不同轧制路径对工业纯钛板机械各向异性及成形性的影响

来源期刊:中国有色金属学报(英文版)2017年第6期

论文作者:刘定凯 黄光胜 龚桂林 王冠刚 潘复生

文章页码:1306 - 1312

关键词:工业纯钛;交叉轧制;各向异性;织构;拉深

Key words:CP-Ti; cross rolling; anisotropy; texture; deep drawing

摘 要:研究了不同轧制路径对工业纯钛板机械各向异性及成形性的影响。路径A和路径B是分别沿原始轧向和横向的单向轧制,路径C是交叉轧制,即每次轧制之后旋转90°继续轧制。测试了不同轧制路径获得板材的 显微织构、力学性能(强度、伸长率)和各向异性。X射线衍射结果表明从路径A到路径C,轧制板材的织构逐渐减弱。与路径A和路径B相比较,路径C轧制的板材的平面各向异性系数更小。拉深实验显示交叉轧制可以有效地避免制耳的产生;杯突实验表明交叉轧制可以提高钛板成型能力。

Abstract: Influence of three different rolling routes on mechanical anisotropy and formability of commercially pure titanium sheet was investigated. Route A and Route B are unidirectional rolling (UR) where the rolling direction is along initial rolling direction (RD) and transverse direction (TD), respectively. Route C is cross rolling (CR) where the rolling direction is changed by 90° after each rolling pass. The microstructure and texture, tensile mechanical properties including strength and elongation, and also the anisotropy of the UR and CR sheets were investigated at room temperature. The XRD results indicate that the texture intensity of rolled samples gradually weakens from Route A to Route C. Compared with Route A and Route B rolled samples, the Route C rolled samples show a smaller planar anisotropy. The deep drawing tests reveal that cross rolling can avoid the occurrence of earing. Erichsen tests indicate that rolling routes have an effect on stretch formability of pure titanium sheet.

Trans. Nonferrous Met. Soc. China 27(2017) 1306-1312

Ding-kai LIU1,2, Guang-sheng HUANG1,2,3, Gui-lin GONG1,2, Guan-gang WANG1,2, Fu-sheng PAN1,2,3

1. State Key Laboratory of Mechanical Transmission, College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloys,Chongqing University, Chongqing 400044, China;

3. Chongqing Research Center for Advanced Materials, Chongqing Academy of Science & Technology, Chongqing 401123, China

Received 8 March 2016; accepted 9 October 2016

Abstract: Influence of three different rolling routes on mechanical anisotropy and formability of commercially pure titanium sheet was investigated. Route A and Route B are unidirectional rolling (UR) where the rolling direction is along initial rolling direction (RD) and transverse direction (TD), respectively. Route C is cross rolling (CR) where the rolling direction is changed by 90° after each rolling pass. The microstructure and texture, tensile mechanical properties including strength and elongation, and also the anisotropy of the UR and CR sheets were investigated at room temperature. The XRD results indicate that the texture intensity of rolled samples gradually weakens from Route A to Route C. Compared with Route A and Route B rolled samples, the Route C rolled samples show a smaller planar anisotropy. The deep drawing tests reveal that cross rolling can avoid the occurrence of earing. Erichsen tests indicate that rolling routes have an effect on stretch formability of pure titanium sheet.

Key words: CP-Ti; cross rolling; anisotropy; texture; deep drawing

1 Introduction

Titanium and titanium-based alloys have been widely used in various engineering and medical fields due to their high elastic limit-to-density ratio, high resistance to corrosion and good biocompatibility [1-3]. Consequently, many researches on pure titanium or CP-Ti have been done in the past decades due to its complex deformation mechanisms [4-6]. CP-Ti has a hexagonal close-packed (hereafter referred to as HCP) structure with a c/a ratio of 1.587, which is lower than the ideal c/a ratio (1.633). Consequently, compared with other HCP metals, the most favorable slip system in CP-Ti is prismatic slip rather than basal slip at room temperature. Though basal slip and pyramidal slip are potential slip systems [1,7,8], the slip systems can only provide four independent slip systems. According to the von Mises criterion, at least five independent slip systems are necessary to accommodate arbitrary plastic strains, so

It is well known that deep drawing is an important and popular process in sheet metal forming. Apart from its employment in electronics products, it is applied widely in the automotive industry for the manufacturing of car body parts [2,21,22]. The deep-drawn products of CP-Ti sheets are always accompanied with earing defects. The occurrence of earing, during the deep drawn process, is undesirable since extra processing is required to trim it, which will improve the costs of productions. Therefore, it is significant to make efforts to reduce earing during the deep drawing of CP-Ti sheets.

