文章编号:1004-0609(2012)10-2839-07

镍基合金表面二硅化钼复合涂层的制备和性能

颜建辉1,李益民2,张厚安3,唐思文1,许剑光1,刘龙飞1

(1. 湖南科技大学 先进材料制备及应用技术研究所,湘潭 411201;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083;

3. 厦门理工学院 材料科学与工程系,厦门 361024)

摘 要:为了改善K403镍基高温合金的高温抗氧化性能,采用大气等离子喷涂在镍基合金表面制备了4种不同结构的MoSi2复合涂层。结果表明:4种结构涂层中K403/NiCoCrAlY/ZrO2/30%(体积分数)ZrO2-MoSi2/MoSi2复合涂层的抗热震性能最好,且该涂层的界面结合强度最高(22.5 MPa)。MoSi2涂层的自身结合强度大于涂层界面结合强度,结合机理以机械咬合式为主。该复合涂层在1 200 ℃氧化120 h后的质量增加仅为3.42 mg/cm2,提高K403合金和传统氧化锆涂层的抗氧化性能。MoSi2复合涂层表面在高温时生成了一层致密的SiO2保护膜,阻碍了氧的扩散,减轻了过渡层NiCoCrAlY/ZrO2界面处的氧化。

关键词:镍基合金;二硅化钼;复合涂层;组织;性能

中图分类号:TB304 文献标志码:A

Preparation and properties of molybdenum disilicide composites coatings on surface of nickel-based alloy

YAN Jian-hui1, LI Yi-min2, ZHANG Hou-an3, TANG Si-wen1, XU Jian-guang1, LIU Long-fei1

(1. Advanced Materials Synthesis and Application Technology Institute,

Hunan University of Science and Technology, Xiangtan 411201, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Department of Material Science and Engineering, Xiamen University of Technology, Xiamen 361024, China)

Abstract: In order to improve the oxidation resistance of nickel-based alloy at high temperature, four kinds of MoSi2 composite coatings were successfully prepared on the nickel-based alloys surface by air plasma spraying. The results indicate that the thermal shock resistance and the adhesion strength (22.5 MPa) of K403/NiCoCrAlY/ZrO2/30%(volume fraction)ZrO2-MoSi2/MoSi2 composites coating are the best among the four kinds of coatings. The self-bonding strength of MoSi2 coating is greater than the interfacial bond strength of the composites coating, and the bond mechanism is mechanical bond with bite combination. The mass increment is only 3.42 mg/cm2 when MoSi2 composites coating is oxidized at 1 200 ℃ for 120 h. Compared with the nickle-based alloy and the conventional thermal barrier coating, the oxidation resistance of the MoSi2 composites coating is improved. During the high-temperature oxidation process, a dense SiO2 layer is formed on the surface of the MoSi2 coating,which hinder the diffusion of oxygen. The oxidation degree of the boundary between the NiCoCrAlY and zirconia ceramic is relieved.

Key words: nickel-based alloy; molybdenum disilicide; composites coating; microstructure; properties

基金项目:湖南省自然科学基金资助项目(11JJ3063, 12JJ9011);湖南省教育厅科研项目(11B047,11C0513);江苏省新型环保重点实验室开放课题基金资助项目(AE201108)

收稿日期:2011-09-13;修订日期:2012-03-28

通信作者:颜建辉,副教授,博士;电话:0731-58290847;E-mail: yanjianhui88@163.com

镍基高温合金因其具有较好的综合性能已被广泛用于制造航空发动机和各类燃气轮机的热端部件。随着航空航天工业的发展,越来越高的涡轮进口温度要求其叶片材料必须具有更高的抗高温氧化腐蚀的能 力[1]。可行的方法是在镍基合金表面涂覆防护涂层。镍基合金的防护涂层主要有金属间化合物涂层、金属涂层、热障涂层和表面改性涂层[2-4]。传统的金属间化合物涂层和金属涂层难以满足高压涡轮叶片长时间抗高温氧化的工作要求,使用温度一般不能超过1 100 ℃。用氧化钇部分稳定的氧化锆陶瓷涂层可降低涡轮叶片表面温度200 ℃左右[5-6] 。但是,通过氧化锆涂层进行离子扩散和通过涂层孔洞或裂纹扩散是传统热障涂层运输氧的两种主要途径[7-8],由此,导致过渡层和氧化锆界面的TGO生长过快,使得氧化锆涂层脱落而过早失效[9-10]。因此,寻找一些具有更好抗高温性能的涂层材料,以突破ZrO2的寿命极限显得非常重要。金属间化合物二硅化钼(MoSi2)具有优异的高温抗氧化性能,在1 000 ℃以上具有延展性,为缓解涂层热应力提供了帮助,是一种发展潜力极大的高温抗氧化涂层[11-12]。所以,把MoSi2作为氧化锆热障涂层的最外层,有望缓解过渡层与陶瓷层界面处的氧化,提高传统氧化锆热障涂层的高温抗氧化性能。为了解决镍基合金与MoSi2热膨胀系数不匹配的问题,使复合涂层同时具有热障功效和更好的抗氧化性,本文作者以MoSi2作为镍基合金的最外层,设计并制备了4种不同结构的MoSi2复合涂层,对复合涂层的组织结构、结合强度、抗热震性能及抗氧化性能进行了初步的探讨,旨在为提高镍基合金的高温抗氧化性能提供基础数据和理论依据。

