DOI: 10.11817/j.issn.1672-7207.2016.05.008

直流电场对35钢盐浴渗氮的影响与动力学分析

陈尧1,周正寿1, 2,孙斐2, 3,戴明阳1,胡静1, 2

(1. 常州大学 材料科学与工程学院,江苏省表面科学与工程技术重点实验室,江苏 常州,213164;

2. 江苏省光伏科学与工程协同创新中心,江苏 常州,213164;

3. 常州轻工职业技术学院 机械工程系,江苏 常州,213164)

摘要:以35钢为材料,研究直流电场催渗盐浴渗氮技术。该技术在渗氮盐浴中通过在被渗样品间施加合适参数的直流电场予以实现。利用光学显微镜、显微硬度计和X线衍射仪对渗层的显微组织、渗层厚度、硬度及物相进行测试和分析。研究结果表明:直流电场可以显著提高渗氮速度,降低渗氮时间;在渗氮温度818 K,施加强度为7.5 V的直流电场时,可将常规渗氮时间100 min所得到的化合层厚度所需时间降低到50 min。同时,施加电场盐浴渗氮使35钢截面显微硬度得到明显提高。电场盐浴渗氮的扩散系数比常规盐浴渗氮提高1.9倍以上,扩散激活能从常规盐浴渗氮的220 kJ/mol降低到181 kJ/mol,从而达到增加渗层厚度的显著效果。同时对直流电场快速盐浴渗氮机理进行分析。

关键词:盐浴渗氮;直流电场;动力学;扩散

中图分类号:TG156.8 文献标志码:A 文章编号:1672-7207(2016)05-1506-07

Effect of direct current field on salt bath nitrding for 35 steel and kinetics analysis

CHEN Yao1, ZHOU Zhengshou1, 2, SUN Fei2, 3, DAI Mingyang1, HU Jing1, 2

(1. School of Materials Science and Engineering, Jiangsu Key Laboratory of Materials Surface Science and Technology,

Changzhou University, Changzhou 213164, China;

2. Jiangsu Collaborative Innovation Center of Photovolatic Science and Engineering, Changzhou University,

Changzhou 213164, China;

3. Department of Mechanical Engineering, Changzhou Institute of Light Industry Technology,

Changzhou 213164, China)

Abstract: Direct current field (DCF) assisted salt bath nitrding technology was developed, using 35 steel as the testing material. This technology was carried out by applying appropriate parameters of DCF between the treated samples in the nitrding salt bath. Characterization of modified surface layers was made by means of optical microscopy, Vickers micro-hardness test and X-ray diffraction analysis. The results show that DCF can significantly reduce the holding duration compared with the conventional process. When nitrding at 848 K with 7.5 V of DCF assisting, the time to get the same thickness of compound layer decreases to less than half by DCF assisting, while the higher surface hardness, modestly higher sub-surface hardness and superior hardness profile were obtained. The results show that the diffusion coefficient of nitrogen enhanced by DCF increases to more than 1.9 times higher than that of NM at each temperature. In addition, activation energy (Q) for the nitrogen diffusion decreases from 220 to 181 kJ/mol. Moreover, the catalyzing mechanism of DCF for salt bath nitriding process was analyzed.

Key words: salt bath nitridng; direct current field; kinetics; diffusion

渗氮能够在钢材表面形成一层保护层,使之具有耐蚀性、抗擦伤、耐磨性等优良的综合性能,从而在某些特定的环境下可以采用普通碳素钢渗氮代替高合金工具钢、不锈钢或其他特殊合金,因此,具有很重要的工程应用价值[1-2]。渗氮方法有固体粉末渗氮法、盐浴渗氮和气相渗氮等,渗氮使用比较多的主要是盐浴渗氮[3-5]。盐浴渗氮操作简单、成本低、工艺易于控制和渗层质量好。但不足的是,在实际应用中,为了增加机械零件表面的渗层厚度,就必须提高渗氮温度和保温时间,造成了极大地能源消耗,降低了生产效率。为此,研究人员做了很多工作[6-7]来促进氮原子在钢中的扩散,降低处理温度和减少时间。周正华等[8-11]对固体粉末渗研究发现,直流电场对固体粉末渗具有显著的促进作用。基于此,本文作者提出了一种直流电场快速盐浴渗氮的方法。此方法是将被渗零件作直流电场的负极,在渗氮盐浴中相对于零件渗氮面放置平行于板状电极作直流电场的正极,在渗扩过程中,在两电极之间施加一定的直流电场。施加适当的直流电场可显著提高渗速,从而达到降低渗氮温度、减少渗氮时间、提高渗剂利用率和高效节能的效果。本文作者研究了直流电场对盐浴渗氮技术的影响,为了进一步探寻直流电场快速盐浴渗氮的特性,同时研究了直流电场对盐浴渗氮动力学的影响,分析了直流电场条件下氮原子的扩散特性,探讨了直流电场在盐浴渗氮作用机理,以促进直流电场快速盐浴渗氮技术的 推广。

