DOI: 10.11817/j.issn.1672-7207.2016.06.044

移动床中褐煤直接热解特性

高豪杰1, 2,朱跃钊1,杜杨1,吴昊1,陈海军1,范红途1

(1. 南京工业大学 机械与动力工程学院,江苏省过程强化与新能源装备技术重点实验室,

江苏 南京,211816;

2. 盐城工学院 汽车工程学院,江苏 盐城,224051)

摘要:为了获得高含水率褐煤在移动床内不经预处理直接热解的可行性及其热解行为,建立管式炉移动床褐煤直接热解实验装置;考察含水率、热解温度和粒径等参数对褐煤热解损失质量、产物产率以及产气特性的影响。研究结果表明:褐煤在热解过程中蒸发出的原位水蒸气参与半焦的气化以及挥发分的重整反应;随着含水率的增加,褐煤的原位水蒸气气化反应加强,碳转化率逐渐提高,H2产率由277.13 mL/g增大至527.77 mL/g;提高热解温度使气体产率逐渐增大,液体和固体产率逐渐降低,碳转化率由38.19%增大至52.74%;增大粒径使煤中水分和挥发分在颗粒内部的停留时间延长,在一定程度上强化半焦的气化反应以及挥发分的重整反应;此外,增大粒径使挥发分在褐煤颗粒孔隙中的传质阻力增大,二次反应加强,褐煤直接热解的最佳粒径为1.6~3.2 mm。

关键词: 褐煤;移动床;直接热解;含水率;粒径

中图分类号: TQ530 文献标志码:A 文章编号:1672-7207(2016)06-2147-06

In-situ pyrolysis behavior of lignite in a moving bed reactor

GAO Haojie1, 2, ZHU Yuezhao1, DU Yang1, WU Hao1, CHEN Haijun1, FAN Hongtu1

(1. School of Mechanical and Power Engineering, Jiangsu Key Laboratory of Process Enhancement and

New Energy Equipment Technology, Nanjing Tech University, Nanjing 211816, China;

2. School of Automotive Engineering, Yancheng Institution of Technology, Yancheng 224051, China)

Abstract: In order to obtain the feasibility of in-situ pyrolysis of high moisture content lignite and its behavior of pyrolysis, a moving bed tubular experimental reactor used for the in situ pyrolysis of lignite was built. The effects of moisture content, temperature and particle size on the mass loss, product yields and gas characteristic of the lignite pyrolysis were studied. The results show that in-situ steam evaporates from the lignite participated the char gasification and volatile steam reforming reaction. With the increase of moisture content, the in-situ steam gasification reaction of lignite is strengthened, accompanied by the rise of carbon conversion ratio. The H2 yield increases from 277.13 mL/g to 527.77 mL/g. The gas yield increases with the rise of pyrolysis temperature, while the liquid and char yield show an opposite trend. The carbon conversion ratio increases from 38.19% to 52.74%. The increase of the particle size prolongs the residence time of moisture and volatile in the interior of the coal particle, and it can strengthen the semi-coke gasification reaction and the volatiles reforming reaction. Furthermore, the rise of particle size increases the mass transfer resistance of the pore in lignite particles, leading to the strengthened secondary reaction. The optimum lignite particle size for its in-situ pyrolysis is 1.6-3.2 mm.

Key words: lignite; moving bed; in-situ pyrolysis; moisture content; particle size