1 实验

基体材料为K403镍基合金,打底层NiCoCrAlY粉末由北京矿冶研究总院提供,粒度为38~74 μm。纳米氧化锆团聚体粉末(8%Y2O3-ZrO2)由武汉材料保护所提供,粒度为20~40 μm。自制近球形MoSi2团聚粉末[12],粒度为30~54 μm。30%(体积分数)ZrO2-MoSi2复合粉末由纳米8%Y2O3-ZrO2和MoSi2团聚粉末按体积比均匀混合而成。根据K403基体与MoSi2膨胀系数的匹配关系,设计了以下4种不同类型复合涂层,采用APS-2000型大气等离子喷涂设备制备涂层,主要喷涂参数及涂层厚度见表1。

1) K403/NiCoCrAlY/MoSi2

2) K403/NiCoCrAlY/ZrO2/MoSi2

3) K403/NiCoCrAlY/ZrO2/30%(体积分数)ZrO2- MoSi2

4) K403/NiCoCrAlY/ZrO2/30%(体积分数)ZrO2- MoSi2/MoSi2

用拉伸法(GB/T8642—2002标准)测定复合涂层的结合强度,试验值为相同试验条件下5个试样的算术平均值。复合涂层的抗热震性能根据航空工业标准HB7269—96进行测试:4种不同类型的复合涂层试样在 1 000 ℃箱式电炉中加热保温5 min,随后放入大气中冷却,反复重复这一过程,直到涂层剥落面积达到5%时,涂层完全失效为止。用记录MoSi2复合涂层失效时的热震次数表征涂层的抗热震性能。

氧化试验于1 200 ℃在马沸炉中进行。样品放入高纯氧化铝坩埚,每隔一定时间,从箱式电阻炉中取出样品,自然冷却后采用分析天平( 感应量10-4 g) 称样品的质量(不计脱落物质量),随后又放入炉中继续氧化,样品在炉中氧化的累计时间为120 h。

利用德国D8-Advance型全自动X射线衍射仪检测涂层的物相组成,采用JSM-5100LV扫描电镜观察涂层的表面和截面形貌。

2 结果与讨论

2.1 MoSi2涂层组织结构

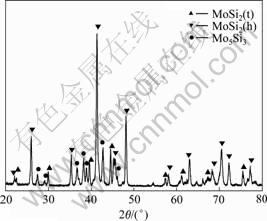

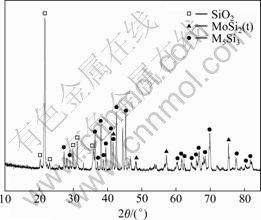

图1所示为MoSi2涂层的表面XRD谱。涂层由MoSi2(t)相、MoSi2(h)相和少量的Mo5Si3相组成。喷涂粉末的MoSi2相是属于稳定的C11b型(简称MoSi2(t))四方晶体结构。由于等离子喷涂火焰温度非常高,MoSi2(t)在等离子射流中,迅速从常温升至高温直至熔化,高温时会发生晶型转变,熔融的MoSi2(t)绝大部分转变为MoSi2(h)晶体结构(MoSi2(h)结构在1 900 ℃以上为不稳定的相[13])。由于熔滴碰撞到基体材料表面后急剧冷却(冷却速度可达106 K/s)、凝固、形成淬冷组织[14],所以在等离子喷涂快速冷却过程中,MoSi2(h)很难发生相变,使得六方结构MoSi2(h)得以保存下来。图2为涂层SEM背散射电子像,涂层经过了加热、加速、变形和冷却等过程形成了典型的层状结构。

