DOI:10.11817/j.ysxb.1004.0609.2020-39449

含镉烟灰在酸性介质中的浸出行为及过程优化

张文娟,马保中,王成彦

(北京科技大学 冶金与生态工程学院,北京 100083)

摘 要:对含镉烟灰的物相组成进行了系统分析,并提出针对性的工艺流程。针对硫酸浸出含镉烟灰的过程,采用响应曲面设计方法对操作条件进行了优化,考察了反应温度、液固比、硫酸浓度及其交互作用对Cd、As、Zn浸出率的影响关系,构建了二阶数学模型和三维响应曲面图,确定了Cd、Zn、As的浸出率分别大于92%、95%和50%的优化浸出条件区域,即反应温度25~60 ℃,液固比6~8 mL/g,硫酸浓度0.3~0.4 mol/L。结果表明:该模型能够准确预测含镉烟灰在硫酸中的浸出效果;在最优区域内,As的浸出率较低,其主要原因是原料中的砷酸锌在低酸条件未分解。

关键词:含镉烟灰;响应曲面法;中心复合设计;酸性浸出

文章编号:1004-0609(2020)-01-0162-10 中图分类号:TF09 文献标志码:A

铅冶炼过程中产生的高温烟气经净化系统后产出铅冶炼烟尘。Cd、As等元素作为铅锌矿和铜铅锌矿中的常见伴生元素,在火法炼铅过程中大部分挥发并富集于冶炼烟尘中[1]。其化学组成复杂,常含有Pb、Zn、In、Bi、As、Cd等多种有价金属[2-3]。Cd、As属于剧毒和致癌元素,其对环境的污染不可逆转[4-5],是国家三废排放标准中严格控制的有害物质。但同时,Cd还是一种重要的稀散金属,是制造合金和Ni-Cd电池的重要原材料[6-7]。因此,对铅烟尘(含镉烟灰)进行资源化和无害化处置,具有重大的经济效益和环境意义。

目前,国内外铅烟尘的处置与利用工艺并不完善。国内多数铅冶炼企业将烟尘返回与原料混合后继续熔炼,使得Cd在系统内不断循环和富集,烟尘中的Cd含量常高达20%以上,为保证冶炼系统的正常生产,需对其进行开路处理。为对烟尘进行综合利用,近年来开展了大量研究工作,其中较多的研究是根据烟尘中CdSO4易溶于水的特性,采用水浸分离Pb、Cd,再以中和沉淀或置换法回收氢氧化镉或海绵镉,由于缺少对原料中物相的清楚认知,浸出过程Cd的浸出率不到90%,Zn浸出率仅60%左右[8]。杨勰等[9]采取了极端的化学手段研究了铅烟尘的浸出性能:20 mL/g的超高液固比,Cd、As、Zn的浸出率分别达49.36%、98.95%和89.12%,但这种近乎分析化学手段的“为浸出而浸出”的做法完全不适用于工业应用。而现已进行工业应用的方法是将烟尘与硫酸造粒,在300 ℃下进行焙烧,使Cd转化为易溶的硫酸镉,与易挥发的As、氟和氯分离;经过浸出,96%的Cd进入溶液。但该工艺的缺点是操作环境差,且未对其他有价金属进行综合回收。除此之外,大量的研究集中于从铅烟尘中回收稀有金属In或者制备高纯金属[10-12]。

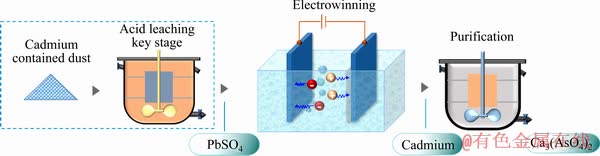

考虑到不同铅冶炼方法所产生烟气中颗粒物排放量不同,如铅冶炼颗粒物排放量一般为1.12~8.26 kg/t Pb,水口山炼铅法每吨粗铅颗粒物排放量为1.854 kg/t,ISP法改造后达3.82 kg/t,卡尔多炉颗粒物排放量在1 kg/t左右,因此,产生的烟尘的组成及金属含量也存在很大差异[13]。本研究以铅富氧熔炼过程产出的底吹炉烟灰为研究对象,对烟灰物相组成进行分析,并提出了如图1所示的工艺流程。该工艺采用硫酸溶液浸出含镉烟灰,浸出渣为含有少量杂质的硫酸铅,可作为炼铅原料返回铅冶炼系统;浸出液含有Cd、Zn、As等元素,通过电积制备海绵镉,电积后液返回浸出工序,待溶液中As浓度较高时则进行开路净化,通过添加石灰进行脱As。本文主要针对含镉烟灰在酸性介质中的浸出行为进行研究,并通过响应曲面法优化浸出过程。

