难以提高。可以看出,在铸锻复合一体化成形中,启锻时间过短时,铸坯固相体积分数太低,液相中的固相枝晶组织细小并游离于液相之中,且相互之间并没有接触,锻压力并没有使枝晶组织充分破碎,从而对力学性能的影响并不是特别显著;而启锻时间过长时,合金中的液相急剧减少,此时的固相体积分数较高甚至完全凝固,凝固的粗大枝晶组织相互连接成一整体,金属的变形抗力较高,且此时在没有液相补充的情况下容易产生裂纹使得制件的力学性能下降。因此,合适的启锻时间对变形铝合金的铸锻复合一体化成形至关重要,不仅可改善其晶粒大小使力学性能显著提高,而且可以防止制件表面及内部宏观缺陷的产生。

图11所示为不同启锻时间下T6状铸锻件室温拉伸断口的SEM像。从图11(a)和(b)可以观察到,启锻时间为0~1 s时,试样的断口有撕裂棱,撕裂棱之间存在细小圆形韧窝且分布不均匀,形成解理断裂和韧性断裂的混合特征。随着启锻时间的延长,合金的断裂形貌发生明显的变化,撕裂棱周围由较深的大韧窝和众多小韧窝组成,塑性断裂明显增加(见图11(d)),表明合金在断裂失效前发生了较大的塑性变形,合金的塑性得到很大的改善;而当启锻时间过长(见图11(f)),断口中韧窝减少且分布不均匀,合金的塑性降低。

3 结论

1) 当启锻时间为3~4 s时,施加锻压力能有效对6061变形铝合金铸坯进行强制补缩和组织密实并使其产生塑性变形,避免了缩孔、裂纹和组织疏松等缺陷产生。

2) 靠近锻压冲头面6061铝合金存在明显的变形组织,且随着启锻时间的延长,铸锻件晶粒明显增大,而中间最后凝固的组织则在锻压力的作用下被压扁压实,发生塑性变形,铸坯靠近下模部分的组织在模具的激冷作用下得到细化。

3) 6061铝合金的抗拉强度和伸长率皆随着启锻时间的延长先增大然后再缓慢减小;当启锻时间为4 s时,其力学性能最高,热处理前后的抗拉强度分别达到211.1和368.9 MPa,伸长率则分别达到17.6%和11.5%。此时,合金的拉伸断口处撕裂棱周围由较深的大韧窝和众多小韧窝组成,塑性断裂明显增加。

REFERENCES

[1] 冯银成, 李落星, 刘 杰, 刘 波, 刘扬胜. 自然时效对6061铝合金显微组织和力学性能的影响[J]. 机械工程材料, 2011, 35(3): 18-21.

FENG Yin-cheng, LI Luo-xin, LIU Jie, LIU Bo, LIU Yang-sheng. Effect of natural aging on microstructure and mechanical properties of 6061 aluminum alloy[J]. Materials for Mechanical Engineering, 2011, 35 (3): 18-21.

[2] NAGESWARA R P, JAYAGANTHAN R. Effects of warm rolling and ageing after cryogenic rolling on mechanical properties and microstructure of Al 6061 alloy[J]. Materials and Design, 2012, 39(8): 226-233.

[3] 刘丘林, 刘允中, 杜 良, 罗 霞, 谢金乐. 喷射成形6061铝合金的热处理工艺[J]. 中国有色金属学报, 2012, 2(2): 350-357.

LIU Qiu-lin, LIU Yun-zhong, DU Liang, LUO Xia, XIE Jin-le. Heat treatment process of spray formed 6061 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 2(2): 350-357.

[4] SHANG Shu-zhen, LU Gui-min, TANG Xiao-ling, ZHAO Zu-xin, WU Cheng-ming. Deformation mechanism and forming properties of 6061 Al alloys during compression in semi-solid state[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1725-1730.

[5] KIM H R, SEO M G, BAE W B.A study of the manufacturing of tie-rod ends with casting/forging process[J]. Journal of Materials Processing Technology, 2002, 125/126(9): 471-476.

[6] 曹韩学, 郝婷婷, 赵东林. 铸锻复合成形后AZ91镁合金的组织和力学性能[J]. 机械工程学报, 2012, 36(8): 42-45.