表1 各涂层的喷涂工艺参数

Table 1 Processing parameters of coatings

图1 MoSi2涂层XRD谱

Fig. 1 XRD pattern of MoSi2 coating

图2 MoSi2涂层截面组织

Fig. 2 Section morphology of MoSi2 coating

2.2 复合涂层的微观组织

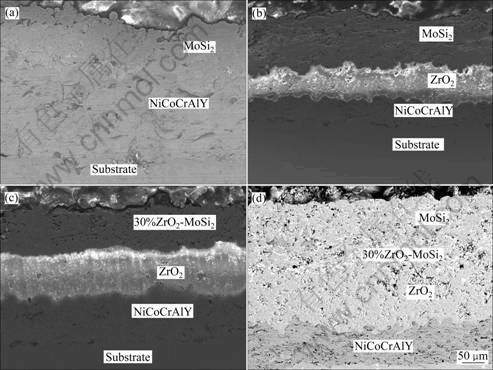

图3所示为4种不同类型复合涂层的截面形 貌。由图3可见,各种涂层的层与层之间的界面均呈“犬齿”状机械结合,界面基本没有出现大的孔洞和裂纹,相互之间结合较好,涂层较致密。K403/NiCo-CrAlY2O3/ZrO2/30%ZrO2-MoSi2/MoSi2复合涂层的ZrO2、30%ZrO2-MoSi2和MoSi2三层之间的两个界面在背散射像下没有明显的区别,表明成分逐渐变化的界面结合较好(见图3(d))。

图3 4种复合涂层的截面形貌

Fig. 3 Cross-section morphologies of four kinds of coatings: (a) K403/NiCoCrAlY/MoSi2; (b) K403/NiCoCrAlY/ZrO2/MoSi2; (c) K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2; (d) K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/MoSi2

2.3 复合涂层的结合强度

4种复合涂层的结合强度见表2。由表2可见,4种不同类型的复合涂层中K403/NiCoCrAlY/MoSi2涂层的抗拉强度最低(为10.27 MPa),K403/NiCoCrAlY/ ZrO2/30%ZrO2-MoSi2/MoSi2复合涂层的结合强度最高(为22.50 MPa),断裂位置均发生在各层的界面处而未发生在层内。可见,4种复合涂层中MoSi2涂层自身结合强度高于所有的界面结合强度,中间层数的引入增加了涂层的结合强度。各种复合涂层的断裂位置如图4所示。对于K403/NiCoCrAlY/MoSi2涂层来说,断裂在NiCoCrAlY和MoSi2涂层界面处发生,该界面处于结合薄弱环节;K403/NiCoCrAlY2O3/ZrO2/MoSi2涂层中的ZrO2/MoSi2界面结合较差,断裂在MoSi2和ZrO2涂层界面处发生;而对于K403/NiCoCrAlY/ ZrO2/30%ZrO2-MoSi2和K403/NiCoCrAlY/ZrO2/30% ZrO2-MoSi2/MoSi2复合涂层来说,约2/3的断裂从NiCoCrAlY和ZrO2界面处发生,约1/3的断裂从基体和NiCoCrAlY界面处发生,说明该复合涂层的主要薄弱环节是NiCoCrAlY/ZrO2界面。

热喷涂MoSi2涂层的结合强度主要取决于喷涂粒子之间、粒子与基体之间的结合状况以及基体和涂层体系中的残余应力状况。粒子沉积过程结束后,材料由高温快速冷却到常温时,涂层与基体不同的热膨胀系数可以产生较大的失配应变。在4种复合涂层中,K403/NiCoCrAlY/MoSi2涂层中的NiCoCrAlY/MoSi2界面热膨胀系数相差最大,制备过程中产生的失配应变最大,界面间产生较大残余应力,导致该界面处产生微裂纹和气孔,故其结合强度低。而对于K403/ NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/MoSi2涂层,由于从金属粘结层到最外层MoSi2采用纳米ZrO2和30%ZrO2-MoSi2作为过渡层材料,使涂层的热膨胀系数逐渐变化,消除了涂层中的成分突变和涂层中的宏观层间界面以及由此造成的物理性质突变,缓解了涂层中的热应力和界面处的应力集中,改善了涂层界面的结合状况,提高涂层的结合强度。

