文章编号:1004-0609(2007)11-1773-06

电场退火对工业纯锌板再结晶织构的影响

杜广煜,赵 骧,何长树,左 良

(东北大学 材料各向异性与织构教育部重点实验室,沈阳 110004)

摘 要:利用X射线衍射的三维取向分布函数,研究工业纯锌板在160 ℃时电场与非电场退火保温不同时间条件下的再结晶织构的形成与演变,同时进行显微硬度测试。结果表明:电场退火推迟轧制工业纯锌板再结晶进程,从而导致电场退火样品的显微硬度值均高于非电场退火样品的显微硬度值。电场显著提高退火后样品的再结晶织构强度,即电场明显促进冷轧{ 018}面织构向再结晶{

018}面织构向再结晶{ 013}<10

013}<10 1>板织构的演变,而且这种影响在再结晶晶粒的长大阶段表现得尤为突出。电场并没有改变工业纯锌板退火过程中再结晶织构的形成机制。

1>板织构的演变,而且这种影响在再结晶晶粒的长大阶段表现得尤为突出。电场并没有改变工业纯锌板退火过程中再结晶织构的形成机制。

关键词:工业纯锌板;电场退火;再结晶织构;取向分布函数;硬度

中图分类号:TG 115.22 文献标识码:A

Effects of electric field annealing on recrystallization textures of pure zinc sheet

DU Guang-yu, ZHAO Xiang, HE Chang-shu, ZUO Liang

(Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education, Northeastern University, Shenyang 110004, China)

Abstract: The effects of electric field on recrystallization texture evolution and microhardness in a pure zinc sheet during annealing at 160 ℃ for different times were studied by means of X-ray diffraction techniques. The microhardness was measured. The results show that the electric field retards the recrystallization process and decreases the microhardness of pure zinc sheet during annealing. The electric field annealing does not change the evolution mechanism of recrystallization texture in the pure zinc sheet, but strengthens the intensity of recrystallization texture,i.e. electric field annealing improves the evolution from cold rolled { 018} texture component to recrystallization {

018} texture component to recrystallization { 013}<10

013}<10 1> texture component, especially at the stage of grain growth.

1> texture component, especially at the stage of grain growth.

Key words: pure zinc sheet; electric field annealing; recrystallization texture; ODF; hardness

研究发现电场对于金属材料的相变和再结晶过程都会产生不同程度影响[1?3],其原因在于电场使金属材料的微观组织发生了变化。在这些研究中,虽然电场对于金属板材再结晶织构的形成和演变的研究起步较晚,但也取得不少成果。王轶农 等[4?5]的研究结果表明:电场退火提高了铜的再结晶织构强度。王轶农等[6]对IF深冲钢板进行电场退火的实验结果表明:电场退火提高了IF深冲钢板再结晶γ纤维织构的强度,降低了再结晶α纤维织构的强度。胡卓超等[7?10]在08Al深冲钢板的电场退火过程中也发现与电场退火IF深冲钢板类似的结果。赵骧等[11?12]还比较了电场与非电场退火IF深冲钢板的塑性应变比,得出了电场退火能够提高IF深冲钢板的塑性应变比的结果。蒋奇武等[13]对高纯铝板电场退火后的再结晶织构进行了研究,发现电场退火能够拓宽再结晶立方织构的形成温度范围。胡卓超等[14?16]还研究了电场对3104铝合金板的再结晶织构的影响,观察到电场退火3104铝合金板中的再结晶立方织构强度高于非电场退火样品的再结晶立方织构的强度,电场退火可促进Al-Mn-Mg合金板再结晶立方织构的形成和发展。

但是到目前为止,有关电场退火对于具有密排六方晶体结构金属板材再结晶织构影响的研究尚未见报道。因此,本文作者利用X射线衍射的ODF分析,探讨了在退火过程中电场对冷轧工业纯锌板再结晶织构和硬度的影响。

1 实验

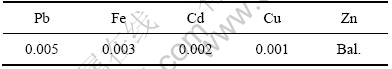

实验采用原始厚度为7.94 mm的工业纯锌板,材料的化学成分列于表1。

表1 实验用工业纯锌板化学成分

Table 1 Chemical composition of pure zinc sheet used in experiment (mass fraction, %)