图1 含镉烟灰综合回收的工艺流程图

Fig. 1 Flowsheet for metal recovery from cadmium contained dust

1 实验

1.1 原料

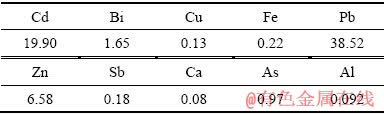

实验所用含镉烟灰由山东恒邦冶炼股份有限公司提供,其主要元素的化学分析结果如表1所示。可以看出,该烟灰中Cd含量高达19.90%,还含有少量的As,属于高毒性冶金副产物。原料的XRD分析结果如图2(a)所示,可以看出,含镉烟灰中元素Pb、Cd主要以硫酸盐形式存在,Zn、Bi则主要以氧化物形式存在。镉烟灰的SEM像(见图2(b))表明,烟灰的颗粒主要呈1 μm左右的球形,少数为不规则颗粒,整体粒度极细。

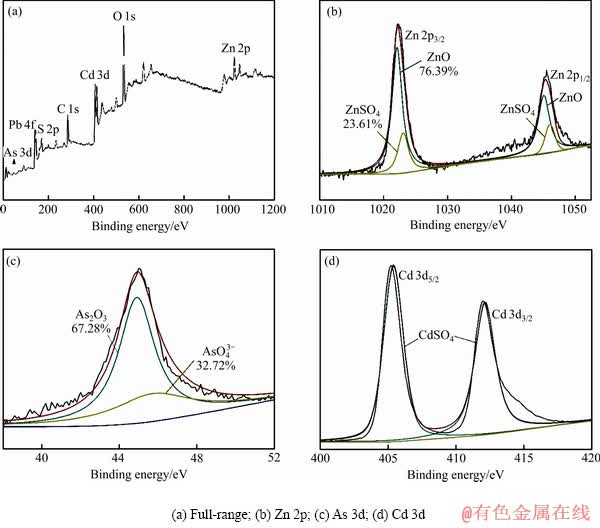

表1 含镉烟灰的主要化学成分

Table 1 Main chemical composition of Cd contained dust (mass fraction, %)

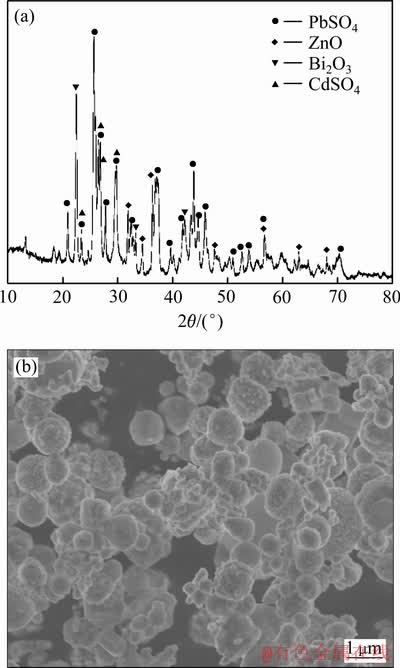

采用XPS对烟灰中的各元素的结合态进行分析,从图3的全谱中可以看出,样品具有明显的Zn 2p、As 3d、Cd 3d、Pb 4f和O 1s的谱线,与化学分析显示的元素组成一致。对Zn 2p的XPS谱图进行拟合,结果表明Zn是以ZnO和ZnSO4两种组成存在(见图3(b)),其中位于1022.1 eV的Zn 2p3/2为ZnO,位于1023.05 eV的Zn 2p3/2证明了原料中还存在少量的ZnSO4,根据峰面积可得到ZnO和ZnSO4的比例为76.39%和23.61%。As 3d的XPS谱图(见图3(c))表明As以2种化学态存在,其中位于44.9 eV的As 3d为As2O3,而位于45.7 eV的则为 ,根据峰面积可得As2O3和

,根据峰面积可得As2O3和 的比例为67.28%和32.72%。图3(d)表明,Cd仅以CdSO4状态存在。

的比例为67.28%和32.72%。图3(d)表明,Cd仅以CdSO4状态存在。

图2 含镉烟灰的XRD谱和SEM像

Fig. 2 XRD pattern(a) and SEM image(b) of Cd contained dust

1.2 实验设计

响应曲面法(Response surface methodology,RSM)是一种利用统计学原理进行实验设计的方法。根据既定设计方案进行实验,再采用计算机软件对所得数据进行处理,建立考察对象(响应值)与影响因素(自变量)在一定范围内的函数关系,从理论上确定未知条件或极端条件下的响应,以确定优化的反应条件或区域[14-15]。本研究中实验方案的设计选用最常用的拟合二阶模型的中心复合设计(Central composite design,CCD),可利用较少的实验点获得与全因素实验相近的结论,并揭示因素间的交互影响及相对显著性顺序;响应数据通过实验获得;响应值与自变量之间的函数关系以及响应曲面的绘制采用计算机软件处理实现[16]。本研究中以Design-Expert 10软件设计、分析功能为主,同时搭配Minitab

