熔体超声处理对7050铝合金铸锭宏观偏析的影响

黎正华,李晓谦,胡仕成,陈铭

(中南大学 机电工程学院 现代复杂装备设计与极端制造教育部重点实验室,湖南 长沙,410083)

摘要:采用SPECTRO-MAXx立式直读光谱仪和Leica金相显微镜,研究超声外场下7050铝合金半连续铸锭中微观组织的演变规律及溶质元素Zn,Mg和Cu的宏观偏析行为。研究结果表明:熔体超声处理后的铸锭组织变得细小,混晶减少,溶质元素的宏观偏析程度得到弱化,且随着超声功率的增大,溶质元素分布更加均衡,在240 W超声功率作用下,Zn,Mg和Cu的偏析比由未加超声时的1.243,1.158和1.190分别降低为1.086,1.098和1.110;超声外场的引入使得液穴变浅,由铸锭收缩引起的溶质元素在枝晶间的横向流动作用减弱;晶粒的有效细化导致液固两相的相对运动速度减弱;溶质原子的扩散程度得到强化是超声弱化偏析的主要原因。

关键词:半连铸;宏观偏析;超声功率;偏析比

中图分类号:TB559;TG249.9 文献标志码:A 文章编号:1672-7207(2011)09-2669-07

Effect of 7050 aluminum alloy melt treated by ultrasonic on macrosegregation in ingot

LI Zheng-hua, LI Xiao-qian, HU Shi-cheng, CHEN Ming

(Key Laboratory of Modern Complex Equipment Design and Extreme Manufacturing, Ministry of Education,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: The macrosegregation behavior of Zn, Mg, Cu solute elements and evolution of microstructure in 7050 aluminum alloy ingots produced by semi-continuous casting process in the ultrasonic filed was investigated using SPECTRO-MAXx and Leica optic microscopy. The results show that microstructure refines, duplex grains structure consisting of coarse-cell and fine-cell dendritic grains decrease, and so does the segregation grade of solute elements when alloy melt is treated by ultrasonic vibration. With the increase of ultrasound power, distribution of solute elements is harmonious. When the ultrasonic power is from 0 to 240 W, the segregation ratio of Zn, Mg, Cu decreases from 1.243, 1.158 and 1.190 to 1.086, 1.098 and 1.110, respectively. The sump height decreases in ultrasonic field, the shrinkage-induced flow of enriched solute among dendrite structure decreases, the velocities of the solid and liquid phases in mushy zone decrease due to microstructure refining, and the diffusion of solute atoms increases, which are the main reasons for suppressing macro-segregation

Key words: semi-continuous casting; macrosegregation; ultrasonic power; segregation ratio

7050铝合金由于具有高强高硬性而广泛应用于航天航空业。因为其合金含量较高,在铸造过程中存在严重的成分偏析。宏观偏析的出现不仅对铸锭的性能有不良的影响,而且增加了铸锭产生热裂的倾向,同时对后续热处理工艺和制品的最终性能有不同程度的影响。宏观偏析缺陷的出现严重限制了铸锭的生产能力,如铸锭的尺寸、合金的组成以及铸造过程中的工艺参数等[1],因此,宏观偏析在产品生产过程的重要性不容忽视。宏观偏析是合金铸锭在凝固过程中的溶质元素分布不均现象,它的出现与合金的凝固过程紧密相关,液相流动过程中的溶质扩散对其起决定性作用,因此,控制液相的流动是控制宏观偏析的主要手段[2-3]。在凝固过程中引入外场作为一种绿色环保的工艺手段在当前得到了广泛的社会关注。Eskin等[4]在7050半连铸过程中引入超声外场后发现铸锭组织细化效果明显,偏析程度减弱,裂纹萌生得到抑制;Nadella等[5]在铝合金半连续铸造过程中施加电磁场发现,在磁场受迫对流的作用下,铸锭中的宏观偏析得到弱化;Zhao等[6]也获得了相同的实验结果;蒋日鹏等[7-10]对超声处理技术进行了研究,但内容多集中于超声对各类合金晶粒尺寸及力学性能的影响,而对宏观偏析的叙述较少,特别是针对超声作用于半连续铸造过程中关于宏观偏析的实验和规律研究则更少。为此,本文作者通过改变超声功率,研究熔体超声处理作用于7050铝合金半连续铸造过程对溶质元素宏观偏析的影响,并从两相区液固相相对运动、铸锭收缩导致的流动以及悬浮晶粒等方面对超声弱化偏析的原因进行说明。