图4 4种复合涂层拉伸试验涂层撕裂面

Fig. 4 Fracture surfaces of four kinds of coatings under tensile testing: (a)~(b) K403/NiCoCrAlY/MoSi2; (c)~(d) K403/NiCoCrAlY/ ZrO2/MoSi2; (e)~(f) NiCoCrAlY/ZrO2/30%ZrO2-MoSi2; (g)~(h) K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/MoSi2

2.4 4种复合涂层的抗热震性能

K403镍基高温合金4种MoSi2复合涂层在1 000 ℃空淬条件下的抗热震次数见表2。由表2可见,K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/MoSi2复合涂层的抗热震性能最好(可达34次),而K403/ NiCoCrAlY/MoSi2抗热震效果最差(仅为5次)。另外,从4种不同类型涂层的结合强度结果来看,K403/ NiCoCrAlY/30%ZrO2-MoSi2/MoSi2涂层内部各个界面结合强度最高,界面之间的机械咬合力较大,能够承受较强的交替变换的冷热载荷能力。

表2 涂层的结合强度

Table 2 Adhesive strength of coatings

热震失效主要是各涂层界面处的热膨胀应力 所致。在反复加热过程中,界面处储积的应变能密 度逐渐增加,K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/ MoSi2复合涂层界面热膨胀系数相差最小,克服了MoSi2表面层与金属底层之间的物理性质突变现象,缓解了涂层中的热应力和界面处应力集中,从而增强了涂层的抗热震能力。图5所示为K403/NiCoCrAlY/ 30%ZrO2-MoSi2/MoSi2涂层热震34次后的截面形貌。由图5可见,ZrO2涂层与NiCoCrAlY出现了横向界面裂纹,在ZrO2涂层内部还出现了少量垂直界面的微裂纹,这些裂纹的存在可以释放部分应力,而最外层的MoSi2涂层内部出现了大量裂纹和MoSi2脱落的现象。

图5 K403/NiCoCrAlY/30%ZrO2-MoSi2/MoSi2涂层热震截面形貌

Fig. 5 Cross-section morphology of K403/NiCoCrAlY/ 30%ZrO2-MoSi2/MoSi2 coating after thermal shocking

热震试验时,加热和冷却过程周期性变化,致使MoSi2涂层内应力也呈周期性变化,即涂层经受循环应力的作用。陶瓷材料有确定的疲劳强度极限,当涂层所经受的循环应力高于涂层的疲劳强度极限时,涂层内将产生裂纹;裂纹一旦形成,脆性的MoSi2陶瓷涂层对其阻碍作用很小。所以,MoSi2内部的裂纹将迅速扩展直至涂层剥落。对于纳米ZrO2涂层来说,由于ZrO2陶瓷层中存在较多的微裂纹和孔隙等缺陷,在高温作用下,当过渡层界面氧化物形成尚不严重时,热膨胀不匹配应力可以通过微裂纹的自由扩展或愈合释放,或者通过形成新裂纹释放。K403/NiCoCrAlY/ 30%ZrO2-MoSi2/MoSi2涂层的热震失效发生在MoSi2表面层与30%ZrO2-MoSi2层的界面处,其断裂是一个裂纹形成与扩展的过程,该失效过程具有连续性:即首先在界面形成微裂纹,然后微裂纹连接形成粗大网状裂纹,最后导致MoSi2陶瓷面层的剥落。

2.5 镍基MoSi2复合涂层的氧化特性

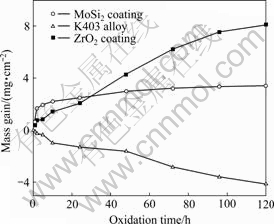

K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/MoSi2复合涂层、氧化锆涂层以及基体材料在1 200 ℃氧化120 h时的氧化动力学曲线如图6所示。由图6可见,K403合金质量减少非常快,氧化层脱落现象严重。ZrO2涂层氧化120 h后质量增加为8.10 mg/cm2,随后还有递增的趋势;MoSi2复合涂层在初始氧化阶段(10 h内)质量增加较快,随着氧化时间的延长,样品质量增加逐渐缓慢,然后呈现平稳趋势。MoSi2复合涂层氧化 120 h后质量增加为3.42 mg/cm2,氧化速率为2.85×10-2 mg/cm2·h。与K403合金和传统氧化锆热障涂层相比,MoSi2复合涂层的抗氧化性能较好。

