6063铝合金旋压管拉伸过程中表面橘皮定量分析

来源期刊:中国有色金属学报(英文版)2018年第5期

论文作者:蔡洋 王小松 苑世剑

文章页码:858 - 865

关键词:6063铝合金;表面粗化;拉伸变形;旋压;橘皮

Key words:6063 aluminum alloy; surface roughening; tensile deformation; spinning; orange peel

摘 要:表面粗化严重到一定程度形成橘皮缺陷。为了定量分析6063铝合金管的表面橘皮现象,通过旋压热处理获得具有不同晶粒尺寸的管材,利用梯形拉伸试样进行拉伸实验。通过激光共聚焦显微镜测量表面粗糙度Ra以反映宏观表面粗化程度,通过EBSD观察微观组织以及原位拉伸过程以反映微观表面粗化行为。结果表明,表面粗糙度随着应变量的增加先增加后轻微减小,对于不同晶粒尺寸的管材都存在一个临界应变量,当应变量低于临界值时不会出现橘皮缺陷。当平均晶粒尺寸为80、105、130和175 μm时,临界应变量分别为10.17%、5.74%、3.15%和1.62%。表面粗化由严重的不均匀变形引起,在大晶粒中局部变形比较严重,导致表面粗化严重。

Abstract: Severe surface roughening during plastic deforming of aluminum alloy parts can produce “orange peel” defects. To analyze “orange peel” of 6063 aluminum alloy tube quantificationally, the tensile tests of trapezoidal specimens were carried out. The tubes with different grain sizes were obtained by spinning and subsequent annealing heat treatment. The macroscopical behavior of surface roughening was characterized by surface roughness Ra using a laser scanning confocal microscope. The corresponding microscopic behavior was reflected by microstructures of specimens and in-situ observation using electron back-scattered diffraction (EBSD). The obtained results show that the surface roughness increased firstly with increasing strain and then decreased slightly. There was a critical strain for aluminum alloy tube, below which “orange peel” defect would not occur. For the tube with a mean grain size of 80, 105, 130 and 175 μm, the critical strains were 10.17%, 5.74%, 3.15% and 1.62%, respectively. Meanwhile, the surface roughening behavior was produced by serious inhomogeneous deformation between grains as strain increased, and was aggravated as the grain size increased due to the larger local deformation in larger grains.

Trans. Nonferrous Met. Soc. China 28(2018) 858-865

Yang CAI1, Xiao-song WANG1,2, Shi-jian YUAN1,2

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory of Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China

Received 21 November 2016; accepted 6 March 2017

Abstract: Severe surface roughening during plastic deforming of aluminum alloy parts can produce “orange peel” defects. To analyze “orange peel” of 6063 aluminum alloy tube quantificationally, the tensile tests of trapezoidal specimens were carried out. The tubes with different grain sizes were obtained by spinning and subsequent annealing heat treatment. The macroscopical behavior of surface roughening was characterized by surface roughness Ra using a laser scanning confocal microscope. The corresponding microscopic behavior was reflected by microstructures of specimens and in-situ observation using electron back-scattered diffraction (EBSD). The obtained results show that the surface roughness increased firstly with increasing strain and then decreased slightly. There was a critical strain for aluminum alloy tube, below which “orange peel” defect would not occur. For the tube with a mean grain size of 80, 105, 130 and 175 μm, the critical strains were 10.17%, 5.74%, 3.15% and 1.62%, respectively. Meanwhile, the surface roughening behavior was produced by serious inhomogeneous deformation between grains as strain increased, and was aggravated as the grain size increased due to the larger local deformation in larger grains.

