DOI:10.19476/j.ysxb.1004.0609.2019.03.02

车用6061-T5铝合金的力学特性及各向异性硬化行为的屈服准则

杜汉斌1,杨海峰2,胡峥楠1,肖海涛1,宋叶红1,杨 震1,李志刚2

(1. 浙江吉利汽车研究院有限公司,宁波 315000;

2. 北京交通大学 机械与电子控制工程学院,北京 100044)

摘 要:对车用6061-T5铝合金材料进行了拉伸和剪切力学试验研究,获取了不同应变下与挤压方向成不同角度的屈服应力和各向异性系数,分析了材料的各向异性特征;并在此基础之上,使用Hill1948和Karafillis-Boyce (K-B)两种各向异性塑性模型对材料进行了标定研究,发现两种屈服准则能够对特定应变下的单拉屈服应力进行较好的预测,但标定的方程系数随不同塑性应变发生明显变化,因此,为了揭示标定的屈服准则系数随塑性应变的变化规律以便完整描述铝合金的硬化特性,将上述两种屈服准则的系数表达成塑性应变的函数关系式,使得改进后的模型能够准确地描述6061-T5铝合金断裂前的完整力学特征。

关键词:6061-T5铝合金型材;屈服行为;硬化特性;各向异性;屈服准则

文章编号:1004-0609(2019)-03-0439-10 中图分类号:TG146 文献标志码:A

随着汽车工业的发展和对环保意识的提升,世界各国都在致力于汽车轻量化技术的研究,以应对当前严峻的能源和环境压力[1]。铝及铝合金具有密度小、导电性好、耐蚀性强、散热性好、易于加工和可重复利用等特点,更重要的是其具有高的比强度。铝合金、镁合金等轻量化结构材料正在逐步取代传统的结构材料如低碳钢[2],铝合金材料以其具有的优势必将在汽车轻量化进程的研究中发挥重要的作用。在汽车设计领域,数值模拟及优化是一种经济有效的方法,而能够很好地描述材料力学特性的弹塑性本构模型是进行有限元仿真的基础。因此,发展适用于6061-T5铝合金的本构模型,对6061-T5铝合金在汽车方面的应用具有重要意义。

屈服是材料塑性行为一个关键特征,对于各向同性材料,经常使用经典的Von Mises屈服准则[3],但是挤压铝合金由于成型过程中工艺的影响,通常呈现出各向异性的特征,因此需要各向异性的屈服准则[4]来表征材料的屈服特性。HILL[5]通过将Von Mises屈服准则进行扩展,发展了第一个二次的正交各向异性屈服准则,由于其形式简单,系数的物理意义明确,在工程上得到广泛应用。为了进一步提高各向异性屈服准则的精度,相关学者在此后又发展了多种各向异性屈服准则[6]。其中通过对应力张量进行线性转换将各向同性方程扩展到各向异性是一种常见的方法,这种方法最早由BARAT等[7-8]使用,后来KARAFILLIS等[9]将这一方法进一步扩展。

关于铝合金的屈服行为,国内外已经有较多学者使用不同的屈服准则对其进行描述。如ZHANG等[10]使用Hill1948和Bron-Besson屈服准则对AA5086铝合金进行了标定比较;LADEMO等[11]对AA7108和AA6063铝合金使用不同标定方法对Hill1948、Barlat1989和Karafillis-Boyce屈服准则进行了标定研究;REYES等[12]使用Barlat1989和Yld2000-2d屈服准则对保险杠用AA7108、AA7003和AA6060铝合金进行了标定;孙成智等[13]研究了Hill 1948、Barlat 1989、Barlat91和Barlat96各向异性屈服准则对铝合金板成形过程的影响等。

上述研究通常是关注铝合金初始屈服的各向异性特征,而没有对随着塑性应变发生变化的各向异性进行描述,而实际上多种铝合金存在这种畸变硬化特征,LOPES等[14]和KUWABARA等[15]分别研究发现,1050-O铝合金和6016-O铝合金的各向异性特征均随着应变硬化发生变化。为了研究6061-T5铝合金的力学特性及各向异性硬化规律,本文首先对6061-T5铝合金在准静态下进行了单轴拉伸和剪切试验,获取不同角度和不同应变下屈服应力和各向异性系数,表征了其力学特性;然后使用试验结果对Hill 1948和Karafillis-Boyce(K-B)两种屈服准则的参数进行了标定并评估了两种屈服准则对6061-T5铝合金的适用性;最后,将确定的屈服准则系数表示为塑性应变的函数,形成了能够表征材料硬化规律的新的弹塑性本构模型。本文的研究结果可以为6061-T5铝合金屈服准则的选择提供参考,并可以为其仿真模拟提供更为准确的本构模型。

