文章编号:1004-0609(2013)12-3289-05

连续冷却条件下半固态7075铝合金的流变性能

李亚庚,毛卫民,朱文志,杨 斌,朱达平

(北京科技大学 铸造研究所,北京 100083)

摘 要:通过差示扫描量热法确定半固态7075铝合金温度与固相分数的关系,采用Couette型同轴双筒流变仪研究连续冷却状态下半固态7075铝合金浆料的表观黏度及其影响因素。结果表明:在连续冷却条件下,当剪切速率( )不变时,冷却速率(v)越大,半固态7075铝合金浆料的表观黏度(ηa)越大;当冷却速率一定时,剪切速率越大,相同温度时半固态7075铝合金浆料的表观黏度越小。对半固态7075铝合金浆料的表观黏度与冷却速率、剪切速率及固相分数(fs)的关系进行数值拟合,为半固态7075铝合金成形的计算机模拟提供了依据:当剪切速率

)不变时,冷却速率(v)越大,半固态7075铝合金浆料的表观黏度(ηa)越大;当冷却速率一定时,剪切速率越大,相同温度时半固态7075铝合金浆料的表观黏度越小。对半固态7075铝合金浆料的表观黏度与冷却速率、剪切速率及固相分数(fs)的关系进行数值拟合,为半固态7075铝合金成形的计算机模拟提供了依据:当剪切速率 =61.235 s-1时,

=61.235 s-1时, ;当冷却速率v=4 ℃/min时,

;当冷却速率v=4 ℃/min时, 。

。

关键词:7075铝合金;半固态;连续冷却;表观黏度

中图分类号:TG 249.2;TG146.2 文献标志码:A

Rheological behavior of semi-solid 7075 aluminum alloy in continuously cooling process

LI Ya-geng, MAO Wei-min, ZHU Wen-zhi, YANG Bin, ZHU Da-ping

(Institute of Foundry, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The apparent viscosity and its affecting factors of the semi-solid slurry of 7075 alloy were studied through a Couette-type viscometer during continuously cooling process. The differential scanning calorimetry (DSC) was performed to examine the solid fraction at different temperature. The results show that the apparent viscosity (ηa) of the slurry increases with the increase of cooling rate (v) when shearing rate ( ) is identical, while it decreases with the increase of shearing rate when cooling rate is identical. The empirical equation that shows the effect of cooling rate, solid fraction (fs) and shear rate on the apparent viscosity is fitted as follows: at

) is identical, while it decreases with the increase of shearing rate when cooling rate is identical. The empirical equation that shows the effect of cooling rate, solid fraction (fs) and shear rate on the apparent viscosity is fitted as follows: at  =61.235 s-1,

=61.235 s-1,  ; at v=4 ℃/min,

; at v=4 ℃/min,  . It provides a model for the simulation of semi-solid 7075 aluminum processing.

. It provides a model for the simulation of semi-solid 7075 aluminum processing.

Key words: 7075 aluminum alloy; semi-solid; continuously cooling; apparent viscosity

20世纪70年代,美国麻省理工学院的FLEMINGS等[1-4]首次提出半固态金属成形。半固态金属成形是金属在液相与固相之间的一种特殊成形工艺,就是在金属凝固过程中,对其施以剧烈的扰动作用,充分改变初生相的形态,得到一种液态金属母液中均匀地悬浮着一定球状初生相的固液混合浆料,利用这种金属浆料直接进行成形,即流变成形;或先将这种浆料凝固成锭坯,再将切分后的锭坯重新加热至半固态两相区,利用这种半固态坯料进行成形加工,即触变成形[5]。这两种方法均称为金属的半固态成形。由于半固态金属成形技术具有许多优势,如成形件致密、力学性能优良、零件形状复杂、模具寿命长等,因此许多专家认为半固态金属成形技术是21世纪的重要加工新方法。

