表面活性剂添加对超细98W-1Ni-1Fe粉末注射成形喂料流变行为的影响

来源期刊:中国有色金属学报(英文版)2013年第6期

论文作者:范景莲 韩 勇 刘 涛 成会朝 高 扬 田家敏

文章页码:1709 - 1717

关键词:超细98W-1Ni-1Fe粉末;球磨;硬脂酸添加;注射成形;流变行为

Key words:ultrafine 98W-1Ni-1Fe powder; ball milling; stearic acid addition; powder injection molding; rheological behavior

摘 要:研究超细98W-1Ni-1Fe粉末的注射成形。系统研究球磨和硬脂酸(SA)添加对粉末特性以及喂料流变行为的影响。结果表明:球磨和SA添加均有效提高喂料的装载量。SA添加可以避免喂料制备过程中粉末与粘结剂间的表面反应,从而缩短混炼时间。SA添加可以降低喂料的粘度,但这种效果随温度升高而逐渐消失,在125 °C以上时变为一种不利的效果。SA添加可以降低注射所需的温度。添加SA的粉末喂料在115 °C时具有最低的粘度及剪切敏感性,而未加SA的粉末喂料在135 °C时才具有最低的粘度及剪切敏感性。同时,添加SA的粉末喂料相比未添加SA的粉末喂料具有较低的温度敏感性及较佳的综合流变性能,因此,更适合于超细98W-1Ni-1Fe粉末的注射成形。

Abstract: Ultrafine 98W-1Ni-1Fe powder injection molding was studied. The influence of ball milling and stearic acid (SA) addition on ultrafine powder characteristics and feedstock rheological behavior was investigated systematically. Results show that ball milling and SA addition can effectively increase powder loading of feedstock. SA addition can also avoid surface interactions between powder and binder during feedstock preparation, thus shortening the mixing time. SA addition is effective in reducing feedstock viscosity, but this effect decreases with increasing temperature and becomes disadvantageous when temperature is higher than 125 °C. SA addition can also reduce the temperature required for injection molding. The feedstock of powder with SA addition gets its best shear stability and lowest viscosity at 115 °C, while the feedstock of powder without SA addition obtains its best shear stability and lowest viscosity at 135 °C. Meanwhile, the former has lower temperature sensitivity and better comprehensive rheology than the latter, so the former is more suitable for ultrafine 98W-1Ni-1Fe injection molding.

Trans. Nonferrous Met. Soc. China 23(2013) 1709-1717

Jing-lian FAN, Yong HAN, Tao LIU, Hui-chao CHENG, Yang GAO, Jia-min TIAN

State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 2 May 2012; accepted 12 December 2012

Abstract: Ultrafine 98W-1Ni-1Fe powder injection molding was studied. The influence of ball milling and stearic acid (SA) addition on ultrafine powder characteristics and feedstock rheological behavior was investigated systematically. Results show that ball milling and SA addition can effectively increase powder loading of feedstock. SA addition can also avoid surface interactions between powder and binder during feedstock preparation, thus shortening the mixing time. SA addition is effective in reducing feedstock viscosity, but this effect decreases with increasing temperature and becomes disadvantageous when temperature is higher than 125 °C. SA addition can also reduce the temperature required for injection molding. The feedstock of powder with SA addition gets its best shear stability and lowest viscosity at 115 °C, while the feedstock of powder without SA addition obtains its best shear stability and lowest viscosity at 135 °C. Meanwhile, the former has lower temperature sensitivity and better comprehensive rheology than the latter, so the former is more suitable for ultrafine 98W-1Ni-1Fe injection molding.

Key words: ultrafine 98W-1Ni-1Fe powder; ball milling; stearic acid addition; powder injection molding; rheological behavior

1 Introduction

Powder injection molding (PIM) has been an attractive method in fabrication of small, intricate, and dimensionally accurate engineering components with both metal and ceramic powders. Fabrication starts with compounding a thermoplastic binder and powder mixture, which is referred as feedstock, followed by injection molding, binder removal and sintering. Mixing of powder and binder is an important phase in this process, as the uniformity of the mixture influences the flow behavior of the feedstock and the sintered properties [1-3].

