文章编号:1004-0609(2011)05-1131-06

碳热还原法合成TiC-SiC复合粉末及其生长机理

胡继林1, 2, 肖汉宁1, 李 青1, 郭文明1, 高朋召1

(1. 湖南大学 材料科学与工程学院,长沙 410082;2. 湖南人文科技学院 化学与材料科学系,娄底 417000)

摘 要:以硅溶胶、炭黑和TiO2为原料,采用碳热还原法合成TiC-SiC复合粉末。研究反应温度和TiO2添加量对合成TiC-SiC复合粉末的物相组成和显微形貌的影响;对反应过程进行热力学分析和计算,探讨TiC-SiC复合粉末的生长机理。结果表明:TiC-SiC复合粉末适宜的合成条件为在1 600 ℃保温1 h;在反应过程中,TiC先于SiC形成,TiC的形成抑制了SiC颗粒的生长;当复合粉末中TiC的含量(质量分数)为10%左右时,SiC的合成过程由气-固(V-S)机理反应转变为气-固机理和气-气机理共同反应;复合粉末主要由球状颗粒、短棒状颗粒以及少量晶须组成;随着复合粉末中TiC含量的增加,SiC晶须的生长受到抑制,其形貌逐步由长纤维状向短棒状和颗粒状过渡。

关键词:TiC-SiC;复合粉末;碳热还原法;生长机理

中图分类号:TQ163

Synthesis and growth mechanism of

TiC-SiC composite powders by carbothermal reduction

HU Ji-lin1, 2, XIAO Han-ning1, LI Qing1, GUO Wen-ming1, GAO Peng-zhao1

(1. College of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. Department of Chemistry and Materials Science,

Hunan Institute of Humanities, Science and Technology, Loudi 417000, China)

Abstract: The TiC-SiC composite powders were synthesized by carbothermal reduction using silica sol, carbon black and titanium oxide as raw materials. The effects of reaction temperature and titanium oxide content on the phase compositions and morphologies of TiC-SiC composite powders were investigated. The thermodynamic analysis and calculation were performed systematically during the reaction, and the growth mechanism of TiC-SiC composite powders was discussed. The results show that synthesizing TiC-SiC composite powders at 1 600 ℃ for 1 h is suitable. In the reaction process, TiC forms ahead SiC, and the formation of TiC inhibits the grain growth of SiC particles. When TiC content (mass fraction) is about 10%, the formation mechanism of SiC is transferred from vapor-solid mechanism to the combination of vapor-solid and vapor-vapor mechanism. The composite powders are mainly composed of spheric particles, short rod-like particles and a small amount of whiskers. With the increase of TiC content in the composite powders, the growth of SiC whiskers is inhibited and the morphology of SiC gradually transferred from long fiber to short rod-like and round-like particles.

Key words: TiC-SiC; composite powder; carbothermal reduction; growth mechanism

碳化硅(SiC)陶瓷因具有高硬度、优良的抗蠕变能力和高温抗氧化性能,已成为引人注目的耐磨和高温结构材料,在机械、化工、能源和军工等领域已获得广泛应用,是很有前途的工程材料[1-3]。和其他许多结构陶瓷一样,SiC陶瓷的断裂韧性低(<4 MPa·m1/2),具有对缺陷和冲击的高度敏感性及较低的可靠性,从而限制了它的应用范围。

