2250 CVC热连轧机支持辊辊形研究

郝建伟1,曹建国1,张 杰1,魏钢城1, 2,周一中2,陈 刚2

(1. 北京科技大学 机械工程学院,北京,100083;

2. 武汉钢铁(集团)公司,湖北 武汉,430083)

摘 要:针对2250 CVC热连轧机支持辊磨损严重、不均匀且出现剥落问题,提出与2250热连轧机CVC工作辊相匹配的支持辊新辊形CVR(CVC-VCR Compounded Roll),采用通用有限元软件ANSYS建立辊系三维弹性变形模型,并在F3机架上进行工业轧制试验。研究结果表明:与原辊形配置相比,CVR辊形配置不仅增加了弯辊力的调控范围,辊缝横向刚度增加11.5%以上,而且轧制过程服役前期和后期的辊间压力分布不均匀度分别降低28.17%和29.1%,辊间压力峰值分别下降27.56%和24.49%;新支持辊CVR自保持性较好,可稳定发挥其性能。

关键词:热轧;轧辊;带钢;磨损;有限元分析

中图分类号:TG333.71 文献标识码:A 文章编号:1672-7207(2007)04-0734-05

Backup roll contour of 2250 CVC hot strip mill

HAO Jian-wei1, CAO Jian-guo1, ZHANG Jie1, WEI Gang-cheng1, 2, ZHOU Yi-zhong2, CHEN Gang2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Wuhan Iron and Steel Company, Wuhan 430083, China)

Abstract: Based on the fact that the backup roll for 2250 CVC tandem mill in hot rolling has serious and non-uniform wear, and the edge spalling often happens, a new backup roll contour named CVR(CVC-VCR Compounded Roll) was proposed, which was designed for the CVC work roll of 2250 hot rolling mill. By adopting the ANSYS software, a three-dimensional finite element roll elastic model was built. The test on the No.3 stand of the large industrial mills was made. The result shows that in comparison with the original roll contour, the adjustment scope of bending force enhances and the roll gap stiffness increases by above 11.5%. Moreover, the non-uniform level of roll contact pressure in the prophase and anaphase rolling service drops by 28.17% and 29.1% separately, and the peak value of roll contact pressure descends by 27.56% and 24.49%, respectively. The CVR contour has good self-maintenance and is capable of exerting itself stably.

Key words: hot rolling; roll; strip; wear; finite element analysis

武钢2250 CVC热连轧机是目前国内产量最大、轧制宽度最大的热连轧机,自2003年建成投产以来,年实际产量已逾487万t。该热连轧机组宽度覆盖范围广(700~2 130 mm),厚度覆盖范围大(1.2~25.4 mm)。通过现场跟踪测试发现2250热连轧机精轧支持辊磨损严重、不均匀,且不时出现剥落现象。在确定轧机机型的情况下,辊形成为带钢板形控制最直接、最有效的手段之一[1-2]。VCR变接触支持辊已经成功应用于工业轧制实践生产[3]。为解决目前2250热连轧机精轧支持辊存在的问题,本文作者对2250 CVC热连轧机精轧支持辊辊形进行研究。

1 2250 CVC热连轧机精轧支持辊磨损特点

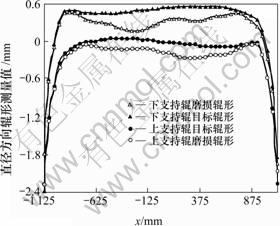

为了研究2250热连轧机精轧支持辊的磨损,在现场跟踪采集分析了90支常规支持辊辊形磨损数据,典型磨损辊形如图1所示。其中,x为辊身长度方向各点与辊身中点的距离。经分析可知:

a. 支持辊磨损严重,且下支持辊的磨损量大于相应的上支持辊磨损量;

b. 支持辊磨损曲线存在明显的不均匀性,80%左右中部呈现近似“S”形,边部两端200 mm处存在高点;

c. 上支持辊磨损量最大处偏向操作侧,而下支持辊磨损量最大处偏向传动侧(左侧为传动侧,右侧为操作侧);

d. 原辊形配置支持辊不时发生掉肉和边部剥落现象。

严重而且不均匀的磨损大大增加了轧辊的损耗,延长了磨辊时间,同时,支持辊辊形的不断变化直接影响辊间接触压力的变化,进而影响弯辊和窜辊的使用效果,导致工作辊承载辊缝形状发生变化,其最终结果将降低热轧板廓和板形质量[4-5]。

