文章编号:1004-0609(2011)11-2946-06

反应挤出法碱分解黑钨矿

赵中伟1, 2, 梁 勇1, 刘旭恒1, 李洪桂1, 陈爱良1, 梁新星1

(1. 中南大学 冶金科学与工程学院,长沙 410083;

2. 稀有金属冶金与材料制备湖南省重点实验室,长沙 410083)

摘 要:针对目前黑钨矿碱法分解工艺中存在的反应温度高、生产效率低等问题,开发了一种黑钨矿碱分解新工艺,以双螺杆挤出机为反应器,采用反应挤出法对高黏度黑钨矿的碱分解过程进行了研究,系统考察浸出时间、温度、螺杆转速和碱用量对钨矿浸出效果的影响。在矿水质量比为2.67:1、碱用量为理论量的1.5倍、温度为120 ℃,螺杆转速为180 r/min和反应时间为2.5 h的条件下,浸出渣中WO3的含量为2.54%,钨矿的浸出率达99.13%。

关键词:反应挤出法;双螺杆挤出机;黑钨矿;氢氧化钠

中图分类号:TF803.21 文献标志码:A

Sodium hydroxide digestion of wolframite by reactive extrusion

ZHAO Zhong-wei1, 2, LIANG Yong1, LIU Xu-heng1, LI Hong-gui1, CHEN Ai-liang1, LIANG Xin-xing1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Hunan Key Laboratory for Metallurgy and Material Processing of Rare Metals, Changsha 410083, China)

Abstract: A novel process was proposed to solve the current disadvantages of high reaction temperature and low productivity in the process of NaOH digestion of wolframite. With a reactor of twin screw extruder, the process of sodium hydroxide digestion of high-viscosity wolframite by reactive extrusion was investigated. The effects of leaching time, temperature, screw rotating speed and NaOH dosage on digestion of wolframite were systematically evaluated. Under the conditions of mass ratio of ore to water 2.67:1, NaOH dosage 1.5 times to stoichiometry, temperature 120 °C, screw rotating speed 180 r/min and reaction time 2.5 h, the content of WO3 in the residue and the WO3 extraction are 2.54% and 99.13%, respectively.

Key words: reactive extrusion method; twin screw extruder; wolframite; sodium hydroxide

钨及其化合物以其独特的物理化学性能,广泛用于生产硬质合金、钨铁、钨材,化工及其他产品[1]。

黑钨矿是钨冶炼重要的矿物资源之一,常用碱浸法来分解[2]。对于一般浸出过程,提高浸出剂浓度有利于反应进行,黑钨矿碱浸过程亦如此。李军等[3]对氢氧化钠与黑钨矿反应的动力学过程进行了研究,结果表明,增大碱浓度有利于提高反应速度。早在20世纪80年代,李洪桂等[4]发明了碱热球磨技术并成功用于处理各类钨矿物。该技术采用较少的水用量,在浸出矿物的同时,利用球磨反应器内钢球对矿物撞击所产生的强烈机械活化作用,破坏了矿物结构、促进了传质、改善了分解过程的动力学条件,使黑钨矿在碱用量不太高的条件下被有效分解[5]。彭泽田[6]、刘政和康忠民[7]以及何传冰等[8]采用高浓度碱溶液对黑钨矿的浸出进行了研究,表明高浓度氢氧化钠创造了良好的动力学条件,在不同程度上提高了碱分解效率。但以上方法均在高压容器中进行,反应温度较高,且为槽式操作,生产效率不高。

众所周知,提高碱浓度通常有两种方法:一种是在矿水比不变的情况下通过增加碱用量来实现;另一种则是在碱用量不变的情况下通过减少水用量来实现。前者虽提高了浸出剂浓度,但同时也增加了碱用量,势必增加试剂消耗,并加重浸出液后续处理的负担。 后者能在不增加碱用量的情况下保证高的碱浓度,但矿浆黏度将随着矿浆浓度的增加而增大,体系的传质过程也因此逐渐困难。在此情况下,传统的浸出设备难以获得理想的传质效果,需要寻求适用于处理高黏度矿浆的新型浸出设备。

