DOI: 10.11817/j.issn.1672-7207.2016.05.040

柴油机缸体上水孔流量测量方法对比

刘震涛,孙朝晖,孙正,黄瑞,俞小莉

(浙江大学 动力机械及车辆研究所,浙江 杭州,310027)

摘要:针对柴油机缸体上水孔的流量测量方法进行不同测量方案的对比研究。通过搭建精度模拟试验台对测量误差进行研究,利用流场影响模拟试验台对流场影响进行研究,为验证对比研究结果,进行上水孔实机测量试验及试验与仿真的对比研究。研究结果表明:在整个流量范围内电磁式、涡轮式的流量平均误差较小,各测量方法的流量误差随着流量及管径的减小而增大,电磁式及孔板式的变化较为明显,流量相对误差甚至超过5%。各测量方法对流场的影响随流量的增大而增加,电磁式和涡轮式影响较小。各上水孔流量最大相对误差在2.5%以下,平均相对误差在1.5%以下,且上水孔压力损失范围与趋势和模拟试验的结果也基本一致,证明测量方案的对比研究结论是有效的。

关键词:柴油机;缸体上水孔;流量测量方法;流场;实机试验

中图分类号:TK427 文献标志码:A 文章编号:1672-7207(2016)05-1760-07

Comparison studies on flow measurement methods for cylinder water hole in diesel engine

LIU Zhentao, SUN Zhaohui, SUN Zheng, HUANG Rui, YU Xiaoli

(Institute of Power Machinery & Vehicular Engineering, Zhejiang University, Hangzhou 310027, China)

Abstract: Several comparative studies on flow measurement methods for Diesel cylinder water hole were finished. An accuracy comparison test bench and a flow field effect comparison test bench were established. To verify the results, real machine measurement experiments and the comparison between simulation and experiment were carried out. The results show that the electromagnetic method and turbine method have relatively low average error through the whole flow range; the errors of all methods become greater when flow & caliber decrease, especially for electromagnetic method and pore-plate method whose relative error even exceed 5%. The flow field effects of all methods become greater when the flow increases (approximately followed by linear of index); the effects of electromagnetic method & turbine method are smaller than others. The maximum flow measurement relative error was lower than 2.5% and the average relative error is lower than 1.5%. The pressure loss range and variation tendency are basically consistent with simulation tests. Comparative results are proved to be effective.

Key words: diesel engine; cylinder water hole; flow measurement method; flow field; real machine experiment

柴油机是一种复杂的动力机械,其冷却系统关系到柴油机的热应力、热变形和磨损等问题[1],随着现代社会对高强度柴油机需求的增大,整机冷却效果对于柴油机性能的影响越来越明显,因此,研究适当的冷却水流量及精确的流场分析成为柴油机研究中的重要环节[2-3]。由于柴油机冷却系统的结构非常复杂,而且主要封闭在缸盖和缸体内部,不易观察和测量[4]。对柴油机而言,上水孔部位的冷却水流量是表征内部流动情况的重要指标,可通过上水孔流量求得单缸的冷却水流量,从而对单缸或者多缸流动分析及流场进行计算。王书义等[5]采用不同测试方法进行了流量测量,屈盛官等[6-7]在此基础上结合数值计算使得流动测试技术更加成熟。然而,对于不同的流量测试方法所产生的效果区别以及对原机流场的影响却少有人进行研究。由于柴油机内部结构和测量环境的复杂性,要保证上水孔流量测试精度比较困难,如果流量失准就没有意义,同样,如果对原机流场造成了较大破坏,得出的流量也没有意义。因此,研究柴油机缸体上水孔冷却水流量的精确测量方法及其对比研究,对工程应用具有指导意义,有助于实现上水孔流量测量的最优化,指导柴油机水套结构的优化设计和试验研究[8]。

1 流量测量方法研究

常用流量测量方法包括差压式、速度式、容积式、质量式和电磁式[9]等几类。差压式测量方法通过测量压差变化来确定流体流量;速度式通过测量管道内流体速度来测量流量;容积式利用标准容积连续定排量测量后,累积相加得流量;质量式通过测量得到流体质量流量;电磁式根据感应电势的变化得到流体速度,进而求得管道内流量。参考以往研究和文献分析,由于容积式流量计对流体物性要求高,流体泄露及气体混入都会使精度发生大的变化[10],而且体积较为庞大,质量式流量计易形成零点漂移,易受流体含气量影响[11],再考虑到上水孔的安装限制,因此,较少应用在其测量过程中。常用的上水孔流量测量方式主要集中于差压式、速度式及电磁式这3类之中。

