Trans. Nonferrous Met. Soc. China 22(2012) 608-612

Effect of milling time on microstructure of Ti35Nb2.5Sn/10HA

biocomposite fabricated by powder metallurgy and sintering

WANG Xiao-peng1, 2, XU Li-juan1, 2, CHEN Yu-yong1, 2, KEE Do-Woo3, XIAO Shu-long1, 2,

KONG Fan-tao1, 2, LIU Zhi-guang1, 2

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals,

Harbin Institute of Technology, Harbin 150001, China;

3. Division of Advanced Material Engineering and Research Center of Advanced Materials Technology,

Chonbuk National University, Chonbuk 561-756, Korea

Received 9 September 2011; accepted 16 January 2012

Abstract: A new β-Ti based Ti35Nb2.5Sn/10 hydroxyapitite (HA) biocompatible composite was fabricated by mechanical milling and pulsed current activated sintering(PCAS). The microstructures of Ti35Nb2.5Sn/10HA powder particles and composites sintered from the milled powders were studied. Results indicated that α-Ti phase began to transform into β-Ti phase after the powders were mechanically milled for 8 h. After mechanical milling for 12 h, α-Ti completely transformed into β-Ti phase, and the ultra fine Ti35Nb2.5Sn/10HA composite powders were obtained. And ultra fine grain sized Ti35Nb2.5Sn/10HA sintered composites were obtained by PCAS. The hardness and relative density of the sintered composites both increased with increasing the ball milling time.

Key words: Ti35Nb2.5Sn/10HA; ultrafine grain; powder metallurgy; milling time

1 Introduction

Recently β titanium alloys are considered one of the valuable materials for medical implants and prostheses due to their excellent biocompatibility, good corrosion resistance and appropriate mechanical properties, moreover, β titanium alloys have lower elastic modulus [1,2] than traditional metal biomaterials. Tissue reaction studies have identified Ti, Nb, Zr, Ta and Sn as non-toxic elements as they do not cause any dangerous reaction in human body [3,4]. Metastable β Ti-Nb based alloys are promising as biomaterials for human bone implants because of the low elastic modulus as well as high corrosion resistance and minimal cytotoxicity. Several metastable β Ti alloys based on the Ti-Nb system, such as Ti-13Nb-13Zr [5], Ti-35Nb-5Ta-7Zr [6] and Ti-29Nb-13Ta-4.6Zr [7], have been developed for biomedical applications, but elastic modulus of these alloys (55-85 GPa) is still higher than that of the human bone (10-30 GPa) [8]. Moreover, most of developed alloys with low elastic modulus have low strength [6]. Ti-Nb-Sn alloys, such as Ti-35Nb-xSn, Ti-40Nb-xSn have been studied as biomaterials [9, 10]. From these researches it can be found that TiNbSn alloys have a low elastic modulus and high strength. But like all metallic biomaterials, TiNbSn alloys have poor biological activity.

It is very known that hydroxyapatite (HA, Ca10(PO4)6(OH)2) has similar chemical component to the inorganic phases of bones and teeth, so HA is a good bioceramic material. And the HA has excellent biocompatibility with hard tissues [11]; however, the mechanical properties of HA are very poor.

Mechanical alloying (MA) is a solid-state powder metallurgical process in which elemental powders are alloyed by repeated deformation/cold welding/ fracture mechanisms under frequent mechanical impacts. The milling time is the most important parameter of MA and is responsible for the final constitution of powders, microstructure and mechanical properties of a particular alloy [12]. PCAS is a rapid sintering technology and it could inhibit grain growth and contamination for long sintering time and high sintering temperature during conventional sintering technology.

In the present work, we used high energy mechanical milling (HEMM) to synthesize Ti35Nb2.5Sn/10HA composite powders by milling for different time, and then fabricated bulk composite samples by pulsed current activated sintering (PCAS) using the milled powders. The sintered composites are expected to combine the bioactivity of hydroxyapatite and the mechanical properties of Ti-based alloys. The effects of milling time on the microstructure and hardness of sintered composites were studied.