图6 涂层和K403合金在1 200 ℃氧化120 h动力学曲线

Fig. 6 Oxidation dynamics curves of coating and K403 alloy at 1 200 ℃ for 120 h

K403合金表面氧化时主要生成NiO、Co2CrO4、NiWO4等物质,没有形成保护性的氧化膜,对基体材料不能起到保护作用。纳米ZrO2涂层氧化120 h后的过渡层和ZrO2界面处形貌如图7(a)所示。由图7(a)可见,涂层中的NiCoCrAlY已经出现明显的氧化现象,界面处反应生成NiO、Al2O3和Cr2O3等复杂的氧化物。高温下热障涂层中由于γ-Al2O3到α-Al2O3的相变,会引起附加的残余应力。若生成Al2O3较厚,则会导致涂层剥落、过早地失效。大量氧化物形成并不断向ZrO2表面层中生长,是导致涂层热稳定失效的主要原因之一。

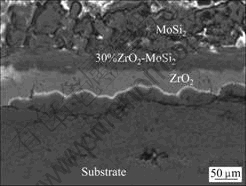

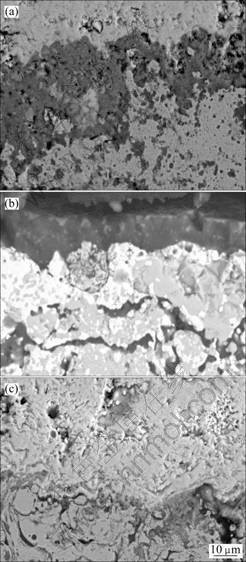

MoSi2复合涂层氧化120 h后的截面形貌如图7(b)和(c)所示,结合涂层氧化后表面X射线衍射结果(图8)可知,MoSi2涂层表面生成了一层致密的SiO2氧化层,SiO2层下面主要是MoSi2和Mo5Si3等物质。由于高温度下SiO2处于流动性较好的状态,质点的迁移能力增强,表面氧化层内部没有裂纹等缺陷,易形成连续而致密的保护膜,能够阻止空气中的氧原子对基体材料的侵入[15]。同时,玻璃态的SiO2能够弥补和填充涂层中的裂纹,具有自愈合功能。这些特点保证了MoSi2涂层具有出色的高温抗氧化性。另外,比较图7(a)和(c)可知,MoSi2复合涂层的过渡层NiCoCrAlY和ZrO2界面处生成的氧化物比传统纳米ZrO2涂层要少。可见,MoSi2复合涂层提高了传统ZrO2涂层的抗氧化性能。

图7 涂层氧化120 h后的截面形貌

Fig. 7 Cross-section morphologies of coating oxidized for 120 h: (a) NiCoCrAlY/ZrO2 boundary of nano-ZrO2 coating; (b) Oxidized K403/NiCoCrAlY/30%ZrO2-MoSi2/MoSi2 coating; (c) NiCoCrAlY/ZrO2 boundary of K403/NiCoCrAlY/30%ZrO- MoSi2/MoSi2 coating

图8 涂层氧化120 h的表面XRD谱

Fig. 8 XRD pattern of MoSi2 coating oxidized for 120 h

3 结论

1) 4种不同结构的MoSi2复合涂层中,层与层之间界面均以咬合形式机械结合;K403/NiCoCrAlY/ ZrO2/30%ZrO2-MoSi2/MoSi2复合涂层的结合强度最高,为22.5 MPa。ZrO2、30%ZrO2-MoSi2、MoSi2这3层之间的界面不明显,成分逐渐变化的界面增加了涂层的结合强度。

2) MoSi2涂层的自身结合强度均大于涂层各界面结合强度。K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/ MoSi2复合涂层的抗热震性能最好,在1 000 ℃保温5 min、空淬条件下的抗热震性能为34次。

3) K403/NiCoCrAlY/ZrO2/30%ZrO2-MoSi2/MoSi2复合涂层在1 200 ℃氧化120 h后的质量增加为3.42 mg/cm2,该复合涂层减轻了传统ZrO2涂层中NiCoCrAlY/ZrO2界面处的氧化,提高了K403高温合金和传统ZrO2热障涂层的高温抗氧化性能,这归因于复合涂层表面生成了一层致密的SiO2保护膜。

REFERENCES

[1] 胡壮麒, 刘丽荣, 金 涛, 孙晓峰. 镍基单晶高温合金的发展[J]. 航空发动机, 2005, 31(3): 1-7.