首先分析柴油机上水孔的相关参数及其影响因素。从宏观上来说,上水孔参数包括孔径、流速、流量等,取决于具体的柴油机机型;从微观上来说,又包括湍流度、流动方向等,取决于具体的柴油机水套结构,不同的内部设计对上水孔流动状态影响很大[12]。因此,选取4种典型的车用柴油机进行建模,根据实机运行时企业实测流量,通过仿真手段得到上水孔的流量范围和流动状态,结合孔径和安装因素进行筛选,从以上3类方案中共筛选出5种具体测量方法,包括皮托管式、孔板式、电磁式、涡轮式和涡街式,然后对它们的测量精度以及对原流场的影响进行对比分析。

1.1 精度对比试验

由于真实柴油机体上测量空间过于狭小,而且环境因素比较复杂,为了便于进行精度分析,各测量方法的精度对比试验在外部环境中进行,保证测量管径与上水孔口径相同,同时保证流速范围和流动状态与仿真一致,试验台框架如图1所示。

图1 精度对比试验台示意图

Fig. 1 Diagram of accuracy comparison test bench

冷却水由定容水槽中流出,通过变频电机及水泵加压,至所需的流量范围后通过稳流段来调整和稳定流动状态,然后通过待测流量计(包括上述的5种流量计:皮托管式、孔板式、电磁式、涡轮式和涡街式)来进行测量,采用高精度称量计来测量冷却水的质量流量(称量计设有自动计时装置,可进行累加及求平均,试验时冷却水密度可认为恒定),换算得到体积流量作为基准值,各待测流量计的测试值均与基准值比较得到各自的相对误差。多余的冷却水通过溢流阀和回水管道返回水槽,使整个过程实现闭式循环。此外,为了与实际上水孔口径保持一致,通过变径装置可以改变测量管的管径,最大限度地模拟真实发动机测量环境,试验的步骤如下。

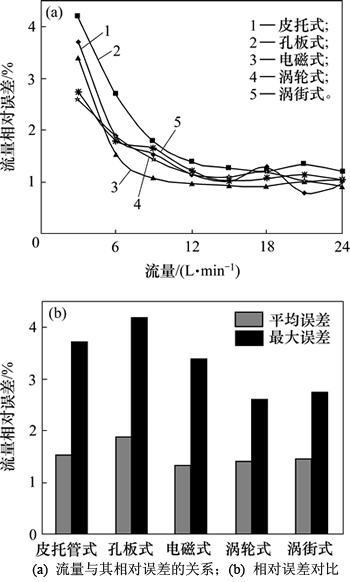

1) 由于选取的4种柴油机的上水孔口径分别为6,8,10和15 mm,先取8 mm作为基准管径,根据仿真结果,在其他参数不变的情况下,将冷却水流量(以基准值为标准)从3.0 L/min增加到24.0 L/min,步长为3.0 L/min,得到各流量计的测量结果。在每一条件下重复进行多次试验,至少获得10组以上的流量进行误差分析,剔除其中个别明显的不规则流量,计算剩余数据的算术平均值、均方差和标准差,得到的流量测量值本身的平均偏差(均方根误差)均在±0.1%以内,计算各流量条件下测量得到的流量算术平均值与基准值的相对误差,鉴于流量平均误差基本在1.5%以上,可以认为测量值本身偏差不会对比较结果产生较大的影响,各测量方法的流量相对误差测量以及对比曲线如图2所示。

图2 各测量方法流量相对误差

Fig. 2 Relative error of flow of all methods

由图2(a)可见:各流量计的最大误差均产生在冷却水流量为3.0 L/min时,其相对误差基本随着流量的减小而逐渐增大。这可能是因为流量太小而接近标定量程范围的极限或者导致管道中残存气泡,从而降低了精度。由图2(b)可见:在整个流量范围内,电磁式、涡轮式和涡街式测量方法的流量平均误差较小,孔板式、皮托管式测量方法的流量相对误差和最大误差都较高。