2 Experimental

Elemental powders of Ti (99.9%, 150 μm), Nb (99.8%, 45 μm), Sn (99.8%, 45 μm) and pure nanoXIM HA powders were prepared as raw materials. The powders were mixed together according to nominal composition of Ti35Nb2.5Sn/10HA (mass fraction, %). At first the initial powders were blended in a plastic jar at a low speed (120 r/min) by a mechanical mixer (ABB ACS 100) for 24 h, and then the blended powders were milled for different time by HEMM in a SPEX milling machine with stainless steel containers and balls in argon atmosphere. The powders were milled for different time from 4 h to 12 h respectively. Isopropyl alcohol was used as process control agent (PCA) during the HEMM process.

The as-milled powders were sintered by PCAS at 1100 °C in a vacuum chamber of 10-3 Pa and a uniaxial pressure of 60 MPa was applied during the sintering. The sintered specimens were cooled in air.

The phases of the Ti35Nb2.5Sn/10HA milled powders and sintered composites were investigated using XRD with Cu Kα radiation. The particle shape of the milled Ti35Nb2.5Sn/10HA powders and the microstructure of bulk specimens after sintering were observed by scanning electron microscopy (SEM). The Vickers hardness of the sintered composite samples was tested at a load of 9.8 N for 15 s. The density was measured by Archimedes’s principle.

3 Results and discussion

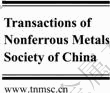

The XRD patterns of the Ti35Nb2.5Sn/10HA milled powders are shown in Fig. 1. The XRD pattern of the mixed powders (Fig. 1(a)) indicates that there are only α-Ti, Nb, Sn and HA. This means that the mechanical milling does not work at low blending speed and it is just a mixing process. The XRD pattern for 4 h-milled powders (Fig. 1(b)) exhibits the decreased α-Ti peaks’ intensity. With increasing milling time, the intensity of α-Ti peaks decreases gradually. In the XRD pattern for 8 h-milled powders (Fig. 1(c)) the peaks of Sn disappear, confirming that Sn has been soluble in Ti to form solid solution of Ti(Sn). As a β-stabilizing element, Nb would help the β-Ti transformation during the HEMM process. The XRD pattern for 12 h-milled powders shows that all the peaks are β-Ti which formed solid solution with Nb and Sn. The diffraction peaks of Ti in Fig. 1 are broadened with increasing the milling time, because grain sizes of these milled powders were refined with increasing the milling time.

Fig. 1 XRD patterns of Ti35Nb2.5Sn/10HA powders produced by mixing and milling: (a) 24 h mixing; (b) 4 h milling; (c) 8 h milling; (d) 12 h milling

The microstructural evolution of the Ti35Nb2.5Sn/10HA powders blended for 24 h and milled for 4-12 h is shown in Fig. 2. Figure 2 shows that the particle size decreases with increasing the milling time. The blended particles are in plate shape and there are many big particles. The surfaces of these particles are DAP, as shown in Fig. 2(a) because there are no mechanical alloying in this process. While the 4 h-milled particles shown in Fig. 2(b) are change greatly, some small fragments particles of HA, Sn and Nb were inserted into the Ti particles; however, there are still many big particles. The particles shown in Figs. 2(c) and (d) show the powders for 8 h-milled and 12 h-milled respectively, and these two milled powders are much smaller and more rounded. Especially, the ultrafine sized Ti35Nb2.5Sn/10HA powders were obtained in the 12 h-milled powders and the average size is about 200 nm.

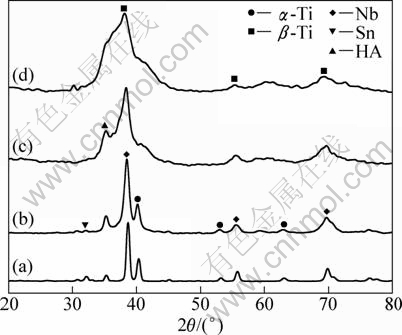

Figure 3 shows the XRD patterns of the Ti35Nb2.5Sn/10HA composite specimens sintered from the powders ball milled for different time. The XRD patterns show that α-Ti phase still exists in the composite specimens sintered from 0 and 4 h-milled powders. But it reduces gradually with the increase of milling time, α-Ti peak almost disappears in the patterns of specimen sintered from 12 h-milled powders, the peaks of β-Ti phase appear because of Nb which is a β-phase stabilizing element. Nb can form homogenous solid solution into β-Ti phase [13]. Also Sn can soluble in its solid state in Ti and Nb to form solid solution. There are some new phases formed in the sintered specimens at high temperature, such as CaTiO3, Ti2O and TixPy. These phases indicate that HA would react with Ti during sintering process. NING [14] and ZHU et al [15] studied the reactions in the Ti/HA sintered composites and suggested that HA would decompose when it was sintered at 1000 °C. Because the sintered temperature is controlled at 1100 °C during the PCAS process, so the reaction is suggested as follow [14]:

Ti+Ca10(PO4)6(OH)→Ti2O+CaTiO3+CaO+TixPy

Fig. 2 SEM images of mixed powder and milled powders: (a) 24 h mixing; (b) 4 h milling; (c) 8 h milling; (d) 12 h milling

Fig. 3 XRD patterns of Ti35Nb2.5Sn/10HA composites sintered from different powders: (a) 24 h mixing; (b) 4 h milling; (c) 12 h milling

Figure 4 shows the scanning electron micrographs (SEM) of the Ti35Nb2.5Sn/10HA composite specimens sintered by PCAS using 24 h-mixed powders and 4 h- and 12 h-milled powders, respectively. Elements Ti and Nb distribute in distinct regions in the sample sintered from 24 h-mixed powders (Fig. 4(a)) and the phase region size is very large. This means all the elements cannot alloy during mixing, and there are many pores due to poor sintering. The microstructure of the sintered specimen from 4 h-milled powders is shown in Fig. 4(b). There are still different component regions, but phase regions size is obvious smaller, and some cracks are found. Figure 4(c) shows the microstructure of the sintered specimen from 12 h-milled powders, compared with those of the specimens sintered from 24 h-mixed or 4 h-milled powders, there is no obviously different regions, the particles size and elements distribution in the sintered specimens are very homogenous, and the grain size is just about 200 nm in average. These results may positively affect the physical and mechanical properties of the specimens.

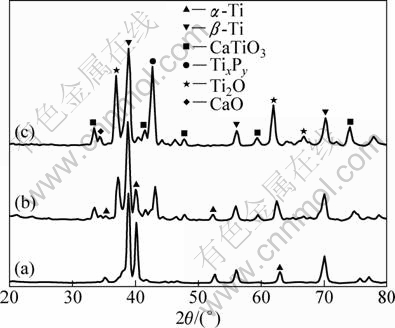

Figure 5 shows the Vicker’s microhardness and relative density of sintered composite samples from different powders. Both microhardness and relative density increase with increasing milling time. The microhardness of the samples sintered from 12 h-milled powders is HV1153, which is much higher than the others. The hardness of sintered samples is influenced by many factors. Among these factors the most important one is milling time, because the grain refinement would be improved with the increase of milling time. And the supersaturated solid solution of Nb into Ti would also increase in the samples sintered from 8 h-milled or 12 h-milled powders. The milling time also can affect the density of sintered samples, and the relative density of sample sintered from 12 h-milled powder increased to 96.34%.

Fig. 4 SEM images of composites sintered from different powders: (a) 24 h mixing; (b) 4 h milling; (c) 12 h milling

Fig. 5 Hardness and relative density of composites sintered from powders with different milling time

4 Conclusions

1) The α-Ti would transform into β-Ti completely after 12 h milling because of the mechanical alloying during the high energy ball milling. Nb and Sn solid diffuse into β-Ti to form Ti(Nb,Sn).

2) The ultra fine sized Ti35Nb2.5Sn/10HA powders are obtained by high energy mechanical milling for 12 h.

3) Bulk Ti35Nb2.5Sn/10HA composites are fabricated by pulse current activate sintering without grain growth due to a short sintering time. And the bulk composites sintered from 12 h-milled powders form ultra fine grains, which also comprise many new phases, such as Ti2O, CaO, TixPy and CaTiO3.

4) The microhardness and relative density all increase with increasing milling time. And the microhardness and relative density of composites sintered from 12 h-milled powders are HV1153 and 96.34%, respectively.

References

[1] KIM H S, LIM S H, YEO I D, KIM W Y. Stress-induced martensitic transformation of metastable β-titanium alloy [J]. Mater Sci Eng A, 2007, 449-451: 322-325.

[2] KOIBE M, CAI Z, FUJII H, BREZNER M, OKANE T. Corrosion behavior of cast titanium with reduced surface reaction layer made by a face-coating method [J]. Biomaterial, 2003, 24: 4541-4549.

[3] OKAZAKI Y, ITO Y, KYO K, TATEISI T. Corrosion resistance and corrosion fatigue strength of new titanium alloys for medical implants without V and Al [J]. Mater Sci Eng A, 1996, 213: 138-147.