Key words: 6063 aluminum alloy; surface roughening; tensile deformation; spinning; orange peel

1 Introduction

Vehicle weight reduction is a particularly important issue for the automotive industry, with the associated improvements to fuel consumption costs, without adversely affecting the safety performance of the vehicle [1-4]. Aluminum alloy tubular parts have been widely used in the automotive industry due to the desirable lightweight and mechanical properties [5-9]. Recent examples of aluminum tube applications in vehicles include body structure, chassis, and exhaust system such as the chassis frame of Volvo jeep and BMW 5-series and the roll-over bar of a Opel car [10-12]; the weight of the aluminum alloy rear axle was reduced by 30% compared with an equivalent steel structure [13]. The 6063 aluminum alloy tube is mainly used in the body structure and chassis of higher-end vehicle, for example, the chassis frame of a Volvo jeep and the roll-over bar of a Opel car were both manufactured using 6063 aluminum alloy tube [14]. However, surface roughening phenomenon such as “orange peel” frequently appears on the structural components, which is predominantly caused by coarse grains and deformation [15,16]. Thus, in actual production, the surface quality of structural components can be improved through the control of grain size and deformation degree.

Lots of research work about surface roughening phenomenon of aluminum alloy were carried out by uniaxial tensile testing of sheet materials [17]. The main influence factors include internal factors (mainly grain size) and external conditions (mainly strain) [17-19]. The researches have shown that the surface roughness is strongly dependent on the grain size of the materials and increases proportionally with grain size, and the deformation-induced surface roughness increases linearly with increasing plastic strain or firstly increases then remains unchanged [20-24].

However, few studies have examined the surface roughening behavior of aluminum alloy in tubes especially for ones which were widely used in automobile. An identified quantitative relationship between surface roughness and factors which include grain size and strain of 6063 aluminum alloy tube has not yet been given definitely. In the current work, the tensile experiments using trapezoidal tensile samples with different grain sizes have been carried out. The tubes were prepared by spinning and annealing process to provide the microstructures with different grain sizes, and the different strains were obtained from the trapezoid specimens after tensile deformation. In addition, the measurement of surface roughness and observation of surface topography were carried out using a confocal scanning laser microscope. Microstructural information was acquired and analyzed by EBSD.

2 Experimental

2.1 Material and preparation

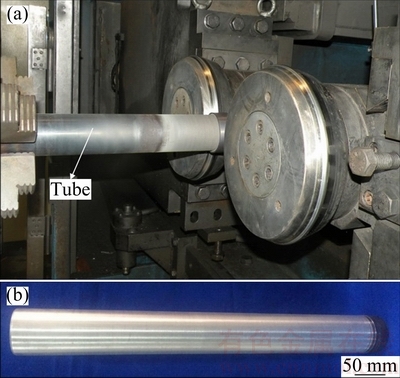

The initial material for this work was extruded 6063-T4 aluminum alloy tube with a nominal outside diameter of 78 mm and nominal thickness of 3.5 mm. The microstructure of tube can be manipulated by plastic deformation and heat treatment [25]. The grain size of tubes can be controlled by spinning with subsequent annealing heat treatment. The tubes were spun at room temperature with a nominal thickness reduction of 5%-10% per pass to give a total reduction of 42.85% after six passes. The equipment used was the high- precision, double-wheeled spinning installation, as shown in Fig. 1(a), which had a spinning roller feed rate of 0.8 mm/r and a mandrel speed of 250 r/min. The spun tubes (Fig. 1(b)) were annealed at 350, 400 and 450 °C for 1 h and furnace-cooled to obtain tubes with three different grain sizes.

2.2 Experimental setup

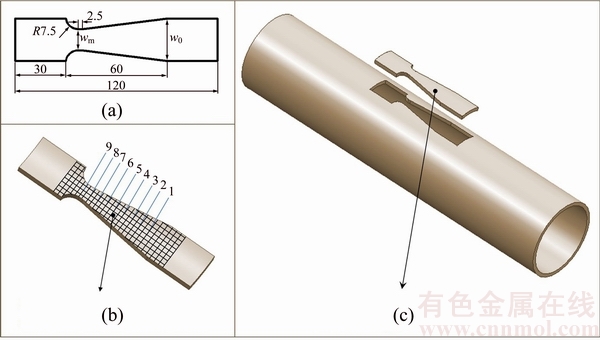

To obtain a series of different and continuous strains, the isosceles-trapezoid-shaped tensile specimen was designed. The differences of microstructure within a single specimen are less than those between two individual specimens. Using trapezoid specimens that can provide continuous strain distributions is better than using several specimens, because a comparatively complete and accurate variation tendency can be obtained by the continuous strains. To make the strain range as large as possible, we assume that the axial stress at part with the minimum width b0 reaches the tensile strength (σb) and the stress at part with the maximum width b1 is equal to the yield strength (σs) [26]. Then, the correlation of the maximum and minimum width can be expressed as follows:

(1)

(1)

The tensile strength σb of 6063-T4 aluminum alloy tube was 179 MPa, and the yield strength σs was 79 MPa [26]. Thus, the maximum and minimum width were designed as 25 mm and 12.5 mm, respectively, and the size of specimen is displayed in Fig. 2. Before stretching, the outer surface of the specimen was mechanically polished for measuring the surface roughness, and the inner surface was printed with mesh grids of 2 mm × 2 mm for analyzing the strain. The tensile tests were performed on an Instron 5569 at a crosshead velocity of 1 mm/min and testing was stopped as necking occurred.

Fig. 1 Double-wheel spinning installation (a) and spun tube (b)

Fig. 2 Geometric dimensions (unit: mm) (a), inner surface (b), and outer surface (c) of trapezoidal specimens

2.3 Measurement method

As Ra is considered to be a reasonable representation of the roughening behavior of the material and is used frequently in industrial applications to quantify the changes in surface morphology, Ra was selected for this work to reflect the degree of surface roughening. For the surface roughness, as shown in Eq. (1), Ra value is defined as the mean of the absolute value of all area values y(x), contained within a profile area S.

(2)

(2)

The measurement of surface roughness Ra was finished by the laser scanning confocal microscope (OSL3000), and was acquired from the mid-length position of each specimen; an area of 2560 μm × 2560 μm was scanned with a vertical resolution of 2 μm. Surface topographies were obtained from the laser scanning confocal microscope.

The strain analysis of specimen was carried out by the ASAME strain measuring system. A pattern of square grids (2 mm × 2 mm) was applied to the undeformed specimen. Two views of an area on the deformed component were photographed at different positions. These offset views were then digitized in two dimensions and photogrammetry principles were applied to determine the three-dimensional map of the area. Based on the known undeformed grid size and the three-dimensional data for each deformed grid, the surface strain was calculated.

Microstructural information was acquired by EBSD with 5.5 μm step size, performed on a Quanta 200 FEG operated at 20 kV. Specimens for EBSD were prepared by mechanical grinding and electropolishing in an electrolyte with 20% perchloric acid in alcohol at a temperature of about -20 °C and a voltage of 25 V for 50 s.

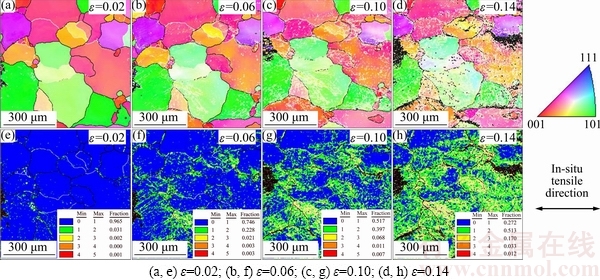

In order to describe the microstructures evolution during tension, in-situ tensile experiment was performed. Before tensile testing the specimen was mechanically polished. The tensile experiment was implemented on the Instron 5569 at a crosshead velocity of 1 mm/min with a small specimen, and stopped as the strain reached 2%, 6%, 10% and 14%. The microstructures at different strains in the marked region were observed when the stretching stopped.