1 实验

1.1 材料和试验采集方式

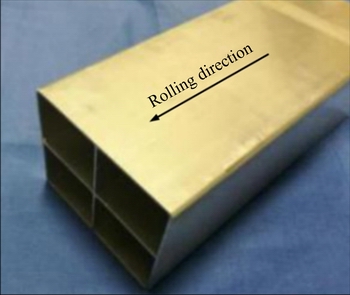

本文对挤压成型的“田”字型6061-T5铝合金型材进行了试验研究,如图1所示。材料的截面尺寸为125 mm×105 mm,厚度为2 mm。为了研究材料的基本力学特性和对本文研究模型的标定和检验,开展了应变率为0.001 s-1的单轴拉伸和简单剪切两种材料试验,所有试验均在载荷为20 kN的Instron万能试验机上进行,该实验机自带应力监测模块,可自动检测、记录试验过程中载荷曲线。传统的应变获取通常通过使用引伸计的方式,这样使得试件宽度方向和厚度方向的应变只能通过卡尺在某一点测量。因此,为了准确获取试件表面任一点的拉伸方向和宽度方向应变,试验采用非接触式数字图像处理技术(DIC)采集应变,具体步骤是首先在试件表面喷涂随机分布的散斑,然后使用垂直试件平面放置的DIC相机采集试验中的图像,最后使用VIC-2D软件处理拍摄的具有散斑的图像来从而计算出试件应变。

图1 6061-T5铝合金型材照片

Fig. 1 Profile of 6061-T5 aluminum alloy

1.2 单轴拉伸试验

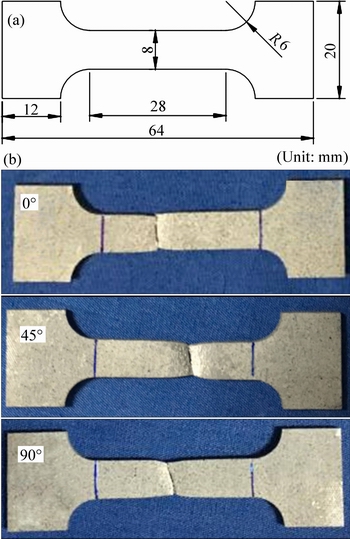

单轴拉伸试验件结构形式及主要尺寸如图2(a)所示。为了研究6061-T5挤压型材的各向异性特征,沿着型材挤压方向所成角度每间隔45°进行取样,共在3个方向进行取样,每个方向取样4件进行重复试验。

拉伸后不同方向的试件如图2(b)所示,从图中可以发现试验后3个方向的试件均发生了明显的颈缩现象,但不同方向的颈缩程度有所不同,45°和90°方向试件的颈缩程度相近,0°方向试件相比45°和90°颈缩程度较小。不同角度下的断口方向也有所不同,0°试件为直口断裂,与挤压方向近似垂直,而45°和90°试件为斜口断裂。

图2 单向拉伸试件和断口情况

Fig. 2 Uniaxial tensile specimen(a) and fracture surfaces of specimens at angles of 0°, 45° and 90°(b)

通过力传感器采集和DIC方法可以分别获取试件的工程应力( ),真实应变(

),真实应变( )和工程应变(

)和工程应变( ),之后通过式(1)将工程应力转换为真实应力(

),之后通过式(1)将工程应力转换为真实应力( )

)

(1)

(1)

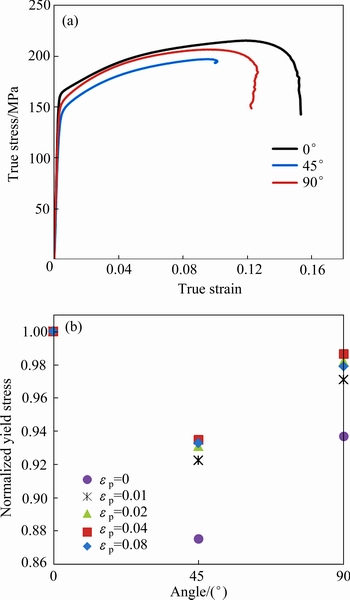

为此得到了材料在不同拉伸角度下的真实应变-应力曲线如图3(a)所示。从图3(a)中可以看出,整体上来说,0°方向试件的屈服应力最大,45°方向试件屈服应力最小,表明该挤压型材具有明显的各向异性特征。材料的初始屈服应力通过0.2%准则确定,为了反映材料在不同应变下的屈服及硬化特性和便于屈服准则的标定,本文分别提取了塑性应变为0、0.01、0.02、0.04和0.08下屈服应力并使用挤压方向屈服应力作为参考进行归一化处理。提取的不同角度在不同应变下归一化屈服应力如图3(b)所示。从图3(b)中可以发现,同一角度在不同应变下的点并不相等,而且同一角度在不同应变下点位置也具有一定的差异,尤其是塑性应变水平为0和0.01的数据与其他3个应变下相比偏离最大。这表明6061-T5铝合金不仅屈服应力具有各向异性的特点,而且在硬化方面也表现出各向异性的特征,尤其是在塑性应变0到0.02之间。