1 实验

1.1 材料

材料为调质态35钢,其化学成分(质量分数,%)为:C 0.36,Si 0.3,Mn 0.72,Cr 0.23,Ni 0.21,Cu 0.24, S 0.022,P 0.023,其余为Fe。基体表面硬度为HV0.01 295,采用线切割制成尺寸为10 mm×10 mm×10 mm(长×宽×高)的样品,用于组织和厚度观察。表面用SiC砂纸磨平,再用Cr2O3抛光粉抛光至镜面,最后用无水乙醇在超声波中清洗,吹干,待用。

1.2 方法

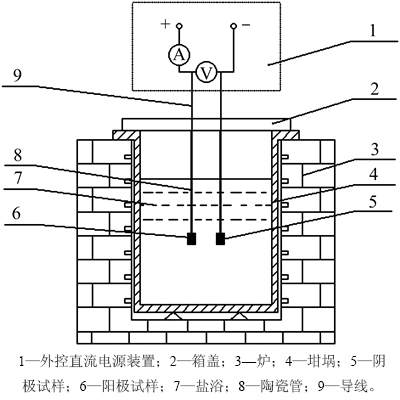

图1所示为进行电场盐浴渗氮研究的实验装置。首先将样品放入623 K空气炉中预热25 min,预氧化完成后将其中16个试样依次放入电场盐浴渗氮实验装置中,在盐浴渗氮过程中施加一定强度的直流电场(1.5~7.5 V),在不同外热温度(818~848 K),保温不同时间(50~120 min)下进行电场盐浴渗氮,其中被渗试样为阴极,进行直流电场盐浴渗氮处理(即施加直流电场的创新技术,用DCF表示); 作为对比,另外12个试样采用常规盐浴渗氮处理(即未施加直流电场的传统技术,用NM表示),常规盐浴渗氮装置仅由图 1中的2,3,4和7部分组成。

处理后的试样,用4%的硝酸酒精溶液腐蚀其截面,采用DMI-3000M型金相显微镜观察组织和渗层厚度; 用D/max 2500型X线衍射仪分析物相,使用Cu Kα射线(λ=0.154 nm),步宽为0.02°,扫描速度为0.2 (°)/min,2θ范围为20°~90°。用HXD-1000TMC型维氏硬度计测量处理后的35钢的截面硬度,加载载荷为0.1 N,保压时间为15 s。高于基体硬度HV0.01 50为有效扩散层[12]。

图1 直流电场渗氮新工艺装置示意图

Fig. 1 Schematic of main part of DCF assisted nitriding apparatus

2 结果与讨论

2.1 直流电场对化合物层的影响

图2所示为不同渗氮工艺条件下35钢的渗层组织。由图2可见:直流电场对盐浴渗氮有明显的促进作用。在常规渗氮工艺条件下,渗氮温度为848 K,保温100 min的化合物层(又称白亮层)厚度为18 μm,当施加强度为7.5 V的直流电场,渗氮温度为848 K,保温50 min就可以得到18.4 μm的化合物层(见图2(b),2(c))。比较图2(b)和图2(d)可知:在其他条件相同的情况下,施加强度为7.5 V的直流电场,白亮层厚度可以从18 μm提高到29 μm。因此,与常规渗氮工艺相比,直流电场可以明显降低渗氮时间和提高化合物层的厚度。