我国褐煤资源较丰富,已探明储量约为1.3×1011 t,由于含水率高(一般为30%~50%)、固定碳含量低和易氧化自燃等原因,尚未被充分利用[1-4]。褐煤高挥发分和高反应活性的特性有利于其直接热解/气化制取原料气体。此外,褐煤中的金属氧化物可起到催化作用,有利于水蒸气分解反应制取富氢气体[5]。褐煤的特性决定其适合用热解或气化的方式进行转化利用[6],该利用方式通常先经预干燥处理(普遍采用蒸发干燥)。然而,褐煤的干燥过程需要消耗大量的热能用于水分脱除,产生的水蒸气也未被利用。而褐煤气化反应所需要的水蒸气又需要蒸汽锅炉提供。因此,预干燥过程和蒸汽制备过程增大了系统的能量浪费和设备投资。热解气化方式因其经济性好,产物利用品质高等特点受到了广泛关注。YIP等[7]通过多种固定床反应器进行了含水率为20%的煤样和干燥煤样的热解实验,发现当温度高于750 ℃时,含水率为20%的煤样的半焦产率低于干燥煤样的产就绪。目前,煤炭热解的相关研究主要为含水率小于20%的煤样,而高含水率褐煤直接热解的研究较少。熊思江等[8]采用固定床管式炉反应器进行了湿污泥高温热解实验,发现提高含水率可增大H2与CO的产率,但是其不能实现连续进料,载气为惰性气氛,挥发分易被载气稀释,使实验结果不能揭示高水分物料的真实特性。朱跃钊等[9]提出了一种褐煤直接热解工艺,将褐煤的干燥和热解在同一个反应器完成,干燥得到的水蒸气可作为气化剂。本文作者在前期褐煤直接热解动力学研究[10]的基础上,采用管式移动床反应器研究高水分褐煤在真实工况下的直接热解特性,其自身水分蒸发所营造的水蒸气气氛内反应,热解室无需通入载气。重点考察含水率、温度和粒径等参数对褐煤直接热解特性的影响。同时,从褐煤利用经济性的角度,对褐煤在真实工况下的直接热解的可行性进行探讨,以期为后期的放大实验提供可靠的实验数据。

1 实验部分

1.1 实验原料与工况

本实验采用内蒙古地区的海拉尔褐煤为原料,经研磨筛分,粒径为0~6.4 mm,采用德国Elementar公司的Vario EL-3元素分析仪进行元素分析,试样的工业分析及元素分析结果分别如表1和表2所示。

为了考察含水率、温度和粒径对实验结果的影响,制定如下的实验工况:1) 将粒径为0~6.4 mm,含水率为37.4%的试样预干燥处理,得含水率为0,15.4%和25.6%的试样,分别在1 000 ℃热解;2) 将粒径为0~6.4 mm,含水率为37.4%的试样分别在600,700,800,900和1 000 ℃条件下热解;3) 将含水率为37.4%的原料破碎筛分成<0.8 mm,0.8~<1.6 mm,1.6~<3.2 mm,3.2~6.4 mm这4种粒径范围,分别在1 000 ℃条件下热解。

表1 褐煤的工业分析(质量分数)

Table 1 Proximate analysis of lignite %

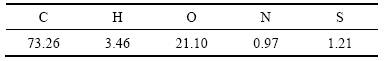

表2 褐煤的元素分析(质量分数)

Table 2 Ultimate analysis of lignite %

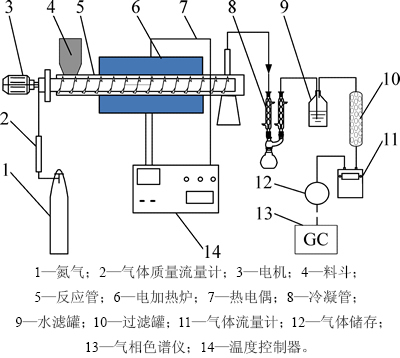

1.2 实验装置与方法

移动床热解系统流程图如图1所示,该系统主要由管式加热炉、移动床反应器、料斗、绞龙驱动机构、温度控制仪、气体冷却净化系统以及气相色谱仪组成。加热炉长为1 m,采用多段控温,精度达±1 ℃。移动床反应器水平固定于管式加热炉中心,材质为耐高温合金钢(长为1.6 m、内径为60 mm)。在实验开始前,先通氮气排净炉内空气,并将反应器加热至设定温度并恒温30 min。驱动轴上安装了螺旋叶片;当实验开始时,启动变频电机带动叶片轴旋转,进而实现物料在反应器内的轴向移动;通过调节驱动轴转速将进料速率控制在16 g/min,热解停留时间为30 min。