图3 单轴拉伸应力-应变曲线和特定塑性应变下归一化屈服应力

Fig. 3 Uniaxial tension true stress-strain curves(a) and normalized yield stress at specific plastic strains(b)

各向异性系数能够反映材料不同方向的塑性变形特征,定义为试件宽度方向和厚度方向塑性应变率的比值,由于采用的二维DIC只能获取试件表面应变信息,不能获取试件厚度方向的应变。因此根据塑性变形过程中的体积不变假设(见式(1)),得到的各向异性系数计算表达式如式(2)和(3)所示:

(2)

(2)

(3)

(3)

式中: 为试样宽度方向应变率;

为试样宽度方向应变率; 为试样厚度方向应变率;

为试样厚度方向应变率; 为试样拉伸方向应变率。

为试样拉伸方向应变率。

根据公式计算得到的6061-T5铝合金在不同角度下的各向异性系数随塑性应变的变化曲线和提取的特定塑性应变0、0.01、0.02、0.04、0.08下的各向异性系数如图4所示。从图4(a)中可以看出,3个角度下各向异性系数变化趋势基本一致,都是随着应变不断增加直至断裂,但是可以发现相比0°和90°方向,45°方向试件的各向异性系数增速相对缓慢。整体上,45°方向的各向异性系数最大,0°方向最小,约为45°方向的1/2。从各向异性系数可以看出,6061-T5铝合金在塑性流动方面同样具有各向异性特征。

图4 单轴拉伸塑性应变-各向异性系数曲线和特定塑性应变下单各向异性系数

Fig. 4 Uniaxial tension plastic strain-Lankford ratio curves(a) and Lankford ratios at specific plastic strains(b)

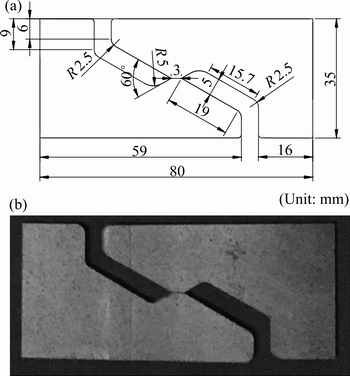

1.3 剪切试验

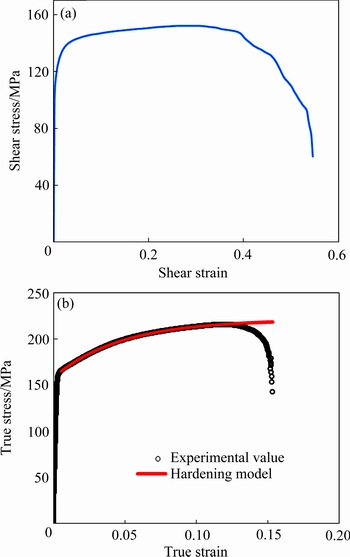

为了检验标定后的模型对剪切应力的预测效果,本文对6061-T5铝合金沿挤压方向进行了剪切试验,试件形状及尺寸和试验后试件如图5所示。从图5(b)中可以看出,在试件断裂前没有发生失稳现象,断裂面沿着变形区两侧U型缺口之间近似直线裂开,断口形貌光滑。试验得到剪切应力应变曲线和提取的0、0.01、0.02、0.04和0.08塑性应变下归一化剪切屈服应力如图6所示。从图6(a)的应力应变曲线可以看出,随着塑性应变的增加,6061-T5铝合金在剪切工况下的强化趋势并不明显,且从图(b)中可以看出强化趋势与单拉工况并不相同。