2.2 直流电场强度对化合物层厚度的影响

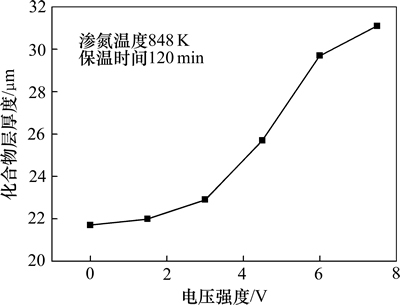

直流电场强度对化合物层厚度的影响如图3所示。由图3可见:当直流电场强度小于3 V时,化合物层厚度增加缓慢;当高于3 V时,化合物厚度急剧增加;当直流电场电压为7.5 V时,化合物层厚度超过30 μm,而在常规条件下只有21.7 μm。这表明直流电场条件下的盐浴渗氮行为与直流电场强度有密切关系。说明当直流电场强度超过一“门槛”值时(3 V)时,直流电场起到的节能效果才会明显。

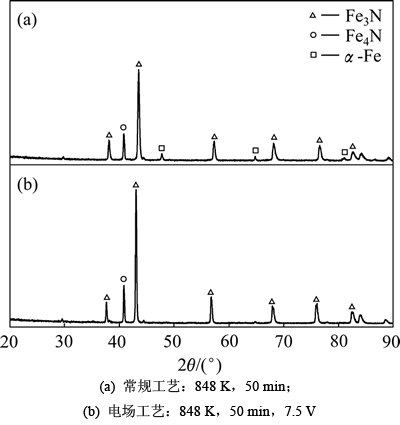

2.3 渗层物相分析

图4所示为35钢有无电场条件下盐浴渗氮试样的X线衍射谱。由图4(a)可见:经848 K,50 min盐浴渗氮处理后的35钢试样主要物相为ε-Fe3N,此外还存在少量γ′-Fe4N,并且还检测到α-Fe;当施加强度为7.5 V的直流电场后的试样的主要物相为ε-Fe3N,并且还有少量γ′-Fe4N组成(图4(b))。图4(a)和4(b)这2组峰的主要区别在于是否有α-Fe存在,图4(b)中没有α-Fe,主要是因为化合物层厚度增加[13]。结果表明:在渗氮过程中,通过直流电场更容易促使活性氮原子向工件表面扩散。因此,通过直流电场作用产生的化合物层厚度明显比常规工艺厚,这与图 2实验结果吻合。

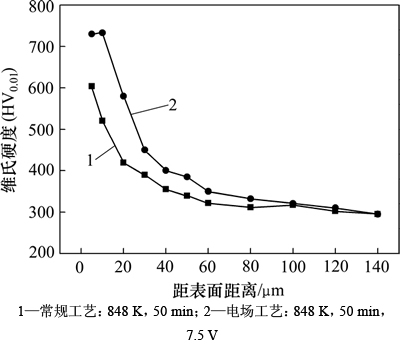

2.4 直流电场对渗层硬度梯度的影响

图5所示为35钢经不同渗氮工艺的截面硬度分布。从图5可以看出:经施加直流电场处理后的试样硬度明显高于常规处理的试样,经过848 K,50 min,7.5 V盐浴渗氮后,试样表面硬度可以达到HV0.01 730,比常规盐浴渗氮的硬度提高1.2倍左右,比基体的硬度提高2.5倍左右。电场盐浴渗氮后距表面10 μm的次表面硬度没有降低,而常规处理时硬度随离表面距离增大而单调下降。此外,直流电场渗氮的有效扩散层厚度达到60 μm,而常规渗氮只有40 μm。说明与常规盐浴渗氮相比,直流电场催渗可以获得较厚的有效硬化层。

图2 848 K时不同渗氮工艺条件下35钢的截面组织

Fig. 2 Cross-sectional microstructure of 35 steel after salt bath nitriding at 848 K

