表面自纳米化304L不锈钢/T2铜扩散连接

罗军,盛光敏,袁新建

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:采用高能喷丸(HESP)对304L不锈钢棒端面进行表面自纳米化(SSNC)处理,在850 ℃下将不锈钢与铜棒进行600 s脉冲加压扩散连接(PPDB)。利用金相显微镜和显微硬度仪对不锈钢棒喷丸端面进行表征,测试接头拉伸强度,对断口和接头剖面进行SEM和EDS分析,并计算Cu原子在不锈钢中的扩散系数。实验结果表明:经SSNC处理在不锈钢表层获得大约60 μm的剧烈塑性变形层。铜与经SSNC处理的不锈钢的接头平均抗拉强度达到228.2 MPa,达到铜基体的83%,比铜与未经SSNC处理的不锈钢的接头的抗拉强度提高20%;铜原子在经SSNC处理的不锈钢中的扩散系数达到8.5×10-14 m2/s,比在未经SSNC处理的不锈钢中高5倍。

关键词:表面自纳米化;扩散连接;扩散系数;不锈钢/铜

中图分类号:TG454 文献标志码:A 文章编号:1672-7207(2013)01-0055-05

Diffusion bonding of SSNC 304L/Cu

LUO Jun, SHENG Guangmin, YUAN Xinjian

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: A 304L austenitic stainless steel, surface self-nanocrystallized (SSNC) by high-energy shot peening (HESP), was studied by optical microscope and micro hardness tester. Original and SSNC 304L austenitic stainless steels were separately joined with copper through pulse-pressure diffusion bonding (PPDB) at 850 ℃ for 600 s. The joint strength was tested by a tensile machine, the longitudinal sections and tensile fractures of joints were analyzed by scanning electron microscope (SEM) and energy dispersive spectroscope (EDS). Additionally, the diffusion coefficient of Cu atom in 304L austenitic stainless steel was achieved. The results show that a severe plastic deformation layer, about 60 μm, was obtained after HESP. The average recorded tensile strength of SSNC 304L /Cu joints is equal to 228.2 MPa, which is 83% of that of Cu bar, 20% more than that of the original 304L/Cu. The diffusion coefficient of Cu atom in SSNC 304L is 8.5×10-14 m2/s, five times higher than that in original 304L.

Key words: surface self-nanocrystallization; diffusion bonding; diffusion coefficient; stainless steel/ copper

不锈钢既是耐蚀材料又是耐热材料,还可以作为低温材料、无磁材料、耐磨材料使用[1],而铜具有优良的导电性﹑导热性﹑延展性和耐蚀性,钢和铜的复合构件能在性能和经济上实现优势互补,具有良好的应用前景[2]。铜还常被用作不锈钢与异种材料间连接的中间层材料[3]。铜与铁在熔点、导热系数、线膨胀系数和力学性能等方面有很大差异,熔焊接头中由于残余应力较大而易导致变形和开裂[4]。相比之下,真空扩散焊作为一种固相连接技术,能获得较高质量和精度的接头,更适用于精密制造[5]。结构材料表面自纳米化技术近年来在异种材料的连接中得到广泛应用[6-7],其原理是利用非平衡处理增加表面层组织的自由能,在保持材料化学组成不变的前提下,获得一定厚度的纳米晶结构,目前常采用剧烈塑性变形技术实现[8-10]。纳米尺度的晶粒具有高体积分数的晶界,能够为原子扩散提供大量通道,从而可以显著提高原子的扩散系数[11]。韩靖等[12]将表面自纳米化技术应用于不锈钢/钛合金的真空扩散焊,改善界面间元素扩散并提高接头性能。目前,关于钢/铜异种金属间固相连接的研究主要集中于通过工艺改进以提高连接性能[13-14],而表面自纳米化技术在其中的应用尚未见报道。本文作者尝试经表面自纳米化处理的304L不锈钢与T2纯铜异种金属间真空条件下的脉冲加压扩散连接,研究结合界面结构与特性,分析表面自纳米化处理对界面原子扩散的影响,以期进一步改善钢/铜异种金属间固相连接性能。