图1 2250热连轧机F3支持辊磨损辊形

Fig.1 Wear contours of backup roll on No.3 stand of 2250 tandem hot rolling mill

2 辊系变形有限元模型及分析

采用ANSYS10.0大型通用有限元分析软件,针对2250宽带钢热轧机,建立辊系变形三维有限元分析模型。为减少计算工作量,考虑到辊系的几何对称性,可取辊系的1/4作为研究对象。采用APDL语言通过辊形曲线函数对轧辊实体建模,并根据配对工作辊与支持辊辊形自动寻找初始接触位置,在辊间及辊与带钢接触区采用细密网格单元进行划分。模型辊间接触采用ANSYS提供的通用点对面接触单元来实现,支持辊和工作辊均采用八节点三维等参数固体单元,总的节点数为34 166个,单元数为30 640个,接触单元数为1 068个,其有限元模型如图2所示。该模型采用的主要计算参数如表1所示。

图2 辊系有限元模型

Fig.2 Finite element model of the roll system

表1 有限元模型主要计算参数

Table 1 Main calculating parameters of infinite model

2.25 m宽带钢热连轧机工作辊为CVC辊形,外方提供的支持辊原辊形中部为平辊段,边部各有200 mm?1 mm倒角的常规辊形,如图3所示。

图3 常规支持辊边部倒角曲线

Fig.3 Chamfer curve of conventional backup roll

在此辊形配置情况下,单位轧制力为12 kN/mm,工作辊不窜辊,弯辊力最小时,分别以带钢宽度为1.25,1.55,1.85和2.15 m 4种工况进行仿真计算。图4所示为不同带钢宽度下工作辊与支持辊辊间接触压力分布的计算结果。由图4可知,辊间接触压力呈现“S”形分布,且尽管带钢宽度不同,应力集中点几乎均出现在距右端部200 mm的位置,并随轧制力的增大,应力集中越严重。这表明支持辊为常规辊形,工作辊采用CVC辊形后,极大地影响了辊间压力的分布,辊间接触的不匹配造成了局部接触区应力集中。

图4 支持辊为常规辊形时辊间接触压力

Fig.4 Roll contact pressure distribution between conventional backup roll and CVC work roll

据文献[6]可知,该类轧机机型中由于支持辊倒角的存在,在开始使用时,支持辊右端倒角处出现明显的接触应力集中,本文的分析结果也同样证实了这点。CVC工作辊辊形极大地影响了辊间压力的分布,辊间接触的不匹配造成了局部接触区应力集中,这势必使其自然磨损速率沿轴向不均匀,从而因个别部位过早严重磨损,服役时间缩短,磨削量增加,造成很大的经济损失。为了减小或消除辊间有害接触区,使辊间接触压力均匀,提高轧机的控制性能,在此提出与CVC辊形相适应的支持辊新辊形CVR,继而分析其控制特性。

3 CVR新辊形设计

VCR支持辊辊形很早就应用于大型工业轧机[7],其核心技术是通过特殊设计的支持辊辊廓曲线,依据辊系弹性变形的特性使在轧制力作用下支持辊和工作辊之间的接触线长度与轧制宽度自动适应,从而消除或减少辊间有害接触区的影响[8-9]。但是,VCR支持辊辊形左右对称,中部几乎为平辊,在工作辊为CVC辊形时,辊间接触压力分布不均匀。为此,根据2250热连轧机精轧支持辊的磨损特点,基于VCR变接触思想,综合考虑支持辊的磨损特点和工作辊的CVC辊形曲线,考虑现场实际条件,设计了新的支持辊辊形CVR辊形,如图5所示。