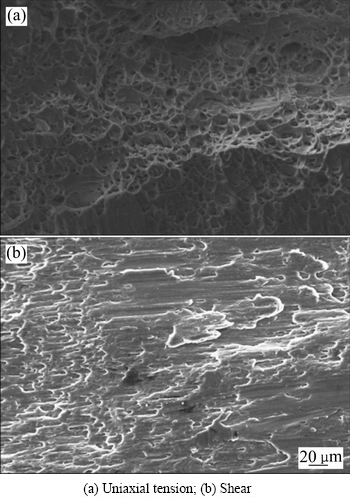

1.4 断口分析与比较

为了进一步理解6061铝合金在单轴拉伸和剪切工况下的断裂机制和两者之间的区别,本文对0°下单轴拉伸试件和剪切试件断口进行了SEM分析,结果如图7所示。从图7(a)中可以看出,准静态单轴拉伸试件中心观察区域属于典型的微孔洞聚集型断裂。可以认为,材料的断裂就是由孔洞不断形核、长大、聚集,产生大大小小的密集的韧窝,最终导致材料丧失承载能力。与单轴拉伸的韧窝断裂的断口形貌相比,剪切断裂的断口形貌的显著特点是其断口上几乎没有韧窝,是由众多的细小的剪切面组成。说明该剪切试样的断裂方式几乎是在剪应力作用下完成的。理论上来说,断口上韧窝的大小与应力三轴度( )有关, 应力三轴度越大,为空洞长大提供的驱动力越大,因此断口上等轴型韧窝所占的面积越大。对于纯剪切实验,应力三轴度接近于0,几乎没有为微空洞的长大提供驱动力,因此,断口上几乎没有韧窝的存在,而是由大量平滑细小的剪切面组成。

)有关, 应力三轴度越大,为空洞长大提供的驱动力越大,因此断口上等轴型韧窝所占的面积越大。对于纯剪切实验,应力三轴度接近于0,几乎没有为微空洞的长大提供驱动力,因此,断口上几乎没有韧窝的存在,而是由大量平滑细小的剪切面组成。

图5 剪切试验试件尺寸及断口照片

Fig. 5 Size of shear specimen(a) and fracture surface photo of specimen(b)

图6 剪切应力-应变曲线和特定塑性应变下归一化屈服应力

Fig. 6 Shear stress-strain curve(a) and normalized yield stress at specific plastic strains(b)

图7 6061-T5铝合金不同工况下的断口形貌

Fig. 7 Fracture morphologies of 6061-T5 aluminum alloy under different conditions

2 各向异性塑性模型

2.1 本构方程和硬化模型

为了描述断裂前材料的应力应变特性,需要使用弹塑性本构模型,屈服准则和塑性势是其中两个基础部分,其中屈服准则用于区分材料弹性部分和塑性部分,塑性势函数梯度即流动法则用来描述塑性应变矢量的增量演化。如果塑性势函数与屈服函数相同,则称为关联流动准则,反之,叫做非关联流动法则。

因为材料弹性应变相对塑性应变很小,所以可将总应变率分解为弹性部分( )和塑性部分(

)和塑性部分( ):

):

(4)

(4)

弹性部分的应力变化率可表示为

(5)

(5)

式中:Ce为弹性模量的矩阵表示。

根据塑性理论并采用关联流动准则,应力与塑性应变率的关系可以表示为

(6)

(6)

式中: 是正的标量比例系数;p为塑性势函数/屈服函数。从宏观上讲,与挤压方向成不同角度单轴拉伸屈服应力用来表示材料的各向异性,从本文1.2节可以看出,6061-T5铝合金的屈服应力各向异性特征在塑性应变为0.02~0.08几乎保持不变,符合各向同性硬化的特征,而在塑性应变为0~0.02时,屈服应力的各向异性特征随着塑性应变增加发生变化,呈现出畸变硬化。这也就意味着材料的屈服面不再随着应变的增加成比例增大,而且屈服面的形状也会发生变化,为了表示材料的这种硬化特征,屈服方程中的系数也要随着塑性应变发生变化。因此,屈服准则可以表达成以下形式

是正的标量比例系数;p为塑性势函数/屈服函数。从宏观上讲,与挤压方向成不同角度单轴拉伸屈服应力用来表示材料的各向异性,从本文1.2节可以看出,6061-T5铝合金的屈服应力各向异性特征在塑性应变为0.02~0.08几乎保持不变,符合各向同性硬化的特征,而在塑性应变为0~0.02时,屈服应力的各向异性特征随着塑性应变增加发生变化,呈现出畸变硬化。这也就意味着材料的屈服面不再随着应变的增加成比例增大,而且屈服面的形状也会发生变化,为了表示材料的这种硬化特征,屈服方程中的系数也要随着塑性应变发生变化。因此,屈服准则可以表达成以下形式

(7)

(7)

式中: 为满足外凸性的屈服方程;

为满足外凸性的屈服方程; 为等效塑性应变;c为屈服方程中的系数。

为等效塑性应变;c为屈服方程中的系数。 表示各向同性的硬化法则(挤压方向硬化曲线),本文采用多元硬化模型[11]:

表示各向同性的硬化法则(挤压方向硬化曲线),本文采用多元硬化模型[11]:

(8)

(8)

式中:Y为初始屈服应力;Ak和Bk为应变硬化系数。

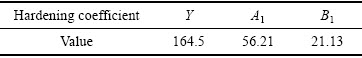

通过最小二乘法得到的硬化模型对挤压方向的应力-塑性应变试验数据拟合效果和试验值对比如图8所示。从图8中可以看出,该硬化模型能够很好地表达挤压方向的试验数据。表1所列为使用挤压方向试验数据标定该硬化模型的系数,本文只使用了一个指数项即k=1。