10软件设计、分析功能为主,同时搭配Minitab 15软件重叠预测功能,完成响应曲面法的实验设计、数据处理和图形绘制。

15软件重叠预测功能,完成响应曲面法的实验设计、数据处理和图形绘制。

图3 含镉烟灰的XPS谱图

图3 XPS spectra of Cd contained dust

1.3 实验方法

浸出实验恒温水浴锅中进行,称取一定量的镉烟灰,按实验要求加入到已达设定温度的浸出液中,待反应结束后过滤、洗涤,浸出渣于恒温干燥箱中进行干燥,采用化学分析确定渣中元素含量,并根据式(1)计算各元素的浸出率:

(1)

(1)

式中:m0、mr为浸出原料和浸出渣的质量;w0、wr为原料和浸出渣中金属元素的含量。

2 结果与讨论

2.1 CCD实验设计

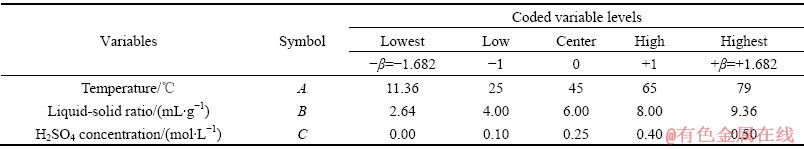

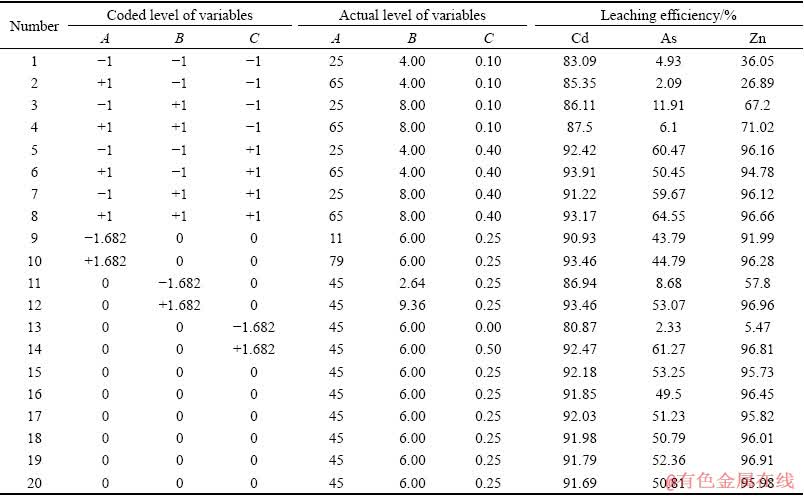

本研究以元素Cd、Zn和As的浸出率为响应值(YCd、YZn、YAs),采用CCD响应设计法对烟灰浸出过程的主要影响因素:温度、硫酸浓度和液固比进行实验设计和分析。实验因素水平设计安排列于表2,其中温度、液固比及H2SO4的设计范围分别为11.36~ 79 ℃、2.64~9.36 mL/g和0~0.50 mol/L。实验设计方案及实验结果见表3,所有实验中浸出时间均为4 h。

2.2 浸出过程的模型建立

表2 烟灰浸出过程CCD因素水平表

Table 2 Variables and levels in central composite design (CCD) for leaching of dust

表3 镉烟灰浸出过程CCD实验方案和实验结果

Table 3 Coded and actual levels of variables with experimental results for leaching of dust

对表3中所获得的实验数据采用Design-Expert 10软件进行统计分析,采用二阶模型进行模拟,可到到Cd、As、Zn浸出率(Y)与浸出温度(A)、液固比(B)、硫酸浓度(C)间之间关系的二阶回归方程,如式(2)、(3)和(4)所示:

10软件进行统计分析,采用二阶模型进行模拟,可到到Cd、As、Zn浸出率(Y)与浸出温度(A)、液固比(B)、硫酸浓度(C)间之间关系的二阶回归方程,如式(2)、(3)和(4)所示:

YCd=91.9347+0.8307A+1.0394B+3.5278C+0.0008A2-0.7045B2-1.9525C2-0.0512AB-0.0262AC-0.8887BC (2)

YAs=51.3938-0.8866A+7.2451B+22.6432C-2.9474A2-7.6903B2-7.3633C2+1.4912AB+0.4387AC+0.2887BC (3)