3 Results and discussion

3.1 Tube obtained by spinning and heat treatment

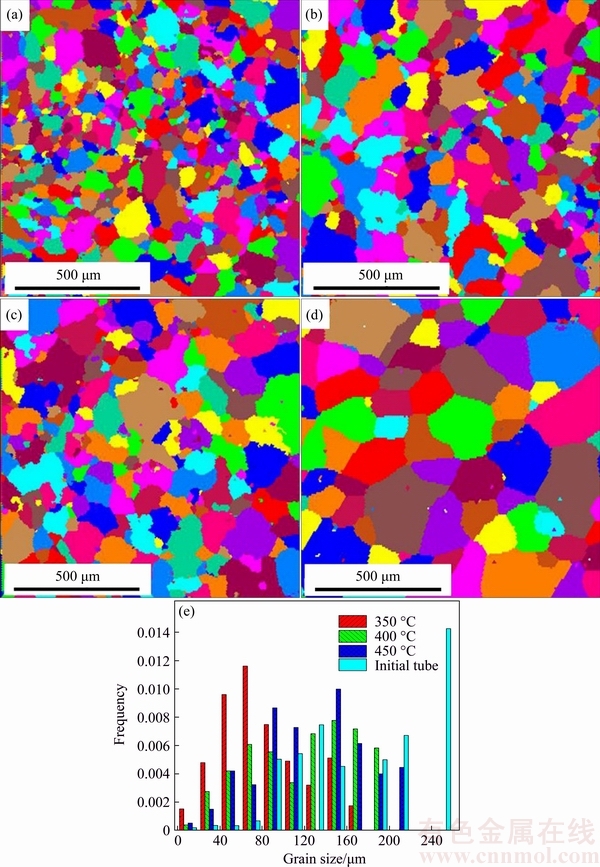

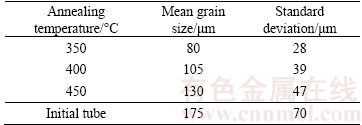

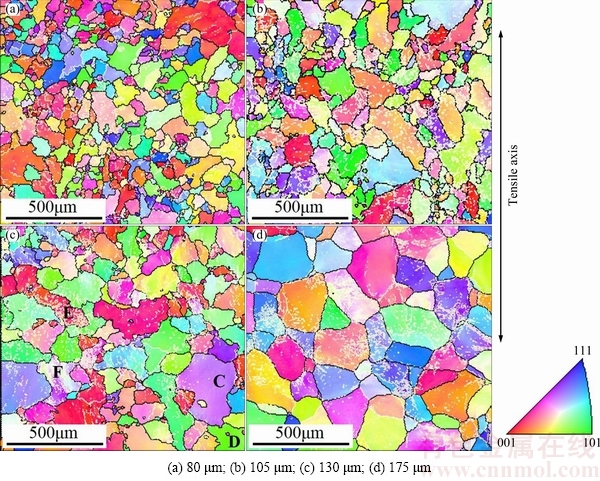

Figures 3(a-d) display the grain size distributions of tubes with different grain sizes. The analysis results listed in Table 1 show that the surface of the spun tube annealed at 350 °C had the smallest mean grain size of 80 μm and the standard deviation (SD) of 28 μm. Increasing the annealing temperature to 400 °C resulted in a mean grain size of 105 μm (SD of 39 μm), while annealing at 450 °C produced a mean grain size of 130 μm (SD of 47 μm). As a reference, the surface of the initial tube had a mean grain size of 175 μm (SD of 70 μm). The distribution frequency histograms of the tubes with different grain sizes are shown in Fig. 3(e).