在SiC基体中添加第二相粒子是克服SiC陶瓷材料脆性的有效途径之一。添加第二相粒子可以改善单一陶瓷材料的强度和断裂韧性。过渡金属元素的硼化物和碳化物由于在高温下仍具有很高的硬度和化学稳定性,因此在许多复合材料体系中作为增强相得到广泛研究[4-5]。TiC具有较高的断裂韧性,高熔点(>3 000 ℃)、高硬度(维氏硬度为28~35 GPa)、良好的导电性和化学稳定性,是一种重要的工程陶瓷材料,已广泛用作航空部件、切削刀具、防弹装甲、机械耐磨部件等[6-8]。关于添加TiC粒子改善SiC陶瓷力学性能研究已有不少文献报道。JIANG等[9]研究了不同TiC添加量对α-SiC的力学性能和氧化行为的影响,在最佳制备条件下,材料的断裂韧性和弯曲强度分别达到7.15 MPa·m1/2和589 MPa。HYUN等[10]以TiC含量(质量分数)为30%的α-SiC和β-SiC粉末为原料,研究了起始α-SiC的含量对热压SiC-TiC复相陶瓷的显微结构和力学性能的影响。为提高SiC-TiC复相陶瓷的力学性能,ROBAYIE等[11]以细磨后的SiC和TiC颗粒为原料,通过热压制备了TiC-SiC复相陶瓷。CHEN等[12]则以TiC和SiC为原料,在1 650~2 000 ℃范围内和Ar气保护条件下,通过两步法制备出TiC-SiC复合材料,并对其力学、热学和电学等性能进行了研究。

要制备性能优良的TiC-SiC复合材料,获得混合均匀且不团聚的TiC和SiC起始粉末原料非常重要。文献所述研究工作[10-12],基本都是用TiC和SiC粉末直接混合然后通过热压烧结来制备TiC-SiC复合材料。但机械混合法难以制备组分均匀的粉末原料,对复合材料的微观结构及性能产生不利影响。合成高纯超细的TiC-SiC复合粉末是制备性能优异的TiC-SiC复合材料的基础,目前,关于采用碳热还原法合成TiC-SiC复合粉末的文献报道较少,对复合粉末的合成反应过程和生长机理研究尚未见文献报道。为进一步改善TiC与SiC的复合效果,本文作者采用溶胶-凝胶和碳热还原法合成TiC-SiC复合粉末,分析了反应温度、TiO2添加量对TiC-SiC复合粉末的物相组成和显微形貌的影响,探讨了TiC-SiC复合粉末的生长机理。

1 实验

采用商品硅溶胶,用阳离子交换树脂除Na+后,Na的质量分数少于0.06%,SiO2为26%~28%;TiO2粉末由汕头市光华化学厂生产,化学纯,含量为99.0%;炭黑为南坪炭黑厂生产,粒径约为20 nm,灰分少于0.1%。

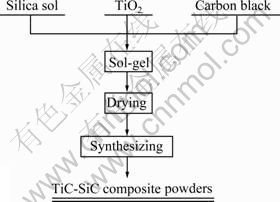

实验流程如图1所示。将各原料按一定比例精确配料,然后以无水乙醇为分散介质,以SiC球石为研磨介质,在行星式球磨机上球磨混合30 min,转速为600 r/min。混合料经80 ℃干燥24 h后获得凝胶样品,然后将凝胶粉末放入石墨坩埚内,在多功能热压炉(F100-1型)中于1 300~1 700 ℃下合成TiC-SiC复合粉末,升温速率为20 ℃/min,保护气氛为Ar气,保温1 h后停止加热,随炉冷却至室温。

图1 TiC-SiC复合粉末合成的实验流程

Fig.1 Procedure of preparation of TiC-SiC composite powders

采用X射线衍射仪(XRD,D/max2200PC) 对所合成的样品进行物相组成分析;用电子分析天平测定反应前后的物料的质量损失,以判断反应进行的程度;采用扫描电镜(SEM,FEI QUANTA200)和透射电镜(TEM,JEM-3010)观察复合粉末的微观形貌。