表1 多元硬化模型系数

Table 1 Coefficients of multi-component strain-hardening model

图8 硬化模型预测与试验值比较

Fig. 8 Comparison between model prediction and test

2.2 各向异性屈服准则

HILL[5]提出了一个六参数的各向异性屈服准则,用来描述具有正交各向异性的材料,该屈服准则可表示为如下二次函数的形式:

(9)

(9)

式中:F、G、H、L、M、N为与材料各向异性相关的系数;x、y、z表示材料的各向异性主轴。对于板材,x轴表示挤压方向,y轴为面内垂直于挤压方向,z轴为板材的厚度方向。 为参考屈服应力,通常取挤压方向屈服应力。

为参考屈服应力,通常取挤压方向屈服应力。

在平面应力状态下,方程可简化为包含4个参数的形式:

(10)

(10)

KARAFILLIS等[9]利用加权法将两个各向同性屈服准则组合到一起,同时利用一个线性转换实现从各向同性到各向异性的转换,提出了如下的各向异性屈服准则(以下简称K-B屈服准则)

(11)

(11)

其中

(12)

(12)

式中: 、

、 、

、 为与各向同性塑性(Isotropic plasticity equivalent, IPE)相关的应力偏张量的主值,在平面应力状态下(

为与各向同性塑性(Isotropic plasticity equivalent, IPE)相关的应力偏张量的主值,在平面应力状态下( ,

, ,

, )这些值表示为

)这些值表示为

;

; (13)

(13)

其中

;

; ;

;

(14)

(14)

式中:c、C、 、

、 、

、 和m为材料参数。指数m可以和晶体塑性理论结合起来,通过改变指数m调整屈服面的形状。因此,当c=0时,对于面心立方材料(FCC)材料,m取8,对于体心立方材料(BCC),m取6。因此,根据参考文献[16],本文对于铝合金取c=0,m=8。

和m为材料参数。指数m可以和晶体塑性理论结合起来,通过改变指数m调整屈服面的形状。因此,当c=0时,对于面心立方材料(FCC)材料,m取8,对于体心立方材料(BCC),m取6。因此,根据参考文献[16],本文对于铝合金取c=0,m=8。

使用单轴拉伸试验结果进行模型的标定,由于关联流动准则被使用,因此,单轴拉伸试验得到的屈服应力和各向异性系数都可以用来进行Hill1948和K-B屈服准则标定。使用与挤压方向成0°、45°和90°方向的归一化单拉屈服应力 、

、 、

、 和挤压方向的各向异性系数r0来标定上述两个屈服准则。Hill1948屈服准则由于其形式简单,系数物理意义明确,可直接通过解方程的方法得到系数。对于形式相对复杂的K-B屈服准则,将通过在Matlab中使用数值求解优化的方法使模型预测结果和上述试验数据之间的误差(

和挤压方向的各向异性系数r0来标定上述两个屈服准则。Hill1948屈服准则由于其形式简单,系数物理意义明确,可直接通过解方程的方法得到系数。对于形式相对复杂的K-B屈服准则,将通过在Matlab中使用数值求解优化的方法使模型预测结果和上述试验数据之间的误差( )达到最小从而确定最优的屈服方程的系数。

)达到最小从而确定最优的屈服方程的系数。

(15)

(15)

式中: 和

和 分别表示屈服准则对单拉屈服应力和各向异性系数的预测;

分别表示屈服准则对单拉屈服应力和各向异性系数的预测; 和

和 为对应的试验值;w为权重,在本文中取1。

为对应的试验值;w为权重,在本文中取1。

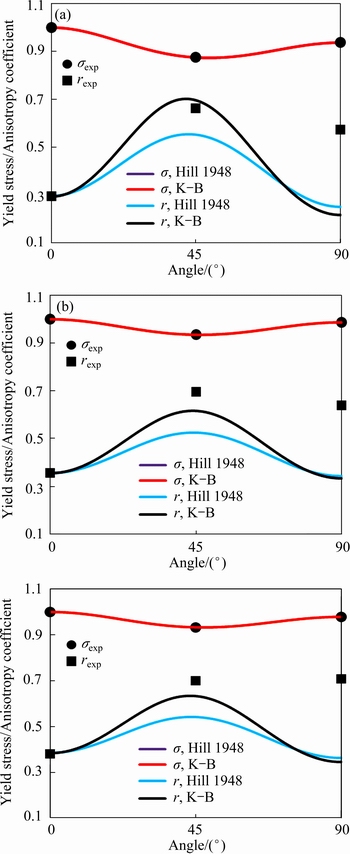

图9 Hill1948和K-B屈服准则对屈服应力和各向异性系数的预测结果和试验值比较

Fig. 9 Comparison between experiment and prediction results of yield stress and anisotropy coefficient by Hill1948 and K-B yield criteria