YZn=96.1428+0.0758A+10.4694B+24.6158C-0.6655A2-6.5893B2-15.8666C2+1.8625AB+0.5625AC-9.1800BC (4)

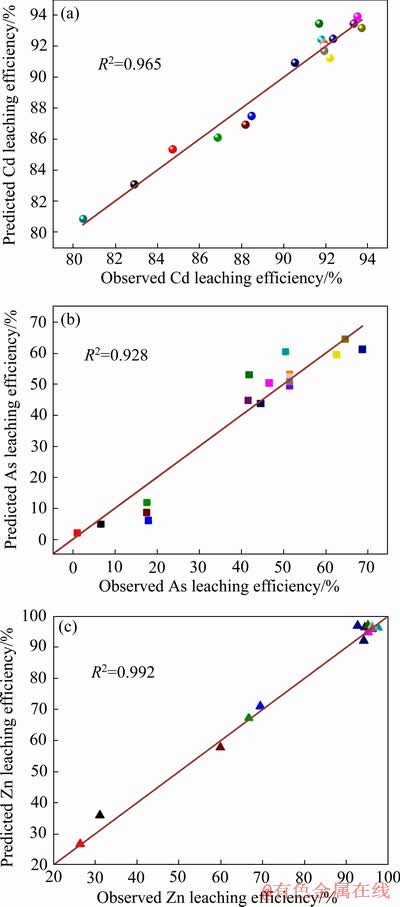

将CCD实验中浸出温度、液固比、硫酸浓度等因素条件的数值分别代入Cd、As、Zn浸出率为响应值的二阶回归方程,即可得到相应浸出实验条件下Cd、As、Zn的预测浸出率,对各金属浸出率的预测值与实验值进行线性拟合,结果如图4所示。

由图4可知,各金属转化率的预测值与实验值拟合所得直线斜率为45°左右,各数据点在直线两侧随机分布。Cd、As和Zn的预测浸出率与实验所得各金属浸出率间具有很好的直线关系,线性相关系数R2分别为0.965、0.928和0.992,表明该模型对实际情况有较好的拟合效果。

为更加直观的表示各因素之间的交互影响,根据式(2)、(3)和(4)所表示的二阶模型,应用Design-Expert 10软件分别绘制Cd、As、Zn浸出率与浸出温度、液固比、硫酸浓度的三维响应曲面图及对应的等值线图。结果如图5~7所示。等值线越密集,曲率越大,说明两因素之间的交互影响越明显。

10软件分别绘制Cd、As、Zn浸出率与浸出温度、液固比、硫酸浓度的三维响应曲面图及对应的等值线图。结果如图5~7所示。等值线越密集,曲率越大,说明两因素之间的交互影响越明显。

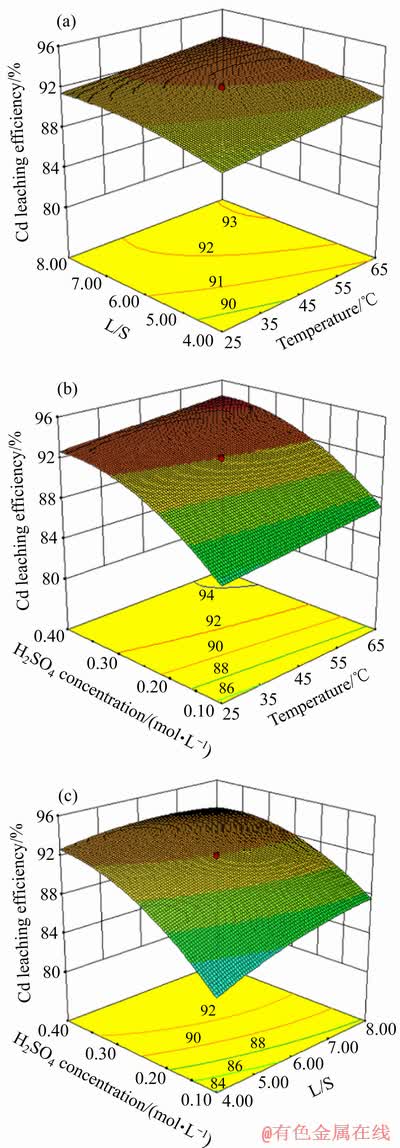

图5显示了所研究范围内3个因素之间任意两者对Cd浸出率的影响及两者间的交互影响,其中图5(a) 显示了硫酸浓度为中等水平0.25 mol/L时反应温度与液固比的影响及其交互影响;图5(b)显示了液固比为中等水平6.00时浸出温度与硫酸浓度的影响及其交互影响;图5(c)显示了浸出温度为中等水平45 ℃时液固比与硫酸浓度的影响及其交互影响。由图5(a)可知,随着反应温度的上升和液固比的增大,Cd的浸出率呈上升趋势,且等值线在两者均较高水平的区域表现出较大曲率,说明两者间的交互作用增强,图5(b)和(c)也表现出相似的变化趋势。综合可知,在设计区域内,高水平的反应温度、液固比、硫酸浓度均有助于Cd的浸出,三者间未表现出明显的影响显著性强弱关系,但高水平区域交互影响较低水平区域更强。