1 试验材料与方法

1.1 试验设备与装置

(1) 超声波发生器:输出功率为105,135,170,200和240 W;输出频率为(19±0.5) kHz。

(2) 超声振动系统:PZT压电陶瓷换能器;45#钢变幅杆;钛合金工具杆。

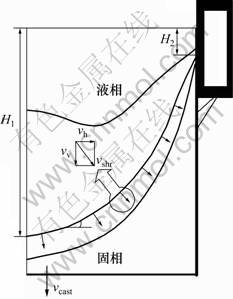

(3) 其他辅助设备:2 t熔炼炉和半连续铸机及配套的温度控制记录仪;热电偶;位移控制操作台;SPECTRO-MAXx立式直读光谱仪,Leica台式金相显微镜,实验装置如图1所示。

图1 超声半连铸示意图

Fig.1 Schematic diagram of ultrasonic semi-continuous casting

1.2 试验材料

试验材料为7050铝合金,由质量分数为99.7%的工业纯铝锭和各种合金母锭在实验室配置而成,材料的合金成分如表1所示。

表1 实验用7050合金成分(质量分数)

Table 1 Alloy composition of 7050 aluminum in experiment %

1.3 试验方案

试验采用的铸造工艺参数为:铸造温度740 ℃,铝熔体液面的上升速度约0.72 mm/s,结晶器以及喷淋水水压约0.10 MPa,在铸造过程中从顶部直接加入超声波并尽可能保持其他铸造工艺条件不变,只通过改变超声功率进行试验对比。(1) 采用“插丝法”测定初始凝固前沿的位置点及其高度,即分别插入铁丝测H1和H2,如图2所示。其中:H1为沿铸锭中心线方向测得的液穴最深处与液面之间的距离;H2为沿结晶器内壁测得的液穴最浅处与液面的距离;定义液穴深度为H=H1-H2。(2) 采用SPECTRO-MAXx立式直读光谱仪对不同工况下的铸锭横截面进行成分测定。采用偏析比q作为偏析量化的指标:q=wmax/wmin(其中,wmax和wmin分别表示横截面内溶质质量分数的最大值和最小值)。(3) 对不同工况下的横截面进行取样,采用Leica金相显微镜观测不同位置的微观组织。

图2 DC铸造过程中液穴测量位置及铸锭收缩引起的流动示意图

Fig.2 Schematic diagram of measure location of sump and shrinkage flow in DC casting

2 结果分析与讨论

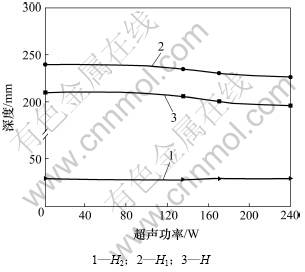

图3所示为实验测得的凝固前沿H1和H2随超声功率变化曲线。从图3可以看出:液穴深度H随着超声功率的增加逐渐变小,未加超声时液穴的深度为210 mm,而240 W超声功率作用时,液穴深度变为197 mm,施加170 W超声后,液穴变浅的趋势趋缓。

图3 740 ℃和0.72 mm/s条件下凝固前沿形态随超声功率变化规律

Fig.3 Evolution of solidifying front shape with ultrasonic power under condition of 740 ℃ and 0.72 mm/s

产生上述现象的原因在于功率超声的作用时,超声的空化效应能够增大熔体的过冷度,提高形核 率,在超声微射流和声流的搅拌作用下,使得形核质点的扩散速度增大,使得液穴里熔体凝固趋于均匀 化[11-15]。合金凝固时,Clausius-Clapeyron方程为[14]:

(1)

(1)

式中:?T为压力改变而导致的熔点改变值;Tm为金

属的凝固点温度;?V为凝固时体积的变化;?H为金属凝固时的焓变。

在压力变化时,?H改变值可以忽略不计,其中压力包括液体金属的静压力,凝固收缩所产生的抽压力以及外加超声场的声压驱动力。由于?T/?p>0,所以,合金熔点随着超声声压的增加而增大,即增大超声功率可使合金的凝固温度升高;分析液穴内温度场的分布情况可知:边部的温度梯度要大于中心的温度梯度。对整个液穴而言,在熔点变化值相同的情况下,必然导致液穴深度H降低和熔池深度H1降低,但是,随着超声功率的增加,超声的热作用机制以及超声空化产生的高温会使得局部的温度升高,因此,在施加170 W功率后液穴变浅的趋势趋缓。