在半固态金属成形过程中,为了获得合格的成形零件,必须了解和掌握半固态金属浆料的流变性,因此,开展半固态金属流变行为的理论及实验研究对改进和发展半固态金属成形技术具有重要意义。国内外不少学者对半固态合金的流变性能进行了研究。BLANCO 等[6]研究了半固态A201铝合金的假塑性和触变性。HU等[7]研究了稳态下半固态Mg2Si/AM60镁基复合材料的流变性能。SILVAA等[8]研究了半固态合金流变性能与微观组织的关系。张友法等[9]利用流变黏度模型对半固态AZ91D镁合金触变注射成形过程进行了数值模拟。王娇娇等[10]采用热模拟压缩试验对半固态6061铝合金表观黏度和剪切速率之间的关系进行了研究。虽然对半固态合金流变行为的研究已开展了若干体系,积累了一定的数据并发现了一些规律,但是,从实际应用看,研究的重点主要集中在亚共晶铝硅合金系列,如A356铝合金及ZL101铝合金等[6, 11-13],而其他合金系列的研究偏少或数据不完整。7075铝合金属于高强度变形铝合金,如果采用传统的塑性加工方法难以将其加工成非常复杂的结构部件,但如果采用机械加工方法成形非常复杂的结构部件则会显著增加生产成本,同时严重浪费铝合金材料。采用半固态金属成形技术有可能将7075铝合金成形为非常复杂的结构部件,同时降低生产成本和提高铝合金材料的利用率,可见7075铝合金在半固态成形中具有广阔的应用市场,研究其流变性能具有重要的现实意义。最近NEAG等[14]使用反向挤压法研究了半固态7075铝合金的流变性能,但仅研究了高固相分数下半固态7075铝合金的流变性能。目前,尚无低固相分数下半固态7075铝合金流变性能的基础数据。因此,本文作者采用Couette型同轴双筒黏度计研究连续冷却条件下的半固态7075铝合金浆料的流变性能,以期提供必要的流变性能理论数据, 从而指导半固态7075铝合金成形的数值模拟。

1 实验

实验用7075铝合金成分如表1所列。

表1 7075铝合金的化学成分

Table 1 Chemical composition of 7075 aluminum alloy (mass fraction, %)

在检测连续冷却条件下的半固态7075铝合金流变性能时,采用自行设计的Couette型同轴双筒黏度计,其结构原理如图1所示。

图1 黏度计示意图

Fig. 1 Schematic diagram of viscometer

石墨外筒与下面电机相连、扭矩传感器与内筒处于同一根轴上,实验时,电机以不同转速带动外筒转动,而内筒静止,这样就在二者之间产生了相对运动,处于外筒和内筒之间的合金液由此受到一定的搅拌和剪切作用。由于合金液具有一定的黏度、这样会在内筒上产生一定的扭矩,该扭矩由扭矩传感器测得并由计算机采集并转换为浆料的表观黏度值。在实验检测中,扭矩与表观黏度的关系可表示为[1]

(1)

(1)

施加在搅拌头上的平均剪切速率由式(2)计算:

(2)

(2)

式中:ηa为稳态表观黏度;M为扭矩;R和r分别为外筒和内筒半径;h为金属液高度; 为电机角速度;n为电机转速;

为电机角速度;n为电机转速; 为平均剪切速率。

为平均剪切速率。

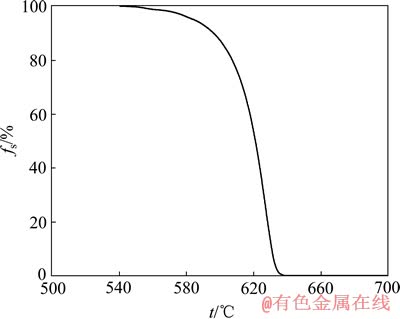

半固态7075铝合金浆料的固相分数可由DSC分析[15]得出,如图2所示。

图2 7075铝合金中固相分数与温度关系

Fig. 2 Relationship between solid fraction of 7075 aluminum alloy and temperature

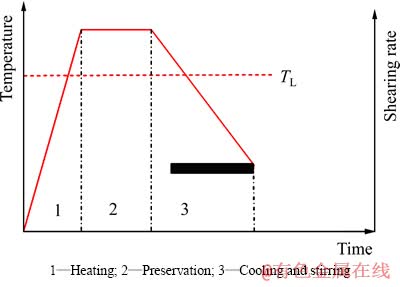

连续冷却条件下的半固态7075铝合金流变性能的检测过程如图3所示。首先将7075铝合金加热熔化至700 ℃,保温30 min,然后分别以4、2及1 ℃/min的冷却速率将7075铝合金熔体冷却;当7075铝合金熔体冷却至液相线以上某一温度时,以一定的剪切速率对其施加搅拌,同时运行采集程序,测得连续冷却条件下半固态7075铝合金浆料的表观黏度变化。