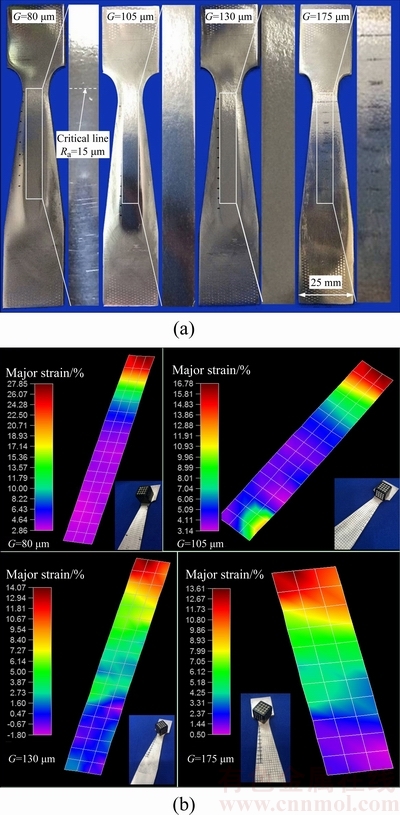

3.2 Macroscopical morphology of surface roughening

After tensile deformation, a significant roughening phenomenon appeared on the macroscopic surface of the specimens, as shown in Fig. 4(a). The larger the grain size, the severer the surface roughening phenomenon. The surface roughening of the specimen with a grain size of 175 μm was the most serious, with only a small part of its surface at each end not being subject to “orange peel” defects. The area of “orange peel” was reduced with decreasing grain size. This suggests that there is a critical strain εc for aluminum alloy, below which “orange peel” defects will not occur. The strain distributions of the specimens with different grain sizes are shown in Fig. 4(b). The maximum strain appeared near the minimum width and the minimum strain near the maximum width.

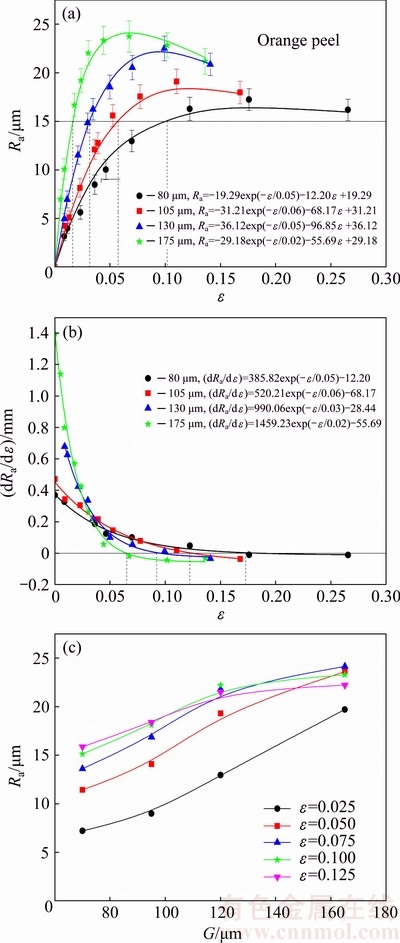

The surface roughness increased firstly with increasing strain and then decreased slightly, as shown in Fig. 5(a). Their roughening rate can be expressed as the slope of the tangent line of the surface roughness-strain curve, and the roughening rate dRa/dε has exponent relation to the strain, as shown in Fig. 5(b). When the roughening rate was equal to zero, the surface roughness reached the maximum value. The larger the grain size, the smaller the strain at which the maximum surface roughness appeared. In addition, as displayed in Fig. 5(c), the surface roughness rose with increasing the grain size. The surface roughness was nearly linearly raised with the grain size when the tensile strain was smaller than 0.1, the surface roughness increased nonlinearly when the strain exceeded 0.1, and the increasing rate was reduced with increasing grain size.

There is a critical strain for aluminum alloy tube, below which “orange peel” defects will not occur. From observations of the surface of the trapezoid specimen with a grain size of 80 μm, it was found that the surface roughening was not serious when the surface roughness was less than 15 μm and the strain was just less than 10.17%. But “orange peel” defects can occur when the strain was greater than this. Using a surface roughness of 15 μm as an index for the occurrence of “orange peel” defects, the critical strain for a grain size of 105 μm was found to be 5.74% according to fitted curve. Using this approach, the critical strain was found to be 3.15% and 1.62% for a grain size of 130 and 175 μm, respectively.

Fig. 3 Grain size distributions of spun tube annealed at 350 °C (a), 400 °C (b), 450 °C (c), initial tube (d) and frequency histogram of prepared tubes (e)

Table 1 Grain size of tubes annealed at different temperatures

Thus, keeping the strain during the tensile deformation of aluminum alloy structural components below these levels should ensure that “orange peel” defects are avoided.

