DOI:10.19476/j.ysxb.1004.0609.2018.07.03

挤压温度对6005A铝合金焊合区域显微组织和力学性能的影响

薛江平,黄东男,左壮壮,玄东坡,吴 南,孙 磊

(内蒙古工业大学 材料科学与工程学院,呼和浩特 010051)

摘 要:针对分流模挤压焊合部位的金属在模具中难以取出进行分析,设计了分析焊缝组织性能的简易模具;采用电子背散射衍射分析(EBSD)和拉伸试验,研究挤压温度对6005A铝合金挤压焊合组织性能的影响。结果表明:挤压温度为500~580 ℃ 时,6005A铝合金焊合组织的平均晶粒尺寸呈先减小后增大的趋势;当在挤压温度为540 ℃时,焊合组织平均晶粒尺寸最小,约为52 μm,且此时的晶粒尺寸均匀程度最佳。焊合组织中小角度晶界所占比例较多,且随着挤压温度的提高,小角度晶界的相对频率都保持在65%左右。焊合部位的屈服强度和抗拉强度随着挤压温度的升高呈先上升后下降的趋势;当挤压温度为540 ℃时,焊合组织的力学性能最好,屈服强度为 68.56 MPa,抗拉强度为119.87 MPa。

关键词:6005A铝合金;分流模挤压;挤压温度;焊合区域;显微组织;力学性能

文章编号:1004-0609(2018)-07-1291-08 中图分类号:TG379 文献标志码:A

随着航空航天、国防军工、汽车船舶等高精尖技术领域对铝合金空心型材需求的增加,对其性能提出了严格的要求[1]。分流模挤压是铝合金空心型材和管材的主要加工方式,焊合是分流模挤压过程中的最复杂过程[2-3]。在分流模挤压过程中,金属经过分流孔分流后,在焊合室内模桥下方经历了一个焊合过程,从而在型材横断面上留下焊缝[4],其焊缝性能直接影响铝型材的成形质量[5-6]。因此,探求焊合区域微观组织演变及焊缝质量是分流模挤压研究的热点问题之一。

分流模挤压是在高温、高压、高摩擦条件下,在几乎密闭的空间(模孔除外)里完成,由于其模腔结构复杂,挤压后保留在焊合室内焊合部位的金属无法完整取出,因此很难对其焊合部位的组织性能进行研 究[7]。目前,通常采用数值模拟技术通过焊合室内的静水应力大小来预测焊合质量,认为其静水应力高于挤压温度下屈服强度的5倍,可满足焊合要求[8]。国内北京有色金属研究院和上海交通大学等[9-10]模拟分析了焊合室高度对静水应力的影响,预测了焊合质量; 等[11]研究了空心铝型材挤压力和静水应力对焊缝的质量和形状的影响。本文作者所在课题组[12-13]模拟分析了异形管材、复杂断面空心铝型材的焊合成形过程。近年来,随着有限元数值模拟技术的发展和塑性本构方程的进一步完善,人们试图采用动态组织模拟的方法来预测分流模挤压过程组织演变,但是因组织演变模型构建过于复杂,尚未得到广泛应用。

等[11]研究了空心铝型材挤压力和静水应力对焊缝的质量和形状的影响。本文作者所在课题组[12-13]模拟分析了异形管材、复杂断面空心铝型材的焊合成形过程。近年来,随着有限元数值模拟技术的发展和塑性本构方程的进一步完善,人们试图采用动态组织模拟的方法来预测分流模挤压过程组织演变,但是因组织演变模型构建过于复杂,尚未得到广泛应用。

为了揭示焊合区域的本质特征,需要对焊合区域组织演变过程及焊缝的结合强度进行研究。由于该过程类似于动态的固态压力焊接过程,为此本文作者设计了略去分流过程和挤出过程,仅保留焊合室的简化可拆分模具,研究了挤压温度为500~580 ℃时,焊合区域的显微组织演变及焊缝的力学性能,为探索焊合机理提供理论基础。

