J. Cent. South Univ. Technol. (2007)01-0024-04

DOI: 10.1007/s11771-007-0005-4

Metal magnetic memory signals from surface of low-carbon steel and low-carbon alloyed steel

DONG Li-hong(董丽虹)1,2, XU Bin-shi(徐滨士)1, DONG Shi-yun(董世运)1, YE Ming-hui(叶明慧)2,

CHEN Qun-zhi(陈群志)3, WANG Dan(王 丹)1, YIN Da-wei(尹大伟)1

(1. National Key Laboratory for Remanufacturing, Armored Force Engineering Institute,

Beijing 100072, China;

2. Department of Basic Course, Ordnance Engineering College, Shijiazhuang 050003, China;

3. Beijing Aeronautical Technology Research Center, Beijing 100076, China)

Abstract: In order to investigate the regularity of metal magnetic signals of ferromagnetic materials under the effect of applied load, the static tensile test of Q235 steel and 18CrNiWA steel plate specimens were conducted and metal magnetic memory signals of specimens were measured during the test process. The influencing factors of metal magnetic memory signals and the relationship between axial applied load and signals were analyzed. The fracture and microstructure of the specimens were observed. The results show that the magnetic signals corresponding to the measured points change linearly approximately with increasing axial load. The microstructure of Q235 steel is ferrite and perlite, whereas that of 18CrNiWA steel is bainite and low-carbon martensite. The fracture of these two kinds of specimens is ductile rupture; carbon content of specimen materials and dislocation glide give much contribution to the characteristics of magnetic curves.

Key words: metal magnetic memory; low-carbon steel; low-carbon alloyed steel; applied load; magnetic signals curve; fracture;

microstructure

1 Introduction

Metal magnetic memory testing(MMT) is a new non-destructive testing(NDT) method which was put forward firstly on the 50th internal welding conference by researchers of Russia in 1997, which can detect the stress concentration zones and defects through the magnetic signals of spontaneous stray field of ferromagnetic materials induced by the applied load and consequently be considered as a prospective NDT technique for early damage diagnosis of ferromagnetic components[1-5]. At present the principle of metal magnetic memory testing proposed shows that the directional and irreversible orientation of magnetic domain will occur in the zones with stress concentration and deformation of ferromagnetic components under the influence of applied load in the circumstance of earth magnetic field, the irreversible variation of magnetic state will be remained even if the applied load is removed, which is the magnetic memory effect[6-9].

However, until now, the physical mechanism of metal magnetic memory phenomenon has been unclear due to lack of systematic test and deeper theory support, and the factors influencing metal magnetic memory signals are too complicated, so research on the rule of magnetic memory signals variation under applied load becomes the key of the method developing further[10-12]. Therefore, in this study, the static tensile tests of the plate specimens made of Q235 steel and 18CrNiWA steel were carried out, the regularity of magnetic memory signals, i.e. normal component of spontaneous stray field under the tensile load, Hy, was studied, and the characteristics of magnetic curves were analyzed in terms of the fracture and microstructure of two kinds of the ferromagnetic materials.

2 Experimental

2.1 Specimen

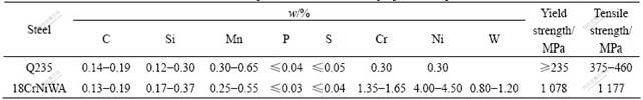

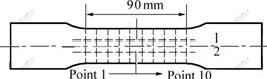

The tested materials were Q235 steel and 18Cr- NiWA steel. Their chemical composition and mechanical properties are listed in Table 1, and the configuration of plate specimen is shown in Fig.1. Its surface roughness was 6 μm. Two parallel lines marked by numbers 1 and 2 were drawn on the surface of the test specimen with 10 mm space vertically. Ten points with constant 10 mm intervals on every horizontal line were chosen to measure their magnetic signals, and the length of the tested zone was 90 mm.