1 试验材料及方法

试验所用材料为304L不锈钢和T2铜棒,直径均为Φ16 mm。铜棒的抗拉强度σb:约为275 MPa,伸长率δ10≥5%,伸长率δ5≥10%。用线切割方式截取长度为30 mm的304L不锈钢棒和T2铜棒,将所得试样在150#,280#,400#,600#,800#,1000#,1200 #以及1500#水砂纸依次打磨。利用气动喷丸技术对不锈钢样进行表面自纳米化处理。所采用的工艺为本课题组前期研究所得的优化工艺[15]:弹丸直径为1 mm,压力为0.6 MPa,时间为5 min,喷嘴与试样表面的距离为5 cm。喷丸后,喷丸面粗糙度增加,需将喷丸面打磨并抛光,保证2试样端面能紧密接触,以满足扩散连接的界面条件。

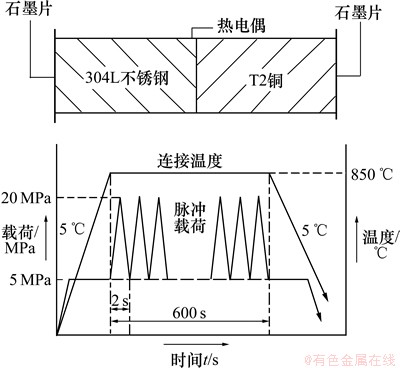

为探索表面自纳米化处理对接头性能的影响,在相同连接工艺条件下分别对喷丸和未喷丸的不锈钢与铜进行连接。连接实验在Gleeble-1500D型热模拟机上进行,其装配方式和工艺如图1所示。试验前对不锈钢和铜进行酸洗(条件为6% HCl,2% HF和92%水,室温,10 s)去除表面氧化膜,并用丙酮清洗表面,清除油脂。采用Ni-Cr、Ni-Al热电偶进行测温,热电偶焊于不锈钢侧距界面1 mm 处,为增强试样与夹具间的导电性,在两者之间加入石墨片。连接时的真空度为1×10-1 Pa,连接后的试样在400 ℃下退火1 h以消除连接残余内应力。

将拉伸试样直径加工为10 mm,用新三思CMT5105 型材料拉伸试验机进行拉伸,加载速率为0.5 mm/min。用OLYMPUS-GX41 型金相显微镜对不锈钢喷丸端纵剖面的组织进行观察,用Vega Tescan型电子扫描显微镜(SEM)、能谱仪(EDS)对拉伸断口和接头剖面的组织进行观察和分析。

图1 试样装配和脉冲加压扩散焊接工艺参数

Fig.1 Assembly of samples and technique parameters for pulsating impact diffusion bonding

2 实验结果及分析

2.1 纳米化不锈钢表征

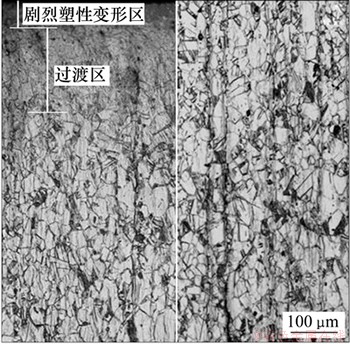

对于低层错能奥氏体不锈钢,剧烈塑性变形过程会引起孪生和应变诱导马氏体相变,通过孪晶分割及马氏体分割形成纳米晶粒组织,同时奥氏体转变为马氏体[16-17]。304L不锈钢属于低层错能奥氏体不锈钢,图2所示为喷丸试样纵剖面金相组织形貌。从图2可见:经过高能弹丸的反复冲击,不锈钢表面发生剧烈塑性变形。与原始组织相比,晶粒已急剧细化,从表面向基体延伸,晶粒细化程度越来越小。共获得约240 μm的塑性变形层,其中剧烈塑性变形层约为60 μm,过渡层约为180 μm。

图2 喷丸试样剖面金相组织形貌

Fig.2 Cross-section microstructure of shot peening sample

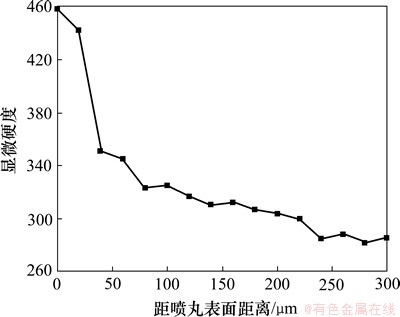

图3所示为经表面自纳米化处理不锈钢的显微硬度值变化曲线。从图3可见:在60 μm的范围内,不锈钢的显微硬度明显高于心部基体;而在60~240 μm的范围内,随着深度的增加,硬度缓慢减小;深度达到240 μm后,显微硬度已经与基体的硬度值相同。结合金相观测、显微硬度测试与本课题组前期研究成果[15],经过上述喷丸处理,在304L不锈钢端面得到纳米层。