将原始板材进行80%轧制变形后获得厚度为1.6 mm的冷轧锌板,然后对冷轧锌板样品进行如图1所示的电场与非电场退火处理。首先将炉温升至160 ℃,待温度稳定后放入样品,分别保温1、3、5、10、15、30 min进行电场与非电场退火,然后将样品放入水中冷却,电场退火时的电场强度为4 kV/cm。

图1 退火工艺示意图

Fig.1 Schematic illustration of annealing processing

将电场与非电场退火样品表面机械抛光后,采用401MVDTM数码显示显微维氏硬度计测试其显微硬度(HV),采用面夹角为136?载荷为0.5 N的正四方角锥金刚石压头加载后保持10 s,直接从硬度计的显示屏上读出显微硬度值。为确保实验结果的准确,每个样品测10个值,然后取其平均值。

在冷轧和电场与非电场退火样品上分别切取20 mm×20 mm正方形进行织构测试。测定时采用Co Kα靶辐射,管电压为35 kV,管电流为40 mA,采用背反射法测量5张不完整极图。扫测按同心圆步方式进行,α由20?~90?,β由0?~360?,测量步长为5?。并由X’Pert Texture 软件计算其ODF。

2 实验结果

2.1 显微硬度

图2所示为冷轧变形量为80%的轧制工业纯锌板,在160 ℃下保温不同时间电场与非电场退火样品的显微硬度。由图可以看出,随着保温时间的延长,无论是电场退火还是非电场退火的样品其显微硬度值均降低,但非电场退火样品的硬度下降趋势比较明显,而电场退火样品的下降趋势则相对比较平缓,在保温时间延长到15 min之后硬度值下降的趋势明显减弱。同时在对应的每个相同的保温时间上,电场退火样品的显微硬度值均要高于非电场退火样品的显微硬度值。

图2 160 ℃时电场与非电场退火工业纯锌板的显微硬度与退火时间的关系

Fig.2 Variations of microhardness(HV) of samples with annealing time annealed at 160 ℃ with and without electric field (deformed 80%)

2.2 工业纯锌板的织构

2.2.1 工业纯锌板的冷轧织构

通过对恒ψ=0?~90?的ODF截面图的分析可以看出,工业纯锌板冷轧和再结晶织构的主织构均集中在ψ=0?的ODF截面图之中,因此,采用具有代表性的ψ=0?的ODF截面图描述全体织构。

图3所示为冷轧压下量为80%工业纯锌样品的 ψ=0?的ODF截面图。由图可以看出冷轧样品的主要织构组分为{ 018}面织构和{

018}面织构和{ 013}<10

013}<10 1>板织构,而且两种织构的强度几乎相等。

1>板织构,而且两种织构的强度几乎相等。

图3 冷轧压下量80%工业纯锌板的ODF图(ψ=0?)

Fig.3 ODF section of pure zinc sheet with 80% cold rolled reduction (ψ=0?)

2.2.2 电场与非电场退火工业纯锌板的再结晶织构

图4和图5所示为冷轧样品在160 ℃保温不同时间经过电场与非电场退火后的再结晶织构的ODF图(ψ=0?)。由图可以看出,所有退火样品的再结晶织构均为{ 013}面织构,即织构的轧面为{

013}面织构,即织构的轧面为{ 018}晶面,轧向则主要集中在<10

018}晶面,轧向则主要集中在<10 1>和<1

1>和<1 01>晶向,即{

01>晶向,即{ 013}<10

013}<10 1>织构组分和<

1>织构组分和< 013><

013>< 101>织构组分的强度最高,二者强度相等,而{

101>织构组分的强度最高,二者强度相等,而{ 018}面织构则完全消失。

018}面织构则完全消失。

图4 160 ℃保温不同时间非电场退火样品的ODF图(ψ=0?)