双螺杆挤出机被广泛地运用于塑料的造粒、着色、混炼以及塑料薄膜、塑料型材、管材生产和塑料注射机的给料机中[9-14]。它将高黏度有机高分子的化学改性反应和成型加工合二为一,简化了生产工艺。在反应挤出过程中,相互啮合的螺杆提供强烈的剪切应力,使物料在机筒内受到强烈的挤压、剪切、搅拌作用,加快传质过程,实现物料间良好的微观混合均匀度。同时,在强烈的剪切热作用和外热作用下,物料发生塑化熔融,使物料间的反应由固-固反应逐步向固-液反应甚至液相反应转变,显著提高了反应速率。与传统的搅拌反应器相比,螺杆挤出机过程连续,操作开放、简单,生产效率高,同时机器的自洁性好,特别适合于高黏度物料体系的传质过程。

本文作者充分利用双螺杆挤出机能为高黏度物料体系提供良好物理化学条件的特点,通过减少水用量来提高浸出剂浓度,采用反应挤出法对高黏度黑钨矿的碱分解过程进行了研究,系统考察了浸出温度、反应时间、螺杆转速和碱用量对浸出效果的影响。

1 实验

1.1 原料及试剂

实验原料为江西赣南黑钨精矿,矿中WO3含量为74.85%(质量分数),Ca含量为0.8%,矿物经过干燥、研磨后过孔径48 μm筛。矿物的XRD谱如图1所示。由图1可知,黑钨精矿中的钨主要以(Fe, Mn)WO4和CaWO4形态存在。氢氧化钠及其他化学分析试剂均为分析纯。

1.2 实验设备

浸出实验在双螺杆挤出机(SYSLG32-Ⅱ型)中进行,其示意图如图2所示,它主要由挤出机筒、螺杆、热电偶、控制面板、加热圈、齿轮箱和支架几部分组成。双螺杆长60 cm, 直径3 cm。螺杆上的螺棱和啮合块(见图3)可以挤出物料,并使物料获得高效的剪切和活化作用。

图1 黑钨矿的XRD谱

Fig.1 XRD pattern of wolframite

图2 双螺杆挤出机示意图

Fig.2 Schematic diagram of twin screw extruder: 1—Barrel; 2—Screw; 3—Thermocouple; 4—Control panel; 5—Feed port; 6—Heating circle; 7—Gear case; 8—Bracket

图3 螺杆的实物图

Fig.3 Optical photo of screws

1.3 实验方法

先将一定质量的氢氧化钠完全溶解在150 mL水中配成溶液,然后加入400 g黑钨精矿进行调浆,当温度升至预先设定值并稳定后,将矿浆从挤出机的入料口中加入并开始计时。在温度为80~120 ℃、螺杆转速为100~180 r/min的条件下反应1~3 h。反应结束后,将挤出料置于热水中溶解、过滤,水洗后烘干。

采用X射线衍射仪(Dmax/2550VB+,Rigaku Corporation, Japan)分析固体样的物相组成,用国标GB/T 14352.1-93分析精矿及浸出渣的钨含量。

2 结果与讨论

2.1 反应温度对钨浸出率的影响

在螺杆转速为120 r/min、碱用量为理论量3倍、反应时间为2.5 h的条件下,考察了温度对钨浸出率的影响,其结果如图4所示。随着浸出温度的升高,渣含钨量不断减少,当温度升至120 ℃时,渣中含钨量已降至1.93%,相当于钨的浸出率为99.33%。

图4 反应温度对黑钨浸出的影响

Fig.4 Effect of temperature on digestion of wolframinte

温度是影响黑钨矿浸出效果的关键因素之一。在传统碱法工艺中,一般为160 ℃左右[4, 6]。而本研究所需温度只有120 ℃,比传统碱法工艺低近40 ℃,在此温度下钨矿的浸出率也与之相当。其原因主要在于传统碱法工艺中,为保证良好传质效果,一般碱浓度不会太高,因此,为有效地分解钨矿,需要有较高的压力和温度。而本研究所使用的双螺杆挤出机克服了传统浸出设备对高黏度物料传质不利的束缚,在碱用量不高的情况下,采用很少的水配制出浓度达65%左右的碱溶液,大幅提高了浸出剂浓度,从动力力学上极大地推动了反应正向进行,保证了反应在较低温度下进行,降低了能耗,节约了生产成本。因此,综合考虑,选取最佳的浸出温度为120 ℃。

2.2 反应时间对钨浸出的影响

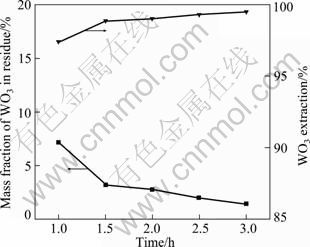

用实际用量为理论量3倍的碱调制矿浆,在浸出温度为120 ℃、 螺杆转速为120 r/min的条件下连续加入双螺杆挤出机内,考察了浸出时间对钨浸出率的影响,其结果如图5所示。随着反应时间的增加,渣中所含不溶性WO3显著降低。当反应时间由1 h延长至2.5 h时,渣中含钨已从7.45%降至1.93%,相应的浸出率由97.43%升至99.33%;随着时间的延长,渣中的含钨量继续下降,但降幅不大。综合考虑生产能耗及浸出效率,选取最佳反应时间为2.5 h。