图3 电压强度与化合物层厚度的关系

Fig. 3 Relationship between depth of compound layer and voltage of DCF

图4 35钢有无电场条件下获得的渗层的XRD谱

Fig. 4 XRD patterns of sample treated

2.5 动力学分析

图6所示为有无直流电场催渗条件下35钢盐浴渗氮化合物层生长动力学曲线。直流电场盐浴渗氮化合物层厚度随时间的变化与常规盐浴渗氮呈现相似规律。渗氮时间相同时,温度越高,化合物层越厚,且直流电场盐浴渗氮化合物层厚度普遍明显高于常规盐浴渗氮。渗氮温度相同时,渗层厚度随时间的增加而增加。在盐浴渗氮初期,化合物层厚度的增幅较大,随着时间的延长,增幅变得缓和,趋于平坦。由图6可见:在相同渗氮温度和时间条件下,直流电场催渗盐浴渗氮的化合物层厚度均比常规盐浴渗氮厚;换句话说,为获得预期的化合物层厚度,直流电场催渗盐浴渗氮可以采用比常规处理更低的温度或更短的时间,从而达到节能降耗的显著作用。

图5 不同渗氮工艺下截面的硬度

Fig. 5 Cross-sectional micro-hardness for samples nitrided with and without DCF applying

图6 35钢不同条件下盐浴渗氮化合物层厚度与时间的关系

Fig. 6 Relationship between thickness of compound layer and nitriding time with and without DCF applying for 35 steel

化合物层生长是依靠氮原子的扩散来完成的,所以化合物层厚度、时间及扩散速率常数满足菲克第二定律[14],即

(1)

(1)

式中:d为化合物层厚度,m;K为有效扩散系数,m2/s;t为盐浴渗氮时间,s。

根据图6所示实验数据获得盐浴渗氮化合物层厚度平方与渗氮时间之间的关系曲线如图7所示。可见各试验温度下电场盐浴渗氮和常规盐浴渗氮化合物层厚度的平方与渗氮时间均呈线性关系,满足式(1)。图7中拟合的直线斜率即为各温度下氮原子的扩散系数K。直流电场增强盐浴渗氮及常规盐浴渗氮在各温度下氮原子扩散系数K见表1。从图7和表1可以看出:在任意温度下,电场盐浴渗氮的扩散系数都比常规盐浴渗氮提高1.9倍以上。因此,直流电场可以显著提高盐浴渗氮的速率。

图7 渗氮化合物层厚度平方与时间关系

Fig. 7 Relationship between square of compound layer thickness and nitriding time with and without DCF applying for 35 steel

表1 氮原子的扩散系数

Table 1 Diffusion coefficient(K) of nitrogen 10-16 m2·s-1

对于扩散控制过程,扩散系数、激活能以及处理温度T之间满足Arrhenius公式[15]:

(2)

(2)

式中:K为扩散系数,m2/s;K0为扩散常数(指前因子);Q为扩散激活能,J/mol;R为气体摩尔常数,8.31 J/(mol·K);T为热力学温度,K。将式(2)两边取自然对数得

(3)

(3)

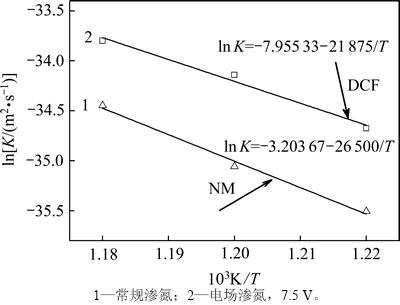

由式(3)可以看出:平均扩散激活能Q取决于ln K与1/T直线关系图的斜率。本研究中ln K与1/T关系如图8所示。

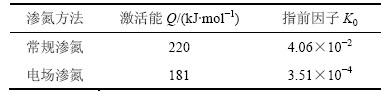

对图8中实验数据进行拟合得到直线方程、直线斜率及直线在ln K轴的截距b, 经过计算分别得到有无电场条件下氮原子在35钢中的扩散激活能Q、指前因子K0(见表2)。可见电场快速盐浴渗氮使氮原子的扩散激活能降低,由此导致电场快速盐浴渗氮化合物层厚度增加。

图8 35钢不同方法盐浴渗氮ln K与1/T的关系

Fig. 8 Relationship between ln K and 1/T during salt bath nitriding with and without DCF for 35 steel

表2 扩散激活能Q与扩散常数K0

Table 2 Activation energy(Q)of nitrogen and pre-exponential constant(K0)

由式(1)和(2)可得

(4)

(4)

将表2所列渗氮的Q和K0代入式(4),就可得到本研究条件下35钢的有无电场条件下渗氮化合物层厚度(dDCF,dNM)与渗氮温度T (K)和渗氮时间t (s)的关系式:

(5)

(5)

(6)

(6)

其中:818 K≤T ≤848 K。

式(5)和(6)具有以下2方面的作用:1) 根据盐浴渗氮工艺参数(温度和时间)预测35钢表层化合物层厚度。2) 为获得预期的化合物层厚度确定35钢盐浴渗氮工艺参数(温度和时间)。

2.6 机理分析

前面一系列实验结果表明直流电场对盐浴渗氮有显著的催渗作用。这应该与直流电场在盐浴渗氮中的作用机制有关。上述渗氮动力学的实验分析结果有助于进一步认识与完善其作用机制。盐浴动力学的分析结果是对渗氮过程中氮原子在被处理样品中扩散特性的某种表征。

直流电场的这种有利作用有以下2个原因:1) 直流电场的物理作用给渗氮盐浴提供额外能量,促进渗剂的电离分解,从而增加活性氮原子浓度,克服了常规渗氮单纯依赖渗剂受热分解产生活性氮原子之不足。活性氮原子通过以下方式产生:

→

→ (7)

(7)

→

→ (8)

(8)

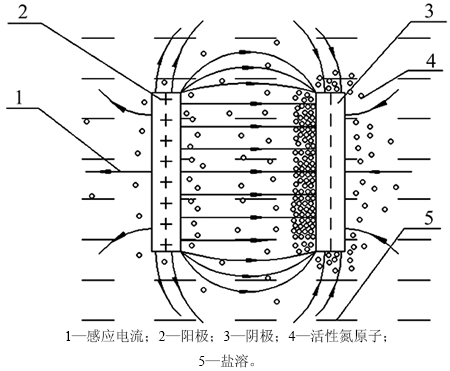

2) 由于试样在电场中是作为负极,渗剂反应产生的活性氮原子可能是带正电荷,因此,在直流电场作用下,活性氮原子向零件(负极)表面定向扩散,其扩散速度显然高于单纯热扩散速度,这样相对减少了坩埚内壁和零件非工作表面对氮原子的吸收,渗剂利用率得到提高,试样表面的高浓度活性氮原子促进表层化合物层的增厚。在直流电场条件下,氮原子在盐浴中的扩散见图9。

图9 直流电场条件下氮在盐浴中的扩散分布

Fig. 9 Distribution of active nitrogen atoms in salt bath in DCF

3 结论

1) 通过在被渗样品间施加合适参数的直流电场,研发了直流电场催渗盐浴渗氮技术。

2) 直流电场盐浴渗氮技术可提高渗剂利用率,具有节能、高效之效果。

3) 直流电场快速渗氮的渗层物相与常规盐浴渗氮一致,主要为ε-Fe3N及少量 γ′-Fe4N。前者的截面显微硬度高于后者。

4)外加直流电场对活性氮原子在试样基体内部的扩散具有显著的促进作用,氮原子扩散系数比常规盐浴渗氮提高1.9倍以上,扩散激活能从常规盐浴渗氮的220 kJ/mol降低到181 kJ/mol,从而增加渗层厚度。

5) 当818 K≤T ≤848 K 时,35 钢有无电场盐浴渗氮化合物层厚度与渗氮温度和时间的关系式为:

6) 直流电场促进渗剂的化学反应,从而增加活性氮原子的产率与活性,克服了常规盐浴渗氮单纯依赖渗剂受热分解产生的活性氮原子数量少的缺点。

参考文献:

[1] 高玉魁. 表面形变处理对32Cr3MoVA钢渗氮层组织和性能的影响[J]. 材料热处理学报, 2005, 26(1): 74-76.

GAO Yukui. Influence of surface straining on microstructure and mechanical property of 32Cr3MoV steel[J]. Transactions of Materials and Heat Treatment, 2005, 26(1): 74-76.

[2] WANG Jun, LIN Yuanhua, YAN Jing, et al. Influence of time on microstructure of AISI 321 austenitic stainless steel in salt bath nitriding[J]. Surface & Coating Technology, 2012, 206(15): 3399-3404.

[3] CAI Wei, MENG Fanna, GAO Xinyan, et al. Effect of QPQ nitriding time on wear and corrosion behavior of 45 carbon steel[J]. Applied Surface Science, 2012, 261(15): 411-414.