1 实验

1.1 挤压模具设计

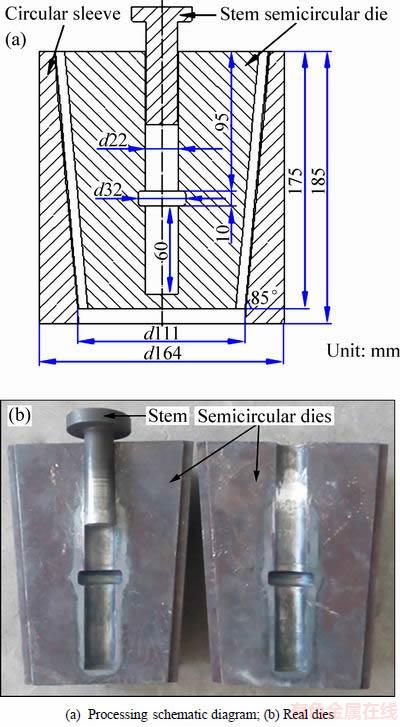

图1所示为本实验中所用挤压模具结构示意图,模具材料选用H13模具钢。由图1可知,为了方便取坯料,将模具设计成两个半圆形,并将两个半圆形模具装入一个套筒内,半圆模具外圆斜度为5°,套筒内圆也设计成斜度为5°,通过内外模具斜度配合使两个半圆模具受到压力作用时会越压越紧,从而避免挤压过程中在两半圆模具缝隙处产生飞边。

图1 挤压模具结构示意图

Fig. 1 Schematic diagram of die structure

1.2 实验材料与方法

本实验中所采用的材料为6005A铝合金,其化学成分如表1所示。实验采用试样尺寸为d 21 mm×65 mm和d 21 mm×80 mm的圆柱坯。

表1 6005A铝合金的化学成分

Table 1 Chemical compositions of 6005A Al-alloy (mass fraction, %)

挤压试验在立式挤压机上进行,挤压速度为30 mm/min,挤压温度分别为500、520、540、560和580 ℃,冷却方式为空冷。图2所示为挤压实验前后的坯料实物对比图。

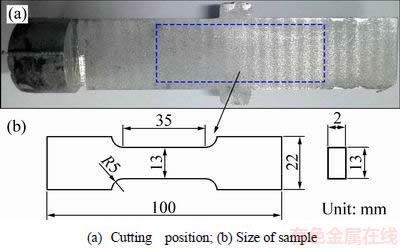

图3所示为拉伸试样尺寸及其EBSD试样的切取位置示意图。将挤压焊合试样从中间部位截取片状件,加工成标准的拉伸试样,在CMT-5105型电子万能试验机上进行力学性能测试,拉伸速率为3 mm/min。在焊合区域切取EBSD试样,将试样经机械研磨抛光后,在-20 ℃下使用5%HCLO4+95%C2H5OH(体积分数)电解液进行电解抛光,电解电压为30 V,之后利用配备HKL Channel 5 EBSD 系统的扫描电镜对样品进行EBSD分析。

图2 挤压实验前后坯料形状

Fig. 2 State and shape of billets

图3 拉伸试样切取位置及尺寸示意图

Fig. 3 Size and cutting position of sample

2 结果与分析

2.1 坯料原始组织形貌

挤压前坯料原始的显微组织形貌和晶粒尺寸分布如图4所示。由图4(a)可以看出,原始坯料的微观组织为等轴晶;由图4(b)可知,原始坯料的晶粒尺寸分布在5~385 μm之间,平均晶粒尺寸为85.36 μm。