Typical particle sizes encountered in PIM are 1-15 μm. However, because of the very high melting point of tungsten (about 3420 °C), the injected microscaled tungsten and tungsten alloy preforms always need a relatively high temperature to get full or nearly full density, then the obtained sintered bodies usually show large-sized grains, which leads to remarkable deterioration of mechanical properties [4-6]. Compared with large-sized particles, the powder with nano or ultrafine scale particles possesses a large surface-to- volume ratio, so the sintering temperature can be remarkably decreased due to the increase of surface energy [7-9]. However, employing powders with particles below 1 μm for PIM of tungsten or tungsten alloy components presents a number of problems not only as regards preparation of a homogeneous feedstock with appropriate rheological properties but also the binder removal [10,11]. Ultrafine particles tend to form agglomerates, which can alter the rheological behavior of the feedstock and consequently the quality of injection molded components [3]. In our previous research, it’s found that the as-received ultrafine 98W-1Ni-1Fe powder had a maximum powder loading of less than 40% when it was used for injection molding. In the view of this reason, there has been very few reported fabrication technology or theory of injection molded tungsten or tungsten alloy bodies using ultrafine powder, although injection molding has been used and investigated in ultrafine ceramics for many years [12-17].

Two main methods, namely ball milling treatment [10] and surfactants adding [14,15,18,19], have been proved to be effective in eliminating powder agglomeration. Therefore, both of them are possible means to obtain homogeneous feedstock and, subsequently, uniform compact structure of the sintered component. However, there has rarely been reported that these two methods were used together to improve the rheology of ultrafine feedstock. In order to solve the problem of ultrafine 98W-1Ni-1Fe powder injection molding, in this work, we firstly tried to adding SA into the as-received ultrafine 98W-1Ni-1Fe powder. Then, ball milling treatment was employed to modify the powder and improve powder loading. At the same time, for comparison, SA was added into the ultrafine 98W-1Ni-1Fe powder prior to ball milling as dispersive surfactant acting on the principle of steric stabilization to modify the powder. The objective of the present work is to investigate the influence of SA addition on the rheological properties of PIM feedstock. In particular, the effects of shear rate and temperature on the viscosity of the different powder-binder mixtures were systematically examined for the first time.

2 Experimental

2.1 Powder and binder characteristics

The starting powder is sol-spray dried 98W-1Ni-1Fe with a BET size of 128 nm. To eliminate agglomeration and modify the powder, the as-received powder was mixed with SA at a mass ratio of 100:1, then it was subjected to ball milling for 5 h using a planetary ball mill. Tungsten balls with a diameter of 7 mm and a stainless steel vial were used for milling at the speed of 200 r/min. Absolute ethyl alcohol was used as wet milling medium, and ball-to-powder mass ratio (BPR) and liquid-to-solid volume ratio (LSR) were maintained at 2:1. In order to compare the effect of SA addition, another powder without SA addition was also ball-milled using the same milling condition as mentioned above. The particle morphologies of these powders were observed by scanning electron microscope (SEM, JSM- 6360LV, JEOL, Japan) and the particle size distributions of these powders were obtained in a laser scattering particle analyzer (Micro-Plvs, Malvern, UK).

A wax-polymer-oil binder was selected for this work because of its low viscosity. The binder consists of paraffin wax (PW), high density polyethylene (HDPE), ethylene-vinyl acetate copolymer (EVA), oil, dioctyl phthalate (DOP) and stearic acid (SA) in a mass ratio of 65:10:5:15:4:1. Table 1 lists the characteristics of each pure component.