图5 反应时间对黑钨浸出的影响

Fig.5 Effect of reaction time on digestion of wolframinte

2.3 螺杆转速对钨浸出的影响

在控制反应温度为120 ℃、反应时间为2.5 h、碱用量为理论量3倍的条件下,考察了螺杆转速对钨浸出率的影响,其结果如图6所示。当转速由100 r/min增至180 r/min时,渣含钨由2.14%降低至1.50%,相应的浸出率由99.29%升高至99.49%。结果表明,转速的增加有利于黑钨矿的浸出。随着转速增加,螺杆对高黏度矿浆的剪切力及机械活化作用将更强[15-16]。同时,在反应的过程中,矿物表面浸出剂更新速度也不断加快,物料中各组分的热交换和质交换速率提高,因此,浸出速率也随之提高。综合考虑,选取最佳螺杆转速为180 r/min。

图6 螺杆转速对黑钨浸出的影响

Fig.6 Effect of screw rotating speed on digestion of wolframinte

2.4 碱用量对钨浸出的影响

在温度为120 ℃、螺杆转速为180 r/min、反应时间为2.5 h的条件下,考察了碱用量(实际用量与理论用量的比值)对钨浸出率的影响,其结果如图7所示。虽然随着碱用量不断增加,渣中含钨量不断减少,但当碱用量为理论量的1.5倍时,渣中含钨量为2.54%,此时浸出率已达99.13%。而文献[17] 在碱用量为理论量1.6倍、分解温度为150~160 ℃、保温2 h的条件下,分解含WO3 为70.07%、含Ca为1.08%的黑钨精矿时,渣中含钨量为3.40%,钨的浸出率仅为98.45%。因此,与传统碱法工艺相比,本研究在碱用量不高,在温度更低的条件下同样获得了较好的浸出效果。因此,综合考虑浸出效果和生产成本,选取最佳的碱用量为理论量的1.5倍。

图7 对黑钨矿浸出的影响

Fig.7 Effect of NaOH dosage on digestion of wolframinte

2.5 强化浸出机理

与传统碱压煮工艺相比,反应挤出黑钨矿碱分解新工艺能在较低温度下实现黑钨矿的高效分解,其原因主要有以下几方面:

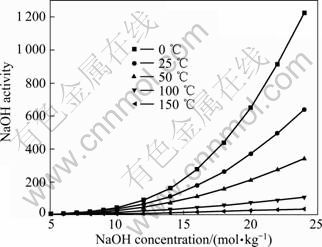

1) 氢氧化钠与黑钨矿反应的动力学研究[3]结果表明,该过程属表面化学反应控制。而根据文献[18]所提供的碱浓度和活度因子的相关数据,计算出碱浓度和活度的关系,如图8所示,氢氧化钠的活度随其浓度的增加而升高,并且升高的趋势随着温度的降低愈加显著。因此,在不影响传质的前提下,在较低温度增大碱浓度,不仅可以增大溶液的沸点,使反应在常压条件下进行而脱离高压设备,而且可以补偿因温度降低导致的表面化学反应速率常数的下降,总体上提高反应速率。本工艺通过大幅减少配水量,极大提高了碱浓度,因而有利于在低温度下实现黑钨矿的有效分解。

图8 不同温度下碱浓度与活度关系图

Fig.8 Relationship between NaOH activity and concentration at different temperatures

2) 在传统的碱浸黑钨矿工艺中,表面化学反应速度是浸出的控制性步骤,提高碱浓度可以增大反应速率。但对于本研究中的高黏度物料体系,首先要解决高浓度碱在该体系中扩散问题,然后才借助高浓度碱对矿物分解的推动作用,而用传统的浸出设备,甚至机械热球磨反应器均无法保证其良好的传质效果。

本工艺以双螺杆挤出机为反应器,在反应挤出过程中,相互啮合、高速旋转的螺杆为机筒内填充的高浓度、高黏度的黑钨矿矿浆提供了强烈的挤压、剪切和搅拌作用,使矿浆得到充分混匀和活化的同时,及时剥除了矿物表面的产物膜,使矿物表面得到不断地更新,提高了矿浆中各组分的热交换和质交换速率,因而增大了黑钨矿的碱浸速率。