2) 根据仿真结果,选取6.0 L/min作为基准流量,在其他参数不变的情况下,按照15,10,8和6 mm的顺序将管径依次减小,研究各测量方法在管径变化时所受到的影响。结果显示:随着管径的减小,各流量计的相对误差都在增大,电磁式和孔板式的变化较明显,当管径为6 mm时误差已超过5%。为寻找原因,将一段试验管路更换为透明管路后重新试验,发现当管径小于10 mm后管内有很多小气泡残留,同时截流后造成的流动状态变化比较明显,可能降低了电磁式和孔板式流量计的精度,建议在小管径、小流量的测试环境下优先排除。

1.2 流场影响对比试验

测量方法对原流场的影响同样表征着测量结果的可信度,为进行对比研究,首先要把测量方法对流场的影响量化,拟用安装流量计后所造成的流体压力损失来表现。同样由于机体测量空间过于狭小,因而压力损失对比试验也在外部环境中进行,试验台框架如图3所示。

图3 压力损失对比试验台示意图

Fig. 3 Pressure loss comparison test bench schematic

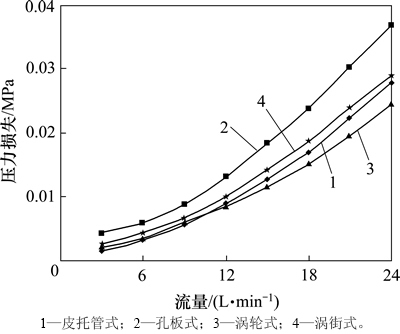

冷却水由定容水槽中流出,通过变频电机及水泵加压,用高精度的流量计测量冷却水流量作为基准值,基准管径与精度对比时一样为8 mm,通过稳流段来调整和稳定流动状态,然后通过待测流量计(由于电磁流量计无压力损失,所以只包括其余4种)和回水管道返回水槽。在待测流量计前后装有水压传感器,测得的压差通过变送器处理后输出。在其他参数不变的情况下,将冷却水流量(以基准值为标准)从3.0 L/min增加到24.0 L/min,步长为3.0 L/min,各流量计的压力损失结果如图4所示。

图4 各测量方法压力损失对比

Fig. 4 Pressure loss comparison of all methods

由图4可见:各测量方法的压力损失随着流量增大近似呈现线性或指数增长,其中孔板式的压力损失最大,表明使用孔板式流量计对原流场的破坏最严重,涡街式和皮托管式的压力损失曲线较接近,涡轮式的压力损失最小,电磁式无压力损失。因此,在各方法精度接近的情况下,建议优先考虑后2种传感器。

2 实机验证试验

经过各测量方法的分析后,还需要进行实机测量试验,通过实机试验数据与仿真数据对比来验证对比研究结果的可靠性。选择与仿真模型一致的(上水孔径为8 mm)某型6缸重型柴油机作为试验机型。

2.1 试验方案设计

图5所示为上水孔分布示意图。首先进行测量方法选型,试验对象为6缸机,每缸共有7个上水孔,各孔分布如图5所示(以缸盖火力面为底面),右上角上水孔编号为1,顺时针旋转分别为2~7号上水孔。

由于试验机型的企业实测数据建立在标准工况下,因此,实机测量试验也采用标准工况。在测量方法选型之前,先进行实机流场及上水孔流量仿真,利用企业已有的三维发动机模型,使用Hypermesh软件进行网格划分,将流体域及固体域网格作为一个整体,使用ANSYS软件中的Fluent模块进行耦合计算。设置好各壁面及边界条件,入口为速度入口,出口为压力出口,进行三维湍流稳态流场计算,得到缸体冷却

图5 上水孔分布示意图

Fig. 5 Diagram of water hole distribution

水套内冷却液流场分布、压力损失等信息[13-14],根据企业数据设定试验用六缸机的总流量为324.0 L/min,由仿真结果得到标准工况下各上水孔流量变化范围为4.2~12.6 L/min。