2.2 Feedstock preparation

Since the powder loading of the as-received powder was less than 40% as mentioned in the introduction section, its rheogical behavior was not discussed. To study the effect of SA on the feedstock rheological behavior, two kinds of 98W-1Ni-1Fe feedstocks with or without SA addition in powder were prepared. Feedstock represents a balanced mixture of powder and binder. The mixing of powder and binder was carried out in a XSS-300 (Kechuang, China) mixer at 130 °C and 50 r/min. This equipment had a chamber volume of 60 cm3 and 70% of this volume was used for tests. The appropriate amount of powder and binder was weighed to produce a feedstock with an optimum solid loading, which was considered to be 50% in this work. Torque evolution was measured during mixing process. This parameter was related to mixture homogeneity, when the values of torque were almost constant. Firstly, the binder components were mixed and small quantities of powder were added to the binder and allowed to blend until the torque was stabilized. After mixing, the feedstock was granulated.

Table 1 Characteristics of each binder component

2.3 Rheological measurements

In order to determine the rheological behavior of feedstocks, an Instron3211 capillary (Instron, UK) was employed. In a capillary rheometer, the fluid is forced by a piston through the capillary. Under conditions of steady flow and from the measurement of the pressure drop and volumetric flow rate through the capillary, the shear stress and shear rate can be determined, from which the viscosity can be calculated. The cavity of the rheometer was preheated to 105, 115, 125, 135 and 145 °C, respectively, for each feedstock prepared. A die diameter of 1.2 mm and a length of 51.1 mm were selected. The shear rate was chosen in a range from 1.79 to 596.1 s-1 and melting time of 10 min was employed for each test.

3 Results and discussion

3.1 Effect of SA addition on powder morphology and particle size distribution

In Fig. 1, powder morphologies and particle size distributions of the different powders are shown. As seen, the ultrafine particles of the as-received powder bind together, forming spherical aggregates. After milling, the powder characteristics change greatly. The aggregates are broken after milling, but there are still many small aggregates in the powder without SA addition. The dispersity of the powder with SA addition is obviously much better than that of the powder without SA addition. It can be observed from the laser particle size distribution curve that the as-received powder is of trimodal distribution, and large sized aggregates (>10 μm) involve a large part of the scale. After milling, the powder without SA addition is still of trimodal distribution, but the aggregate size decreases greatly, which is in agreement with the SEM images. Aggregates with size of 0.5-10 μm make up the most proportion, which is unfavorable for the effective packing of powder. The powder with SA addition after milling has unimodal distribution, so the powder size appears as continuous distribution, which is beneficial for the particle packing.

Fig. 1 Scanning electron micrographs and particle size distributions of different powders

Table 2 gives the variation in mean diameter (D10, D50, D90) and apparent density of the powder before and after milling. The mean diameters drop markedly after milling, which confirms that the aggregation is effectively eliminated. Meanwhile, the mean diameter of the powder with SA addition is higher than that without SA addition, maybe caused by SA which is viscous and plays a role of binder among particles. It can also be observed that the apparent density increases greatly after milling, while the apparent density of the powder with SA addition is higher than that of powder without SA addition, which confirms that the powder with SA addition has more effective particle packing than the powder without SA addition.