2 结果与讨论

2.1 复合粉末的物相分析

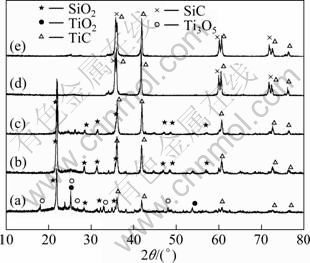

图2所示为不同温度下合成的Ti/Si摩尔比为20:80的TiC-SiC复合粉末的XRD谱。从图2中可以看出,合成温度对粉末样品的物相组成有很大影响。当合成温度为1 300 ℃时,粉末样品的XRD谱上存在SiO2、TiO2、Ti3O5和TiC的衍射峰,表明TiO2和炭黑的混合物在1 300 ℃下开始发生碳热还原反应。当合成温度为1 400 ℃时,粉末样品的XRD谱主要为SiO2和TiC的衍射峰,而TiO2和Ti3O5的衍射峰消失。随着反应温度的升高,TiC的衍射峰增强。当反应温度为1 500 ℃时,所得粉末样品的XRD衍射峰变化不大,仍然以SiO2和TiC的衍射峰为主,这表明SiO2和炭黑的混合物在该温度下仍无明显的碳热还原生成SiC的反应。反应温度进一步升高至1 600 ℃时,从XRD谱上可看到,主晶相为SiC和TiC,其他晶相已消失,这表明在此温度下碳热还原反应已基本完全。合成温度进一步升高至1 700 ℃时,复合粉末特征峰的峰形更加尖锐,这表明在此温度下生成的SiC和TiC的晶粒更大,结晶度更好。

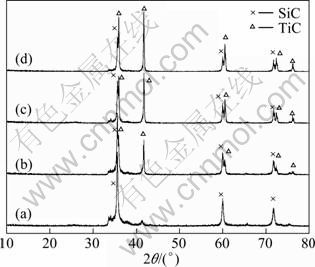

图3所示为1 600 ℃下不同Ti/Si摩尔比复合粉末样品的XRD谱。从图3中可以看出,随着Ti/Si摩尔比的增加,所制得粉末样品的TiC衍射峰强度明显增强,表明有更多的TiC生成。同时,XRD谱中仅有SiC和TiC的衍射峰,无其他杂质的衍射峰存在,说明合成反应已完全。

图2 不同温度下Ti/Si摩尔比为20:80的样品的XRD谱

Fig.2 XRD patterns of composite powders with Ti/Si molar ratio of 20:80 at different temperatures: (a) 1 300 ℃; (b) 1 400 ℃; (c) 1 500 ℃; (d) 1 600 ℃; (e) 1 700 ℃

图3 在1 600 ℃下不同Ti/Si摩尔比粉末样品的XRD谱

Fig.3 XRD patterns of composite powders obtained at 1 600 ℃ with different Ti/Si molar ratios: (a) n(Ti)?n(Si)=0?100; (b) n(Ti)?n(Si)= 10?90; (c) n(Ti)?n(Si)=20?80; (d) n(Ti)?n(Si)=30?70

2.2 合成反应转化程度分析

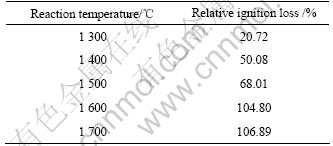

SiO2和TiO2的碳热还原反应均会生成CO气体,用CO气体逸出导致的样品质量损失可评价反应过程进行的程度。本研究以实测反应质量损失量与理论质量损失量的比值来判断反应进行的程度。TiC-SiC复合粉末样品合成过程中相对质量损失量随温度的变化如表1所列。

表1 复合粉末样品的相对质量损失量与合成温度的关系

Table 1 Relationship between relative ignition loss and reaction temperature for products

由表1可知,随着反应温度的升高,相对质量损失量也随之增加。当反应温度为1 500 ℃时,相对质量损失量为68.01%,而反应温度升高至1 600 ℃时,相对质量损失量达到104.80%,超过了理论质量损失量,反应温度继续升高到1 700 ℃时,相对质量损失量增加约2%。以上结果表明,在1 600 ℃下碳热还原反应已基本完成,与XRD分析的结果一致。