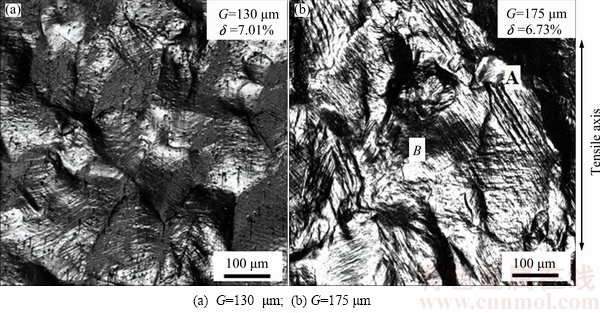

3.3 Microscopic behavior of surface roughening

Positions on the trapezoid specimen with strain of 7% were selected, and the surface morphologies of the specimens with mean grain size of 130 and 175 μm are shown in Figs. 6(a) and (b), respectively. There are obvious concave-convex characteristics on the surface morphologies. Clear slip bands appeared in the grains, and the neighboring slip lines were parallel to each other. The distribution of slip lines showed an obvious inhomogeneity in different areas. In the material with large grain size, as shown in Fig. 6(b), there were more slip lines in Grain A but few slip lines in Grain B, which means that there were more slip systems participating in Grain B. In the microstructure with the smaller grain size, as shown in Fig. 6(a), obviously the distribution of slip lines were relatively uniform, and the difference of slip lines in different areas was receded. In other words, the inhomogeneous deformation among grains or inside grains resulted in the surface roughening phenomenon.

Fig. 4 Trapezoidal specimens with different grain sizes (a) and strain distribution after tensile deformation (b)

Figure 7 shows the IPF maps of samples with mean grain sizes of 80, 105, 130 and 175 μm at positions with 12% strain. Low angle grain boundaries (LAGBs, 2°-15°) and high angle grain boundaries (HAGBs, >15°) are shown with black and white lines, respectively. The different orientations of grains are shown by different colors.

Fig. 5 Relationship between surface roughness Ra and effective strain ε (a), roughening rate dRa/dε and effective strain ε (b), and surface roughness Ra and grain size of trapezoidal tensile specimens (c)

The standard deviation of grain size of material increased with increasing average grain size, as listed in Table 1, which suggests that the inhomogeneity of the grain size distribution was more serious if the average grain size was larger. LAGBs distributed uniformly in the grains with mean grain size of 80 μm, as shown in Fig. 7(a), indicating that the deformation was homogeneously scattered in different grains. With increasing average grain size, the fraction of LAGBs increased and the deformation in different grains became relatively non-uniform, as shown in Fig. 7(b). While the grain size increased to 130 μm, the inhomogeneity of LAGBs distribution became more serious, and fewer LAGBs were found in the Grain C and D, but concentrated LAGBs appeared in the Grain E and F, as shown in Fig. 7(c). Figure 7(d) shows the microstructure with a mean grain size of 175 μm, which exhibited the most serious local deformation. From the microscopic behavior of the surface roughening one can conclude that the deformation inhomogeneity increased with increasing the grain size. Consequently, the surface roughening behavior was aggravated by increasing grain size.

Fig. 6 SEM images of 2D surface morphology of trapezoidal tensile specimen with different grain sizes

Fig. 7 IPF maps of specimens with different mean grain sizes at strain of 12% after deformation

Figure 8 shows the IPF and KAM evolution images in process of in-situ tensile test. When the strain attained 0.02, the formation of LAGBs was discovered in a few grains, and the KAM value was small and the deformation concentrated around a few grain boundaries. With the strain attained to 0.06, the number of LAGBs increased around the grain boundaries where the LAGBs appeared in the last step, but there were few LAGBs in other grains and so did the KAM value distribution. This means that the plastic deformation only occurred in several grains and the deformation inhomogeneity was serious. When the strain reached 0.1, the LAGBs appeared in more grains, and the KAM value increased obviously and extended to the larger region, indicating that more grains participated in the deformation, therefore the overall deformation was enhanced and local deformation was receded. With further increasing the strain, almost all grains involved in the deformation. These results were consistent with the evolution of surface roughness which firstly increased and then decreased with increasing strain.