Table 2 Characteristics of powders before and after milling

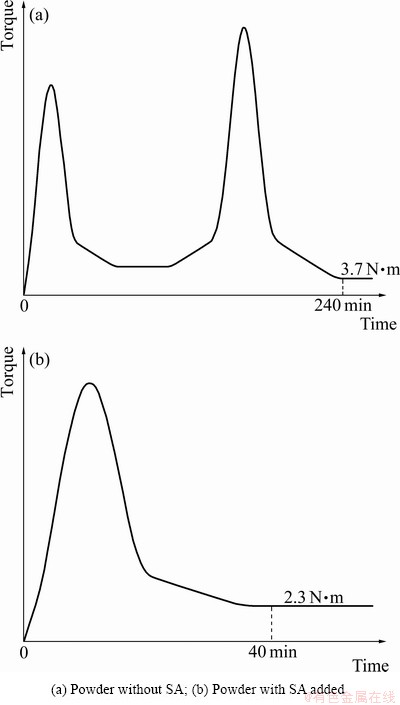

3.2 Effect of SA addition on torque evolution

Figure 2 shows the torque evolution during feedstock preparation. As seen, the powder without SA addition takes about 240 min during feedstock preparation; it is much longer than that of powder with SA addition, which is 40 min. The former experiences two torque peaks during mixing, whereas the latter experiences only one torque peak. The first torque peak appears when powder is added into binder, after that it decreases and levels off for the first time. At this point, the mixture is taken, and it’s found that the powder has not been wetted by the binder at all. Then the torque curve rises to the second peak before it decreases and levels off for the second time. Thereafter, a sticky mixture of powder and binder is obtained. So it can be concluded that a surface interaction between powder and binder, which is revealed by the second peak, has occurred before they wet and mix homogeneously. However, this surface interaction has not occurred in powder with SA addition, because it experiences only one torque peak. This means that SA has adsorbed on powder surface during ball milling and plays as a bridge between powder and binder (as shown in Fig. 3), which greatly improves the compatibility of powder and binder.

Fig. 2 Schematic diagrams of torque evolution during feedstock preparation

Fig. 3 Schematic illustration of SA adsorbed on powder surface

It can also be observed that, the feedstock with SA added in powder has a lower final torque value than that of the powder without SA addition, which shows that SA additive improves the feedstock fluidity during mixing.

3.3 Effect of SA addition on shear stress

Figure 4 shows the variation in the shear stress of feedstocks with shear rate. As seen, the shear stresses of these two feedstocks increase with the shear rate increasing in all the temperature ranges investigated. Meanwhile, the temperature also has important influence on the shear stress. When temperature changes in the range of 105-115 °C, the feedstock shear stress of the powder without SA added is much higher than that of the powder with SA addition, which means that the feedstock rheology of the powder with SA addition is better than that of the powder without SA in this temperature range. When temperature is increased to 125 °C, the shear stresses of the two feedstocks are nearly equal to each other. When temperature is in the range of 135-145 °C, the feedstock shear stress of the powder with SA added is mainly higher than the powder without SA addition, which is opposite to the situation in the temperature range of 105-115 °C. This may be caused by the losing of SA at higher temperatures, leading to a change in the way in which the surfaces of the various species interact and resulting in a higher viscosity [12].

Fig. 4 Variations in shear stress of feedstocks with shear rate and temperature

3.4 Effect of shear rate on feedstock viscosity

The viscosity of feedstocks, which relates the shear stress to the shear strain rate, as well as the sensitivity of the viscosity to temperature and shear rate, is usually used to evaluate the rheological properties of various feedstocks [20]. A perfect feedstock is desired to have low viscosity and sensitivity to temperature and shear rate to minimize problems due to a fluctuating molding condition in the actual PIM process [21]. Figure 5 shows the apparent viscosity versus the shear rate at various temperatures for two kinds of feedstocks. It is indicated that the viscosities of all the feedstocks decrease as the shear rate increases when plotted on a log-log basis, which accords with pseudoplastic behaviors, as shown in Figs. 5(a-e), that is [22]:

,

,  (1)

(1)

where τ is the shear stress (Pa),  is the shear rate (s-1), K is a constant, η is the viscosity of feedstock and n is the flow behavior index (n<1). The n indicates the sensitivity of viscosity to the shear rate and it can be determined by plotting the logarithm of viscosity against the logarithm of the shear rate. A higher n means slower change rate of the viscosity with the variation ofshear rate and better deformation stability of feedstock. However, n>1 indicates a dilatant material where the powder and binder would separate under high shear rate. The variation in the value of n at different temperatures for the two feedstocks is shown in Fig. 5(f). It should be noted that the n value for the feedstock of powder without SA addition is always higher than that of the powder with SA addition at all the temperatures investigated except for 115 °C, at which the two feedstocks have the same n value. This indicates that the viscosity of the feedstock of the powder with SA added is more sensitive to shear rate than that of the other. The n value for the feedstock of the powder with SA added first increases as the temperature rises and gets its maximum value at 115 °C, which is 0.774, afterward, there is a consecutive decrease when temperature further increases. The n value for the feedstock of the powder without SA added gets its maximum value at 135 °C, which is 0.81. This tells us that the feedstock with SA addition has its best shear stability at 115 °C, and the feedstock without SA addition has its best shear stability at 135 °C. So 115 °C and 135 °C are the preferable temperatures for injection molding of the two feedstocks, respectively.