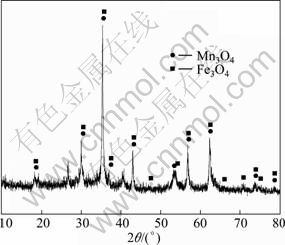

3) 氢氧化钠浸出黑钨矿时,在温度高于102 ℃,且没有氧化剂存在的条件下,分解产物中铁主要以FeO形式存在,而锰则生成Mn(OH)2[19],如反应(1)~(3)所示。在本研究中,高黏度的黑钨精矿在双螺杆挤出机内反应是全开放的,反应过程中热矿浆可不断与空气接触,在此氧化条件下,反应生成的FeO和Mn(OH)2被氧化,分别生成Fe3O4和Mn3O4,如图9所示。而由反应(4)~(6)可知, Fe3O4和Mn3O4的生成消耗了FeO和Mn(OH)2,推动了反应(1)和(2)向正反应方向的进行,促进了黑钨矿的分解。

FeWO4+2NaOH=Fe(OH)2+Na2WO4 (1)

MnWO4+2NaOH=Mn(OH)2+Na2WO4 (2)

Fe(OH)2=FeO+H2O (3)

6FeO+O2=2Fe3O4 (4)

Mn(OH)2=MnO+H2O (5)

6MnO+O2=2Mn3O4 (6)

图9 浸出渣的XRD谱

Fig.9 XRD pattern of leaching residue

3 结论

1) 利用双螺杆挤出机可为高黏度物料创造良好物理化学条件的特点,实现了黑钨矿在低温、低碱用量和低水用量条件下的连续高效分解。

2) 在浸出温度为120 ℃、螺杆转速为180 r/min,浸出时间为2.5 h和碱用量为理论量1.5倍的条件下,浸出渣含钨为2.54%,浸出率达99.13%。

3) 反应挤出碱分解黑钨矿所得残渣主要成分为Fe3O4和Mn3O4。

4) 与传统黑钨矿浸出设备相比,双螺杆挤出机加料连续、高效、自洁性好、操作简单。

REFERENCES

[1] 《有色金属提取冶金手册》编委会. 有色金属提取冶金手册: 稀有高熔点金属(上)[M]. 冶金工业出版社, 1999: 3-6.

《Handbook for Extractive Metallurgy of Nonferrous Metals》Editorial Committee. Handbook for extractive metallurgy of nonferrous metals: Rare refractory metals (Part 1)[M]. Beijing: Metallurgical Industry Press, 1999: 3-6.

[2] 李洪桂. 稀有金属冶金学[M]. 北京: 冶金工业出版社, 1990: 28.

LI Hong-gui. Metallurgy of rare metals[M]. Beijing: Metallurgical Industry Press, 1990: 28.

[3] 李 军, 李洪桂, 刘茂盛, 李晋尧. 氢氧化钠与黑钨反应动力学研究[J]. 中南矿冶学院学报, 1985(4): 128-136.

LI Jun, LI Hong-gui, LIU Mao-sheng, LI Jin-yao. A study of kinetics of reaction between wolframite and NaOH[J]. Journal of Central-South Institute of Mining and Metallurgy, 1985(4): 128-136.

[4] 李洪桂, 刘茂盛, 思泽金, 戴朝嘉, 何雅康, 等. 白钨精矿与黑白钨混合矿碱分解方法及设备: 中国, CN85100350[P]. 1986-8-27.

LI Hong-gui, LIU Mao-sheng, SI Ze-jin, DAI Chao-jia, HE Ya-kang, et al. Method and equipment of alkali decomposition of scheelite and scheelite-wolframite blends: China, CN85100350[P]. 1986-8-27.

[5] 李洪桂. 钨矿物原料碱分解的基础理论及新工艺[M]. 长沙: 中南工业大学出版社, 1997: 119-128.

LI Hong-gui. Basic theory and new technology of alkali decomposition of tungsten mineral [M]. Changsha: Central South University of Technology Press, 1997: 119-128.

[6] 彭泽田. 高钙黑钨精矿的低压高碱浸取[J]. 中国钨业, 1996(10): 16-19.

PENG Ze-tian. Caustic decomposition of wolframite with high calcium under low pressure and high concentration of NaOH[J]. China Tungsten Industry, 1996(10): 16-19.

[7] 刘 政, 康忠民. 高浓度液碱浸出黑钨精矿[J]. 南方冶院科技, 1991(1): 27-29.