图1 热解系统流程图

Fig. 1 Schematic diagram of pyrolysis system

热解产物中的可凝性组分(焦油+水)通过冷凝管和活性炭过滤器收集,不可凝组分(气体)则通过铝箔采样袋收集(每隔2 min采集1袋),并记录瞬时流速。待实验结束后,采用德国Sartorius 公司的BSA 822天平称量半焦和液体产物的质量。为了确保实验结果的可靠性,每个实验条件重复5次,实验数据取5次结果的平均值。采用上海科创GC 9800型气相色谱仪进行气体成分分析,并采用多组结果的平均值。

1.3 实验过程的评价指标

在本实验中,褐煤直接热解气化过程的主要评价指标有产气率、碳转化率、燃气热和H2和CO体积比V(H2)/V(CO)。

1) 产气率。产气率是指气化单位质量原料所得到的气体燃料在标准状态下的体积[8],产气率分为湿基产气率(包含水分) 和干基产气率,本实验以干基计算产气率,单位为mL/g。

2) 碳转化率。本实验的碳的转化率是指褐煤中的碳元素转化为气体燃料的比例,即气体中碳总质量与热解原料中碳总质量之比,是评价煤炭热解气化效果的重要指标。

3) 燃气热值。本实验热解所得气体采用低位热 值[8],采用简化公式进行计算,即

(1)

(1)

式中:QLHV为标准状态下气体的低位热值,MJ/m3(0 ℃,标准大气压);φ(CO),φ(H2),φ(CH4)和φ(C2Hm)分别为CO,H2,CH4和C2Hm烃类的体积分数,%。

4) V(H2)/V(CO)。V(H2)/V(CO)是煤炭热解/气化制备合成气的重要的参考指标[11],通过改变实验条件可调节热解气体中V(H2)/V(CO),可用于定向合成化工原料。

2 结果与讨论

2.1 含水率的影响

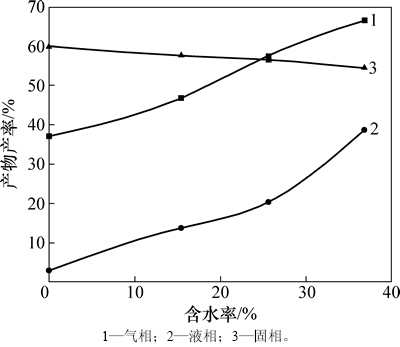

含水率分别为0%,15.4%,25.6%和37.4%的褐煤在1 000 ℃下直接热解的干基产物产率如图2所示。由图2可知:随着含水率的增加,褐煤热解的气、液相产物产率逐渐增大,而固相产物(半焦)的产率逐渐降低。这是因为褐煤热解过程中水分的蒸发使反应器内产生了原位水蒸气氛围,褐煤的含水率越高水蒸气产生量就越大,水蒸气对整个反应的促进作用就越强;褐煤中蒸发出的原位水蒸气,在系统内参与了2种反应:一方面与挥发分发生水蒸气重整反应(式(7)),另一方面则与半焦产生水蒸气气化反应(式(2)和式(3))。未反应的水蒸气经冷凝后变成液态水并融入热解液,使热解液相产率随着含水率增加而增大。

图2 1 000 ℃条件下不同含水率褐煤的热解产物产率

Fig. 2 Effect of lignite moisture content on yield of pyrolysis products at 1 000 ℃