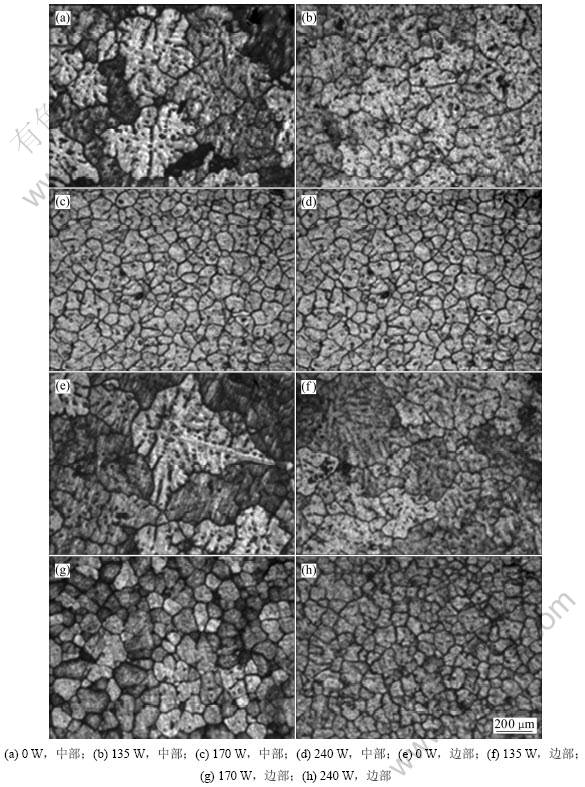

图4所示为半连续铸造过程中,不同超声功率作用下铸锭中心和边部的微观组织。从图4可见:无超声作用时,铸锭边部和中心均存在混晶,即粗大的晶粒与细小的晶粒混杂在一起,晶粒尺寸差异特别明显(如图4(a)和4(e)),观察超声外场作用下铸锭微观组织发现,混晶逐渐减少,边部和中心组织均得到不同程度的细化,且组织分布更为均匀,近球形。对比功率超声作用后的凝固组织发现,超声功率对铸锭凝固组织的细化效果不同,240 W功率超声作用对铸锭具有最佳的细化效果。其原因可能是由于超声波的空化效应和声流效应对形核和形核长大过程的作用,显著提高形核率[7-15],晶核随着液相运动,扩散到铸锭各个部位,从而促进了整个铸锭的形核,使形成的组织更为均匀。超声波的空化效应和声流效应随着超声功率的增加而增强,因此超声功率越大,微观组织的球化细晶效果越好。

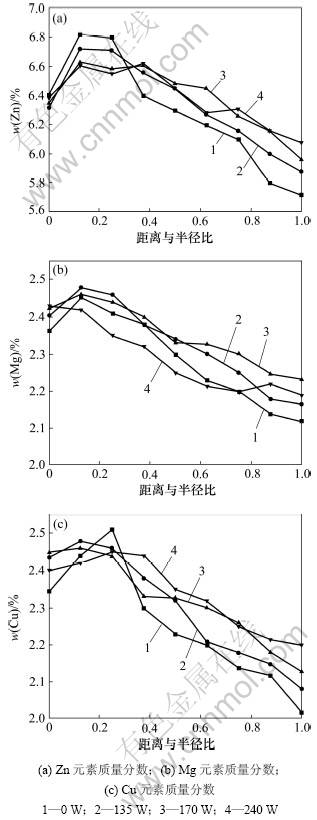

图5所示为溶质元素Zn,Mg和Cu在铸锭横截面内的径向分布,其中:Y坐标轴相当于结晶器壁,右端为铸锭的中心,横坐标为沿半径方向结晶器壁与测量点之间的距离与铸锭半径的比。由图5可知:溶质元素Zn,Mg和Cu均存在逆偏析,铸锭中心部位溶质元素含量低于铸锭边部。通过对比未加超声和施加功率超声工况,溶质元素分布变化曲线在超声作用下均趋于平坦,溶质元素分布变得均匀。在实验所测得的功率条件下,超声功率越大,曲线越平坦,溶质元素径向分布越均匀。