根据对比研究结果,从精度方面考虑,在该流量范围内,电磁式、涡轮式和涡街式流量计效果较好,然而在小管径和小流量的情况下,管内可能有气泡残留,根据之前流量,可能会明显降低电磁式流量计的精度,加上试验机型上水孔的结构紧凑而且数目很多,电磁式流量计安装和调试过程较为复杂,受到一定的限制,因此将之排除。从流场影响方面考虑,电磁式和涡轮式流量计的压力损失最小。经过综合考虑后,选择涡轮式流量计来测量上水孔流量,用来对比仿真结果。

选取涡轮流量计作为测量用传感器后,采用该测量方法对原机流场影响进行仿真。为评估方案的合理性提供依据,对每个采购的涡轮流量计都进行了压力损失测量,再根据出厂时的标定点进行修正,得到各流量计的压力损失-流量关系曲线。将流量计及安装装置添加到模型中形成新流场,通过Fluent模块的UDF功能,将各流量计的压力损失-流量关系编入算例中的测量段,模拟真实涡轮流量计的压力损失,采用k-e湍流模型进行稳态计算。结果表明:加装涡轮流量计对各缸流量的影响均小于0.7%,对各上水孔流速的影响均小于1%,说明对原流场的影响较小,测试方案的合理性得到了验证,进而通过该模型计算各上水孔加装流量计后造成的压力损失。

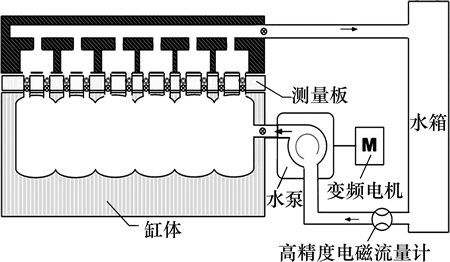

流量计安装方案如图6所示。将测量板放入机体和缸盖之间,流量传感器从中打孔进入,信号通过屏蔽电缆传导出来,经变送器处理后,通过数据采集设备上传到计算机中。

图6 流量计安装示意图

Fig. 6 Diagram of flowmeter installation

整个试验台框架如图7所示。总流量使用高精度电磁流量计进行测量,布置在水泵进口前,同时,每缸出水口均布置1个高精度电磁流量计来测量单缸总流量。在柴油机进出水口各布置1个水压传感器来测量压差。变频电机和水泵布置在发动机进水口前,测量板内部加装42个涡轮流量计,测量各上水孔流量。在试验过程中,控制试验条件与仿真保持一致,即保证六缸机总流量为324.0 L/min。

图7 实机测量试验台示意图

Fig.7 Diagram of real machine measurement test bench

2.2 试验结果分析

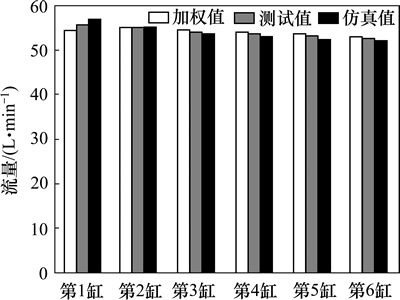

实机测试得出流量数据后,为验证仿真模型和结果的可靠性,应先比较单缸的总流量数值,比较对象包括每一缸7个上水孔流量的加权值、每一缸出水口处电磁流量计的测试值以及仿真得出的每一缸总流量,结果如图8所示。

由图8可见:加权值、测试值和仿真值三者之间非常接近,最大相对误差为3.4%,验证了仿真模型和高精度流量计测试值的可靠性。对所有上水孔流量测量值都进行过误差分析,得到的流量测量值本身的最大偏差(极限误差)均在±0.2%以内,将各上水孔流量的算术平均值与仿真得出的流量进行对比,计算出它们的相对误差,并标明最大相对误差出现的上水孔位置,结果如图9所示。

图8 各缸总流量对比

Fig. 8 Total flow comparison for each cylinder

图9 各缸上水孔流量相对误差对比

Fig. 9 Relative flow error comparison of water holes in each cylinder

由图9可见:流量最大相对误差有些反常,第1缸、第4缸和第5缸的最大误差甚至超过10%,经调查后发现这是个别流量计损坏和由于机体锈蚀而被部分堵塞所致,换上正常流量计同时在冷却水中喷洒除锈剂后重新测试,这些部位的流量相对误差都下降到了4%以下。然而,每一缸上水孔的最大流量误差集中出现在7号位置,包括1-7,2-7,4-7,5-7和6-7,为寻找原因,对比企业柴油机水套图纸后发现,实机缸盖水套结构在7号上水孔附近与仿真模型不一致,可能出现了部分流动死区,因此,将仿真模型按照实机结构进行修改,重新计算后将结果进行比较,结果如图10所示。