图9所示为Hill 1948和K-B屈服准则对不同应变下单拉屈服应力和各向异性系数预测和试验值,由于在不同应变下两个屈服准则对于试验数据的拟合效果相近,因此本文只展示了塑性应变为0、0.04和0.08的预测效果图。从图中可以看出,3个应变下两个屈服准则对单轴拉伸屈服应力的预测效果几乎完全相同,但是对于各向异性系数,Hill 1948和K-B屈服准则对0°和90°各项系数预测效果相近,但是K-B屈服准则对于45°各向异性系数的预测效果要明显优于Hill 1948屈服准则。

Hill 1948和K-B屈服准则在0,0.04和0.08塑性应变下对6061-T5铝合金预测的在平面 的屈服面如图10所示。从图10中可以看出,两个屈服准则预测不同应变下的屈服面的形状完全不同,Hill948屈服面呈现椭圆形,而K-B屈服面为近似六边形。对于剪切屈服应力,两个屈服准则的预测结果都存在一定的误差。

的屈服面如图10所示。从图10中可以看出,两个屈服准则预测不同应变下的屈服面的形状完全不同,Hill948屈服面呈现椭圆形,而K-B屈服面为近似六边形。对于剪切屈服应力,两个屈服准则的预测结果都存在一定的误差。

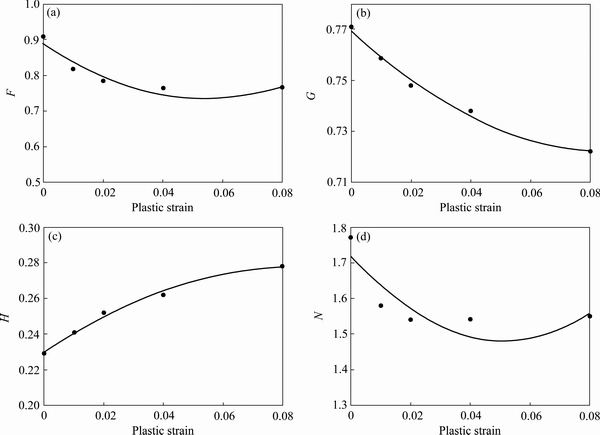

Hill 1948屈服准则中的系数F、G、H、N在塑性应变0、0.01、0.02、0.04和0.08下标定结果如图11所示,从图11中可以看出,不同应变下模型的系数发生了一定的变化,这种变化可能是由于材料在硬化过程中微观结构发生了变化,而这种变化反过来会引起材料屈服面的变化。为了描述屈服面的这种变化和获得任意应变下材料的屈服面,使用了如下的二次多项式函数式(16)对Hill 1948屈服准则在不同塑性应变下的系数进行了拟合。拟合效果和系数如图10和表2所示。

(16)

(16)

图10 Hill1948和K-B屈服准则在不同塑性应变下的屈服面( )

)

Fig. 10 Yield surfaces of Hill 1948(a) and K-B yield criteria at specific plastic strains ( )(b)

)(b)

图11 函数(16)对Hill1948屈服准则系数的预测曲线和试验值

Fig. 11 Prediction curve of function (16) on coefficients of Hill 1948 and comparison with experiments

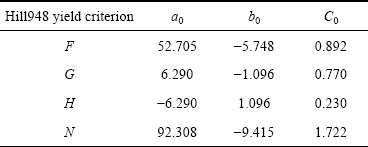

表2 二次多项式函数中的系数

Table 2 Yield criterion coefficients

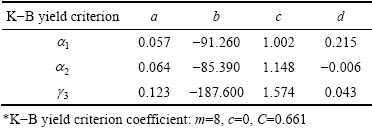

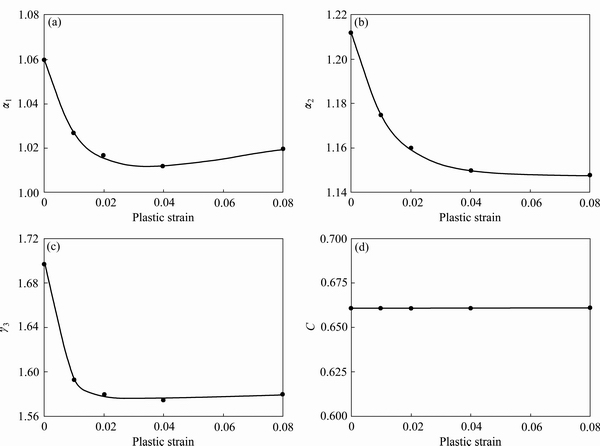

K-B屈服准则在塑性应变0,0.04和0.08下标定的系数如图12所示,从图中可以看出不同应变下模型的系数C保持不变,但是K-B屈服准则的其他3个系数 、

、 和均与塑性应变表现出了一定的变化关系。针对K-B屈服准则的系数,本文提出了如下形式的指数函数式(17)。拟合效果和系数如图12和表3所示,可以看出该函数很好拟合了准则系数在不同应变下的试验结果。