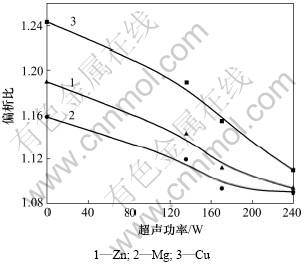

图6所示为Zn,Mg和Cu溶质元素偏析比随超声功率变化规律。由图6可见:未加超声时,Zn,Mg和Cu溶质元素的偏析比分别为1.243,1.158和1.190;240 W超声作用时,偏析比降为1.086,1.098和1.110,偏析程度显著降低。

由于7050合金的合金成分高,Zn,Mg和Cu溶质分配系数K分别为0.45,0.43和0.17[5],因此,在常规凝固过程中均存在逆偏析。对于超声抑制7050铝合金半连铸过程溶质元素逆偏析的主要原因如下。

2.1 超声对两相区流场的影响

导致合金元素宏观偏析的主要原因为液固相的相对运动,因此,对纯液相的流场研究对溶质分布的影响没有多大意义。对于两相区,根据固相分数的不同,可以分为浆状区和糊状区,在2个部分的流场分布情况是截然不同的。浆状区的固相分数为0~0.3,固相强加在液相上的拉液力相对很小,影响溶质分布流场的因素主要是溶质浮力流和外场强迫对流。在浆状区内,固相悬浮在液相中,由于固相和液相的密度不一样,固相在伴随液相运动的过程中速度存在差异,固液相的相对速度越小,液穴内溶质分布越均匀。液固相相对运动速度公式为[5]:

(2)

(2)

式中: 为固相速度;

为固相速度; 为液相的速度;gs为固相分数;

为液相的速度;gs为固相分数; 为固相密度;

为固相密度; 为液相密度;ds为晶粒尺寸;g为重力加速度;

为液相密度;ds为晶粒尺寸;g为重力加速度; 为固液相混合熔体的相对黏度。

为固液相混合熔体的相对黏度。

图4 不同超声功率作用下的微观组织结构

Fig.4 Microstructures obtained by different ultrasonic powers

图5 不同超声功率下溶质元素径向分布情况

Fig.5 Solute concentration profile in radial direction under different ultrasonic powers

图6 Zn,Mg和Cu溶质元素偏析比随超声功率变化规律

Fig.6 Evolution of segregation ratio of Zn, Mg and Cu with ultrasonic power

经分析可知:超声对凝固组织有明显的细化效果,在0~240 W有效功率范围内,超声功率越大,细化效果越明显。在一定固相分数下,由于施加功率超声,使得晶粒尺寸ds晶粒尺寸减小,由于超声对凝固组织的细化作用,使得两相区内液固相相对速度减小,从而弱化了铸锭的逆偏析。

在糊状区,固相分数为0.3~1,固相晶粒之间相互搭接形成了一个刚性骨架,有效地阻碍了液相的流动,固相的运动速度和铸造速度相同,影响液相径向流动主要原因是铸锭的收缩。铸锭在凝固的同时体积收缩,对于铝合金而言体收缩率为6%~8%,铸锭收缩的同时导致液相沿体积收缩方向流动,由于补偿的液相流体溶质成分含量要高于铸锭的平均成分,因此,控制凝固前沿富集溶质的液相收缩流动是抑制铸锭宏观偏析的有效手段。对此引入DC铸造过程铸锭收缩如图6所示,铸锭收缩速度分量可正交分解为一个水平分量vh和vv [5]。

(3)

(3)

式中:vshr为铸锭收缩引起的流速; 为收缩率;gl为液相分数;vcast为铸造速度。

为收缩率;gl为液相分数;vcast为铸造速度。

水平分量沿铸锭的半径方向指向铸锭的表面,竖直分量与铸造速度方向相同,虽然会导致竖直方向的宏观偏析,但是,对径向分布情况没有影响;而水平分量会使溶质由铸锭的中心向表面运动,尽管这一物理过程发生得很慢,运动的距离很短,但是,当所有的溶质都存在这种运动趋势时,在铸锭的表面将形成正偏析,中心部位由于没有更加富集的熔体进行补偿,将形成负偏析。由上面分析可知:超声场的加入使得液穴变浅,并且超声功率越大,液穴深度越浅。由于  <45°,因此,由铸锭收缩引起的对径向宏观偏析起影响作用的速度水平分量随超声功率的增加而减少,使得偏析程度降低。