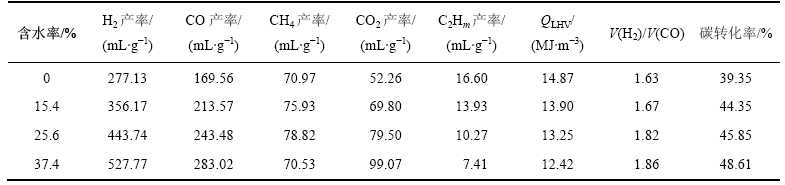

1 000 ℃条件下不同含水率褐煤的热解气特性如表3所示。由表3可知:随着含水率的增加,碳转化率逐渐增大,气体释放总量也随之增加,气体中 H2,CO2和CO 的产率逐渐增大,C2烃类气体产率逐渐降低;气体中H2的产率由277.13 mL/g增大至 527.77 mL/g,CO的产率由169.56 mL/g增大至 283.02 mL/g,CO2的产率由52.26 mL/g增大至 99.07 mL/g,CH4的产率先增大后减小,C2Hm的产率由16.60 mL/g减小至7.41 mL/g。这是因为水分的析出使褐煤颗粒内部生成更多孔隙结构,增加了总反应面积,同时孔隙结构延缓了大分子焦油的析出,增加了其在煤粒中的停留时间。含水率的增加促进了大分子挥发分的裂解,有利于H2和CO等低热值气体的生成(式(3),式(5)和式(6)),导致热解气热逐渐减小,变化范围在12.42~14.87 MJ/m3。这是由于热解气体中的H2浓度增大而CO浓度减小,H2的体积热值较低[12]。

热解过程的主要反应如式(2)~(7)所示,其中M为大分子有机物。

C+H2O→CO+H2+131 kJ/mol (2)

C+2H2O→CO2+2H2+75 kJ/mol (3)

C+CO2→2CO+173 kJ/mol (4)

CH4+H2O→CO+3H2+206 kJ/mol (5)

CH4+2H2O→CO2+4H2+165 kJ/mol (6)

M(g)+H2O(g)→CO+H2 (7)

由表3和图2可以看出:在相同温度下,含水率的增大使褐煤的热解转化率提高,气体产率增大,气体中的H2浓度大幅增加。当褐煤含水率为37.4%,热解气体中H2产率高达527.77 mL/g,V(H2)/V(CO)达1.86。本实验中的最高氢气产率与梁杰等[13]褐煤氧气-水蒸气气化实验中的氢气产率相当。结果表明:未经干燥褐煤的直接热解可有效提高产气率和H2浓度,其在自身营造的水蒸气气氛内直接热解的效果与外部通入水蒸气气化所达到的产气效果接近。

赵淑蘅等[14]进行了褐煤与稻壳加水共热解的实验,发现当添加水分的质量大于原料质量的60%时,气相产物产率达到最大值,之后添加水分对气相产率的影响较小。由于本文主要探讨利用褐煤自身水分进行热解/气化的影响因素,而所选海拉尔褐煤的含水率一般低于40%,因此,未进行更高含水率褐煤的热解实验。

2.2 热解温度的影响

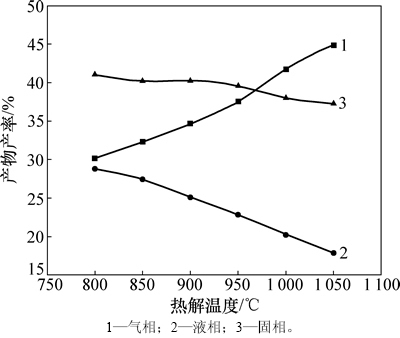

热解温度对含水率为37.4%的海拉尔褐煤热解特性的影响如图3所示。由图3可以看出:当热解温度从800 ℃升高至1 050 ℃时,气相产物产率明显提高,由44.97%增大至 71.66%,液相和固相产物的产率则相应地降低,且液相产物与固相产物产率的降低幅度相当。这说明提高热解温度强化了褐煤热解吸热反应的进行,气体产率的增加主要来自挥发分的二次裂解、挥发分的水蒸气重整以及半焦水蒸气气化反应。

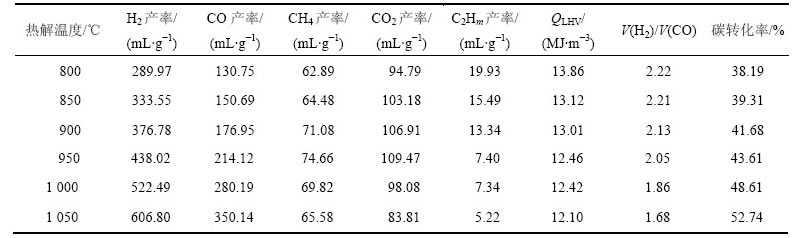

热解温度对气体产物组成的影响如表4所示。由于热解过程以吸热为主,因此,提高热解温度有利于气体的生成。由表4可知:随着温度的增大碳转化率逐渐提高,气体产率也随之增大;当热解温度为1 050 ℃时,碳转化率达到最大值,为52.74%;此外,