Table 1 Chemical composition and mechanical properties of specimens

Fig.1 Specimen shape and measured points

2.2 Experimental equipments

The tensile test was carried out on a servo hydraulic MTS810 system with static error of ±0.5%. The magnetic memory signals, i.e. the normal component of spontaneous stray field under tensile load, Hy, were measured on the EMS-2003 metal magnetic memory apparatus. The probe used in the test was fixed on a 3D electrical scanning platform made of non-magnetic materials and could be controlled to walk automatically with 2.5 μm pace along the direction of X-axis, Y-axis and Z-axis, respectively, which could collect the magnetic memory signals of each measured point on the horizontal lines from point 1 to point 10 in turn exactly to avoid magnetic interfering signals and manual-operating errors. The specimens loaded to the predetermined load were placed on the non-magnetic material platform in terms of a constant manner and Hy of point 1 to point 10 was measured by the probe in turn along every measured line during the tensile test process.

The fracture and microstructure of the specimens were observed on Quant 200 scanning electronic microscope and Olympus GX51 optical microscope, respectively.

3 Results

3.1 Static tensile test of Q235 steel and 18CrNiWA steel

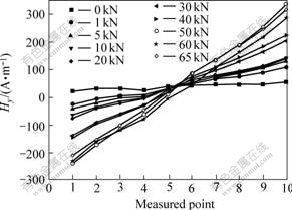

The Hy data of all the measured points corresponding to different load levels were collected during the test process, and so magnetic signals curves of applied loads vs magnetic signals of each measured line were obtained. Though the magnetic memory signals measurement was conducted on the two measured lines of each specimen only one representative set of results is shown here due to the remarkable similarity.

Fig.2 shows the magnetic memory signals change of the measured points of Q235 steel specimen with theapplied load from 0 (unloaded state) to 65 kN(state to be fracture). As the specimen is demagnetized before tensile test its initial signals data are very weak. Then with increasing uniaxial load the shape of the magnetic curve is transformed gradually to magnetic ordered state, which present linear relation nearly from one end to the other along the measured line and magnetic signals on the left side are negative whereas on the right side positive using the central section of the plate-shape specimen as the boundary.

Fig.2 Relationship between applied load and Hy of Q235 steel

For the unloaded specimen, all the measured points on the measured line have small initial magnetic signals whose Hy is positive in the range of 22-55 A/m, negative magnetic signals occur on the left side of the magnetic curve under 1 kN. The slope of the curve increases gradually with increasing applied load. Obvious plastic deformation in the specimen appears at 50 kN, it seems that the slope reaches the maximum, which hardly changes with increasing the applied load except the one at 60 kN. The specimen is fractured at 68 kN.

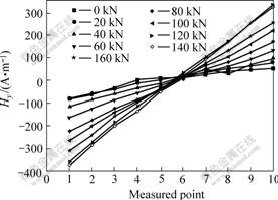

The initial magnetic signals of the specimens of 18CrNiWA steel are very similar to those of Q235 steel specimens, ranging from -82 to 53 A/m(see Fig.3). The slope of the magnetic signals curves increases continuously with increasing the load except the one at 160 kN. The specimen is fractured at 167.3 kN. The residual deformation of the specimens measured at 120 kN is 0.5% and 1.1% at 160 kN.

Fig.3 Relationship between applied load and Hy of

18CrNiWA steel

3.2 Microstructure and fracture of specimens

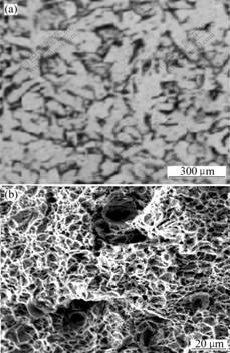

C and Fe are the main elements of Q235 steel which belongs to common carbon structure steel. Besides, there are Mn, Si, S and P elements additionally introduced from steel production process. The microstructure and fracture of Q235 steel are shown in Fig.4. The white crystal grain is ferrite and black massive structure is perlite in the optical image of Q235 steel. Due to the mass fraction of carbon element solutionized in ferrite is less than 0.021 8%, carbon mainly exists in perlite in the form of Fe3C. Due to good plasticity the elongation of Q235 steel specimen reaches 28%. A lot of dimples observed in the SEM image of the fracture show that the fracture of Q235 steel belongs to microvoid coalescence fracture.