<45°,因此,由铸锭收缩引起的对径向宏观偏析起影响作用的速度水平分量随超声功率的增加而减少,使得偏析程度降低。

为了更好地反映铸锭收缩对径向宏观偏析的影响,引入凝固过程水平方向溶质传递距离公式[5]:

(4)

(4)

式中: 为液穴切线与水平方向的夹角;A为常数,与合金的成分有关;Lm为糊状区高度;

为液穴切线与水平方向的夹角;A为常数,与合金的成分有关;Lm为糊状区高度; 为收缩率;C0为合金元素的液相成分。(dLh/dR)/C0能有效地反映铸锭径向的相对偏析程度。分析式(4)可知:随着液穴的变浅,铸锭径向的偏析比变小,即铸锭的径向宏观偏析程度随着超声功率的增加而降低。

为收缩率;C0为合金元素的液相成分。(dLh/dR)/C0能有效地反映铸锭径向的相对偏析程度。分析式(4)可知:随着液穴的变浅,铸锭径向的偏析比变小,即铸锭的径向宏观偏析程度随着超声功率的增加而降低。

2.2 超声对悬浮晶粒的影响

在凝固过程中,固相的溶质平均浓度要低于液相的溶质平均浓度,因此,液相中先结晶悬浮晶粒的形成和长大过程是造成偏析的一个重要原因。悬浮晶粒中溶质浓度相对较低,随着液相的运动而运动,在运动的过程中长大,由于重力和浮力的相互作用,最终沉积。凝固过程中的溶质传输决定着凝固组织中的成分分布,并影响到凝固组织的结构,在悬浮晶粒表面的溶质浓度要高于液相中的溶质浓度,悬浮晶粒由于成分过冷不断长大,导致了非平衡凝固组织的形成,表现为径向的混晶分布,如图4所示。由于混晶的成分与液相成分存在差异,因此,将造成铸锭径向的宏观偏析。溶质原子扩散程度的估计参数在一定程度上能反映溶质元素在凝固过程的扩散情况,溶质扩散程度的估计参数 [2]为:

[2]为:

(5)

(5)

式中:D为固相扩散系数; 为扩散时间,即局部凝固时间;l为扩散距离,可用半枝晶间距表示。由图4可知:施加超声后,晶粒组织得到了明显细化。在相同的扩散时间内,l变小,溶质的扩散程度增加,因此施加超声场加速了凝固过程溶质的扩散,降低了悬浮晶粒表面的成分过冷,抑制了悬浮晶粒的长大,同时空化效应有效提高了整个熔体的过冷度,增加形核率,使得液相的结晶过程趋于整体化,晶粒的生长趋于均匀化,表现为横截面的晶粒细化和晶粒呈等轴晶状,从而抑制了非平衡凝固组织的形成,弱化了偏析。

为扩散时间,即局部凝固时间;l为扩散距离,可用半枝晶间距表示。由图4可知:施加超声后,晶粒组织得到了明显细化。在相同的扩散时间内,l变小,溶质的扩散程度增加,因此施加超声场加速了凝固过程溶质的扩散,降低了悬浮晶粒表面的成分过冷,抑制了悬浮晶粒的长大,同时空化效应有效提高了整个熔体的过冷度,增加形核率,使得液相的结晶过程趋于整体化,晶粒的生长趋于均匀化,表现为横截面的晶粒细化和晶粒呈等轴晶状,从而抑制了非平衡凝固组织的形成,弱化了偏析。

3 结论

(1) 在外加超声场作用下,7050铝合金熔体结晶温度升高,液穴变浅,有利于溶质元素在截面尺寸范围内的均衡分布和扩散。

(2) 熔体超声处理加大了溶质在凝固过程中的扩散程度,减少了局部的成分过冷,使得晶粒的生长条件趋于均匀化,抑制了非平衡凝固组织的形成,弱化了偏析的程度。

(3) 超声处理有效的细化了铸锭组织,使得两相区液固相相对速度减小,铸锭收缩引起的径向流速减小,径向偏析程度降低,有效地改善了溶质元素的逆偏析,但不能消除逆偏析。

参考文献:

[1] Eskin D G, Zuidema J Jr. Structure formation and macrosegregation under different process conditions during DC casting[J]. Materials Science and Engineering A, 2004, 384: 232-244.

[2] 周尧和, 胡壮麟, 介万奇. 凝固技术[M]. 北京: 机械工业出版社, 1998: 112-121.

ZHOU Yao-he, HU Zhuang-lin, JIE Wan-qi. Solidification technology[M]. Beijing: China Machine Press, 1998: 112-121.