图4 实测浸出率与预测浸出率的关系

Fig. 4 Relationship between observed and predicted leaching efficiency

图5 Cd浸出效果响应曲面图

Fig. 5 Response surface plots of effects of variables on Cd leaching efficiency

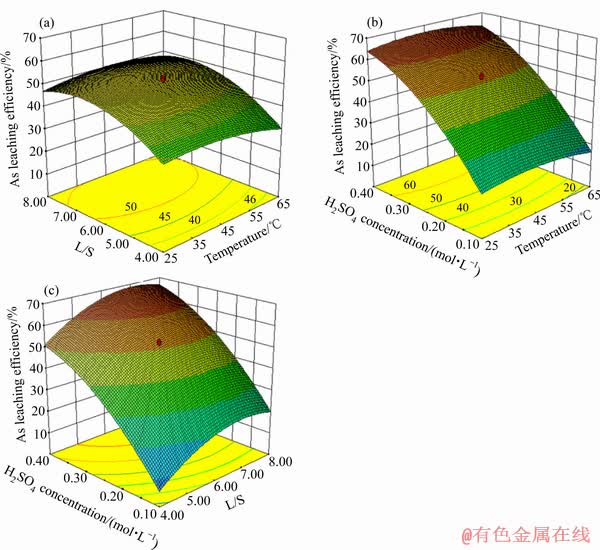

图6 As浸出效果响应曲面图

Fig. 6 Response surface plots of effects of variables on As leaching efficiency

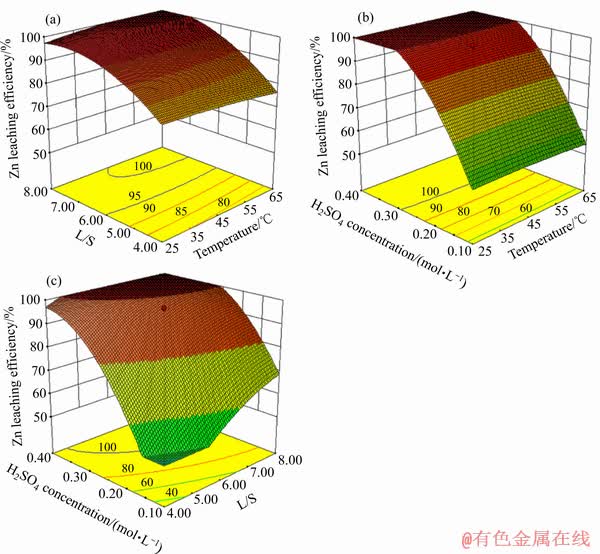

图7 Zn浸出效果响应曲面图

Fig. 7 Response surface plots of effects of variables on Zn leaching efficiency

图6显示了研究范围内三因素之间任意两者对As浸出率的影响及两者间的交互影响,其中图6(a)显示了硫酸浓度为中等水平0.25 mol/L时浸出温度与液固比的影响及两者交互影响;图6(b)显示了液固比为中等水平6.00时浸出温度与硫酸浓度的影响及AC交互影响;图6(c)显示了浸出温度为中等水平45 ℃时液固比与硫酸浓度的影响及两者交互影响。图6(a)和图6(c)所示响应曲面呈现较饱满的弧面,说明浸出温度与液固比之间、液固比与硫酸浓度之间存在显著的交互作用;图6(b)所示等值线曲率较小且相互平行,可知,在液固比为6.00时,设计范围内浸出温度对As的浸出率几乎无影响,As浸出率主要受硫酸浓度的影响,并随硫酸浓度的增大而升高。直接采用水浸出时,As的浸出率仅2.33%,虽可实现Cd、As的初步分离,但Cd的浸出率也只达到80.87%。