图3 喷丸试样显微硬度随距离表面深度变化曲线

Fig.3 Microhardness of SSNC sample along depth from top surface

2.2 接头抗拉强度及断口分析

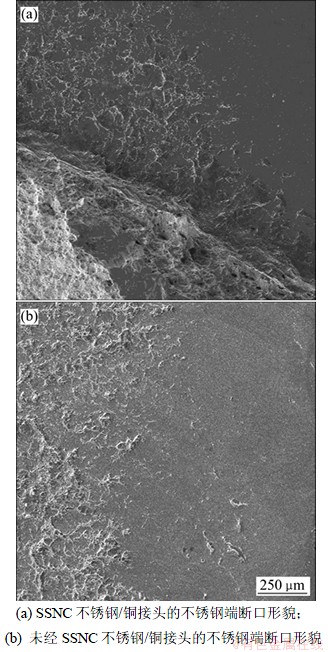

图4所示为温度T=850 ℃、脉冲压力P=5~20 MPa、脉冲次数N=300次、脉冲频率f=0.5 Hz、脉冲前保温时间t1=0 s、脉冲后保温时间t2=0 s,连接时间为600 s的接头断口的SEM形貌。对比图4(a)和(b)可见:在SSNC不锈钢/铜接头的不锈钢端断面上有大量铜存在;而未经SSNC的不锈钢/铜接头的不锈钢端断面上只有一些撕裂残留物。这说明在此连接工艺下,表面自纳米化能有效促进铁/铜原子间的相互扩散,从而提高接头性能。

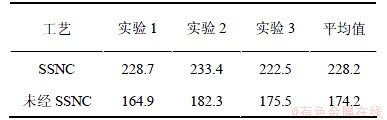

表1给出在相同连接工艺下,SSNC不锈钢/铜接头和未经SSNC的不锈钢/铜接头的抗拉强度。从表1中可知:经喷丸处理获得的平均接头强度比未经喷丸处理获得的接头强度高54 MPa,并达到T2铜棒的抗拉强度值(约为275 MPa)的83%,比铜与未经SSNC处理的不锈钢的接头的抗拉强度提高20%。3组经过喷丸处理的接头的抗拉强度均明显高于未经喷丸处理的接头抗拉强度,说明在此工艺条件下表面自纳米化对铁/铜原子间相互扩散的促进作用是普遍有效的。

图4 接头断口的SEM形貌

Fig.4 Tensile fractures SEM in joints

表1 接头抗拉强度

Table 1 Tensile strength of bonded joints MPa

2.3 接头剖面SEM及能谱分析

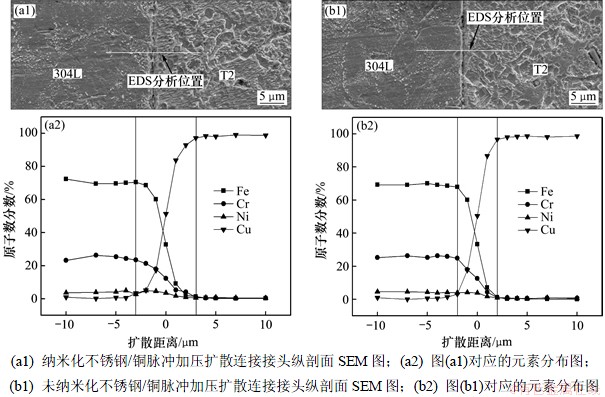

图5中(a1)~(a2), (b1)~(b2)分别为5 000倍下纳米化和未纳米化不锈钢/铜脉冲加压扩散连接接头纵剖面的SEM形貌及相对应的元素分布图。从SEM图中可以得出:

(1) 经喷丸处理的不锈钢/铜的结合处形成许多微连接,而未经喷丸处理的不锈钢/铜的结合处存在清晰缝隙。这是因为经喷丸处理后不锈钢端面的晶粒细小,具有高体积分数的晶界,能够为铜原子扩散提供大量通道因此在相同的工艺条件下,经喷丸处理的不锈钢/铜更易形成有效连接。

(2) 喷丸处理的不锈钢端界面局部存在微小晶粒。这是因为在850 ℃下,经喷丸处理的不锈钢发生回复再结晶并形成新的晶粒,这将在一定程度上削弱纳米化的作用。为进一步验证纳米化在此连接工艺条件下的有效性,计算铜原子在不锈钢中的扩散系数。

图5 连接接头剖面的SEM形貌及成分分布曲线

Fig.5 Longitudinal SEM and curves of composition in joint

铜原子向不锈钢扩散可以认为是在无限长物体中扩散,根据Cu-Fe二元相图[18],Cu-Fe间相互扩散不会形成新相,因而可以用菲克定律求出Cu元素的扩散系数。取界面位置为原点(x=0),结合材料本身特点可以确定:焊接时间t=0时,铜棒中Cu的初始摩尔浓度C1=100,不锈钢中Cu的初始浓度C2=0,仅扩散偶一侧存在原始浓度。此时可以采用式(1)计算扩散系数。

(1)

(1)

其中:D为Cu原子在扩散连接中的扩散系数;C为在x处Cu原子的摩尔浓度;t为扩散时间(取600 s);C0为铜棒中Cu原子的摩尔浓度。

令误差函数 ,根误差函数表查出Z的值就可以求出扩散系数:

,根误差函数表查出Z的值就可以求出扩散系数:

(2)

(2)

按上述方法计算出Cu原子在经表面自纳米化的304L不锈钢中的平均扩散系数Davg=8.5×10-14 m2/s,而未经表面自纳米化的不锈钢中Cu原子的扩散系数为Davg=1.4×10-14 m2/s。由此得出,不锈钢表面自纳米化处理对铜元素扩散具有显著影响。表面自纳米化处理与真空条件下的脉冲加压扩散相结合能有效促进304L不锈钢与T2纯铜异种金属间的连接。

3 结论

(1) 采用弹丸直径为1 mm、压力为0.6 MPa、时间为5 min、喷嘴与试样表面的距离为5 cm的喷丸工艺,在304L不锈钢喷丸端面获得大约60 μm厚的剧烈塑性变形层。

(2) 在连接时间t=600 s,连接温度为850 ℃的条件下,表面自纳米化304L不锈钢/铜的平均接头强度达到228.2 MPa,约为T2铜棒抗拉强度的83%,比未经处理的接头强度高54 MPa。

(3) 在连接时间t=600 s,连接温度为850 ℃的条件下,表面自纳米化处理将Cu原子在304L不锈钢中的扩散系数提高5倍。

参考文献:

[1] 肖纪美. 不锈钢的金属学问题[M]. 北京: 冶金工业出版社, 2006: 8-9.

XIAO Jimei. Metallography problems in stainless steels[M]. Beijing: Metallurgical Industry Press, 2006: 8-9.

[2] 张金库, 张伟强, 王大伟, 等. 钢、铜复合套筒堆焊方法研究[J]. 煤矿机械, 2010, 31(7): 90-92.

ZHANG Jinku, ZHANG Weiqiang, WANG Dawei, et al. Studies on welding process of pile welding copper/steel composite bolt sleeves[J]. Coal Mine Machinery, 2010, 31(7): 90-92.

[3] Elrefaey A, Tillmann W. Solid state diffusion bonding of titanium to steel using a copper base alloy as interlayer[J]. Journal of Materials Processing Technology, 2009, 209(5): 2746-2752.

[4] 李亚江, 王娟, 刘鹏. 异种难焊材料的焊接及应用[M]. 北京: 化学工业出版社, 2004: 1-3.

LI Yajiang, WANG Juan, LIU Peng. Welding and application of heterogeneous materials[M]. Beijing: Chemical Industry Press, 2004: 1-3.

[5] LI Yajiang,LIU Peng, WANG Juan, et al. XRD and SEM analysis near the diffusion bonding interface of Mg/Al dissimilar materials[J]. Vacuum, 2007, 82(1): 15-19.