Fig.4 ODF sections of samples annealed at 160 ℃ for different times without electric field (ψ=0?): (a) t=1 min; (b) t=3 min; (c) t=5 min; (d) t=10 min; (e) t=15 min; (f) t=30 min

图5 160 ℃保温不同时间电场退火样品的ODF图(ψ=0?)

Fig.5 ODF sections of samples annealed at 160 ℃ for different times with electric field (ψ=0?): (a) t=1 min; (b) t=3 min; (c) t= 5 min; (d) t=10 min; (e) t=15 min; (f) t=30 min

图6所示为电场与非电场退火样品的主要织构组分{ 013}<10

013}<10 1>织构随保温时间的变化。结合ODF截面图(图4,5)可以看出:随着退火时间的延长,电场与非电场退火样品的{

1>织构随保温时间的变化。结合ODF截面图(图4,5)可以看出:随着退火时间的延长,电场与非电场退火样品的{ 013}<10

013}<10 1>织构的强度的变化趋势是随着退火温度的降低而降低。但是无论退火时间的长短,电场退火样品的{

1>织构的强度的变化趋势是随着退火温度的降低而降低。但是无论退火时间的长短,电场退火样品的{ 013}<10

013}<10 1>织构的强度始终高于非电场退火样品的{

1>织构的强度始终高于非电场退火样品的{ 013}<10

013}<10 1>织构的强度。当退火时间为1 min和30 min时,电场退火样品的{

1>织构的强度。当退火时间为1 min和30 min时,电场退火样品的{ 013}<10

013}<10 1>织构强度与非电场退火样品的强度相近。退火时间为3、5、10和15 min时电场退火样品的{

1>织构强度与非电场退火样品的强度相近。退火时间为3、5、10和15 min时电场退火样品的{ 013}<10

013}<10 1> ({

1> ({ 013}<101>)织构的强度明显高于非电场退火样品的{

013}<101>)织构的强度明显高于非电场退火样品的{ 013}<10

013}<10 1> ({

1> ({ 013}<1

013}<1 01>)织构的强度。

01>)织构的强度。

图6 电场和非电场退火样品{ 013}<10

013}<10 1>织构组分的强度随时间的变化

1>织构组分的强度随时间的变化

Fig.6 Variations of {10 3}<10

3}<10 1> texture intensities with annealing time in specimens annealed with and without electric field

1> texture intensities with annealing time in specimens annealed with and without electric field

3 分析与讨论

3.1 电场对工业纯锌板显微硬度的影响

比较电场与非电场退火后样品的显微硬度,结果表明:随着保温时间的延长,电场与非电场退火样品的显微硬度值均降低,其中非电场退火样品的硬度下降趋势比电场退火样品明显,即电场退火样品的硬度均高于非电场退火样品的硬度。这表明电场退火能够推迟轧制工业纯锌板再结晶进程。

根据金属的电子理论,空位具有负电性,各种晶格缺陷,特别是位错及位错缠结区和晶界等相当于空位密集区。在电场的作用下,由于实验中样品作为正极,所以在样品表面富集感应正电荷。由于空位带负电荷,样品表面处的空位被正电荷吸引并相互抵消,导致样品表面空位浓度降低,形成一个浓度梯度,促进样品内部的空位持续向表面空位浓度低的区域扩散空位的加速扩散导致金属内部特别是位错和晶界空位密集区的空位贫化,从而降低了样品中空位的密度,进而降低了晶格缺陷能,降低了再结晶驱动力。因此电场退火推迟了轧制工业纯锌板再结晶进程,由此导致电场退火样品的显微硬度值均要高于非电场退火样品的显微硬度值。

3.2 电场对工业纯锌板再结晶织构的影响

冷轧前工业纯锌板的织构是接近{0001}晶面(大约偏离7?)的{ 018}晶面的面织构。经过80%压下量的冷轧之后,工业纯锌板的主要织构组分转变成为强度几乎相等的两种类型的冷轧织构,即{