is the shear rate (s-1), K is a constant, η is the viscosity of feedstock and n is the flow behavior index (n<1). The n indicates the sensitivity of viscosity to the shear rate and it can be determined by plotting the logarithm of viscosity against the logarithm of the shear rate. A higher n means slower change rate of the viscosity with the variation ofshear rate and better deformation stability of feedstock. However, n>1 indicates a dilatant material where the powder and binder would separate under high shear rate. The variation in the value of n at different temperatures for the two feedstocks is shown in Fig. 5(f). It should be noted that the n value for the feedstock of powder without SA addition is always higher than that of the powder with SA addition at all the temperatures investigated except for 115 °C, at which the two feedstocks have the same n value. This indicates that the viscosity of the feedstock of the powder with SA added is more sensitive to shear rate than that of the other. The n value for the feedstock of the powder with SA added first increases as the temperature rises and gets its maximum value at 115 °C, which is 0.774, afterward, there is a consecutive decrease when temperature further increases. The n value for the feedstock of the powder without SA added gets its maximum value at 135 °C, which is 0.81. This tells us that the feedstock with SA addition has its best shear stability at 115 °C, and the feedstock without SA addition has its best shear stability at 135 °C. So 115 °C and 135 °C are the preferable temperatures for injection molding of the two feedstocks, respectively.

Fig. 5 Shear rate dependence of viscosity ((a) 105 °C; (b) 115 °C; (c) 125 °C; (d) 135 °C; (e) 145 °C) and values of n (f) at various temperatures

3.5 Effect of temperature on feedstock viscosity

The variations in the viscosity of feedstocks with temperature are shown in Fig. 6. As seen, the viscosities of the two feedstocks mainly decrease with increasing the temperature at lower shear rate (1.79-17.88 s-1) and the feedstock with SA added always has lower viscosity at this stage. When the shear rate increases to above 59.61 s-1, which is in the shear rate range of PIM process, the viscosities of the two feedstocks first decrease to their minimum value with temperature rising and then they continually increase when temperature further increases. At this stage, it can be observed that the feedstock with SA addition mainly has higher viscosity than that of the feedstock without SA addition except for at the temperature of 115 °C. The feedstock with SA addition obtains its lowest viscosity at 115 °C, while the feedstock without SA added gets its lowest viscosity at 135 °C. This means that SA addition can reduce the temperature required for injection molding of ultrafine 98W-1Ni-1Fe, and this result is consistency with the research of injection molding of submicrometer zirconia reported in Ref. [12]. This also confirms that 115 °C and 135 °C are the preferable temperatures for injection molding of the two feedstocks, respectively.

Fig. 6 Variations in feedstock viscosity with temperature at different shear rates

The dependence of temperature on the viscosity can be expressed by an Arrhenius equation [22]:

(2)

(2)

where E is the activation energy for viscous flow, R is the gas constant, T is the temperature and η0 is the reference viscosity at the reference temperature T0. The flow activation energy E determines the sensitivity of the viscosity to temperature. A large E indicates a high sensitivity of the viscosity to temperature change. When the injection melt enters the die cavity, a temperature gradient can be generated in the injected body. If the melt viscosity greatly fluctuates with temperature, stress concentration or cracks will be formed in some big injected bodies due to the inconsistent shrinkage. In general, low temperature sensitivity (small E) is desirable to minimize problems, such as stress concentration, cracks and shape distortion. In order to get rid of the influence of shearing on the temperature sensitivity, the E values of these feedstocks are calculated at a shear rate of 1.79 s-1, which is closed to the zero-shear. At this shear rate, the natural logarithm of the viscosities of the two feedstocks is plotted against the reciprocal of temperature in Fig. 7. The E values can be determined by linear fit, and the feedstock with SA added is calculated as 53.4 kJ/mol while the feedstock without SA added is determined as 83.8 kJ/mol. From the E values, it can be inferred that the feedstock with SA addition has lower temperature sensitivity.