Fig. 8 IPF evolution images (a-d) and KAM evolution images (e-h) observed with EBSD in process of in-situ tensile test

4 Conclusions

1) As the strain increased, the surface roughness initially increased and then decreased slightly, with the roughening rate decreasing exponentially. For the same strain, the surface roughness increased almost linearly with grain size when the strain was less than 0.1. As the strain was larger than 0.1, the surface roughness displayed a nonlinear increasing.

2) There was a critical strain for the aluminum alloy tubes, below which “orange peel” defects would not occur. As the mean grain sizes were 80, 105, 130 and 175 μm, the critical strains were 10.17%, 5.74%, 3.15% and 1.62%, respectively.

3) The surface roughening degree was firstly aggravated and then receded with increasing strain. In addition, the local deformation was enhanced with increasing grain size, thus, the surface roughening degree was aggravated with increasing grain size.

References

[1] YUAN Shi-jian, HE Zhu-bin, LIU Gang. New developments of hydroforming in China [J]. Materials Transactions, 2012, 53: 787-795.

[2] CAI Yang, WANG Xiao-song, YUAN Shi-jian. Pre-form design for hydro-forming of aluminum alloy automotive cross members [J]. The International Journal of Advanced Manufacturing Technology, 2016, 86: 463-473.

[3] JORGE R M N, VALENTE R A F, ROQUE A P, PARENTE M P L, FERNANDES A A. Numerical simulation of hydroforming process involving a tubular blank with dissimilar thickness [J]. Materials and Manufacturing Processes, 2007, 22: 286-291.

[4] HIRSCH J. Aluminium in innovative light-weight car design [J]. Materials Transactions, 2011, 52: 818-824.

[5] WU Y, LIAO H J. Corrosion behavior of extruded near eutectic Al-Si-Mg and 6063 alloys [J]. Journal of Materials Science & Technology, 2013, 29: 380-386.

[6] REITZ W. Review of: “Metallic materials for lightweight applications” edited by MGH Wells, EB Kula, and JH Beatty [J]. Material and Manufacturing Process, 2007, 27: 315-316.

[7] CUI Ji-rang, ROVEN H J. Recycling of automotive aluminum [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 2057-2063.

[8] WANG W R, CHEN G L, LIN Z Q. Application of new VBHF optimization strategy to improve formability of automobile panels with aluminum alloy sheet [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 471-477.

[9] TABATABAEI S A, FARAJI G, MASHADI M M, PANAHI M S, TABATABAEE S M, GHAHVECHI R B. Preform shape design in tube hydroforming process using equi-potential line method [J]. Materials and Manufacturing Processes, 2013, 28: 260-264.

[10] MILLER W S, ZHUANG L, BOTTEMA J, WITTEBROOD A, SMET P De, HASZLER A, VIEREGGE A. Recent development in aluminium alloys for the automotive industry [J]. Materials Science and Engineering A, 2000, 280: 37-49.

[11] KOCHAN A. Audi moves forward with all-aluminium cars [J]. Assembly Autom, 2000, 20: 132-135.

[12] AZIM A, ALI A, BARKAWI S B, NURAINI A A, FAIEZA A A, ISMAIL T H T, SALWANI M S, NURSHERIDA J M, NABILAH M S, AINI S S, SHAHRIL M, NORHIDAYAH M H. Performance of aluminium alloy side door subjected to pole impact test [J]. Applied Mechanics and Materials, 2012, 165: 280-284.

[13] HIRSCH J. Automotive trends in aluminium-The European perspective [J]. Metals Forum, 2004, 28: 15-23.

[14] LANG L H, WANG Z R, KANG D C, YUAN S J. Hydroforming highlights: Sheet hydroforming and tube hydroforming [J]. Journal of Materials Processing Technology, 2004, 151: 165-177.

[15] KOSTER W P, FIELD M, KAHLES J F, FRITZ L J, GATTO L R. Surface integrity of machined structural components [R]. Cincinnati, Oh: Metcut Research Associates Inc, 1970: 970-1700.