018}晶面的面织构。经过80%压下量的冷轧之后,工业纯锌板的主要织构组分转变成为强度几乎相等的两种类型的冷轧织构,即{ 018}面织构和{

018}面织构和{ 013}<10

013}<10 1> ({

1> ({ 013}<1

013}<1 01>)板织构。再经过160 ℃保温不同时间的电场与非电场退火之后,形成了以{

01>)板织构。再经过160 ℃保温不同时间的电场与非电场退火之后,形成了以{ 013}<10

013}<10 1> ({

1> ({ 013}<1

013}<1 01>)板织构为主织构的{

01>)板织构为主织构的{ 013}面织构,而{

013}面织构,而{ 018}面织构完全消失。在再结晶织构形成的过程中,{

018}面织构完全消失。在再结晶织构形成的过程中,{ 018}面织构逐渐被吞噬,与此同时{

018}面织构逐渐被吞噬,与此同时{ 013}面织构逐渐增强,再结晶织构主要集中在{

013}面织构逐渐增强,再结晶织构主要集中在{ 013}<10

013}<10 1>和{

1>和{ 013}<1

013}<1 01>板织构的位置,它们来自于强度相当的冷轧{

01>板织构的位置,它们来自于强度相当的冷轧{ 018}面织构和{

018}面织构和{ 013}<10

013}<10 1>与{

1>与{ 013}<1

013}<1 01>板织构的转变。而在再结晶织构演变的过程中,电场退火样品的再结晶织构的强度始终高于非电场退火样品的再结晶织构的强度,即电场提高了退火样品再结晶织构的强度,而且再结晶织构强度提高程度与退火时间密切相关,退火时间较短(1 min)和较长(30 min)时,电场退火样品的再结晶织构的强度提高幅度不大,当退火时间为3、5、10、15 min时,电场退火样品的再结晶织构强度显著提高。

01>板织构的转变。而在再结晶织构演变的过程中,电场退火样品的再结晶织构的强度始终高于非电场退火样品的再结晶织构的强度,即电场提高了退火样品再结晶织构的强度,而且再结晶织构强度提高程度与退火时间密切相关,退火时间较短(1 min)和较长(30 min)时,电场退火样品的再结晶织构的强度提高幅度不大,当退火时间为3、5、10、15 min时,电场退火样品的再结晶织构强度显著提高。

当退火时间为1 min时,时间较短,此时回复已经完成且再结晶晶核已经形成,同时还有一部分已经形核的再结晶晶粒开始长大,即再结晶刚刚开始不久。在这一阶段,由于回复和再结晶晶核的形成已经完成,所以冷轧织构{ 018}面织构完全消失,只有再结晶织构{

018}面织构完全消失,只有再结晶织构{ 013}<10

013}<10 1>与{

1>与{ 013}<1

013}<1 01>板织构存在。在此阶段,电场退火样品的再结晶织构的强度,略高于非电场退火样品的再结晶织构的强度。这是由于再结晶刚刚开始的原因所致,因为此时电场对再结晶织构的影响刚刚开始,其效果还不十分明显。随着退火时间的延长,再结晶晶粒继续长大,电场退火对于再结晶织构的影响不断增加,电场退火样品的再结晶织构{

01>板织构存在。在此阶段,电场退火样品的再结晶织构的强度,略高于非电场退火样品的再结晶织构的强度。这是由于再结晶刚刚开始的原因所致,因为此时电场对再结晶织构的影响刚刚开始,其效果还不十分明显。随着退火时间的延长,再结晶晶粒继续长大,电场退火对于再结晶织构的影响不断增加,电场退火样品的再结晶织构{ 013}<10

013}<10 1> ({

1> ({ 013}<1

013}<1 01>)的强度与非电场退火样品的再结晶织构{

01>)的强度与非电场退火样品的再结晶织构{ 013}<10

013}<10 1> (

1> ( 013<1

013<1 01>)的强度之间的差别逐渐加大,在退火时间为5 min时二者之间的差别达到最大。随着退火时间的进一步延长,电场与非电场退火样品的再结晶织构{

01>)的强度之间的差别逐渐加大,在退火时间为5 min时二者之间的差别达到最大。随着退火时间的进一步延长,电场与非电场退火样品的再结晶织构{ 013}<10

013}<10 1> (

1> ( 013<1

013<1 01>)的强度的差别开始逐渐缩小,退火时间为30 min时二者之间的差别又达到最小,基本上与电场与非电场退火1 min时样品的再结晶织构的强度的差别相当。此时,再结晶晶粒的长大已经基本结束,再结晶即将完成[1]。