Fig.4 SEM images of Q235 steel

(a) Microstructure; (b) Fracture

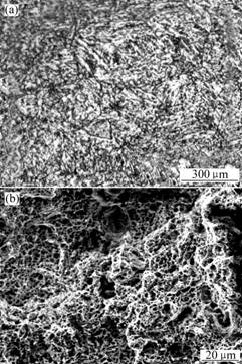

The mechanical properties of 18CrNiWA steel are good due to containing a lot of alloy elements, thus it is usually used to make some important components bearing heavy-load and its microstructure is low-carbon martensite and bainite. The fracture includes three parts: fiber zone, radiation zone and shear lip, belonging to ductile rupture. A lot of dimples exist in the SEM image(Fig.5) of 18CrNiWA steel, which are smaller and shallower than the ones in the fracture of Q235 steel, indicating that the ductility of 18CrNiWA steel is lower than that of Q235 steel.

Fig.5 SEM images of 18CrNiWA steel

(a) Microstructure; (b) Fracture

4 Analysis

The two types of the demagnetized static tensile specimens have relatively small and uniform initial magnetic signals before loading, close to that of the earth magnetic field(40 A/m). The generation and distribution of initial magnetic signals of specimens are related to the machining and conveying process of specimens and the chemical constitution and microstructure of the tested materials.

The initial magnetic curve with small signals is transformed to approximate straight-line with certain slope in the tensile test, and the slope of magnetic curve shows an increasing tendency with increasing applied load. The specimen of Q235 steel has bigger deformation quantity in the test process due to good plasticity, the slope of magnetic curves hardly vary in the plastic deformation stage, whereas they vary continuously in the elastic deformation stage. Although 18CrNiWA steel has good composite mechanical properties, it has poorer plasticity than Q235 steel. The specimen has a small quantity of elongation in the tensile test, and the slope of magnetic curve keeps increasing when the specimen is loaded. The variation of magnetic signal curves results from the change of magnetic domain under the effect of axial load which increases the volume of magnetic domain parallel to its direction and makes the magnetic domain structure ordering, consequently the magnetic signals of the measured points on the whole measured line are uniformed linearly with increasing the applied load, Hy of the magnetic signals presented is changed from positive to negative gradually according to points 1-10. As shown in Figs.4 and 5, the two test materials have good plasticity and ductility, and the specimens have obvious deformation in plastic deformation stage. In this stage the plastic deformation proceeds through dislocation glide, hence the specimens are elongated. Q235 steel has better plasticity and larger elongation than 18CrNiWA steel, the dislocation movement in the specimen is very active and the density of dislocation increases with increasing the elongation, which pins the magnetic domain and ceases the process of magnetic domain ordering powerfully, accordingly the slope of magnetic curve is nearly a constant in the plastic deformation stage. While due to a smaller strain of the 18CrNiWA steel specimen the dislocation activity is very gentle, which has weak influence on pinning the magnetic domain structure, therefore the slope of magnetic curve increases continuously in the tensile test.

However, there are two exceptions in the variation of slope of magnetic curves, one is Hy of Q235 steel at 60 kN and the other is that of 18CrNiWA steel at 160 kN, which are probably related with microdefect in the specimens.

The carbon contents of the two investigated materials are really close, their initial magnetic signals are small and uniform relatively, which have a tendency of linearization with increasing the applied load, and the Hy values of specimens at the point of failure have the same order. It can be concluded that the carbon content in the tested materials plays a significant role in the characters of magnetic curves. Carbon element, as the inclusion in steel, which can solutionize in the α-Fe or form cementite, i.e. Fe3C, causes a lot of damage to the crystal lattice integrity of Fe atom and then has an important influence on the magnetic property of ferromagnetic materials and consequently contributes to the linearization of magnetic signals curve under the effect of axial load.