图3 连续冷却实验方案示意图

Fig. 3 Schematic diagram of continuously cooling experiment process

2 结果与讨论

2.1 冷却速率对表观黏度的影响

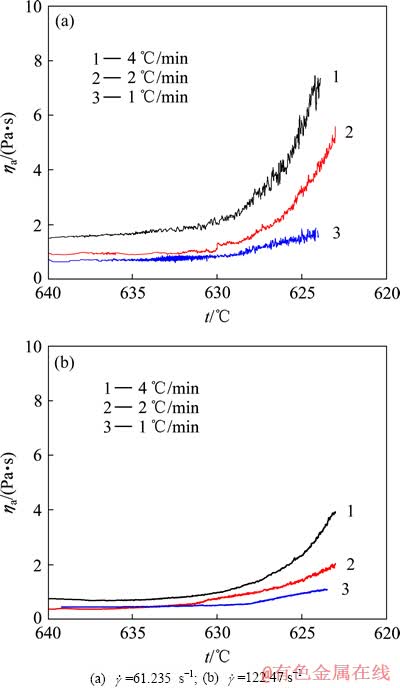

当剪切速率不变时,不同冷却速率下的半固态7075铝合金浆料表观黏度随时间的变化如图4所示。从图4中可以看出,当剪切速率相同时,7075铝合金浆料的冷却速率越大,相同温度下的表观黏度越大。表观黏度随着温度的降低逐渐增加,其增加的速度并不均匀。在较高温度时的表观黏度的变化速率较小,而在较低温度时的表观黏度的变化速率急剧增加,且不同剪切速率下表观黏度差距越来越大。该结果与BRABAZON等[16]对Al-Si合金及甄子胜等[17]对AZ91D镁合金的研究结果类似。

图4 冷却速率对半固态7075铝合金浆料表观黏度的影响

Fig. 4 Influence of cooling rate on apparent viscosity of semi-solid 7075 aluminium alloy slurry

半固态金属浆料是由固相和液相组成的,属于两相混合流体,因此其流体特性也由两相共同决定。对于半固态金属浆料的黏度,可由式(3)确定:

(3)

(3)

(4)

(4)

(5)

(5)

式中:ηL为液相本身的黏度,与温度有关,对于大多数金属液来讲,其黏度随温度的变化并不显著;ηSL为半固态浆料中固相颗粒之间的相互碰撞以及固相颗粒本身对液态金属流动的阻碍作用而引起的黏度的增大,与固相分数fs、固相颗粒的形态s以及尺寸d有关。

将7075铝合金从液态开始连续冷却并同时施以搅拌作用,当温度低于其液相线温度时,铝合金熔体中开始析出初生固相α(Al)。在凝固初期,由于固相分数相对较小,而且在铝合金熔体流动过程中固相颗粒与固相颗粒之间的碰撞和摩擦几率也很小,因此式(3)中的ηSL项可以忽略。此时半固态7075铝合金浆料的流动阻力,或称黏度,主要来自于液相本身的黏度ηL,因此表观黏度较低而且增长缓慢。随着温度的连续下降(即凝固的继续进行),浆料中的固相分数不断增大,而液相则越来越少,此时固相颗粒之间的碰撞便不可忽略,而且随着固相分数的增大,这种碰撞变得越来越频繁,因此式(3)中的ηSL项的值迅速增大,并且成为半固态7075铝合金浆料流动阻力中很重要的一部分,因此,其表观黏度迅速上升。

连续冷却过程中不断凝固产生的固相晶粒在剪切力的作用下会发生由枝晶向非枝晶的转变,这种非枝晶化转变主要表现为在剪切力作用下枝晶臂根部从母体上脱落而引起的枝晶碎化,而该碎化过程进行的程度是与搅拌时间是成正比的。当冷速较高时,具有枝晶形态的固相晶粒受搅拌的时间相对较短,其非枝晶化程度不如低冷速时的充分,因此,组织不如低冷速时的圆整,导致较大的ηSL,从而使得半固态7075铝合金浆料的表观黏度较高。