在1 600 ℃下的实际质量损失量超过理论质量损失量的主要原因是:在高温下SiO2的碳热还原反应分两步进行,首先还原为气态SiO,然后再进一步还原转变为SiC(见表2);合成过程中有部分SiO与CO气体一起从系统中逸出,从而造成实测质量损失量超过理论质量损失量。

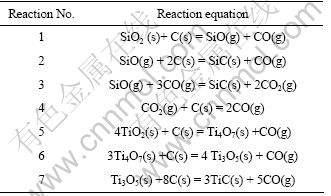

表2 TiC-SiC粉末合成过程中体系可能发生的反应[13-16]

Table 2 Possible reactions of TiC-SiC powder during synthesis

2.3 复合粉末的显微结构分析

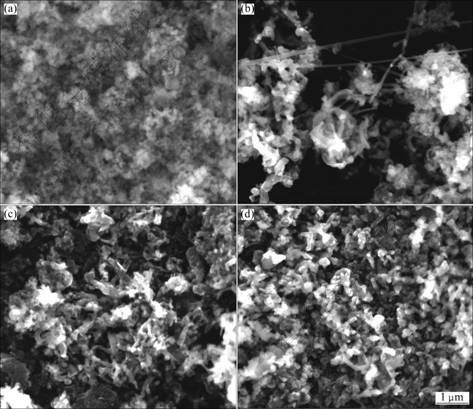

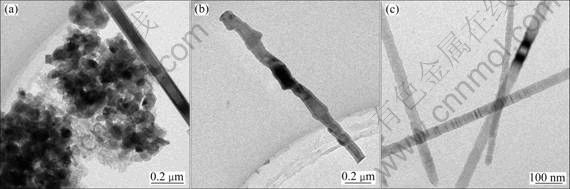

在1 600 ℃下保温1 h所得不同Ti/Si比粉末样品的SEM像如图4所示。从图4(a)~(d)中可以看出,纯SiC粉末样品主要为球状颗粒。加入Ti源后,不同Ti/Si比的复合粉末的微观形貌发生改变。从图4(b)中可以看出,样品中除颗粒外,还有一定数量的晶须(或纤维)出现。用TEM对晶须进行了进一步的观察,其典型的结构特征如图5所示。由图5可见,粉末中的晶须比较细长,直径在30~100 nm之间。从外形上看,既有内部空心的竹节状晶须(见图5(a)),也有表面不平滑的较粗的长棒状晶须(见图5(b)),还有一些实心的具有孪晶结构的纤维状晶须(见图5(c))。以上结构表明,当复合粉末中含有一定量的TiC时,Ti的存在改变了SiC粉末的生长方式。比较图4(b)~(d)可知,随着复合粉末中TiC含量的增加,SiC晶须的生长受到抑制,逐步由长纤维状向短棒状和颗粒状过渡。

图4 在1 600 ℃下合成的不同Ti/Si摩尔比粉末样品的SEM像

Fig.4 SEM images of powder samples with different Ti/Si ratios synthesized at 1 600 ℃ for 1 h: (a) n(Ti)?n(Si)=0?100;

(b) n(Ti)?n(Si)=10?90; (c) n(Ti)?n(Si)=20?80; (d) n(Ti)?n(Si)=30?70

图5 在1 600 ℃下合成Ti/Si摩尔比为10?90的粉末样品的TEM像

Fig.5 TEM images of powder samples with n(Ti)?n(Si)=10?90 synthesized at 1 600 ℃ for 1 h

2.4 合成机理

TiC-SiC复合粉末在高温合成过程中可能发生的化学反应如表2所列。

由表2可知,SiC的合成主要是按反应(1)~(3)进行,其中反应(1)是关键。由热力学分析表明,在1 750 ℃反应(1)的?GT才开始变为负值,这高于合成SiC的实际温度,主要原因在于:一方面热力学理论分析是假定气相的压力均为0.1 MPa,而在本实验条件下,实际上SiO和CO气体的分压是很低的;另一方面,前驱体凝胶粉末中的SiO2和炭黑粒子均非常小,两者的反应活性大大增加,这两方面的因素都促使反应(1)可以在较低的温度下发生。图2所示的XRD谱表明在1 600 ℃下SiC的合成反应已发生。