5 Conclusions

1) The magnetic signals of Q235 and 18CrNiWA steel specimens demagnetized before tensile test are very small, approaching that of earth magnetic field. The curves of magnetic signals present characteristic of linear variation with increasing applied load in the tensile test.

2) Q235 steel has good plasticity, the slope of the magnetic curve does not change in the plastic deformation stage nearly. However, 18CrNiWA steel has higher elastic limit and poorer plasticity than Q235 steel, and its slope of magnetic curve increases continuously due to the weak pinning effect of dislocation on magnetic domain.

3) The fractures of the two types of specimens are ductile rupture and a lot of dimples exist in the fracture of the two types of specimens. The microstructure of Q235 steel is ferrite and perlite, whereas that of 18CrNiWA steel is bainite and low carbon martensite.

4) The content of carbon element plays a significant role in the formation of linear variation characteristic of magnetic signals curve.

References

[1] DUBOV A A Technique for monitoring the bends of boiler and steam-line tubes using the magnetic memory of metal[J]. Thermal Engineering, 2001, 48(4): 289-295.

[2] CHECHKO P. Using the method of magnetic memory of metal to evaluate the service life of the items of power equipment at the Konakovo District Power Station[J]. Thermal Engineering, 2002, 49(12): 1028-1031.

[3] DOUBOV A A.Express method of quality control of a spot resistance welding with usage of metal magnetic memory[J]. Welding in the World, 2002, 46(S): 317-320.

[4] DOUBOV A A, DEMIN E A, MILYAEV A I, et al. The experience of gas pipeline stress-strain state control with usage of the metal magnetic memory method as compared with conventional methods and stress control means[J]. Welding in the World, 2002, 46(9/10): 29-33.

[5] DOUBOV A A. A Study of metal properties using the method of magnetic memory[J]. Metal Science and Heat Treatment, 1997, 39(9/10): 401-402.

[6] HUANG Song-ling, LI Lu-ming, SHI Ke-ren, et al. Magnetic field properties caused by stress concentration[J]. J Cent South Univ Technol, 2004, 11(1): 23-26.

[7] WANG Wen-jing. Study on the metal magnetic memory testing and application[D]. Heilongjiang: College of Mechanical Science and Engineering, Daqing Petroleum Institute,2003.(in Chinese)

[8] ZHANG Wei-ming, Doubov A A, SUN Hai-tao, et al. The metal magnetic memory phenomenon of high-strength steel in the process of gringding[J]. Ordnance Transaction, 2005, 26(3): 375-378. (in Chinese)

[9] LI Lu-ming, HUANG Song-ling, WANG Lai-fu. Research on magnetic testing method of stress distribution[J]. Trans Nonferrous Met Soc China, 2002, 12(3): 387-391.

[10] LI Lu-ming, HUANG Song-ling, WANG Xiao-feng, et al. Magnetic field abnormality caused by welding residual stress[J]. Journal of Magnetism and Magnetic Materials, 2003, 261: 387-391.

[11] LI Lian-xiu. Study on problems of magnetostriction and metal magnetic memory[J]. Non-destructive Testing, 2004, 26(3): 109-112. (in Chinese)

[12] ZHONG Wei-chang. The theory base of metal magnetic memory testing: elastic-plastic strain magnetization of ferromagnetic materials[J]. Non-destructive Testing, 2001, 23(10): 424-426. (in Chinese)

(Edited by CHEN Wei-ping)

Foundation item: Projects(50235030, 50505052) supported by the National Natural Science Foundation of China

Received date: 2006-04-13; Accepted date: 2006-06-18

Corresponding author: DONG Li-hong, Doctoral candidate; Tel: +86-10-66718541; E-mail: lihong.dong@126.com