Fig. 7 Correlation between viscosity and reciprocal of temperature from various feedstocks

A comprehensive flow index αSTV [23] is generally used to evaluate the comprehensive rheological properties of the feedstock:

(3)

(3)

where S is the sensitivity to shear rate, T is the sensitivity to temperature and V is the viscosity of the feedstock. The higher the αSTV, the better the rheological properties. The αSTV values are determined to be 48.42 and 29.32 for the feedstock with and without SA addition, respectively. Therefore, it can be verified that the feedstock with SA addition is more suitable for the injection molding of ultrafine 98W-1Ni-1Fe powder.

4 Conclusions

1) Ball milling greatly diminishes the agglomeration of ultrafine 98W-1Ni-1Fe particles and increases powder loading of feedstock, while SA addition further improves particle dispersity.

2) SA additive can effectively improve the compatibility of powder and binder, leading to easier mixing and better feedstock fluidity during mixing.

3) At lower temperatures (<125 °C), the feedstock of the powder with SA addition has better rheology than the feedstock of the powder without SA addition, whereas at higher temperatures (>125 °C) the situation is just opposite.

4) SA addition can reduce the temperature required for injection molding of ultrafine 98W-1Ni-1Fe.

5) The feedstock of powder with SA is more suitable for ultrafine 98W-1Ni-1Fe injection molding.

References

[1] GERMAN R M. Powder injection molding [M]. New Jersey: MPIF, 1990: 12-17.

[2] GERMAN R M, HENS K F, LIN S T. Key issues in powder injection molding [J]. Bulletin of American Ceramic Society, 1991, 70(1): 294-302.

[3] SURI P, ATRE S V, GERMAN R M, SOUZA J P. Effect of mixing on the rheology and particle characteristics of tungsten-based powder injection molding feedstock [J]. Materials Science and Engineering A, 2003, 356: 337-344.

[4] FAN J L. Tungsten alloys and the new technologies for their preparation [M]. Beijing: Metallurgical Industry Press, 2006: 227-228. (in Chinese)

[5] LIN T, ZHAO F, ZHANG L Y, WU C Y, GUO Z M. Fine grain tungsten produced with nanoscale powder [J]. Journal of University of Science and Technology Beijing, 2005, 12(3): 277-280.

[6] ZHOU Z J, MA Y, DU J, LINKE J. Fabrication and characterization of ultra-fine grained tungsten by resistance sintering under ultra-high pressure [J]. Materials Science and Engineering A, 2009, 27: 701- 704.

[7] FANG Z Z, WANG H. Densification and grain growth during sintering of nanosized particles [J]. International Materials Review, 2008, 53(6): 326-352.

[8] JIANG Q. Size-dependent initial sintering temperature of ultrafine particles [J]. Journal of Materials Science and Technology, 1998, 14: 171-172.

[9] HAN Y, FAN J L, LIU T, CHENG H C, TIAN J M. The effects of ball-milling treatment on the densification behavior of ultra-fine tungsten powder [J]. International Journal of Refractory Metals and Hard Materials, 2011, 29: 743-750.

[10] TRUNEC M, DOBSAK P, CIHLAR J. Effect of powder treatment on injection molded zirconia ceramics [J]. Journal of the European Ceramic Society, 2000, 20: 859-866.

[11] NYBORG L, CARLSTROM E, WARREN A, BERTILSSON H. Guide to injection molding of ceramics and hardmetals: Special consideration of fine powder [J]. Powder Metallurgy, 1998, 41(1): 41-45.