和均与塑性应变表现出了一定的变化关系。针对K-B屈服准则的系数,本文提出了如下形式的指数函数式(17)。拟合效果和系数如图12和表3所示,可以看出该函数很好拟合了准则系数在不同应变下的试验结果。

(17)

(17)

表3 指数函数中的系数

Table 3 Coefficients of exponential function

3 分析和讨论

图12 函数(17)对K-B屈服准则系数的预测曲线和试验值比较

Fig. 12 Prediction curves of function (17) on coefficients of K-B and comparison with experiments

本文对6061-T5铝合金在准静态工况下进行了单轴拉伸和剪切试验并对Hill1948和K-B两个屈服准则进行了标定研究。使用了关联流动准则,因此屈服应力和各向异性系数都可用来进行屈服准则的标定,由于本文关注6061-T5铝合金的屈服应力的硬化过程,因此使用了单拉试验得到的3个方向的屈服应力和挤压方向的各向异性系数进行了Hill1948和K-B两个屈服准则的标定。从2.1节中屈服准则对不同方向的屈服应力和各向异性系数的预测效果可以看出,两个屈服准则对屈服应力的预测效果很好,但是对各向异性系数的预测效果较差。下一步工作将采用非关联流动准则使用两个不同的函数分别预测屈服应力和各向异性系数以达到更加理想的预测效果。除此之外,对于屈服准则的标定来说,单轴拉伸试验是一种简单有效的试验方式。但是如果要想更加准确地获得材料在双轴工况下的屈服面,需要使用双拉试验数据进行屈服准则的标定和验证。因此,后期可以考虑通过增加十字拉伸试验或缺口试验来获得双拉工况下试验数据并将这些数据加入到模型系数的标定当中。

4 结论

1) 6061-T5铝合金在屈服应力和塑性流动均表现出了各向异性特征,不同角度下的拉伸后的试件的断口形貌也不相同,挤压方向为直断口,而与挤压方向成45°和90°的试件为斜断口。

2) 使用单轴拉伸试验得到的不同塑性应变下的试验数据对两种关联流动屈服准则Hill1948和K-B进行了标定,结果表明两种屈服准则能够对特定应变下的单拉屈服应力进行较好的预测。

3) 6061-T5铝合金在塑性应变为0到0.02之间的应变硬化呈现出畸变硬化特征,而在塑性应变0.02至0.08基本上为各向同性硬化,为了描述该铝合金的这种硬化特征,在上述两个屈服准则的基础上通过使用二次函数和指数函数分别将两种屈服准则系数与塑性应变建立函数关系,使得改进后的模型能够完整地描述6061-T5铝合金断裂前的力学行为。

REFERENCES

[1] 陈树海, 马 柯, 黄继华, 夏 军, 张 华, 赵兴科. 钢/铝异种金属双熔池TIG熔钎焊接头的显微组织与力学性能[J]. 中国有色金属学报, 2011, 21(12): 3076-3081.

CHEN Shu-hai, MA Ke, HUANG Ji-hua, XIA Jun, ZHANG Hua, ZHAO Xing-ke. Microstructure and mechanical property of joint by TIG welding-brazing with dual weld pools for steel/aluminum dissimilar metals[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(12): 3076-3081.

[2] 叶延洪, 何 静, 蔡建鹏, 孙加民, 邓德安. 6061-T651铝合金薄板接头的焊接变形[J]. 中国有色金属学报, 2014, 24(10): 2435-2442.

YE Yan-hong, HE Jing, CAI Jian-peng, SUN Jia-min, DENG De-an. Weldingdeformationsof 6061 T651 Al alloythin platejoints[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2435-2442.

[3] MISES R. Mechanics of solids in plastic state[J]. Goettingen News Mathematical Physics, 1913, 4: 582-592. (in German)

[4] ESMAEILIZADEH R, KHALILI K, MOHAMMADSADEGHI B, ARABI H. Simulated and experimental investigation of stretch sheet forming of commercial AA1200 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 484-490.

[5] HILL R. A theory of the yielding and plastic flow of anisotropic metals[J]. Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences, 1948, 193(1033): 281-297.

[6] BANABIC D. 金属板材成形工艺:本构模型及数值模拟[M]. 何祝斌, 林艳丽, 刘建光, 译. 北京: 科学出版社, 2015.

BANABIC D. Sheet metal forming processes: constitutive modeling and numerical simulation[M]. HE Zhu-bin, LIN Yan-li, LIU Jian-guang, transl. Beijing: Science Press, 2015.