在本实验中,碳热还原反应之初主要靠SiO2与C颗粒之间的直接接触,是纯粹的固-固反应,生成的SiO气体与C颗粒通过反应(2)生成SiC颗粒,该反应是以C颗粒为核的气-固反应,因此,反应物C颗粒的形状和大小决定了产物SiC颗粒的形状和大小,所以反应式(2)是生成SiC颗粒的主要反应。随着反应的进行,SiO2与C颗粒之间的接触逐渐减弱,同时生成的SiC阻碍了C的固相扩散以及SiO的气相扩散。这样,SiC就可能通过SiO和CO按反应(3)生成,而该反应是两种气体SiO和CO之间的气-气反应,反应产物SiC独立成核生长,与C颗粒的大小无关,因此,反应(3)可能是SiC晶须生长的主要反应[17-18]。

TiC的合成主要是反应(5)~(7),可见TiO2在与C反应的过程中首先要生成Ti4O7、Ti3O5等中间产物,最后才生成TiC。经热力学计算,反应(5)、(6)和(7)的起始反应温度分别为1 087、1 182和1 334 ℃,当温度高于1 334 ℃时,TiC按反应(7)大量生成。由此可知,在1 300 ℃以上反应所得样品中应该没有Ti4O7的存在,因为在1 300 ℃时,Ti4O7的生成以及向Ti3O5转化的反应早已完成。此外,由于凝胶粉末中炭黑颗粒完全覆盖在TiO2颗粒的表面,大大增加了两者的接触面积,从而也使得反应物之间能够在较低的温度下发生,生成TiC。这一分析结果与XRD的测试结果一致。

由热力学分析和XRD的测试结果可知,TiC先于SiC形成,而且先形成的TiC会抑制SiC颗粒的生长,同时改变其生长方式。当体系中TiC含量较小时(10%左右),可以促使SiC以气-固机理形成球状和短棒状结构,同时以气-气机理生成晶须结构。而当体系中的TiC含量较大(≥20%)时,SiC则主要以气-固机理反应生成球状和短棒状等结构。

3 结论

1) 采用溶胶-凝胶和碳热还原法合成了TiC-SiC复合粉末。合成反应温度对复合粉末的形成起重要作用,在本实验条件下,合适的反应条件为在1 600 ℃下保温1 h。

2) 当复合粉末中TiC含量为10%左右时,TiC的生成一方面可以抑制SiC颗粒的长大,同时改变了SiC颗粒的生长方式,使得SiC的合成从气-固机理转变为气-固机理和气-气机理共同作用,从而促使SiC从单一的球状晶体转变为形成球状、棒状以及晶须等多样化结构。

3) 体系中TiC的含量增加到20%以上时,SiC通过气-固机理反应生成球状和棒状结构。

REFERENCES

[1] LI Ke-zhi, WEI Jian, LI He-jun, WANG Chuang, JIAO Geng-sheng. Silicon assistant carbothermal reduction for SiC powders[J]. J Univ Sci Technol Beijing, 2008, 15(4): 484-488.

[2] XU X, MEI S, FERREIRA J M F, NISHIMURA T, HIROSAKI N. Silicon carbide ceramics through temperature-induced gelation and pressureless sintering[J]. Mater Sci Eng A, 2004, 382(1/2): 335-340.

[3] 丁玉生, 董绍明, 高 乐, 何 平, 张翔宇, 江东亮. 烧结温度对Cf/siC复合材料结构及性能的影响[J]. 无机材料学报, 2008, 23(6): 1151-1154.