[4] 蔡伟, 魏国方, 孟凡娜, 等. QPQ盐浴复合处理时间对304不锈钢耐磨性的影响[J]. 材料热处理学报, 2013, 34(1): 153-156.

CAI Wei, WEI Guofang, MENG Fanna, et al. Influences of QPQ salt bath treatment time on wear resistance of 304SS[J]. Transactions of Materials and Heat Treatment, 2013, 34(1): 153-156.

[5] LI Huiyou, LUO Defu, YEUNG C F, et al. Microstructural studies of QPQ complex salt bath heat-treated steels[J]. Journal of Materials Processing Technology, 1997, 69(1/2/3): 45-49.

[6] 熊光耀, 赵明娟, 赵龙志, 等. 稀土对模具钢QPQ渗层组织和性能的影响[J]. 热加工工艺, 2010, 39(4): 117-119.

XIONG Guangyao, ZHAO Mingjuan, ZHAO Longzhi, et al. Influence of RE on microstructure and properties of die steel by QPQ salt-bath treatment[J]. Hot Working Technol, 2010, 39(4): 117-119.

[7] 熊光耀, 何柏林, 周泽杰. 稀土La对5CrMnMo钢QPQ渗层组织和性能的影响[J]. 材料保护, 2008, 41(10): 95-98.

XIONG Guangyao, HE Bolin, ZHOU Zejie. Influence of RE La on microstructure and properties of 5CrMnMo steel by QPQ salt-bath treatment[J]. Materials Protection, 2008, 41(10): 95-98.

[8] 周正华, 谢飞, 胡浩波, 等. 直流电场对粉末法渗铝的影响[J]. 材料热处理学报. 2008, 29(6): 154-157.

ZHOU Zhenghua, XIE Fei, HU Haobo, et al. Influence of direct current field on powder aluminizing[J]. Transactions of Materials and Heat Treatment, 2008, 29(6): 154-157.

[9] ZHOU Zhenghua, XIE Fei, HU Jing. A novel powder aluminizing technology assisted by direct current field at low temperatures[J]. Surface & Coating Technology, 2008, 203(1/2): 23-27.

[10] 周正华, 谢飞, 潘献波, 等. 施加直流电场的快速粉末渗铬工艺[J]. 材料热处理学报. 2011, 32(2): 130-133.

ZHOU Zhenghua, XIE Fei, PAN Xianbo, et al. Rapid power chromizing technology assisted by direct current field[J]. Transactions of Materials and Heat Treatment, 2011, 32(2): 130-133.

[11] XIE Fei, SUN Li, PAN Jianwei. Characteristics and mechanisms of accelerating pack boriding by direct current field at low and moderate temperatures[J]. Surface & Coating Technology, 2012, 206(11/12): 2839-2844.

[12] PODGORNIK B, VIZINTIN J, LESKOVSEK V. Wear properties of induction hardened, conventional plasma nitrided and pulse plasma nitrided AISI sliding conditions[J]. Wear, 1999, 232(2): 231-242.

[13] JACQUET P, COUDERT J B, LOURDIN P. How different steel grades react to a salt bath nitrocarburizing and post-oxidation process: influence of alloying elements[J]. Surface & Coating Technology, 2011, 205(16): 4064-4067.

[14] CHEN Fanshiong, WANG Kuoliang. The kinetics and mechanism of multi-component diffusion on AISI 1045steel[J]. Surface & Coating Technology. 1999, 115(2/3): 239-248.

[15] SEN S, SEN U, BINDAL C. An approach to study of borided steels[J]. Surface & Coating Technology, 2005, 191(2/3): 274-285.

(编辑 陈爱华)

收稿日期:2015-07-03;修回日期:2015-11-14

基金项目(Foundation item):江苏高校优势学科建设工程项目(2014006);江苏省研究生创新基金资助项目(SCZ100431322)(Project(2014006) supported by PAPD of Jiangsu Higher Education Institutions; Project(SCZ100431322) supported by Jiangsu Province Graduate Student Innovation Fund)

通信作者:胡静,博士,教授,从事金属材料表面改性研究;E-mail: jinghoo@126.com