LIU Zheng, KANG Zhong-ming. High concentration of caustic decomposition of wolframite[J]. Science and Technology of Southern Institute of Metallurgy, 1991(1): 27-29.

[8] 何传冰, 江行镇, 罗庆文. 黑钨精矿碱分解工艺改进[J]. 稀有金属, 1991(6): 401-404.

HE Chuan-bing, JIANG Xing-zhen, LUO Qing-wen. Process improvement of caustic decomposition of wolframite[J]. Chinese Journal of Rare Metals, 1991(6): 401-404.

[9] ZUIDERDUIN W J C, GAYMANS R J. Polycarbonate modified with crystallisable bis-ester tetra-amide units in a reaction extrusion process [J]. Reactive & Functional Polymers, 2008, 68: 527-534.

[10] VERGNES B, BERZIN F. Modeling of reactive system in twin-screw extrusion: Challenges and applications [J]. Comptes Rendus Chimie, 2006, 9(11/12): 1409-1418.

[11] CHAIYAKUL S, JANGCHUD K, JANGCHUD A, WUTTIJUMNONG P, WINGER R. Effect of extrusion conditions on physical and chemical properties of high protein glutinous rice-based snack[J]. LWT-Food Science and Technology, 2009, 42: 781-787.

[12] 杨景峰, 罗志刚, 罗发兴, 汪明振. 淀粉反应挤出改性及挤出过程中淀粉颗粒变化[J]. 粮食与油脂, 2006(11): 14-16.

YANG Jing-feng, LUO Zhi-gang, LUO Fa-xing, WANG Ming-zhen. Starch modification using reactive extrusion and changes of its granules in processing [J]. Journal of Cereals & Oils, 2006 (11): 14-16.

[13] 张 鹰, 烟 伟, 高世双, 郑安呐, 韩哲文. 反应挤出法合成S/B多嵌段共聚物的研究[J]. 高分子学报, 2002(5): 677-681.

ZHANG Ying, YAN Wei, GAO Shi-shuang, ZHENG An-na, HAN Zhe-wen. Study on S/B multi-block copolymer polymerized by reactive extrusion [J]. Acta Polymerica Sinica, 2002(5): 677-681.

[14] 李兆丰, 顾正彪, 洪 雁. 反应挤出法技术在变性淀粉生产中的应用[J]. 粮食与饲料工业, 2003(10): 37-39.

LI Zhao-feng, GU Zheng-biao, HONG Yan. Application of reactive extrusion in the production of modified starches [J]. Cereal & Feed Industry, 2003(10): 37-39.

[15] 刘 萍, 宋国君. 用反应挤出法进行ABS接枝马来酸酐的研究[J]. 青岛大学学报, 2001, 16(2): 68-71.

LIU Ping, SONG Guo-jun. Study on grafting of MAIIC anhydride to acrylonitrile-butadene-styrene conpolymer by reactive extrusion [J]. Journal of Qingdao University, 2001, 16(2): 68-71.

[16] 杨振国, 李 滨. 用反应挤出法制备尼龙6塑料[J]. 功能高分子学报, 1996, 9(4): 582-588.

YANG Zhen-guo, LI Bin. Preparation of nylon6 resin by reactive extrusion[J]. Journal of Functional Polymers, 1996, 9(4): 582-588.

[17] 刘茂盛, 孙培梅, 李运姣, 李洪桂. 碱法热球磨分解高钙黑钨精矿[J]. 稀有金属, 1993, 17(2): 85-88.

LIU Mao-sheng, SUN Pei-mei, LI Yun-jiao, LI Hong-gui. Caustic decomposition of wolframite with high calcium through mechanical activation [J]. Chinese Journal of Rare Metals, 1993, 17(2): 85-88.

[18] PETRENKO S V, PITZER K S. Thermodynamics of aqueous NaOH over the complete composition range and to 523 K and 400 MPa [J]. J Phys Chem B, 1997, 101: 3589-3595.

[19] 李洪桂. 关于钨矿原料氢氧化钠分解的几个理论问题的浅见[J]. 江西有色金属, 1995, 9(1): 40-44.

LI Hong-gui. Analysis on some fundamental problems about the caustic decomposition of tungsten concentrates [J]. Jiangxi Nonferrous Metals, 1995, 9(1): 40-44.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划项目(2007CB613603)

收稿日期:2010-11-08;修订日期:2011-01-15

通信作者:赵中伟,教授,博士;电话:0731-88830476;E-mail: zhongweizhao@hotmail.com