图10 各缸上水孔流量相对误差修正对比

Fig. 10 Relative flow error comparison of water holes in each cylinder after correction

由图10可见:此时所有上水孔流量最大相对误差在2.5%以下,平均相对误差在1.5%以下,考虑到实机测量环境的复杂性,对比之前精度对比试验中涡轮流量计的测试结果,二者还是比较一致的,说明精度对比研究结果是可靠的。

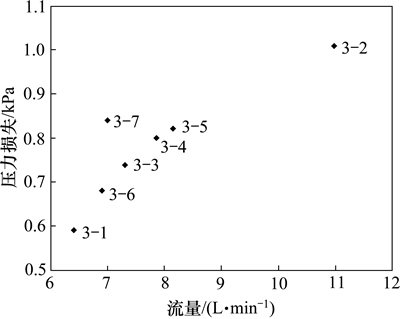

由于柴油机上水孔测量空间限制,无法实测每孔的压力损失。之前已证明仿真模型和流量仿真结果的可靠性,故采用修改后的模型计算各上水孔装流量计后造成的压力损失进行对比,任取一缸为例(本次抽取第3缸),仿真结果如图11所示。

图11 单缸各上水孔压力损失仿真结果

Fig. 11 Pressure loss simulation chart for water holes of single cylinder

由图11可见:仿真得出的第3缸所有上水孔3-1~3-7的压力损失在0.5~1.1 kPa之间,其流量在6.0~11.4 L/min之间,而且流量较大的上水孔其压力损失也较大,各上水孔的压力损失与流量之间呈现正相关,基本与之前流场影响对比试验中测得的压力损失范围和趋势一致,说明流场影响对比研究的结果是可靠的。

3 结论

1) 在其他条件不变的情况下,改变流量和管径进行精度对比测量试验。结果表明:在整个流量范围内电磁式、涡轮式和涡街式流量计的流量平均误差较小,但各测量方法的流量相对误差随着流量及管径的减小而增大,电磁式及孔板式流量计流量变化比较明显,在管径为6 mm时相对误差甚至超过5%。

2) 在其他条件不变的情况下,改变流量进行流场影响对比试验,用压力损失将对原流场的影响量化。结果表明:各测量方法的压力损失随流量的增大近似呈现线性或指数增长,其中电磁式流量计无压力损失,涡轮式流量计压力损失较小。

3) 各上水孔流量测量结果的最大相对误差在2.5%以下,平均相对误差在1.5%以下,上水孔压力损失范围、趋势和对比试验结果也基本一致,证明对比研究的结论有效。

参考文献:

[1] 崔艳伟. 柴油机冷却系统一维与三维联合仿真[D]. 大连: 大连理工大学, 2013: 11-15.

CUI Yanwei. One-dimensional and three-dimensional co-simulation of cooling system in a diesel engine[D]. Dalian: Dalian University of Technology, 2013: 11-15.

[2] 陈美园, 毕玉华, 申立中, 等. 基于正交试验的发动机冷却水套优化[J]. 机械制造, 2012, 50(9): 49-52.

CHEN Meiyuan, BI Yuhua, SHEN Lizhong, et al. Engine cooling water jacket optimization based on orthogonal experiment[J]. Machinery, 2012, 50(9): 49-52.

[3] 周祺, 薛冬新, 唐斌, 等. 某中速柴油机冷却液流动及流固耦合传热计算分析[J]. 柴油机, 2013, 35(1): 17-21.

ZHOU Qi, XUE Dongxin, TANG Bin, et al. The flow and fluid-solid coupled heat transfer analysis of a medium speed diesel engine cooling system[J]. Diesel Engine, 2013, 35(1): 17-21.

[4] 杜志良, 陈文杰, 黎程, 等. 发动机缸盖水路分布测试系统研制[J]. 柴油机设计与制造, 2010, 16(4): 28-31.

DU Zhiliang, CHEN Wenjie, LI Cheng, et al. Experimental design work on test system for water flow distribution in diesel engine[J]. Design & Manufacture of Diesel Engine, 2010, 16(4): 28-31.