利用幂律定律, ,对图4中

,对图4中 为61.235 s-1时表观黏度与冷却速率及固相分数的关系进行拟合,结果如下:

为61.235 s-1时表观黏度与冷却速率及固相分数的关系进行拟合,结果如下:

(6)

(6)

式中: 为浆料的表观黏度,Pa·s;v为冷却速率,℃/min;fs为半固态7075铝合金浆料的固相分数。

为浆料的表观黏度,Pa·s;v为冷却速率,℃/min;fs为半固态7075铝合金浆料的固相分数。

2.2 剪切速率对表观黏度的影响

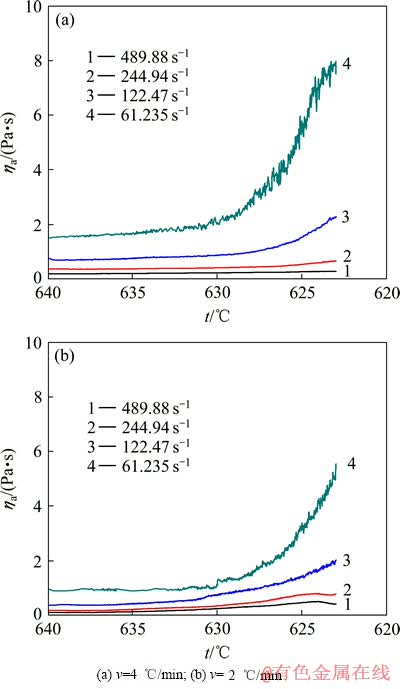

当冷却速率相同时,不同剪切速率下的半固态7075铝合金浆料的表观黏度如图5所示。由图5可 知,当冷却速率相同时,剪切速率越大,相同固相分数下半固态7075铝合金浆料的表观黏度越低。因为当剪切速率较大时,对半固态7075铝合金浆料熔体的搅拌作用增强,更有利于枝晶的破碎,固相晶粒比低剪切速率时的更圆整,因此高剪切速率下的η SL比较小,半固态7075铝合金浆料的表观黏度也就更低。

图5 剪切速率对半固态7075铝合金浆料表观黏度的影响

Fig. 5 Influence of shearing rate on apparent viscosity of semi-solid 7075 aluminium alloy slurry

同样利用幂律定律对图5中冷却速率为4 ℃/min时表观黏度与剪切速率及固相分数的关系进行数值拟合,结果如下:

(7)

(7)

3 结论

1) 在连续冷却条件下,当剪切速率相同时,半固态7075铝合金浆料的表观黏度随冷却速率的增加而增加,如当剪切速率为61.235 s-1时,表观黏度与冷却速率及固相分数的定量关系为 。

。

2) 在连续冷却条件下,当冷却速率相同时,半固态7075率合金浆料的表观黏度随剪切速率的增加而降低,如当冷却速率为4 ℃/min时,其表观黏度与剪切速率及固相分数的定量关系为 。

。

REFERENCES

[1] SPENCER D B, MEHRABIAN R, FLEMINGS M C. Rheological behaviour of Sn-15Pb in the crystallization range[J]. Metallurgical Transactions A, 1972, 3: 1925-1932.

[2] MEHRABIAN R, FLEMINGS M C. Diecasting of partially solidified alloys[J]. American Foundry Society Transactions, 1972, 80: 173-182.

[3] FLEMINGS M C, MEHRABIAN R. Casting semi-solid metals[J]. American Foundry Society Transactions, 1973, 81: 81-88.

[4] FLEMINGS M C. Behavior of metal alloys in the semi-solid state[J]. Metallurgical Transactions, 1991, 22(5): 957-981.

[5] 毛卫民. 半固态金属流变铸造技术的研究进展[J]. 特种铸造及有色合金, 2010, 30(1): 24-35.

MAO Wei-min. Semi-solid metal forming technology[J]. Special Casting & Nonferrous Alloys, 2010, 30(1): 24-35.