图5 常规辊形CON和CVR辊形对比

Fig.5 Comparison between conventional CON and CVR backup roll contour

4 CVR性能分析

热轧板形控制性能评价指标主要包含辊缝凸度调节域、辊缝横向刚度、板形控制效率曲线和辊间接触压力分布不均匀度及峰值[10-14]。为了评价CVR的性能,利用前述辊系变形有限元模型,对2250热连轧机在不同轧制条件下的425种工况进行仿真计算。现以工业轧机常轧宽度1.55 m带钢为代表,对改进前、后辊形配置下的性能进行评价。

4.1 凸度调节域

辊缝凸度调节域是指轧机各板形调控技术对承载辊缝的二次凸度Cw2和四次凸度Cw4的最大调节范围,反映了承载辊缝调节柔性。图6所示为支持辊采用带倒角的常规辊形和CVR辊形进行仿真计算的结果,后者调节域面积略有增大。由此可见,采用CVR支持辊保持了常规倒角支持辊的性能,在一定程度上增加了辊缝的调节柔性。

图6 常规辊形和CVR辊形辊缝凸度调节域

Fig.6 Roll gap adjustment area between conventional contour and CVR contour

4.2 承载辊缝横向刚度

辊缝横向刚度是衡量承载辊缝在轧制压力变动时的稳定性参数,如图7所示。其中:CON为常规支持辊,CVR为本文提出的新辊形支持辊;Fw为变辊力。

图7中,曲线1和3分别为采用常规支持辊且弯辊力为0 MN和最大值1.5 MN时的承载辊缝特性曲线,它们之间的距离为采用常规支持辊下的弯辊力对承载辊缝的调节幅度;曲线2和4分别为采用CVR支持辊且弯辊力为0 MN和最大值1.5 MN时的承载辊缝特性曲线,同样,它们之间的距离为CVR辊形下的弯辊力对承载辊缝的调节幅度。对于常规带倒角支持辊,横向刚度分别为86.3 kN/μm和92.8 kN/μm,而对于CVR支持辊,它们分别为96.2 kN/μm和105.0 kN/μm,横向刚度分别增加11.5%和13.1%。从图6和图7还可以看出,在采用常规倒角支持辊时,弯辊力调节范围为219.95 μm,而采用CVR支持辊时,弯辊力调节范围变为231.80 μm,可见,采用CVR辊形后既增加了刚性特性,又兼顾了柔性。

1—CON, Fw=0 MN; 2—CVR, Fw=0 MN;

3—CON, Fw=1.5 MN; 4—CVR, Fw=1.5 MN;

图7 常规辊形和CVR辊形的辊缝刚度特性

Fig.7 Roll gap stiffness characteristics between conventional contour and CVR contour

4.3 辊间接触压力

辊间接触压力分布不均匀度和峰值,可用来衡量轧机及其板形控制手段的使用性能,反映轧制过程中轧辊表面磨损分布程度和轧辊辊身产生边部剥落的可能性。辊间接触压力分布不均匀度表示沿接触线长度方向辊间压力的最大值和其平均值的比值。常规支持辊/ CVC工作辊和CVR支持辊/CVC工作辊2种辊形配置在带钢宽度为1.55 m,轧制力为18.6 MN,窜辊为负的最大位置150 mm,弯辊力为1.5 MN工况下,在支持辊服役前期的辊间接触压力分布不均匀度分别为2.13和1.53;2种辊形配置在服役前期的辊间接触压力峰值分别为1.415 GPa和1.025 GPa;服役后期2种配置的辊间接触压力分布不均匀度分别为2.68和1.90;服役后期的辊间接触压力峰值分别可达1.96 GPa和1.48 GPa。采用CVR辊形后辊间接触压力分布不均匀度在服役前后期分别下降28.17%和29.10%,辊间压力峰值分别下降27.56%和24.49%。因此,CVR可以明显改善辊间压力分布情况,在轧制过程中可稳定发挥其板形控制性能,并有利于减小轧辊辊身边部产生剥落的可能性,提高轧制过程的稳定性。