图7显示了研究范围内三因素之间任意两者对Zn浸出率的影响及两者间的交互影响,其中图7(a)显示了硫酸浓度为中等水平0.25 mol/L时浸出温度与液固比的影响及两者交互影响;图7(b)显示了液固比为中等水平6.00时浸出温度与硫酸浓度的影响及两者交互影响;图7(c)显示了浸出温度为中等水平45 ℃时液固比与硫酸浓度的影响及两者交互影响。综合可知,在第三因素的中等水平条件下,任意两因素的高水平区域均有可能实现Zn的完全浸出。图7(a)和(b)显示浸出温度与液固比之间、浸出温度与硫酸浓度之间的交互作用较弱,设计范围内浸出温度对Zn的浸出效果影响很弱,Zn浸出率随液固比和硫酸浓度的升高而升高,图7(c)显示了相同的变化趋势。此外,由表3可以看出,在酸浓度为0 mol/L时,Zn的浸出率仅5.47%,因此要实现在浸出过程中Cd、Zn的高效回收,就需要在一定的酸性条件下进行。

2.3 浸出过程优化区域

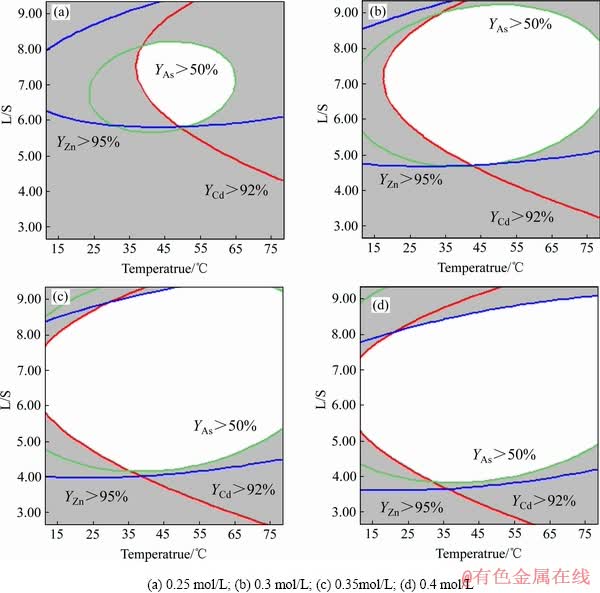

根据拟合所得Cd、As、Zn三元素模型,可分别得到各元素的优化浸出条件区域,而为了实现烟尘中多金属的综合回收,可使各金属均达到较高浸出率的条件区域更符合实际需求。利用Minitab 15软件的重叠等值线功能,依次模拟了硫酸浓度为0.25、0.3、0.35、0.4 mol/L时,Cd浸出率高于92%、Zn浸出率高于95%、As浸出率高于50%的区域,如图8所示,图中白色区域即为目标区域。由图8可知,随着硫酸浓度的逐渐升高,白色区域面积逐渐增大,且向低液固比区扩展的趋势明显,说明酸用量满足一定要求时,便不再是浸出的关键控制因素。

15软件的重叠等值线功能,依次模拟了硫酸浓度为0.25、0.3、0.35、0.4 mol/L时,Cd浸出率高于92%、Zn浸出率高于95%、As浸出率高于50%的区域,如图8所示,图中白色区域即为目标区域。由图8可知,随着硫酸浓度的逐渐升高,白色区域面积逐渐增大,且向低液固比区扩展的趋势明显,说明酸用量满足一定要求时,便不再是浸出的关键控制因素。

图8 不同硫酸浓度时Cd、Zn、As预测浸出效果重叠图

Fig. 8 Overlaid contour plots of Cd, As and Zn leaching efficiency affected by leaching temperature and L/S ratio at different H2SO4 concentrations

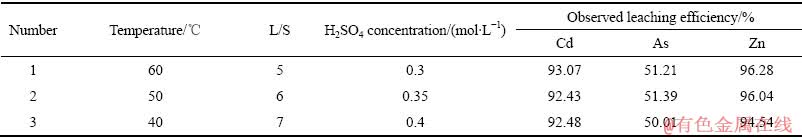

2.4 优化区域验证

根据图9所示的等值线叠加图,在优化目标区域内的选取任意实验点开展验证实验,用于考察二阶拟合模型对金属浸出效果拟合的合适性和准确性,结果如表4所示。从表4中可知,实际浸出率与理论预测值吻合较好,说明采用响应曲面法对含镉烟灰硫酸浸出过程进行优化是比较成功的。