[6] BLANCO A, AZPILGAIN Z, LOZARES J, KAPRANOS P, HURTADO I. Rheological characterization of A201 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1638-1642.

[7] HU Yong, HE Bo-lin, YAN Hong. Rheological behavior of semi-solid Mg2Si/AM60 magnesium matrix composites at steady state[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S): s388-s887.

[8] SILVAA M, LEMIEUXB A, CHEN G. Characterization of semi-solid slurry using a novel “Rheo-Characterizer” apparatus[J]. Journal of Materials Processing Technology, 2009, 209(5): 5892-5901.

[9] 张友法, 刘勇兵, 曹占义, 张 亮, 张倩倩. 半固态AZ91D镁合金触变注射成形过程数值模拟及参数优化[J].中国有色金属学报, 2008, 18(4): 703-709.

ZHANG You-fa, LIU Yong-bing, CAO Zhan-yi, ZHANG Liang, ZHANG Qian-qian. Numerical simulation and parameters optimization of thixomolded process for semisolid AZ91D magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 703-709.

[10] 王姣姣, 尚淑珍, 路贵民, 张万宁, 唐小玲, 于建国. 汽车用铝合金零件的半固态压铸数值模拟[J]. 中国有色金属学报, 2012, 22(4): 1045-1052.

WANG Jiao-jiao, SHANG Shu-zhen, LU Gui-min, ZHANG Wan-ning, TANG Xiao-ling, YU Jian-guo. Numerical simulation of semi-solid die-casting process of automobile aluminum alloy part[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 1045-1052.

[11] 张先念, 张恒华, 邵光杰, 许珞萍, 红 梅. 半固态A356铝合金流变特性研究[J]. 铸造, 2005, 54(1): 44-48.

ZHANG Xian-nian, ZHANG Heng-hua, SHAO Guang-jie, XU Luo-ping, HONG Mei. Investigation on the rheological behavior of semi-solid A356 aluminum alloy[J]. Foundry, 2005, 54(1): 44-48.

[12] NAFISI S, LASHKARI O, GHOMASHCHI R, AJERSCH F, CHARETTE A. Microstructure and rheological behavior of hypereutectic semi-solid Al-Si alloy under low shear rates compression test[J]. Materials Science and Engineering A, 2008, 492: 377-382.

[13] 石俊涛, 唐靖林, 朱跃峰. 半固态A356合金静态剪切流变性能的初步研究[J]. 特种铸造及有色合金, 2001(2): 10-12.

SHI Jun-tao, TANG Jing-lin, ZHU Yue-feng. Rheological behavior of semisolid A356 aluminum alloy at steady[J]. Special Casting & Nonferrous Alloys, 2001(2): 10-12.

[14] NEAG A, FAVIER V, BIGOT R, POP M. Microstructure and flow behaviour during backward extrusion of semi-solid 7075 aluminium alloy[J]. Journal of Materials Processing Technology, 2012, 212: 1472-1480.

[15] BIROL Y. Solid fraction analysis with DSC in semi-solid metal processing[J]. Journal of Alloy and Componds, 2009, 486: 173-177.

[16] BRABAZON D, BROWNE D J, CARR A J. Experimental investigation of the transient and steady state rheological behavior of Al-Si alloys in the mushy state[J]. Materials Science and Engineering A, 2003, 356: 69-80.

[17] 甄子胜, 毛卫民, 闫时建, 崔成林, 赵爱民, 钟雪友. 连续冷却条件下半固态AZ91D镁合金组织及流变特性[J]. 金属学报, 2003, 39(1): 71-74.

ZHEN Zi-sheng, MAO Wei-min, YAN Shi-jian, CUI Cheng-lin, ZHAO Ai-min, ZHONG Xue-you. Microstructure and rheological behavior of semi-solid state AZ91D alloy in continuously cooling process[J]. Acta Metallurgica Sinica, 2003, 39(1): 71-74.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2011CB606302-1);国家自然科学基金资助项目(51074024)

收稿日期:2012-10-24;修订日期:2013-08-29

通信作者:毛卫民,教授,博士;电话:010-62332882;E-mail: weiminmao@263.net