DING Yu-sheng, DONG Shao-ming, GAO Le, HE Ping, ZHANG Xiang-yu, JIANG Dong-liang. Effect of sintering temperature on microstructure and properties of Cf/SiC composites[J]. Journal of Inorganic Materials, 2008, 23(6): 1151-1154.

[4] ZHANG Xing-hong, HU Ping, HAN Jie-cai, MENG Song-he. Ablation behavior of ZrB2–SiC ultra high temperature ceramics under simulated atmospheric re-entry conditions[J]. Compos Sci Technol, 2008, 68(7/8): 1718-1726.

[5] 颜建辉, 张厚安, 李益民. TiC-TiB2增强MoSi2复合材料的力学性能及抗氧化行为[J]. 中国有色金属学报, 2009, 19(8): 1424-1430.

YAN Jian-hui, ZHANG Hou-an, LI Yi-min. Mechanical properties and oxidation resistance behavior of TiC-TiB2 reinforced MoSi2 composites[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(8): 1424-1430.

[6] DURLU N. Titanium carbide based composites for high temperature applications[J]. J Eur Ceram Soc, 1999, 19(13/14): 2415-2419.

[7] VALLAURI D, DEORSOLA F A. Synthesis of TiC-TiB2-Ni cermets by thermal explosion under pressure[J]. Mater Res Bull, 2009, 44(7): 1528-1533.

[8] SUN Lan, PAN Jin-sheng, LIN Chang-jian. Wear behavior of TiC-MoSi2 composites[J]. Mater Lett, 2003, 57(7): 1239-1243.

[9] JIANG D L, WANG J H, LI Y L, MA L T. Studies on the strengthening of silicon carbide-based multiphase ceramics I: The SiC-TiC system[J]. Mater Sci Eng A, 1989, 109: 401-406.

[10] HYUN G A, YOUNG W K, JUNE G L. Effect of initial α-phase content of SiC on microstructure and mechanical properties of SiC-TiC composites[J]. J Eur Ceram Soc, 2001, 21(1): 93-98.

[11] ROBAYIE J A, KOPP C, HAUSNER H. The influence of processing parameters on microstructure and mechanical properties of SiC-TiCp ceramics[J]. Ceram Int, 1995, 21(4): 297-301.

[12] CHEN J, LI W J, JIANG W. Characterization of sintered TiC-SiC composites[J]. Ceram Int, 2009, 35(8): 3125-3129.

[13] SHARMA N K, WILLIAMS W S, ZANGVIL A. Formation and structure of silicon carbide whiskers from rice hulls[J]. J Am Ceram Soc, 1984, 67(11): 715-720.

[14] BIERNACKI J J, WOTZAK G P. Stoichiometry of the C + SiO2 reaction[J]. J Am Ceram Soc, 1989, 72(1): 122-129.

[15] HASSINE N A, BINNER J G P, CROSS T E. Synthesis of refractory metal carbide powders via microwave carbothermal reduction[J]. Int J Refract Met Hard Mater, 1995, 13(6): 353-358.

[16] PREISS H, BERGER L M, SCHULTZE D. Studies on the carbothermal preparation of titanium carbide from different gel precursors[J]. J Eur Ceram Soc, 1999, 19(2): 195-206.

[17] RAMAN V, BHATIA G, BHARDWAJ S, SRIVASTVA A K, SOOD K N. Synthesis of silicon carbide nanofibers by sol-gel and polymer blend techniques[J]. J Mater Sci, 2005, 40(6): 1521-1527.

[18] SILVA P C, FIGUEIREDO J L. Production of SiC and Si3N4 whiskers in C + SiO2 solid mixtures[J]. Mater Chem Phys, 2001, 72(3): 326-331.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50972042)

收稿日期:2010-06-10;修订日期:2010-10-02

通信作者:肖汉宁,教授,博士;电话:0731-88822269; E-mail:hnxiao@hnu.cn