[3] Flemings M C. Our understanding of macrosegregation: Past and present[J]. ISIJ International, 2000, 40(9): 833-841.

[4] Eskin G I, Makarov G S. Effect of cavitation melt treatment on the structure refinement and property improvement in cast and deformed hypereutectic Al-Si alloys[J]. Materials Science Forum, 1997, 242: 65-70.

[5] Nadella R, Eskin D G. Macrosegregation in direct-chill casting of aluminum alloys[J]. Progress in Materials Science, 2008, 53: 421-480.

[6] ZHAO Zhi-hao, CUI Jian-zhong. Effect of low-frequency magnetic field on microstructures and macrosegregation of horizontal direct chill casting 7075 aluminum alloy[J]. Journal of Materials Processing Technology, 2007, 182: 185-190.

[7] 蒋日鹏, 李晓谦, 张立华, 等. 超声施振方式对纯铝凝固组织细化规律的研究[J]. 材料工程, 2009(2): 6-7.

JIANG Ri-peng, LI Xiao-qian, ZHANG Li-hua, et al. Research on the solidification structure refining laws of pure aluminum under different methods of ultrasonic vibration[J]. Journal of Materials Engineering, 2009(2): 6-7.

[8] Jiang X, Xu H. Effect of power ultrasound on solidification of aluminum A356 alloy[J]. Material Letters, 2005, 59(3): 190-193.

[9] 胡化文, 陈康华, 黄兰萍, 等. 超声熔体处理对Al-Zn-Mg-Cu合金显微组织和性能的影响[J]. 金属热处理, 2005, 30(5): 43-46.

HU Hua-wen, CHEN Kang-hua, HUANG Lan-ping, et al. Effect of ultrasonic melt treatment on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy[J]. Heat treatment, 2005, 30(5): 43-46.

[10] 刘荣光. 超声波在铝熔体中的声场和空化效应及其对凝固过程影响[D]. 长沙: 中南大学机电工程学院, 2007: 22-24.

LIU Rong-guang. The acoustic field and cavitation of the ultrasound in aluminum melts and the effect of ultrasonic vibration on solidification[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 22-24.

[11] 李新涛, 高学鹏, 李廷举, 等. 连铸造过程中超声细晶技术的研究[J]. 稀有金属材料与工程, 2007, 36(3): 377-380.

LI Xin-tao, GAO Xue-peng, LI Ting-ju, et al. An experimental study of grain refinement by ultrasonic treatment during continuous casting[J]. Rare Materials and Engineering, 2007, 36(3): 377-380.

[12] 范金辉, 翟启杰. 物理场对金属凝固组织的影响[J]. 中国有色金属学报, 2002, 12(1): 11-15.

FAN Jin-hui, ZHAI Qi-jie. Effect of physical field on metal solidification structure[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(1): 11-15.

[13] 庞磊, 张兴国, 郝海, 等. 7050铝合金晶粒细化的研究[J]. 特种铸造及有色合金, 2007, 27(6): 479-481.

PANG Lei, ZHANG Xing-guo, HAO Hai, et al. Grain refinement of 7050 aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2007, 27(6): 479-481.

[14] 高学鹏, 李廷举. 外场作用下水平连铸制备Al-1%Si合金线材的研究[D]. 大连: 大连理工大学材料科学与工程学院, 2007: 42-46.

GAO Xue-peng, LI Ting-ju. Research on horizontal continuous casting Al-1%Si alloy wire materials under outfield treatment[D]. Dalian: Dalian University of Technology. School of Material Processing Engineering, 2007: 20-46.

[15] 黎正华, 李晓谦, 张明, 等. 超声作用下半连铸7050铝合金的偏析行为及形成机制[J]. 中国有色金属学报, 2011, 21(2): 318-323.

LI Zheng-hua, LI Xiao-qian, ZHANG Ming, et al. Segregation behavior and formation mechanism of 7050 aluminum alloy produced by semi-continuous casting under ultrasonic field[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 318-323.

(编辑 杨幼平)

收稿日期:2010-08-23;修回日期:2010-12-04

基金项目:国家重点基础研究发展规划(“973”计划)项目(2010CB731700)

通信作者:李晓谦(1958-),男,湖南长沙人,博士,教授,从事材料成型与控制方面的研究;电话:0731-88877380;E-mail: meel@csu.edu..cn