[16] ZHOU X H, SU X. Effects of deformation mode on surface roughening of austenitic stainless steels [J]. Materials Science and Technology, 2013, 27: 1040-1044.

[17] SHI Y, WU P D, LLOYD D J, EMBURY D. Numerical study of surface roughening in blow-formed aluminum bottle with crystal plasticity [J]. Materials Science and Engineering A, 2015, 638: 97-105.

[18] YANG L, ZHAN L H, WU W. Analysis method for orange peel structure on aluminium–lithium alloy surface during stretch forming process [J]. Materials Research Innovations, 2014, 18: S2-5-S2-11.

[19] STOUDT M R, LEVINE L E, CREUZIGER A, HUBBARD J B. The fundamental relationships between grain orientation, deformation-induced surface roughness and strain localization in an aluminum alloy [J]. Materials Science and Engineering A, 2011, 530: 107-116.

[20] BORKAR H, SEIFEDDINE S, JARFORS A E. In-situ EBSD study of deformation behavior of Al-Si-Cu alloys during tensile testing [J]. Materials & Design, 2015, 84: 36-47.

[21] KAHL S, PENG R L, CALMUNGER M, OLSSON B, JOHANSSON S. In situ EBSD during tensile test of aluminum AA3003 sheet [J]. Micron, 2014, 58: 15-24.

[22] ZHAO Z, RAMESH M, RAABE D, CUITINO A, RADOVITZKY M R. Investigation of three-dimensional aspects of grain-scale plastic surface deformation of an aluminum oligocrystal [J]. International Journal of Plasticity, 2008, 24: 2278-2297.

[23] WOUTERS O, VELLINGA W P, van TIJUM R, de HOSSON J T M. On the evolution of surface roughness during deformation of polycrystalline aluminum alloys [J]. Acta Materialia, 2005, 53: 4043-4050.

[24] STOUDT M R, HUBBARD J B, LEIGH S. On the relationship between deformation-induced surface roughness and plastic strain in AA5052—Is it really linear? [J] Metallurgical and Materials Transactions A, 2011, 42: 2668-2679.

[25] CHEN Yi-Zhe, LIU Wei, YUAN Shi-jian. Strength and formability improvement of Al-Cu-Mn aluminum alloy complex parts by thermomechanical treatment with sheet hydroforming [J]. JOM, 2015, 67: 938-947.

[26] CAI Y, WANG X S, YUAN S J. Analysis of surface roughening behavior of 6063 aluminum alloy by tensile testing of a trapezoidal uniaxial specimen [J]. Materials Science and Engineering A, 2016, 672: 184-193.

蔡 洋1,王小松1,2,苑世剑1,2

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家重点实验室,哈尔滨 150001

摘 要:表面粗化严重到一定程度形成橘皮缺陷。为了定量分析6063铝合金管的表面橘皮现象,通过旋压热处理获得具有不同晶粒尺寸的管材,利用梯形拉伸试样进行拉伸实验。通过激光共聚焦显微镜测量表面粗糙度Ra以反映宏观表面粗化程度,通过EBSD观察微观组织以及原位拉伸过程以反映微观表面粗化行为。结果表明,表面粗糙度随着应变量的增加先增加后轻微减小,对于不同晶粒尺寸的管材都存在一个临界应变量,当应变量低于临界值时不会出现橘皮缺陷。当平均晶粒尺寸为80、105、130和175 μm时,临界应变量分别为10.17%、5.74%、3.15%和1.62%。表面粗化由严重的不均匀变形引起,在大晶粒中局部变形比较严重,导致表面粗化严重。

关键词:6063铝合金;表面粗化;拉伸变形;旋压;橘皮

(Edited by Bing YANG)

Foundation item: Project (IRT1229) supported by Program for Chang-jiang Scholars and Innovative Research Team in University, China

Corresponding author: Xiao-song WANG; Tel/Fax: +86-451-86415754; E-mail: hitxswang@hit.edu.cn

DOI: 10.1016/S1003-6326(18)64719-3