当热解温度从800 ℃提高到1 050 ℃时, H2产率由280.97 mL/g增大至606.80 mL/g。这是因为当温度升高时,系统为热解所提供的能量相应地增大。一方面有利于褐煤中有机物的C-H键迅速断裂,生成H2;另一方面,高温下的水蒸气气化反应有利于H2的生成。随着温度升高,气相中CO的产率由130.75 mL/g逐渐增加至283.02 mL/g,而CO2的产率则变化不大。热解气相中V(H2)/V(CO)逐渐减小,范围为1.68~2.22。气体中CH4的产率则随着温度的升高而降低,而C2烃类的产率则逐渐减小。这是因为在较高的热解温度下,褐煤中的水分同热解产物如C和CH4等发生重整反应加强[15],且高温有利于大分子碳氢化合物的二次裂解,生成H2等小分子气体。此外,随着热解温度的升高,气体热值逐渐降低,为12.10~13.86 MJ/m3。

图3 不同热解温度下褐煤热解产物产率

Fig. 3 Effect of temperature on yield of lignite pyrolysis products

表3 1 000 ℃时不同含水率褐煤的热解产气特性的影响

Table 3 Effect of moisture content on gas characteristic of lignite pyrolysis at 1 000 ℃

表4 温度对褐煤热解产气特性的影响

Table 4 Effect of pyrolysis temperature on gas characteristic of lignite

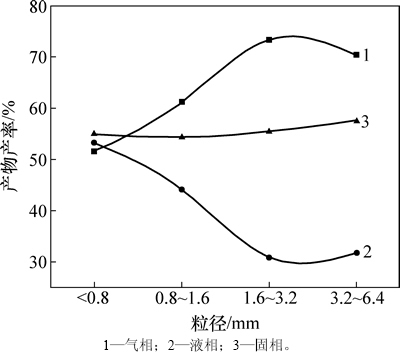

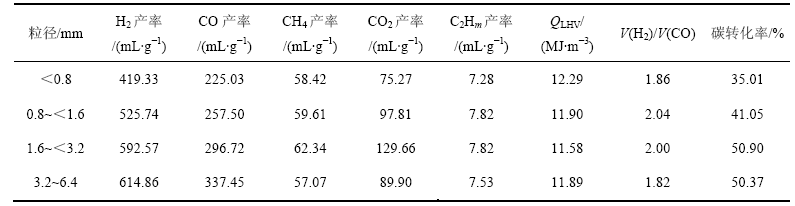

2.3 粒径的影响

不同粒径褐煤在1 000 ℃下的热解产物分布如图4所示。从图4可以看到:随着颗粒粒径的增大,热解的半焦产率逐渐增大,即褐煤的挥发分析出量逐渐增大。这可能是由于2个方面的原因:1) 随着粒径的增加,加热速率降低,挥发分析出量减小;2) 随着粒径的增大,颗粒间的传热传质阻力增大,挥发分脱离褐煤颗粒的速率减慢,挥发分析出量减小。

试样粒径对气体产物组成的影响如表5所示。由表5和图4可知:在0~3.2 mm内,随着粒径增大碳转化率逐渐升高,气体产率也有大幅度提高,液体产率随着粒径增大而降低;这是因为当粒径增大时,使二次反应得到强化,褐煤热解逸出的挥发分在颗粒内部的停留时间延长,在一定程度上促进了挥发分的二次裂解和缩聚反应[16]。同时,粒径增大使褐煤中水分的脱出时间延迟,有利于原位水蒸气同半焦及挥发分发生反应。当粒径继续增大时,碳转化率和气体产率开始逐渐下降,这是因为大粒径阻碍了颗粒的传热和挥发分的析出,导致煤颗粒热解不充分。