[6] HAN Jing, SHENG Guangmin, ZHOU Xiaoling. Diffusion bonding of surface self-nanocrystallized Ti-4Al-2V and 0Cr18Ni9Ti by means of high energy shot peening[J]. ISIJ International, 2008, 48(9): 1238-1245.

[7] CAO Zhong, SUN Lixian, CAO Xueqiang, et al. Low- temperature pack aluminizing of X80 pipeline steel through addition of zinc and surface self-nanlcrystallization[J]. Advanced Materials Research, 2011(233/234/235): 2516-2521.

[8] Bohdan NM, Georgiy IP. Ultrasonic impact peening for the surface properties’ management[J]. Journal of Sound and Vibration, 2007, 308(3/4/5): 855-866.

[9] WANGTing, WANGDongpo, LIUGang, et al. Investigations on the nanocrystallization of 40Cr using ultrasonic surface rolling processing[J]. Applied Surface Science, 2008, 255(5): 1824-1829.

[10] OmarH, JedL, RoyceF. Laser and shot peening effects on fatigue crack growth in friction stir welded 7075-T7351 aluminum alloy joints[J]. International Journal of Fatigue, 2007, 29(3): 421-434.

[11] LU Ke. Nanocrystalline materials crystallized from amorphous solids: Nanocrystallization, structure and properties[J]. Materials Science & Engineering R: Reports, 1996, 16(4): 161-221.

[12] 韩靖, 盛光敏, 胡国雄, 等. 表面纳米化不锈钢与钛合金扩散连接中的扩散系数[J]. 焊接学报, 2008, 29(5): 25-29.

HAN Jing, SHENG Guangmin, HU Guoxiong, et al. Diffusion coefficient during diffusion bonding of surface self- nanocrystallinzation 0Cr18Ni9Ti and TA17[J]. Transactions of the China Welding Institution, 2008, 29(5): 25-29.

[13] Krishnan J, Bhanumurthy K, Gawde P S, et al. Manufacture of a matrix heat exchanger by diffusion bonding[J]. Journal Materials Processing Technology, 1997, 66(1/2/3): 85-89.

[14] 陈艳, 吴鲁海, 薛小怀, 等. 铜在不锈钢中的扩散研究[J]. 机械工程材料, 2005, 29(8): 19-21.

CHEN Yan, WU Luhai, XUE Xiaohuai, et al. Diffusion of copper in type 316 stainless steel[J]. Materials for Mechanical Engineering, 2005, 29(8): 19-21.

[15] 韩靖, 盛光敏, 胡国雄. 高能喷丸0Cr18Ni9Ti不锈钢自纳米化机理[J]. 中南大学学报: 自然科学版, 2009, 40(3): 644-649.

HAN Jing, SHENG Guangmin, HU Guoxion. Self- nanocrystallized mechanism for 0Cr18Ni9Ti by means of high energy shot peening[J]. Journal of Central South University: Science and Technology, 2009, 40(3): 644-649.

[16] 胡国雄. 金属材料表面自纳米化工艺、表征及机理研究[D]. 重庆: 重庆大学材料学院, 2007: 63-64.

HU Guoxiong. Investigation of processing, characterization and mechanism of surface self nano-crystallization in metallic materials[D]. Chongqing: Chongqing University. College of Materials Science and Engineering, 2007: 63-64.

[17] 刘忠良. 0Cr18Ni9钢超音速微粒轰击(SFPB)表面纳米化机理与性能研究[D]. 西安: 西安理工大学材料科学与工程学院, 2008: 37-42.

LIU Zhongliang. Investigation of 0Cr18Ni9 stainless steel supersonic fine particles bombaeding (SFPB) surface nanocrystallization’s mechanism and property[D]. Xi’an: Xi’an University of Technology. College of Materials Science and Engineering, 2008: 37-42.

[18] ASM Handbook: Alloy phase diagrams[M]. 9th ed. Ohio: ASM International, 1992: 734-735.

(编辑 邓履翔)

收稿日期:2012-01-13;修回日期:2012-04-24

基金项目:国家自然科学基金资助项目(50675234)

通信作者:盛光敏(1958-),男,湖北仙桃人,教授,博士生导师,从事异种金属连接研究;电话:15923026226;E-mail: gmsheng@cqu.edu.cn