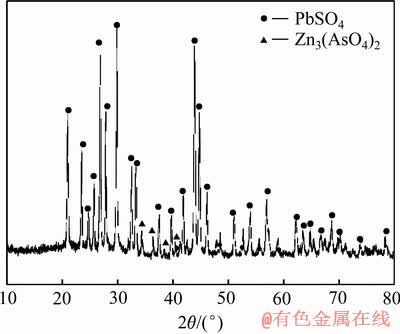

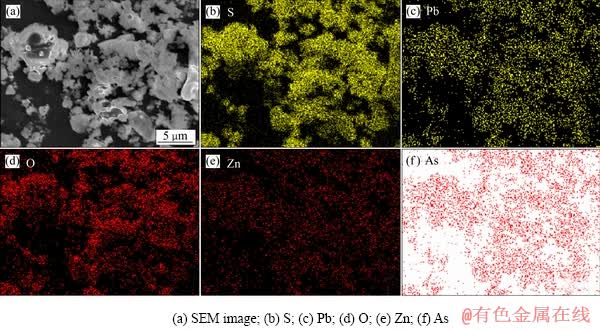

图9为浸出渣的XRD谱,可以看出其主要组成为硫酸铅;相比原料的XRD谱,浸出后CdSO4及ZnO的衍射峰消失,并出现明显的Zn3(AsO4)2的衍射峰,这进一步验证了镉烟灰中砷酸盐的存在。此外,浸出过程中As难以完全溶出,其主要原因就是砷酸锌在弱酸条件下难以分解,而在Zn 2p的XPS谱图中未检测到砷酸锌的存在,则是因为其相对含量较少。由浸出渣的EDS分析(见图10)可以看出,其主要的元素分布为Pb、S、O,未分解的As和Zn分布相同且均匀分布于浸出渣中,难以观察出独立矿物,这也表明在浸出过程中砷酸锌受主体矿物的影响,与浸出剂接触面积小,难以被溶出。

图9 浸出渣的XRD谱

Fig. 9 XRD pattern of leaching slag

表4 验证实验结果

Table 4 Results of verification experiments

图10 浸出渣的SEM像及EDS谱

Fig. 10 SEM image(a) and EDS spectra((b)-(f)) of leaching slag

3 结论

1) 含镉烟灰中Cd以CdSO4存在,Zn以ZnO和ZnSO4存在,为了实现Cd、Zn的高效浸出,需要酸性条件下操作,其中以Zn3(AsO4)2形式的As难以在弱酸条件下溶出,造成酸浸过程中As的浸出率较低。

2)采用响应曲面设计方法中的中心复合设计法,对硫酸浸出镉烟灰的过程进行了优化,构建了Cd、As、Zn浸出率与反应温度、液固比及硫酸浓度等因素之间的数学模型,并重点研究了影响因素在Cd、As、Zn浸出过程中的交互影响关系。

3) 确定了Cd、Zn和As的浸出率分别大于92%、95%和50%的优化浸出条件区域,在反应温度25~ 60 ℃,液固比6~8 mL/g,硫酸浓度0.3~0.4 mol/L的条件下,可获得在目标区域内稳定的浸出效果。验证实验结果表明,响应曲面设计法对镉烟灰酸浸出过程具有良好的拟合、预测效果。

REFERENCES

[1] 余德彪, 王建平, 徐 乐, 李德梅. 中国镉资源现状分析及可持续发展建议[J]. 中国矿业, 2015, 24(4): 5-8.

YUDe-biao, WANG Jian-ping, XU Le, LI De-mei. Situation analysis and sustainable development suggestion of cadmiun resources in China[J]. China Mining Magzine, 2015, 24(4): 5-8.

[2] 邱定蕃, 柴立元. 有色冶金与环境保护[M]. 长沙: 中南大学出版社, 2015: 263-285.

QIU Ding-fan, CHAI Li-yuan. Nonferrous metallurgy and environmental protection[M]. Changsha: Central South University press, 2015: 263-285.

[3] SPEAR T M, SVEE W, VINCENT J H, STANISICH N. Chemical speciation of lead dust associated with primary lead smelting[J]. Environmental Health Perspectives, 1998, 106(9): 565-571.

[4] HALATEK T, LUTZ P, KRAJNOWA A. Assessment of neurobehavioral and biochemical effects in rats exposed to copper smelter dusts[J]. Journal of Environmental Science and Health Part A, 2011, 46(3): 230-241.

[5] JUShao-hua, LU Shuai-dan, PENG Jin-hui, ZHANGLi-bo, SRINIVASAKANNAN C, GUO Sheng-hui, LI Wei. Removal of cadmium from aqueous solutions using red mud granulated with cement[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 3140-3146.

[6] KATO T, LIZUKA M, INOUE T, IWAI T, ARAI Y. Distillation of cadmium from uranium–plutonium–cadmium alloy[J]. Journal of nuclear materials, 2005, 340(2/3): 259-265.

[7] SEBASTIAN R, ALZOLA R P.Effective active power control of a high penetration wind diesel system with a Ni–Cd battery energy storage[J]. Renewable Energy, 2010, 35(5): 952-965.

[8] 曲 超, 陈 涛, 崔其磊. 炼铅底吹炉烟灰中镉的回收工艺研究[J]. 黑龙江冶金, 2016, 36(5): 14-15.