01>)的强度的差别开始逐渐缩小,退火时间为30 min时二者之间的差别又达到最小,基本上与电场与非电场退火1 min时样品的再结晶织构的强度的差别相当。此时,再结晶晶粒的长大已经基本结束,再结晶即将完成[1]。

从电场与非电场退火样品的再结晶主织构{ 013}<10

013}<10 1> (

1> ( 013<1

013<1 01>)的强度的差别随退火时间的变化可以看出,电场对于工业纯锌板再结晶织构的影响主要体现在再结晶晶粒的长大阶段,而对于纯锌板的回复和再结晶初始阶段的影响不大。关于这种现象的机理还有待于进一步的研究。

01>)的强度的差别随退火时间的变化可以看出,电场对于工业纯锌板再结晶织构的影响主要体现在再结晶晶粒的长大阶段,而对于纯锌板的回复和再结晶初始阶段的影响不大。关于这种现象的机理还有待于进一步的研究。

另外,通过对比冷轧工业纯锌板的电场与非电场退火样品的再结晶主织构的类型与强度可以看出:虽然电场与非电场退火样品的再结晶主织构的强度差别明显,但是电场与非电场退火样品的再结晶主织构的类型完全相同,而且电场与非电场退火样品的再结晶主织构随保温时间的变化趋势基本相同。由此说明电场退火并未改变工业纯锌板再结晶织构的形成机制。

4 结论

1)电场退火样品的显微硬度大于非电场退火的样品的显微硬度,其原因在于电场退火推迟了冷轧工业纯锌板再结晶进程。

2)电场明显促进了冷轧压下量为80%工业纯锌板的冷轧{ 018}面织构向再结晶{

018}面织构向再结晶{ 013}<10

013}<10 1>板织构的演变,而且这种影响在再结晶晶粒的长大阶段表现得尤为突出,在回复和再结晶初始阶段影响甚微。

1>板织构的演变,而且这种影响在再结晶晶粒的长大阶段表现得尤为突出,在回复和再结晶初始阶段影响甚微。

3)电场退火并没有改变工业纯锌板退火过程中再结晶织构的形成机制。

REFERENCES

[1] Misra A K. A novel solidification technique of metals and alloys: Under the influence of applied potential[J]. Metall Trans A, 1985, 16: 1354?1355.

[2] Sprecher A F, Mannan S L, Conrad H. On the temperature rise associated with the electroplastic effect in titanium[J]. Scripta Metallurgica, 1983, 17(6): 769?772.

[3] Liu W, Liang K M, Zheng Y K. Effect of an electric field during solution treatment of 2091 Al-Li alloy[J]. Journal of Materials Science Letters, 1996, 15: 1327?1329.

[4] 王轶农, 何长树, 赵 骧, 左 良, 支起争, 梁志德. 电场退火对冷轧工业纯铜再结晶及织构的影响[J]. 金属学报, 2000, 36(2): 126?130.

WANG Yi-nong, He Chang-shu, Zhao Xiang, ZUO Liang, ZHI Qi-zheng, LIANG Zhi-de. Effect of electric field annealing on recrystallization and recrystallization texture of a cold-rolled copper[J]. Acta Metallurgica Sinica, 2000, 36(2): 126?130.

[5] He C S, Zhang Y D, Wang Y N, Zhao X, Zuo L, Esling C. Texture and microstructure development incold-rolled interstitial free (IF) steel sheet during electricfield annealing[J]. Scripta Materialia, 2003, 48: 737?742.

[6] 王轶农, 何长树, 蒋奇武, 王 刚, 赵 骧, 左 良. 电场退火(Ti+Nb)IF深冲钢板再结晶及织构的研究[J]. 钢铁, 2001, 36(7): 42?44.