5 CVR的轧制试验及应用效果

为了验证所设计支持辊CVR的性能,并在2250热连轧机精轧F3机架上进行上机轧制试验,投入连续工业应用。图8所示为CVR上机轧制和实验下机后实测辊形。这里通过轧辊自保持参数Rtc来评价改进前后支持辊的自保持能力[15],得出:采用CVR后,F3上支持辊的轧辊自保持参数Rtc由原来的86.9%提高到91.6%,F3下支持辊的轧辊自保持参数Rtc由原来的79.5%提高到88.3%;改进后的辊形磨损趋于均匀化,磨损辊形具有良好的保持性。由此可证明,采用CVR支持辊后,改善了辊间接触压力分布,有效降低了辊间压力尖峰,从而避免了宏观表面疲劳失效的过早形成,新辊形稳定,其性能比原支持辊性能优良。

图8 2250热连轧机F3支持辊实测辊形对比

Fig.8 Comparison among backup roll contours before and after service on No.3 stand of 2250 hot rolling mill

6 结 论

a. 在2250热连轧机原辊形配置情况下,支持辊存在磨损严重、不均匀且出现剥落问题。其磨损分布形式呈现近似“S”形。在原辊形配置下,辊间接触压力分布不均是导致支持辊的磨损不均的主要原因。

b. 针对2250目前的辊形配置情况及存在的问题,提出了新的支持辊辊形CVR,采用通用有限元ANSYS建立了三维辊系变形模型,通过仿真计算,发现CVR不仅增加了弯辊力的调控功效和横向刚度特性,而且采用CVR后可以明显降低辊间压力峰值和辊间接触压力分布不均匀度。

c. 对设计的CVR进行工业试验,现场实际结果证明CVR具有很强的保持性,可稳定发挥其性能,现已应用于大型工业轧机实际生产,并可推广应用到其他同类轧机中。

参考文献:

[1] 曹建国, 张 杰, 陈先霖, 等. 宽带钢热连轧机选型配置与板形控制[J]. 钢铁, 2005, 40(6): 40-43.

CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Selection of strip mill configuration and shape control[J]. Iron and Steel, 2005, 40(6): 40-43.

[2] 陈先霖. 宽带钢冷连轧机的机型设计问题[C]//2005年中国钢铁年会论文集. 北京: 冶金工业出版社, 2005: 511-514.

CHEN Xian-lin. Strip mill configuration design of cold tandem mills[C]//CSM 2005 Annual Meeting Proceedings. Beijing: Metallurgy Industry Press, 2005: 511-514.

[3] 何安瑞, 曹建国, 吴庆海, 等. 热轧精轧机组变接触支持辊综合性能研究[J]. 上海金属, 2001, 23(1): 14-17.

HE An-rui, CAO Jian-guo, WU Qing-hai, et al. Study on comprehensive function of varying contact-length backup roll in finishing mill of hot rolling[J]. Shanghai Metals, 2001, 23(1): 14-17.

[4] 何安瑞, 张清东, 曹建国, 等. 宽带钢热轧支持辊辊形变化对板形的影响[J]. 北京科技大学学报, 1999, 21(6): 565-567.

HE An-rui, ZHANG Qing-dong, CAO Jian-guo, et al. Effect of back-up roll profile in hot wide strip mill on the strip profile and flatness[J]. Journal of University of Science and Technology Beijing, 1999, 21(6): 565-567.

[5] 何安瑞, 张清东, 张 杰, 等. 板带钢热轧支持辊不均匀磨损及其解决措施[J]. 上海金属, 2000, 22(2): 19-22.

HE An-rui, ZHANG Qing-dong, ZHANG Jie, et al. Non-uniform wear of backup rolls in hot strip rolling and its solution measurement[J]. Shanghai Metals, 2000, 22(2): 19-22.