CAO Han-xue, HAO Ting-ting, ZHAO Dong-lin. Microstructure and mechanical properties of AZ91 magnesium alloy after casting-forging combined forming[J]. Materials for Mechanical Engineering, 2012, 36(8): 42-45.

[7] 齐丕骧, 齐 霖. 双重挤压铸造研究[J]. 铸造技术, 2008, 29(3): 307-311.

QI Pi-xiang, QI Lin. Investigation on dual squeeze casting[J]. Foundry Technology, 2008, 29(3): 307-311.

[8] JIANG Ju-fu, WANG Ying, LI Yuan-fa, QU Jian-jun, SHAN Wei-wei, LUO Shou-jing. A double control forming technology combining die casting and forging for the production of Mg alloy components with enhanced properties[J]. Journal of Materials Processing Technology, 2012, 212(5): 1191-1199.

[9] 王顺成, 郑开宏, 戚文军, 蔡 畅, 王海艳. 铸锻一体化成形技术与装备研究[J]. 特种铸造及有色合金, 2013, 33(3): 220-223.

WANG Shun-cheng, ZHENG Kai-hong, QI Wen-jun, CAI Chang, WANG Hai-yan. Research on equipments and intergrated forming technology of casting and forging[J]. Special Casting & Nonferrous Alloys, 2013, 33(3): 220-223.

[10] 彭 勇, 王顺成, 郑开宏, 戚文军, 陈和兴, 周海涛. 锻压力对铸锻复合成形6061铝合金组织性能的影响[J]. 铸造, 2013, 62(4): 324-329.

PENG Yong, WANG Shun-cheng, ZHENG Kai-hong, QI Wen-jun, CHEN He-xing, ZHOU Hai-tao. Effect of forging pressure on microstructure and mechanical properties of 6061 alloy prepared by casting-forging compound forming[J]. Foundry, 2013, 62(4): 324-329.

[11] MAISONNETTE D, SUERY M, NELIAS D, CHAUDET P, EPICIER T. Effects of heat treatments on the microstructure and mechanical properties of a 6061 aluminium alloy[J]. Materials Science and Engineering A, 2011, 528(6): 2718-2724.

[12] 齐丕骧. 变形铝合金挤压铸造[J]. 特种铸造及有色合金, 2008, 28(10): 769-772.

QI Pi-xiang. Squeezing casting for wrought aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2008, 28(10): 769-772.

[13] 齐乐华, 李贺军, 罗守靖, 杨琦雯. 液态挤压过程变形特征研究[J]. 塑性工程学报, 1997, 4(3): 43-46.

QI Le-hua, LI He-jun, LUO Shou-jing, YANG Qi-wen. Research on the deformation characteristics of the liquid extrusion process [J]. Journal of plasticity engineering, 1997, 4(3): 43-46.

[14] 李远发, 苏平线. 液态压铸锻造双控成形技术研究[J]. 特种铸造及有色合金, 2007, 26(9): 568-571.

LI Yuan-fa, SU Ping-xian. Double control formation technology of liquid squeezing forming[J]. Special Casting & Nonferrous Alloys, 2007, 26(9): 568-571.

[15] CHEN Yong-nan, WEI Jiang-feng, ZHAO Yong-qing, ZHANG Xue-min. Tensile properties and microstructure of Ti14 alloy after semi-solid forging[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 2610-2616.

[16] 刑书明, 鲍培伟. 金属挤压铸造[M]. 北京: 国防工业出版社, 2011.

XIN Shu-ming, BAO Pei-wei. Metal squeeze casting[M]. Beijing: National Defence Industry Press, 2011.

[17] KIM W Y, KANG C G, KIM B M. Deformation behavior of wrought aluminum alloys in incremental compression experiment with a closed die[J]. Journal of Materials Processing Technology, 2007, 191(1/3): 372-376.

[18] KANG C G, CHOI J S, KIM K H. The effect of strain rate on macroscopic behavior in the compression forming of semi-solid aluminum alloy[J]. Journal of Materials Processing Technology, 1999, 88(1/3): 159-168.

(编辑 何学锋)

基金项目:国家科技部科研院所技术开发专项项目(2013EG115006); 广东省部产学研结合科技创新平台建设项目(2012B090600051)

收稿日期:2013-03-27;修订日期:2013-10-27

通信作者:王顺成,高级工程师,博士;电话:020-61086182;E-mail: wangsunceng@163.com