2.2 挤压温度对焊合部位组织形貌的影响

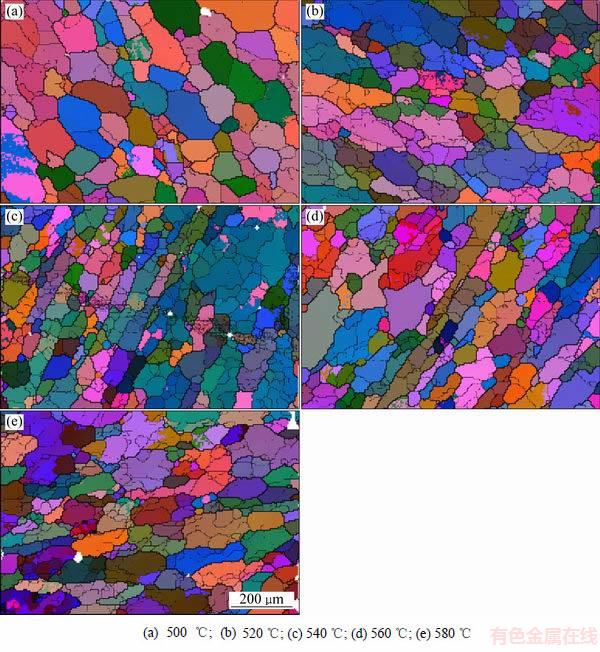

图5所示为不同挤压温度下焊合部位样品的显微组织形貌,图中大角度晶界(>15°)以粗线表示, 小角度晶界(2°~15°)以细线表示。综合图5(a)~(e)可知,挤压焊合后样品的显微组织主要由等轴晶粒和沿焊缝方向的长条状晶粒组成。其中长条状晶粒在变形合金中很常见,是原始组织中粗大晶粒被拉长产生的,呈现变形组织的特征,其原因是变形量小或变形温度低导致合金没有足够的变形储能来触发再结晶[14]。在晶粒内部出现了较多亚晶界,这是因为铝合金的层错能高,晶粒发生了动态回复;在晶界边界处有细小的等轴晶组织,说明合金在焊合过程发生了动态再结晶。当挤压温度为500 ℃时,其显微组织形貌与原始组织最为相似,主要以较大尺寸的等轴晶粒为主,但晶粒分布变得不均匀,在晶界处分散着少量细小的等轴晶粒。随着挤压温度的升高,大尺寸等轴晶粒减少,沿焊缝方向被拉长的长条状晶粒和细小的等轴晶组织逐渐增加,且在挤压温度为540 ℃时晶粒尺寸均匀化程度最好;但当继续升高挤压温度时,焊合区的晶粒尺寸又开始逐渐增大,小尺寸等轴晶粒数量逐渐减少,大尺寸等轴晶和沿焊缝方向的长条状晶粒逐渐增多,其原因是由焊合区的高温和静水应力的共同作用而形成 的[15-16]。

图4 原始坯料的显微组织形貌和晶粒尺寸分布

Fig. 4 Microstructure and grain size of original material

图5 不同挤压温度下焊合部位样品的EBSD晶粒形貌图

Fig. 5 EBSD images showing grain morphology of welding zone at different extrusion temperatures

图6 不同挤压温度下6005A铝合金的晶粒直径占样品面积的分数

Fig. 6 Area fraction of grain size of 6005A extruded at different extrusion temperatures

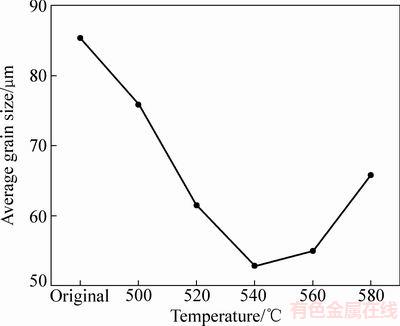

图6所示为不同挤压温度下焊合试样的晶粒尺寸分布图。由图6可知,与原始材料的晶粒相比,焊合后样品的晶粒尺寸变小。当挤压温度为500 ℃时,其晶粒尺寸主要分布在7.5~177.5 μm之间,其中20 μm以下的小尺寸晶粒所占比例较少,仅为9%,而100 μm以上的大尺寸晶粒所占比例较多,约为27%(见图6(a))。当挤压温度为520 ℃时,20 μm以下的小尺寸晶粒所占比例增加,100 μm以上的大尺寸晶粒所占比例减少(见图6(b))。当挤压温度为540 ℃时,20 μm以下的小尺寸晶粒所占比例继续增加,100 μm以上的大尺寸晶粒所占比例继续减少;此时20 μm以下的小尺寸晶粒所占比例约为23%,100 μm以上的大尺寸晶粒所占比例约为14%(见图6(c))。当挤压温度继续升高时,20 μm以下的小尺寸晶粒所占比例开始逐渐减少,100 μm以上的大尺寸晶粒所占比例开始逐渐增加(见图6(d)和(e))。图7所示为原始坯料和焊合后样品的平均晶粒尺寸变化,可以看出焊合后的平均晶粒尺寸明显减小。当挤压温度为500~580 ℃时,随着挤压温度的升高,其平均晶粒尺寸先减小后增大;当挤压温度为500 ℃时,平均晶粒尺寸最大,约为76 μm;在挤压温度为540 ℃时平均晶粒尺寸最小,约为52 μm,说明选择合理的挤压温度可以控制晶粒的细化程度。