It is well established that the earing defect, during the deep drawing process, is primarily caused by the planar anisotropy of sheet metal. OHWUE and KOBAYASHI [23] found that the earing always occurs in 45° direction by experiment and simulation and the correlation between ΔR/Rave and the average earring height is not always true.

It is common for CP-Ti to develop texture during the sheet rolling process, in which most grains exhibit their c-axis titling at about ±35° in the TD [15,16]. This is called preferred grain orientation, which will result in strong anisotropy in CP-Ti. Accordingly, the earing defect can be reduced by weakening the texture of the rolled CP-Ti sheets. It has been demonstrated by ZHANG et al [24,25] that CR is quite effective in reducing the mechanical anisotropy of magnesium alloy markedly by weakening the basal texture. TANG et al [22] have investigated the effect of UR and CR on mechanical anisotropy and deep drawing behavior of AZ31 magnesium alloy sheets. The experiment result on Mg-0.6%Zr (mass fraction) of XIONG et al [26] showed that compared with the UR sheets, the CR sheets exhibited a more uniform microstructure, larger grain size and weaker texture intensity. Above studies indicate that the anisotropy of the CP-Ti sheets might be also reduced by the CR. However, the literatures about CR applied on CP-Ti are rather limited. Therefore, the present work aims to systematically investigate the influence of three different rolling routes on the mechanical anisotropy and formability of CP-Ti sheets.

2 Experimental

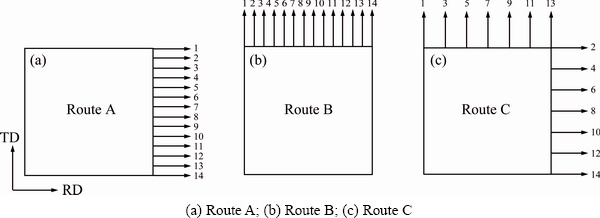

As-rolled CP-Ti sheets with a thickness of 3 mm were cut into square samples with dimensions of 80 mm × 80 mm, then the square samples were subjected to annealing at 650 °C for 2 h before rolling. Three different rolling routes were conducted at a rolling reduction per pass of 0.15 mm. A schematic view of the applied rolling routes is presented in Fig. 1. Route A and Route B are UR where the rolling direction is along initial RD and TD, respectively. Route C is CR where the rolling direction is changed by 90° after each rolling pass. All samples were rolled from 3 mm to 0.9 mm in thickness. After the final pass, all specimens were annealed at 650 °C for 30 min.

The tensile specimens with 25 mm in gage length, 6 mm in gage width and 0.9 mm in gage thickness were machined from the annealed sheets with the longitudinal axis along RD of the sheets, 45° to rolling direction and TD in the sheet plane. Tensile tests were conducted using a CMT6305-300kN electronic universal testing machine, at room temperature with an initial strain rate of 3×10-3 s-1.

In order to examine the influence of different rolling routes on the formability, deep drawing test and Erichsen test were performed. The circular blanks with diameter of 80 mm were machined from rolled sheets for the deep drawing test. Deep drawing tests were conducted at a punch speed of 5 mm/min. The blank holder force was 4.0 kN. Anti-wear hydraulic oil was used as the lubricant for deep drawing tests. The main dimensions of tools used for the deep drawing tests are as follows: punch diameter 50.0 mm; punch shoulder radius 5.0 mm; die hole diameter 51.8 mm, die shoulder radius 6.4 mm. The samples with dimensions of 50 mm × 50 mm were cut from rolled sheets for Erichsen tests. The Erichsen tests were conducted using a hemispherical punch with a diameter of 20 mm at room temperature. The punch speed was set to be 5 mm/min and the blank holder force was 10 kN. Anti-wear hydraulic oil was used as the lubricant. The Erichsen value was measured when the samples started to fracture.

Fig. 1 Schematic diagram of three rolling routes

The optical microscopy samples were treated by mechanical polishing and electro-polishing. The electro- polishing was performed under a controlled temperature of -40 °C using a voltage of 30 V for 60-90 s, and the solution was constituted with 6 mL perchloric acid, 94 mL methanol. The chemical etching solution was composed of 6 mL HNO3, 3 mL HF and 91 mL H2O.