[5] 王书义, 王宪成, 段初华. 发动机冷却水三维流动的试验研究[J]. 装甲兵工程学院学报, 1994, 8(1/2): 8-14.

WANG Shuyi, WANG Xiancheng, DUAN Chuhua. Experimental investigation on three-dimensional flow of cooling water in engine[J]. Journal of Armored Force Engineering Institute, 1994, 8(1/2): 8-14.

[6] 屈盛官, 夏伟, 王颖, 等. 高强化柴油机气缸套周围冷却水流动的数值模拟和试验研究[J]. 内燃机工程, 2004, 25(4): 32-35.

QU Shengguan, XIA Wei, WANG Ying, et al. Numerical simulation and experimental research on cooling water flow around cylinder liner for heavy duty diesel engine[J]. Chinese Internal Combustion Engine Engineering, 2004, 25(4): 32-35.

[7] 王兆文, 黄荣华, 成晓北, 等. 车用柴油机气缸盖热负荷的改善[J]. 华中科技大学学报(自然科学版), 2008, 36(8): 99-102.

WANG Zhaowen, HUANG Ronghua, CHENG Xiaobei, et al. Decrease of thermal load of cylinder head in vehicle diesel engines[J]. J Huazhong Univ of Sci & Tech (Natural Science Edition), 2008, 36(8): 99-102.

[8] 张露, 贾月梅, 张伟. 发动机缸体冷却水套的CFD分析与优化设计[J]. 交通科学与工程, 2011, 27(2): 63-68.

ZHANG Lu, JIA Yuemei, ZHANG Wei. CFD analysis and optimal design on engine cylinder block cooling water jacket[J]. Journal of Transport Science and Engineering, 2011, 27(2): 63-68.

[9] 王池, 王自和, 张宝珠, 等. 流量测量技术全书[M]. 北京: 化学工业出版社, 2012: 23-37.

WANG Chi, WANG Zihe, ZHANG Baozhu, et al. Flow measurement technique handbook[M]. Beijing: Chemical Industry Press, 2012: 23-37.

[10] 何君, 门金来, 陈杰. 容积式流量计性能及应用[J]. 机械设计与研究, 2012, 28(3): 119-121.

HE Jun, MEN Jinlai, CHEN Jie. Research on the characteristics and application of positive displacement flowmeter[J]. Machine Design and Research, 2012, 28(3): 119-121.

[11] 邢建文, 关卫红, 李伟. 质量流量计计量准确度的影响因素[J]. 中国仪器仪表, 2013(9): 49-51.

XING Jianwen, GUAN Weihong, LI Wei. The influence factors of mass flowmeter metering accuracy[J]. China Instrumentation, 2013(9): 49-51.

[12] 王兆文, 赵强, 陈雄, 等. 基于正交设计方法的气缸盖上水孔流量测量技术[J]. 农业机械学报, 2014, 45(4): 42-46.

WANG Zhaowen, ZHAO Qiang, CHEN Xiong, et al. Flowrate measurement of upper-nozzles in cylinder head based on orthogonal design method[J].Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(4): 42-46.

[13] 张克鹏, 田豪, 邵林, 等. 基于固流耦合的柴油机缸体水套数值模拟[J]. 汽车实用技术, 2012(2): 20-24.

ZHANG Kepeng, TIAN Hao, SHAO Lin, et al. Fluid-solid coupling based numerical simulation of the engine block water jacket[J]. Automobile Technology, 2012(2): 20-24.

[14] 张沛毅. 基于流固耦合法的发动机冷却均匀性研究[D]. 昆明: 昆明理工大学交通工程学院, 2012: 10-30.

ZHANG Peiyi. Fluid-solid coupling based cooling uniformity research of engine[D]. Kunming: Kunming University of Science and Technology. Department of Traffic Engineering, 2012: 10-30.

(编辑 陈爱华)

收稿日期:2015-05-27;修回日期:2015-09-23

基金项目(Foundation item):国家高技术研究发展计划(863计划)项目(2012AA111709) (Project(2012AA111709) supported by the National High-Tech Research and Development Program (863 Program) of China)

通信作者:黄瑞,助理研究员,从事发动机热管理相关研究;E-mail: hrss@zju.edu.cn