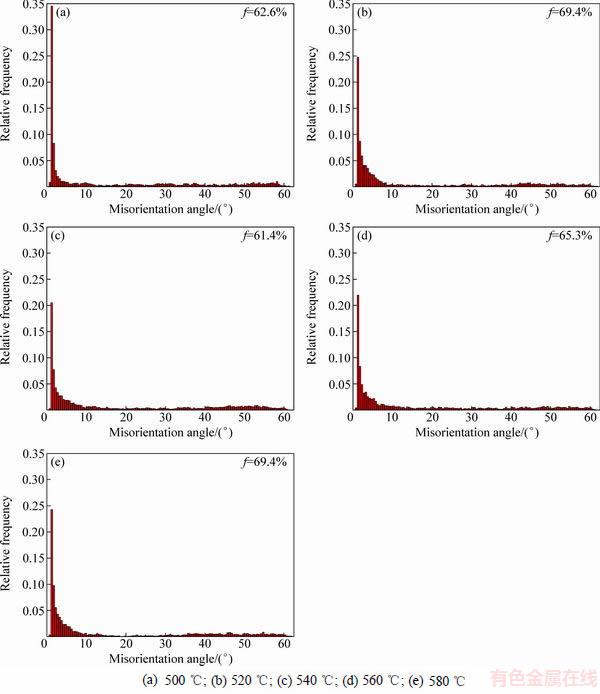

图8所示为不同挤压温度下样品的晶界取向差分布图,f的数值表明小角度晶界(2°~15°)占有的比例。综合图8(a)~(e)可知,在不同挤压温度下焊合后,样品的显微组织中小角度晶界所占比例较多。说明焊合后样品的显微组织中存在大量的形变组织,在晶粒内形成大量的亚结构。随着挤压温度的升高,小角度晶界的相对频率相差不大,都在65%左右。

图7 原始材料和不同挤压温度下样品的平均晶粒尺寸

Fig. 7 Grain size of initial sample and extruded sample at different extrusion temperatures

图8 不同挤压温度下的晶粒取向差分布

Fig. 8 Relative frequency of misorientation angle at different extrusion temperatures

2.3 挤压温度对焊合部位力学性能的影响

不同挤压温度焊合后的6005A铝合金室温拉伸性能如表2所示,其屈服强度和抗拉强度随挤压温度升高的变化规律如图9所示。拉伸试验结果显示,试样的断裂位置均发生在焊合面处,说明焊合面处的力学性能最差。结合表2与图9可知,屈服强度、抗拉强度随着挤压温度的升高呈现先上升后下降的趋势。当挤压温度为500 ℃时,屈服强度和抗拉强度最低,分别为44.23和57.44 MPa。随着挤压温度的升高,合金强度也逐渐升高,当挤压温度为540 ℃时,达到最高,屈服强度为68.56 MPa,抗拉强度为119.87 MPa,同时伸长率也达到最大值10.4%。随着挤压温度的进一步提高,屈服强度和抗拉强度开始下降,伸长率也逐渐降低。主要原因是随着挤压温度的升高,焊合区显微组织的晶粒细化效果越好,晶粒内部位错增多,而显著的晶粒细化使合金晶界增多,阻碍了位错的运动,降低了位错的可动性,从而提高了合金的强度;根据Hall-Petch关系式也可以说明随着晶粒的细化其材料的强度提高[17]。但当挤压温度继续升高时,屈服强度、抗拉强度均开始逐渐下降。这与焊合区微观组织的平均晶粒变化规律相同,进一步说明了合金的强度与晶粒的细化程度有关。挤压温度升高,焊合样品的平均晶粒尺寸变大,晶粒尺寸的不均匀性提高,导致晶粒间的变形协调性变差,在拉伸时裂纹容易形成而使材料强度降低[14]。

表2 6005A铝合金不同温度焊合后的室温力学性能

Table 2 Mechanical properties of welded A6005 alloys at different extrusion temperatures

图9 挤压温度对6005A铝合金屈服强度和抗拉强度的影响

Fig. 9 Effect of welding temperature on yield strength and tensile strength of 6005A Al-alloys

3 结论

1) 在挤压温度为500~580 ℃时,随着挤压温度的升高,其平均晶粒尺寸先减小后增大。当挤压温度为500 ℃时,平均晶粒尺寸最大,约为76 μm。然后,随着挤压温度的升高,其平均晶粒尺寸减小。当挤压温度为540 ℃时,平均晶粒尺寸最小,约为52 μm,且此时的晶粒尺寸均匀程度最好。但当继续提高挤压温度时,平均晶粒尺寸开始逐渐增大。