[12] ALLAIRE F, MARPLE B R, BOULANGER J. Injection molding of submicrometer zirconia: Blend formulation and rheology [J]. Ceramic International, 1994, 20: 319-325.

[13] SONG J H, EVANS J R G. The injection molding of fine and ultra-fine zirconia powders [J]. Ceramic International, 1995, 21: 325-333.

[14] SONG J H, EVANS J R G. Ultrafine ceramic powder injection molding: the role of dispersants [J]. Journal of Rheology, 1996, 40(1): 131-152.

[15] XIE Z P, LUO J S, WANG X, LI J B, HUANG Y. The effect of organic vehicles on the injection molding of ultrafine zirconia powders [J]. Materials & Design, 2005, 26: 79-82.

[16] LUO J S, YI Z Z, XIAO B, GAO Y, XIE Z P, LI J B, HUANG Y. Injection molding of ultra-fine zirconia (Y-TZP) powders [J]. Journal of Ceramic Processing Research, 2006, 7(1): 14-19.

[17] YU P C, LI Q F, FUH J Y H, LI T, HO P W. Micro injection molding of micro gear and using nano-sized zirconia powder [J]. Microsystem Technology, 2009, 15: 401-406.

[18] TSENG W J. Influence of surfactant on rheological behaviors of injection-molded alumina suspensions [J]. Materials Science and Engineering A, 2000, 289: 116-122.

[19] LIU W, XIE Z P, CUI J. Surface modification of ceramic powders by titanate coupling agent for injection molding using partially water soluble binder system [J]. Journal of European Ceramic Society, 2012, 32: 1001-1006.

[20] REN S B, HE X B, QU X H, Humail I S, LI Y. Effects of binder compositions on characteristics of feedstocks of microsized SiC ceramic injection molding [J]. Powder Metallurgy, 2007, 50: 255-259.

[21] REN S B, HE X B, QU X H, Humail I S, Wei Y P. Influence of binder composition on rheological behavior of injection-molded microsized SiC suspensions [J]. Journal of University of Science and Technology Beijing, 2008, 15: 297-301.

[22] Huang B Y, Liang S Q, Qu X H. The rheology of metal injection molding [J]. Journal of Materials Processing Technology, 2003, 137: 132-137.

[23] Li Y M, Qu X H, Huang B Y. Evaluation of rheological properties of metal injection molding feedstocks [J]. Journal of Materials Engineering, 1999, 7: 32-35. (in Chinese).

范景莲,韩 勇,刘 涛,成会朝,高 扬,田家敏

中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:研究超细98W-1Ni-1Fe粉末的注射成形。系统研究球磨和硬脂酸(SA)添加对粉末特性以及喂料流变行为的影响。结果表明:球磨和SA添加均有效提高喂料的装载量。SA添加可以避免喂料制备过程中粉末与粘结剂间的表面反应,从而缩短混炼时间。SA添加可以降低喂料的粘度,但这种效果随温度升高而逐渐消失,在125 °C以上时变为一种不利的效果。SA添加可以降低注射所需的温度。添加SA的粉末喂料在115 °C时具有最低的粘度及剪切敏感性,而未加SA的粉末喂料在135 °C时才具有最低的粘度及剪切敏感性。同时,添加SA的粉末喂料相比未添加SA的粉末喂料具有较低的温度敏感性及较佳的综合流变性能,因此,更适合于超细98W-1Ni-1Fe粉末的注射成形。

关键词:超细98W-1Ni-1Fe粉末;球磨;硬脂酸添加;注射成形;流变行为

(Edited by Chao WANG)

Foundation item: Project (51074187) supported by National Natural Science Foundation of China; Project (50925416) supported by National Natural Science Funds for Distinguished Young Scholars; Project (51021063) supported by Creative Research Group of National Nature Science Foundation of China

Corresponding author: Jing-lian FAN; Tel/Fax: +86-731-88836652; E-mail: fjl@csu.edu.cn

DOI: 10.1016/S1003-6326(13)62652-7