QU Chao, CHEN Tao, CUI Qi-lei. Experimental research on recovery of cadmium from bottom blowing furnace soot of lead smelting[J]. Heilongjiang Metallurgy, 2016, 36(5): 14-15.

[9] 杨 勰, 李宏煦, 李 超. 铅冶炼烟尘的物性分析及浸出性研究[J]. 化工环保, 2014, 34(5): 493-498.

YANG Xie, LI Hong-xu, LI Chao. Characterization and leachability of lead smelting dust[J]. Environmental Protection of Chemical Industry, 2014, 34(5): 493-498.

[10] SAWAI H, RAHMAN I M M, TSUKAGOSHI Y, WAKABAYASHI T, MAKI T, MIZUTANI S, HASEGAWA H. Selective recovery of indium from lead-smelting dust[J]. Chemical Engineering Journal, 2015, 277: 219-228.

[11] 高照国, 曹耀华, 刘红召. 含铟铅烟尘提铟试验研究[J]. 稀有金属, 2010, 34 (3): 413-419.

GAO Zhao-guo, CAO Yao-hua, LIU Hong-zhao. Indium extraction process from lead soot with indium[J]. Rare Metal, 2010, 34 (3): 413-419.

[12] 刘 远, 郑雅杰, 孙召明. 锌冶炼含镉烟尘制备高纯镉粉的新工艺[J]. 中国有色金属学报, 2014, 24(4): 1070-1075.

LIU Yuan, ZHENG Ya-jie, SUN Zhao-ming. New technology of high purity Cd powder prepared from roasting dust of zinc smelting[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 1070-1075.

[13] 张 飞, 曾 科. 铅冶炼行业现状及重金属污染防治对策分析[J]. 世界有色金属, 2018(9): 1-3.

ZHANG Fei, ZENG Ke.Analysis of lead smelting industry situation and countermeasuresforprevention and treatment of heavy metal Pollution[J].World Nonferrous Metal, 2018(9): 1-3.

[14] OBENG D P, MORRELL S, NAPIER-MUN T J. Application of central composite rotatable design to modelling the effect of some operating variables on the performance of the three-product cyclone[J]. International Journal of Mineral Processing, 2005, 76(3): 181-192.

[15] 张 勇, 郭朝晖, 王 硕, 肖细元. 响应曲面法对铝灰中AlN的水解行为[J]. 中国有色金属学报, 2016, 26(4): 919-927.

ZHANG Yong, GUO Zhao-hui, WANG Shuo.Hydrolysis behavior of AlN in aluminum dross with response surface methodology[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 919-927.

[16] GUO Xue-yi, LIU Jing-xin. Optimization of low-temperature alkaline smelting process of crushed metal enrichment originated from waste printed circuit boards[J]. Journal of Central South University, 2015, 22(5): 1643-1650.

Leaching behavior of Cd contained dust in acid medium and process optimization

ZHANG Wen-juan, MA Bao-zhong, WANG Cheng-yan

(School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: A systematic analysis for Cd contained dust was conducted and a flow sheet for metal recovery was proposed. The central composite design was used to optimize the operating conditions of leaching process. Second-order polynomial models of high significance and 3D response surface plots were constructed to show the interaction effects of temperature, L/S ratio and H2SO4 concentration on the leaching efficiency of Cd, As and Zn. Optimum area of leaching efficiency of Cd, Zn and As bigger than 92%, 95% and 50%, respectively, is obtained by the overlaid contours at temperature of 20-60 ℃, L/S ratio of 6-8 mL/g and H2SO4 concentration of 0.3-0.4 mol/L. The models are proved to be reliable and accurate in predicting the leaching process by the verified experiment in the optimal area. Within the optimal area, the leaching efficiency of As is lower and the main reason is attributed to the insolubility of zinc arsenate.

Key words: Cd contained dust; response surface method; central composite design; acidic leaching

Foundation item: Project(2018YFC1900404) supported by the National Key Research and Development Program of China; Project (FRF-TP-17-037A1) supported by the Fundamental Research Funds for the Central Universities, China; Project(2018T110045) supported by the Postdoctoral Science Foundation of China

Received date: 2019-01-08; Accepted date: 2019-04-25

Corresponding author: WANG Cheng-yan; Tel: +86-10-62333170; E-mail: chywang@yeah.net

(编辑 李艳红)

基金项目:国家重点研发计划资助项目(2018YFC1900404);中央高校基本科研业务费资助项目(FRF-TP-17-037A1);中国博士后基金特别资助项目(2018T110045)

收稿日期:2019-01-08;修订日期:2019-04-25

通信作者:王成彦,教授,博士;电话:010-62333170;E-mail:chywang@yeah.net