3 Results and discussion

3.1 Microstructure and texture evolution

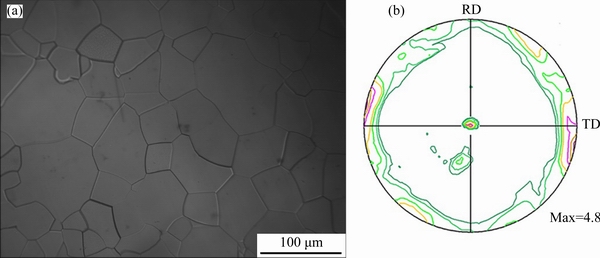

The optical microstructure and (0002) pole figure of as-rolled sheets in annealing condition are shown in Figs. 2(a) and (b), respectively. It can be seen that the microstructure in ND-RD plane consists of equiaxed grains without twins in the as-rolled sheet and the average grain size is about 58 um. Texture in the as-rolled sheet in annealing condition mainly includes basal texture and prismatic texture. The maximum texture intensity is about 4.8, as shown in Fig. 2(b). The texture data show that the c-axis of most grains is normal to sheet plane or parallel to TD.

Fig. 2 Optical microstructure (a) and (0002) pole figure (b) of as-rolled sheets in annealing condition

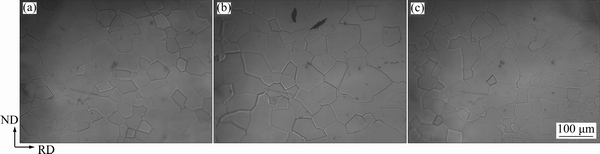

Fig. 3 Microstructures of rolled sheet produced by Route A (a), Route B (b) and Route C (c) in annealed condition

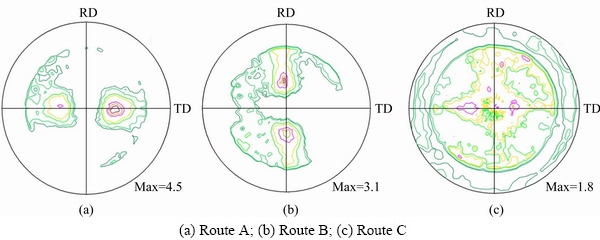

Fig. 4 (0002) pole figures of various samples in annealed condition

The optical microstructures of the CP-Ti sheets produced by Routes A, B and C are shown in Fig. 3. All of them consist of uniform equiaxed grains. Figure 3 shows that the average grain size is 40 μm for Route A, 50 μm for Route B and 38 μm for Route C, respectively, which indicates that the grain size can be affected by changing the rolling route very weakly. Figure 4 shows the (0 0 0 2) pole figures of the sheets processed by Route A, Route B and Route C in annealed condition. After fourteen unidirectional rolling passes, the Route A rolled samples exhibit a typical rolling texture of CP-Ti, i.e., the peaks tilting from the ND to the TD at ±(20-40)° (TD split texture) [16], as shown in the Fig. 4(a). Compared with as-rolled sheets, the texture intensity of the sample rolled by Route A almost keeps unchanged, but the texture type changed due to the rotation of grain. The Route B rolled sheet exhibits a texture with most grains having their c-axis lying about ±(20-40)° from ND to the initial RD, as shown in Fig. 4(b), compared with Route A, the double peak rotated about 90°, which is related with the change of roll direction. In addition, the texture intensity of sheets rolled by Route B is weaker than that in the as-rolled sheets. It is obvious that the texture of Route C rolled sample is more dispersed compared with that of Route A and Route B rolled sample, as shown in Fig. 4(c). Moreover, the texture intensity decreases from 4.5 in Route A to 1.8 in Route C, which suggests that CR could effectively weaken texture intensity of CP-Ti sheets as compared to UR.