随着粒径的增加,H2和CO的产率逐渐增大,其中H2产率由393.35 mL/g增大至614.86 mL/g,CO的产率由225.09 mL/g增大至337.45 mL/g。这是因为当粒径增大时,褐煤中水分和挥发分的停留时间变长,更多的水蒸气参与了半焦的气化反应以及挥发分的重整反应,生成了H2和CO。此外,CO2,CH4和C2烃类的产率则随着粒径的增大先升高而降低。随着热解温度的增加,气体热逐渐降低,为11.58~12.29 MJ/m3。

总体而言,粒径对热解过程的影响表现为粒径对传热传质过程和挥发分二次反应的影响2个方面。增大粒径使煤粉颗粒热传导速率降低,导致热解反应不充分。此外,提高粒径使挥发分在褐煤颗粒孔隙结构中的传质阻力增大,停留时间延长,造成二次反应加强。此外,实验验证得出褐煤直接热解的最佳粒径范围为1.6~3.2 mm,而当粒径大于3.2 mm时,气体产率逐渐下降。

图4 1 000 ℃条件下不同粒径褐煤的热解产物产率

Fig. 4 Effect of particle size on yield of lignite pyrolysis products at 1 000 ℃

表5 1 000 ℃条件下粒径对褐煤热解产气特性的影响

Table 5 Effect of particle size on gas characteristic of lignite pyrolysis at 1 000 ℃

3 结论

1) 不经预干燥的褐煤直接热解可有效提高产气率;随着含水率的提高,褐煤的原位水蒸气气化反应加强,H2产率增大,气体中H2的产率由277.13 mL/g增大至527.77 mL/g,CO的产率变化不大,V(H2)/V(CO)由1.63增大至1.86,气体热值逐渐减小,其范围为12.42~14.87 MJ/m3。

2) 提高热解温度强化了褐煤的直接热解反应,气体产率的增加主要来自挥发分的二次裂解、挥发分的水蒸气重整以及半焦水蒸气气化反应,气体产率逐渐增大,液体和固体产率逐渐降低,气体中H2产率逐渐增大;碳转化率也随着温度提高逐渐增大,本实验的最大碳转化率为52.74%。

3) 随着粒径的增加,半焦的水蒸气气化反应以及挥发分的裂解反应逐渐加强,气体产率逐渐增大,液体和固体产率逐渐降低,气体中H2产率逐渐增大,提高粒径使挥发分在褐煤颗粒孔隙中的传质阻力增大,二次反应加强,但过大的粒径容易导致热解不充分,通过实验验证褐煤直接热解的最佳粒径范围为1.6~3.2 mm。

参考文献:

[1] LI Hexing, XU Qunjie, ZHANG Daquan. Development status of lignite quality improvement technology [J]. Advanced Materials Research, 2011, 356(10): 1205-1210.

[2] 王占宽, 李俊忠. 600 MW机组高水分褐煤燃烧技术分析[J]. 华北电力技术, 2008 (3): 16-18.

WANG Zhankuan, LI Junzhong. Analysis of high content lignite combustion technology in 600 MW unit[J]. North China Electric Power, 2008(3): 16-18.

[3] HOU Ao, WANG Ze, SONG Weili, et al. Thermogravimetric analysis on gasification reactivity of Hailar lignite[J]. Journal of Thermal Analysis and Calorimetry, 2012, 109(1): 337-343.

[4] 赵虹, 郭飞, 杨建国. 印尼褐煤的吸附特性及脱水研究[J]. 煤炭学报, 2008, 33(7): 799-802.

ZHAO Hong, GUO Fei, YANG Jianguo. Adsorption characteristic of Indonesia lignite and dewater experiment[J]. Journal of Coal Science and Engineering, 2008, 33(7): 799-802.

[5] LIU Shuqin, WANG Yuan, ZHAO Ke, et al. Enhanced-hydrogen gas production through underground gasification of lignite[J]. Mining Science and Technology (China), 2009, 19(3): 389-394.

[6] ROBERT M, GAUTHAM K, OYEBOLA D, et al. Hydrogen rich syngas production from oxy-steam gasification of a lignite coal: a design and optimization study[J]. Applied Thermal Engineering, 2015, 90(5): 13-22.

[7] YIP K, WU H, ZHANG D. Effect of inherent moisture in collie coal during pyrolysis due to in-situ steam gasification[J]. Energy & Fuels, 2007, 21(5): 2883-2891.