[7] BARLAT F, LIAN K. Plastic behavior and stretchability of sheet metals. Part Ⅰ: A yield function for orthotropic sheets under plane stress conditions[J]. International Journal of Plasticity, 1989, 5(1): 51-66.

[8] BARLAT F, LEGE D J, BREM J C. A six-component yield function for anisotropic materials[J]. International Journal of Plasticity, 1991, 7(7): 693-712.

[9] KARAFILLIS A P, BOYCE M C. A general anisotropic yield criterion using bounds and a transformation weighting tensor[J]. J Mech Phys Solids, 1993, 41(12): 1859-1886.

[10] ZHANG S Y, LEOTOING L, GUINES D, THUILLIER S. Calibration of material parameters of anisotropic yield criterion with conventional tests and biaxial test[J]. Key Engineering Materials, 2013, 554/557(1/4): 2111-2117.

[11] LADEMO O G, HOPPERSTAD O S, LANGSETH M. An evaluation of yield criteria and flow rules for aluminium alloys[J]. International Journal of Plasticity, 1999, 15(2): 191-208.

[12] REYES A, HOPPERSTAD O S, LADEMO O G, LANGSETH M. Modeling of textured aluminum alloys used in a bumper system: Material tests and characterization[J]. Computational Materials Science, 2006, 37(3): 246-268.

[13] 孙成智, 陈关龙, 林忠钦, 赵亦希. 各向异性屈服准则对铝合金板成形预测精度的影响[J]. 塑性工程学报, 2004, 11(3): 59-63.

SUN Cheng-zhi, CHEN Guan-long, LIN Zhong-qin, ZHAO Yi-xi. Effects of anisotropic yield criteria on the prediction of sheet metal forming of aluminum alloy sheet[J]. Journal of Plasticity Engineering, 2004, 11(3): 59-63.

[14] LOPESA B, BARLAT F, GRACIO J J, JFF D, RAUCH E F. Effect of texture and microstructure on strain hardening anisotropy for aluminum deformed in uniaxial tension and simple shear[J]. International Journal of Plasticity, 2003,19(1): 1-22.

[15] KUWABARA T, MORI T, ASANO M, HAKOYAMA T, BARLAT F. Material modeling of 6016-O and 6016-T4 aluminum alloy sheets and application to hole expansion forming simulation[J]. International Journal of Plasticity, 2017, 93:164-186.

[16] CVITANIC V, VLAK F, LOZINA Z. A finite element formulation based on non-associated plasticity for sheet metal forming[J]. International Journal of Plasticity, 2008, 24(4): 646-687.

Mechanical properties and yield criteria with anisotropic hardening of 6061-T5 aluminum alloy used in vehicle

DU Han-bin1, YANG Hai-feng2, HU Zheng-nan1, XIAO Hai-tao1, SONG Ye-hong1, YANG Zhen1, LI Zhi-gang2

(1. Zhejiang Geely Automobile Research Institute Co., Ltd., Ningbo 315000, China;

2.School of Mechanical, Electronic and Control Engineering, Beijing Jiaotong University, Beijing 100044, China)

Abstract: The uniaxial and shear tests were conducted on 6061-T5 aluminum alloy extruded profiles which were widely used in the vehicle components. The yield stress and anisotropic coefficient at different strains and angles with extrusion direction were obtained and its anisotropic behavior were represented. Furthermore, two plastic criteria, Hill1948 and Karafillis and Boyce (K-B), were adopted to describe the material plastic behavior and the coefficients of the plastic models were calibrated. The results show that these two plastic criteria can predict the tension yield stress at specific strains fairly well, whereas, the coefficient values change largely with plastic strain. Therefore, the changing law of the coefficients with plastic stain was investigated and the hardening characteristics were completely described, the coefficients of the plastic criteria were expressed as functions of plastic strain and the corresponding plastic criterion were revised, and the results illustrates that the improved plastic criterion can describe the complete plastic and hardening behavior of the material prior to fracture.

Key words: 6061-T5 aluminum alloy extruded profiles; plastic behavior; hardening characteristics; anisotropy; yield criterion

Foundation item: Project(M17L00040) supported by Zhejiang Key Laboratory of Automobile Safety Technology, China; Project(M17JB00120) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2018-03-01; Accepted date: 2018-08-28

Corresponding author: LI Zhi-gang; Tel: +86-13436980207; E-mail: zgli@bjtu.edu.cn

(编辑 李艳红)

基金项目:浙江省汽车安全技术研究重点实验室开放基金资助项目(M17L00040);中央高校基本科研业务费资助项目(M17JB00120)

收稿日期:2018-03-01;修订日期:2018-08-28

通信作者:李志刚,副教授,博士;电话:13436980207;E-mail:zgli@bjtu.edu.cn