WANG Yi-nong, HE Chang-shu, JIANG Qi-wu, WANG Gang, ZHAO Xiang, ZUO Liang. Research on recrystallization and texture of interstitial free (IF) steel under annealed with electric field[J]. Iron and Steel, 2001, 36(7): 42?44.

[7] Hu Z C, He C S, Zhao X, Zuo L. Effects of external electric field on recrystallization texture and microstructure of 08Al killed steel sheet[J]. Journal of Materials Science, 2004, 39: 4231?4234.

[8] 胡卓超, 赵 骧, 左 良. 电场对08Al深冲钢板再结晶织构的影响[J]. 金属学报, 2003, 39(2): 213?216.

HU Zhuo-chao, ZHAO Xiang, ZUO Liang. Effects of external electric field on recrystallization texture of 08Al killed steel sheets[J]. Acta Metallurgica Sinica, 2003, 39(2): 213?216.

[9] 胡卓超, 赵 骧, 左 良. 电场对08Al深冲钢板退火织构的影响[J]. 钢铁研究学报, 2004,16(1): 57?61.

HU Zhuo-chao, ZHAO Xiang, ZUO Liang. Effects of electric field on annealing texture of 08Al killed steel sheets[J]. Journal of Iron and Steel Research, 2004, 16(1): 57?61.

[10] Zhao X, Hu Z C, Zuo L. Effects of external electric field on AlN precipitation and recrystallization Texture of deep-drawing 08Al killed steel sheet[J]. Mater Sci Technol, 2006, 22(6): 747?750.

[11] 赵 骧, 何长树, 徐 俊, 左 良. 电场退火对IF深冲钢板塑性应变比(r值)的影响[J]. 金属学报, 2006, 42(8): 827?829.

ZHAO Xiang, HE Chang-shu, XU Jian-zhen, ZUO Liang. Effects of electric field annealing on plastic stress ratio (r value) of IF deep drawing steel sheet[J]. Acta Metallurgica Sinica, 2006, 42(8): 827?829.

[12] Zhao X, He C S, Xu J, Zuo L. Effects of electric field annealing on recrystallization texture and plastic strain ratio (r value) of IF steel sheet[J]. Mater Sci Froum, 2007, 539/543: 3478?3483.

[13] 蒋奇武, 王存胜, 王 福, 左 良, 王治国. 电场作用下高纯铝箔再结晶织构的研究[J]. 中国有色金属学报, 2001, 11(4): 598?601.

JIANG Qi-wu, WANG Cun-sheng, WANG Fu, ZUO Liang, WANG Zhi-guo. Research about recrystallization texture of the high purity aluminum foil under electric field[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 598?601.

[14] 胡卓超, 刘沿东, 赵 骧, 左 良, Esling C. 电场对Al-Mn-Mg合金的微结构和织构形成的影响[J]. 材料研究学报, 2004, 18(5): 477?484.

HU Zhuo-chao, LIU Yan-dong, ZHAO Xiang, ZUO Liang, Esling C. Microstructure and textures variation of Al-Mn-Mg alloy sheets under external electric field[J]. Chinese Journal of Materials Research, 2004, 18(5): 477?484.

[15] Hu Z C, Zhang Y D, Zhao X, Zuo L, WANG F, Esling C. Electric field annealing on 3104 aluminim alloy sheets: Evolution of microstructure and texture[J]. Solid State Phenomena, 2005, 105: 169?174.

[16] 胡卓超, 赵 骧, 左 良, 王 福, Esling C. 电场退火对3104铝合金板显微组织与再结晶织构的影响[J]. 中国有色金属学报, 2004, 14(8): 1366?1371.

HU Zhuo-chao, ZHAO Xiang, ZUO Liang, WANG Fu, Esling C. Effects of electric field annealing on microstructure and recrystallization texture of 3104 aluminum alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1366?1371.

基金项目:国家自然科学基金与上海宝山钢铁集团资助项目(50374028);博士点基金资助项目(20050145030)

收稿日期:2007-06-25;修订日期:2007-09-12

通讯作者:赵 骧,教授,博士生导师;电话:024-83681723;E-mail: zhaox@mail.neu.edu.cn

(编辑 袁赛前)