[6] 窦 鹏, 李友国, 梁开明, 等. CVC热轧机支持辊接触应力有限元分析[J]. 清华大学学报: 自然科学版, 2005, 45(12): 1668-1671.

DOU Peng, LI You-guo, LIANG Kai-ming, et al. Finite element analysis of contact stress on the backup roll of CVC hot rolling mills[J]. Journal of Tsinghua University: Science and Technology, 2005, 45(12): 1668-1671.

[7] 杨 荃, 陈先霖, 徐耀寰, 等. 应用变接触长度支持辊提高板形综合调控能力[J]. 钢铁, 1995, 30(2): 48-51.

YANG Quan, CHEN Xian-lin, XU Yao-huan, et al. Applying VCL backup-roll to raise the control level of strip shape[J]. Iron and Steel, 1995, 30(2): 48-51.

[8] CHEN Xian-lin. Varying contact back-up roll for improved strip flatness[J]. Steel Technology International, 1994, 95: 174-178.

[9] CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Control of roll contour for strip profile and flatness in hot rolling[C]//44th Mechanical Working and Steel Processing Conference Proceeding. Florida, 2002: 1001-1010.

[10] 何安瑞, 张清东, 许健勇, 等. 1 800 mm虚拟轧机板形控制性能[J]. 北京科技大学学报, 2004, 26(1): 91-94.

HE An-rui, ZHANG Qing-dong, XU Jian-yong, et al. Shape control performance of 1 800 mm virtual mills[J]. Journal of University of Science and Technology Beijing, 2004, 26(1): 91-94.

[11] 陈先霖, 张 杰, 张清东, 等. 宽带钢热连轧机板形控制系统的开发[J]. 钢铁, 2000, 35(7): 28-33.

CHEN Xian-lin, ZHANG Jie, ZHANG Qing-dong, et al. Development in profile and flatness control system of hot strip mills[J]. Iron and Steel, 2000, 35(7): 28-33.

[12] 杨光辉, 曹建国, 张 杰, 等. SmartCrown四辊冷连轧机工作辊辊形[J]. 北京科技大学学报, 2006, 28(7): 669-671.

YANG Guang-hui, CAO Jian-guo, ZHANG Jie, et al. SmartCrown work roll contour of a 4-hi tandem cold rolling mill[J]. Journal of University of Science and Technology Beijing, 2006, 28(7): 669-671.

[13] 贾生晖, 曹建国, 张 杰, 等. 冷连轧机SmartCrown轧辊磨损辊形对板形调控能力影响[J]. 北京科技大学学报, 2006, 28(5): 468-470.

JIA Sheng-hui, CAO Jian-guo, ZHANG Jie, et al. Effect of SmartCrown work roll wear contour pattern on controllability of profile and flatness in tanden cold rolling mills[J]. Journal of University of Science and Technology Beijing, 2006, 28(5): 468-470.

[14] 鲁海涛, 曹建国, 张 杰, 等. 冷连轧带钢单锥度辊边降控制[J]. 北京科技大学学报, 2006, 28(8): 774-777.

LU Hai-tao, CAO Jian-guo, ZHANG Jie, et al. Edge drop control of a taper roll during continuous cold rolling[J]. Journal of University of Science and Technology Beijing, 2006, 28(8): 774-777.

[15] 曹建国, 陈先霖, 张清东, 等. 宽带钢热轧机轧辊磨损与辊形评价[J]. 北京科技大学学报, 1999, 21(2): 188-190.

CAO Jian-guo, CHEN Xian-lin, ZHANG Qing-dong, et al. Roll wear pattern and appraisal of roll contour in hot wide strip mill[J]. Journal of University of Science and Technology Beijing, 1999, 21(2): 188-190.

收稿日期:2006-11-17

基金项目:北京科技大学科技发展专项基金资助项目(20050311890)

作者简介:郝建伟(1979-),男,河北石家庄人,博士研究生,从事板带轧机行为与控制研究

通讯作者:郝建伟, 男, 博士研究生; 电话: 010-62334898; E-mail: haojw888@163.com