HU Zhuang-qi, LIU Li-rong, JIN Tao, SUN Xiao-feng. Development of the Ni-base single crystal superalloys[J]. Aeroengine, 2005, 31(3): 1-7.

[2] 郭建亭, 周兰章, 李谷松. 高温结构金属间化合物及其强韧化机理[J]. 中国有色金属学报, 2011, 21(1): 1-34.

GUO Jian-ting; ZHOU Lan-zhang; LI Gu-song. High temperature structural intermetallics and their strengthening- softening mechanisms[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 1-34.

[3] WANG B, SUN C, GONG J, HUANG R. Oxidation behaviour of the alloy IC-6 and protective coatings[J]. Corrosion Science, 2004, 46(3): 519-528.

[4] KHOR K A, YANG J. Transformability of t-ZrO2 and lattice parameters in plasma sprayed rake earth oxides stabilized zirconia coatings[J]. Scripta Materialia, 1997, 37(9): 1279-1286.

[5] VOEVODIN A A, ZABINSKI J S. Nanocomposite and nanostructured tribological materials for space applications[J]. Composites Science and Technology, 2005, 65(5): 741-748.

[6] GUO F A, TRANNOY N, GERDAY D. An application of scanning thermal microscopy analysis of the thermal properties of plasma-sprayed yttria-stabilized zirconia thermal barrier coating[J]. Journal of the European Ceramic Society, 2005, 25(7): 1159-1166.

[7] 郭洪波, 宫声凯, 徐惠彬. 先进航空发动机热障涂层技术研究进展[J]. 中国材料进展, 2009, 28(9/10): 18-26.

GUO Hong-bo, GONG Sheng-kai, XU Hui-bin. Progress in thermal barrier coatings for advanced aeroengines[J]. Materials China, 2009, 28(9/10): 18-26.

[8] LEE W Y, STINTON D P, BERNDT C C. Concept of functionally graded materials for advanced thermal barrier coating applications[J]. J Amer Ceram Soc, 1996, 79(12): 3003-3012.

[9] MOHSEN S, ABBAS A F, AKIRA K. Microstructural analysis of YSZ and YSZ/Al2O3 plasma sprayed thermo barrier coatings after high temperature oxidation[J]. Surface & Coatings Technology, 2008, 202(14): 3233-3238.

[10] 刘纯波, 林 锋, 蒋显亮. 热障涂层的研究现状与发展趋势[J]. 中国有色金属学报, 2007, 17(1): 1-13.

LIU Chun-bo, LIN Feng, JIANG Xian-liang. Current state and future development of thermal barrier coating[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 1-13.

[11] YAN Jian-hui, XU Hong-mei, ZHANG Hou-an. MoSi2 oxidation resistance coatings for Mo5Si3/MoSi2 composites[J]. Rare Metals, 2009, 28(4): 418-422.

[12] 颜建辉, 张厚安, 徐红梅, 吴海江, 唐思文. 喷涂用MoSi2粉末的制备及其在等离子弧中的熔化特性[J]. 中国有色金属学报, 2011, 21(4): 836-842.

YAN Jian-hui, ZHANG Hou-an, XU Hong-mei, WU Hai-jiang, TANG Si-wen. Preparation of MoSi2 powder used for plasma-spraying and its melting characteristics in plasma arc[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 836-842.

[13] 颜建辉, 张厚安, 李益民, 唐思文. 离子喷涂及真空热处理过程中MoSi2涂层的相演变[J]. 焊接学报, 2008, 32(8): 29-33.

YAN Jian-hui, ZHANG Hou-an, LI Yi-min, TANG Si-wen. Phases evolution of molybnenum silicide coating in plasma spraying and heat treatment process[J].Transactions of the China Welding Institution, 2008, 32(8): 29-33.

[14] TOTEMEIER T C, WRIGHT R N, SWANK W D. FeAl and Mo-Si-B intermetallic coatings prepared by thermal spraying[J]. Intermetallics, 2004, 12: 1335-1344.

[15] 常 春, 李木森, 陈传中, 田雷言. MoSi2高温氧化层的微观结构[J]. 金属学报, 2003, 39(2): 126-130.

CHANG Chun, LI Mu-shen, CHEN Chuan-zhong, TIAN Lei-yan. Microstructure of high-temperature oxidation layer of molybdenum disilicide[J]. Acta Metallrugica Sinica, 2003, 39(2): 126-130.

(编辑 李艳红)