[8] 熊思江, 章北平, 冯振鹏, 等. 湿污泥热解制取富氢燃气影响因素研究[J]. 环境科学学报, 2010, 30(5): 996-1001.

XIONG Sijiang, ZHANG Beiping, FENG Zhenpeng, et al. The effect of experimental condition on wet sludge pyrolysis for hydrogen-rich fuel gas[J]. Acta Scientiae Circumstantiae, 2010, 30(5): 996-1001.

[9] 朱跃钊, 高豪杰, 陈海军, 等. 一种褐煤直接干燥-热解一体化工艺和系统: CN103074093B[P]. 2014-07-02.

ZHU Yuezhao, GAO Haojie, CHEN Haijun, et al. A self-proposed integrated process and system for direct drying and pyrolysis of lignite: CN103074093B[P]. 2014-07-02.

[10] 孙丽娜, 高豪杰, 陈海军, 等. 利用热分析研究褐煤的热解特性[J]. 林产化学与工业, 2014, 34(1): 117-120.

SUN Lina, GAO Haojie, CHEN Haijun, et al. Pyrolysis characteristics of hailar lignite by thermal analysis technique[J]. Chemistry and Industry of Forest Products, 2014, 34(1): 117-120.

[11] 李琳娜, 应浩, 涂军令, 等. 木屑高温水蒸气气化制备富氢燃气的特性研究[J]. 林产化学与工业, 2011, 31(5): 18-24.

LI Linna, YING Hao, TU Junling, et al. High-temperature steam gasification of sawdust for production of hydrogen-rich gas[J]. Chemistry and Industry of Forest Products, 2011, 31(5): 18-24.

[12] PENG Lixin, WANG Yong, LEI Zhihong, et al. Co-gasification of wet sewage sludge and forestry waste in situ steam agent[J]. Bioresource Technology, 2012, 114(2): 698-702.

[13] 梁杰, 冯银辉, 张彦春, 等. 褐煤地下气化制氢工艺的研究[J]. 化工学报, 2004, 55(S1): 39-43.

LIANG Jie, FENG Yinhui, ZHANG Yanchun, et al. Technology for production hydrogen through underground brown coal gasification[J]. Journal of Chemical Industry and Engineering, 2004, 55(S1): 39-43.

[14] 赵淑蘅, 蒋剑春, 孙云娟, 等. 褐煤与稻壳加水共热解特性研究[J]. 煤炭转化, 2012, 35(1): 9-12.

ZHAO Shuheng, JIANG Jianchun, SUN Yunjuan, et al. Study on the co-pyrolysis of lignite and rice husk with adding H2O[J]. Coal Conversion, 2012, 35(1): 9-12.

[15] YANG Guolai, CHEN Hanping, MI Tie, et al. Influence of different procedure parameters on the characteristics of producer gas from biomass gasification[J]. Renewable Energy Resources, 2007, 25(3): 34-38.

[16] VIMAL R P, DARSHIT S U, RAJESH N P. Gasification of lignite in a fixed bed reactor: Influence of particle size on performance of downdraft gasifier[J]. Energy, 2014, 78(15): 323-332.

(编辑 刘锦伟)

收稿日期:2015-06-06;修回日期:2015-08-15

基金项目(Foundation item):“十二五”国家科技支撑计划项目(2014BAJ01B00);江苏省工业支撑计划(BE2013127);江苏省环保厅重点课题(2013028);江苏省普通高校研究生科研创新计划项目(CXZZ13_0431)(Project(2014BAJ01B00) supported by the National Science and Technology Pillar Program during the 12th “Five-year” Plan Period; Project(BE2013127) supported by the Support Programmes on the Industry of Jiangsu Province; Project(2013028) supported by the Jiangsu Provincial Environmental Protection Department; Project(CXZZ13_0431) supported by the Programmes for Graduate Research and Innovation of Colleges and Universities in Jiangsu Province)

通信作者:朱跃钊,博士,教授,从事生物质热化学转化研究;E-mail:zyz@nitech.edu.cn