[4] HE G, HAGIWARA M. Ti alloy design strategy for biomedical applications [J]. Mater Sci Eng C, 2006, 26: 14 -19.

[5] KOVACS P, DAVIDSON J A. The electrochemical behavior of a new titanium alloy with superior biocompatibility [C]//Titanium’92 Science and Technology. Warrendale: TMS, 1993: 2705-2712.

[6] AHMED T, LONG M, SILVERTRI J, RUIZ C, RACKET H. A new low modulus, biocompatible titanium alloy [C]//Titanium ’95 Science and Technology. London, UK: The Inst Mater, 1995: 1760-1767.

[7] DAISUKE K, MITSUOM N, MASAHIKO M, YOSIHISA K, TOSHIAKI Y. Design and mechanical properties of new β type titanium alloys for implant materials [J]. Mater Sci Eng A, 1998, 243: 244-249.

[8] LONG M, RACK H J. Titanium alloys in total joint replacement—A materials science perspective [J]. Biomaterials, 1998, 19: 1621-1639.

[9] HANADA S, OZAKI T, TAKAHASHI E, WATANABE S, YOSHIMI K, ABUMIYA T. Composition dependence of Young’s modulus in beta titanium binary alloys [J]. Mater Sci Forum, 2003, 426-432: 3103-3108.

[10] MATUSMOTO H, WATANABE S, HANADA S. Beta TiNbSn alloys with low Young’s modulus and high strength [J]. Mater Trans, 2005, 46: 1070-1078.

[11] TAKAYUKI K, SATOSHI N, KIMIHIRO Y. Enhanced osteo-bonding by negative surface charges of electrically polarized hydroxyapatite [J]. Biomed Mater Res, 2001, 57 (4): 477-484.

[12] XIONG J Y, LI Y C, WANG X J, HODGSON P, WEN C. Mechanical properties and bioactive surface modification via alkali-heat treatment of a porous Ti-18Nb-4Sn alloy for biomedical applications [J]. Acta Biomater, 2008, 4: 1963-1968.

[13] HIROAKI M, SADAO W, SHUJI H. Microstructures and mechanical properties of metastable-TiNbSn alloys cold rolled and heat treated [J]. J Alloys Compd, 2007, 439: 146-155.

[14] NING C Q, ZHOU Y. On the microstructure of biocomposites sintered from Ti, HA and bioactive glass [J]. Biomaterials, 2004, 25: 3379-3387.

[15] ZHU S L, WANG X M, XIE G Q, QIN F X, YOSHIMURA M, INOUE A. Formation of Ti-based bulk glassy alloy/hydroxyapatite composite [J]. Scripta Mater, 2008, 58: 287-290.

球磨时间对粉末冶金制备Ti35Nb2.5Sn/10HA生物复合材料微观组织的影响

王晓鹏1, 2,徐丽娟1, 2,陈玉勇1, 2,禹基道3,肖树龙1, 2,孔凡涛1, 2,刘志光1, 2

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家重点实验室,哈尔滨 150001;

3. 全北国立大学 先进材料工程研究部,全州 561756,韩国

摘 要:采用高能机械球磨和脉冲电流活化烧结方法制备了一种新型的β-钛合金基体的Ti35Nb2.5Sn/10HA生物复合材料。研究了机械球磨不同时间的Ti35Nb2.5Sn10HA粉体以及烧结样品的微观组织。结果表明:经机械球磨8 h后,粉体中的α-钛开始向β-钛转化。当球磨时间达到12 h时,球磨粉体中的α-钛相完全转化为β-钛相,而且得到超细尺寸的复合粉体。用球磨12 h的粉末烧结制备的复合材料具有超细晶粒结构,烧结得到的复合材料的硬度和相对密度都随着球磨时间的延长而增加。

关键词:Ti35Nb2.5Sn/10HA;超细晶粒;粉末冶金;球磨时间

(Edited by YANG Hua)

Foundation item: Project (ZJY0605-02) supported by the Natural Science Foundation of Heilongjiang Province, China; Project (310703002) supported by the National Research Foundation of Korea (NRF) grant funded Korea Government

Corresponding author: XU Li-juan; Tel/Tax: +86-451-86418802; E-mail: xljuan@hit.edu.cn

DOI: 10.1016/S1003-6326(11)61221-1