2) 在不同挤压温度下焊合后,样品的显微组织中小角度晶界所占比例较多。且随着挤压温度的升高,小角度晶界的相对频率相差不大,都在65%左右。

3) 焊合部位铝合金的屈服强度和抗拉强度随着挤压温度的升高呈现先上升后下降的趋势。当挤压温度为540 ℃时,力学性能最好,屈服强度为68.56 MPa,抗拉强度为119.87 MPa。

REFERENCES

[1] 谢建新. 金属挤压技术的发展现状与趋势[J]. 中国材料进展, 2013, 32(5): 257-263.

XIE Jian-xin. Current situation and development trends of metals extrusion technology[J]. Materials China, 2013, 32(5): 257-263.

[2] 黄东男, 于洋, 李有来, 左壮壮. 复杂断面空心铝型材分流模挤压焊合过程金属流变行为分析[J]. 材料工程, 2014(9): 68-75.

HUANG Dong-nan, YU Yang, LI You-lai, ZUO Zhuang-zhuang. Metal flowing behavior during welding process of porthole extrusion for complicate Al-alloy profile[J]. Journal of Materials Engineering, 2014(9): 68-75.

[3] 谢建新, 刘静安. 金属挤压理论与技术[M]. 2版. 北京: 冶金工业出版社, 2012.

XIE Jian-xin, LIU Jing-an. Theory and technology for metal extrusion[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2012.

[4] 冯 迪, 张新明, 孙 峰, 史兴宽, 陈艳峰, 李飞龙. 铝合金空心型材挤压焊合问题的研究进展[J]. 材料导报, 2013, 27(19): 6-9.

FENG Di, ZHANG Xin-Ming, SUN Feng, SHI Xing-kuan, LI Fei-long. Research and progress in weld seams of aluminum alloy hollow profile extrusion[J]. Materials Review, 2013, 27(19): 6-9.

[5] DEN BAKKER A J, WERKHOVEN R J, SILLEKENS W H. The origin of weld seam defects related to metal flow in the hot extrusion of aluminum alloys EN AW-6060 and EN AW-6082[J]. Journal of Materials Processing Technology, 2014, 214(11): 2349-2358.

[6] YU J, ZHAO G, CHEN L. Investigation of interface evolution, microstructure and mechanical properties of solid-state bonding seams in hot extrusion process of aluminum alloy profiles[J]. Journal of Materials Processing Technology, 2016, 230: 153-166.

[7] 黄东男, 于 洋, 宁 宇, 马 玉. 分流模挤压非对称断面铝型材有限元数值模拟分析[J]. 材料工程, 2013(3): 32-37.

HUANG Dong-nan, YU Yang, NING Yu, MA Yu. FEM simulation of an Al-alloy profile with Non-symmetrical cross section during porthole extrusion[J]. Journal of Materials Engineering, 2013(3): 32-37.

[8] 黄东男, 李有来, 左壮壮, 马 玉. 异形管材分流模挤压焊合过程金属流变及模具受力的模拟分析[J]. 材料科学与工艺, 2015(2): 25-32.

HUANG Dong-nan, LI You-lai, ZUO Zhuang-zhuang, MA Yu. Simulation analysis of metal flowing behaviors and die stress distributions during porthole extrusion of a special pipe[J]. Materials Science &Technology, 2015(2): 25-32.

[9] 程 磊, 谢水生, 黄国杰, 和优锋. 焊合室高度对分流组合模挤压成形过程的影响[J]. 稀有金属, 2008, 32(4): 442-446.

CHENG Lei, XIE Shui-sheng, HUANG Guo-jie, HE You-feng. Effects of height of welding chamber heights on extrusion forming process of porthole die[J]. Chinese Journal of Rare Metals, 2008, 32(4): 442-446.

[10] TANG D, ZHANG Q, LI D, PENG Y. A physical simulation of longitudinal seam welding in micro channel tube extrusion[J]. Journal of Materials Processing Technology, 2014, 214(11): 2777-2783.

[11]  S, BOZACI A. Experimental and numerical study on the strength of aluminum extrusion welding[J]. Materials, 2015, 8(7): 4389-4399.

S, BOZACI A. Experimental and numerical study on the strength of aluminum extrusion welding[J]. Materials, 2015, 8(7): 4389-4399.

[12] 黄东男, 张志豪, 李静媛, 谢建新. 焊合室深度及焊合角对方形管分流模挤压成形质量的影响[J]. 中国有色金属学报, 2010, 20(5): 954-960.

HUANG Dong-nan, ZHANG Zhi-hao, LI Jing-yuan, XIE Jian-xin. Influences of welding chamber depth and welding angle on forming quality of extrusion of square tube by porthole die[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 954-960.

[13] 黄东男, 李静媛, 张志豪, 谢建新. 方形管分流模双孔挤压过程中金属的流动行为[J]. 中国有色金属学报, 2010, 20(3): 488-495.

HUANG Dong-nan, LI Jing-yuan, ZHANG Zhi-hao, XIE Jian-xin. Metal flowing behaviors during diplopore extrusion of square tube with porthole die[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 488-495.

[14] 杨俊英, 高 飞, 宁海石, 宋宝韫. 加热温度对AZ31镁合金连续挤压组织与性能的影响[J]. 锻压技术, 2014, 39(5): 106-111.

YANG Jun-ying, GAO Fei, NING Hai-shi, SONG Bao-yun. Effect of heating temperature on microstructure and properties of AZ31 magnesium alloy in conform process[J]. Forging & Stamping Technology, 2014, 39(5): 106-111.

[15] YU J, ZHAO G, ZHANG C, CHEN L. Dynamic evolution of grain structure and micro-texture along a welding path of aluminum alloy profiles extruded by porthole dies[J]. Materials Science and Engineering: A, 2017, 682: 679-690.

[16] FAN X H, TANG D, FANG W L, LI D Y, PENG Y H. Microstructure development and texture evolution of aluminum multi-port extrusion tube during the porthole die extrusion[J]. Materials Characterization, 2016, 118: 468-480.

[17] 陈克华, 梁 伟, 王顺旗, 薛晋波, 王红霞, 边丽萍. 等通道转角挤压Al-Mg2Si合金的组织与性能研究[J]. 稀有金属材料与工程, 2010(2): 352-356.

CHEN Ke-hua, LIANG Wei, WANG Shun-qi, XUE Jin-Bo, WANG Hong-xia, BIAN Li-ping. Microstructure and properties of Al-Mg2Si alloys after equal channel angular pressing[J]. Rare Metal Materials and Engineering, 2010(2): 352-356.

Influence of extrusion temperature on microstructure and mechanical properties of welding zone of 6005A aluminum alloy

XUE Jiang-ping, HUANG Dong-nan, ZUO Zhuang-zhuang, XUAN Dong-po, WU Nan, SUN Lei

(School of Materials Science and Engineering, Inner Mongolia University of Technology, Hohhot 010051, China)

Abstract: A new die was designed to solve the problem that the alloy was difficult to be taken out when it was welded by porthole die extrusion. The effect of the extrusion temperature on microstructure and mechanical properties of 6005A aluminum alloy was studied by electron backscattered diffraction (EBSD), combined with the mechanical tensile properties test. The results show that the average grain size of the welding zone will be reduced at first and then improved when the extrusion temperature is in the range of 500-580 ℃, the average grain size is the smallest of about 52 μm and the uniformity is the best at 540 ℃. The percentage of the low angle boundaries of welding zone is the highest and the relative frequency of low angle boundaries keeps at 65% with the rise of extrusion temperature. The tensile strength and yield strength of the welding zone will be improved at first and then reduced with the increase of extrusion temperature. And the mechanical property of 6005A aluminum alloy is the best at 540 ℃, the yield strength and tensile strength are 68.56 MPa and 119.87 MPa, respectively.

Key words: 6005A aluminum alloy; porthole die extrusion; extrusion temperature; welding zone; microstructure; mechanical property

Foundation item: Project(51364027) supported by the National Natural Science Foundation of China; Project (10381007) supported by the Middle and Young Aged Academic Key Project of Inner Mongolia University of Technology, China

Received date: 2017-05-23; Accepted date: 2017-07-20

Corresponding author: HUANG Dong-nan; Tel: +86-471-6577257; E-mail: dongnan_huang@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51364027);内蒙古工业大学中青年学术骨干项目(10381007)

收稿日期:2017-05-23;修订日期:2017-07-20

通信作者:黄东男,教授,博士;电话:0471-6577257;E-mail:dongnan_huang@163.com