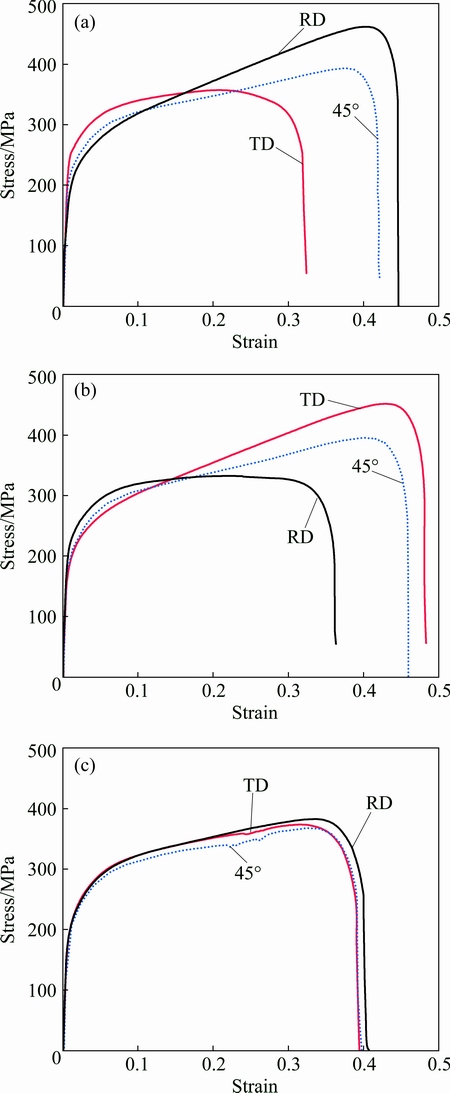

Fig. 5 Stress-strain curves of Route A (a), Route B (b) and Route C (c) in annealed condition in three different loading directions (RD, 45°, TD)

3.2 Mechanical properties

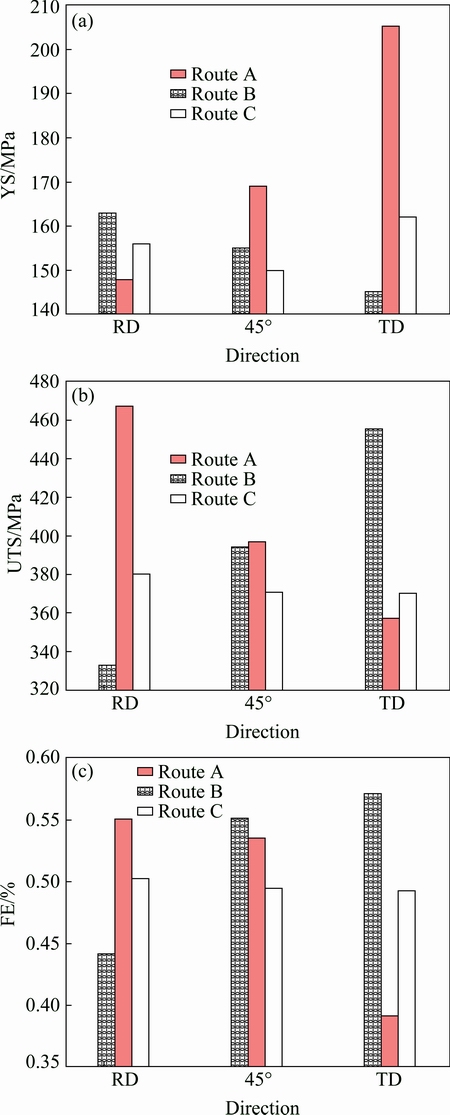

True stress–strain curves of rolled and subsequently annealed CP-Ti sheets during tension at room temperature are shown in Fig. 5. The corresponding mechanical properties, i.e., 0.2% yield stress (YS), the ultimate strength (UTS) and failure elongation (FE) are shown in Fig. 6. It is clearly observed in Fig. 6(a) that the yield strength in the Route A rolled sample mainly depends on the tensile direction. The highest yield strength is measured along the TD and the lowest along the RD, and the yield strength difference is 57 MPa. This is mainly due to the fact that the UR CP-Ti sheet exhibits yield anisotropy. According to the study of ZHU et al [8] and ROTH et al [18], when the tensile stress axis is along RD, deformation must be accommodated by the operation of the more easy prismatic slip mode. On the other hand, when the tensile stress axis is along TD, the deformation mode will be the more difficult basal slip or

Fig. 6 Tensile yield stress (a), ultimate tensile stress (b) and elongation of Route A (c), Route B and Route C in annealed condition in three different loading directions (RD, 45°, TD)

In order to evaluate anisotropy behavior, the plastic strain ratio (r-value), normal anisotropy ( ) and planar anisotropy Δr were calculated using the following formulas:

) and planar anisotropy Δr were calculated using the following formulas:

(1)

(1)

(2)

(2)

(3)

(3)

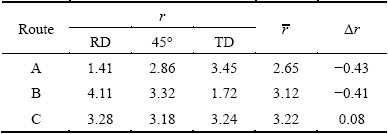

where b0 and L0 are initial width and length, b and L are width and length of samples after deformation, respectively. The anisotropy parameters of Route A, Route B and Route C samples are summarized in Table 1. Route A samples show an average r value of 2.65 and the r value increases gradually from RD to TD, Route B samples exhibit an average r value of 3.12 and the r value decreases gradually from RD to TD; both groups have shown strong anisotropy, which is not beneficial to the forming of CP-Ti sheets. On the contrary, the Route C samples show a high average r value, and at the same time the planar anisotropy Δr value is low, which indicates the low earing tendency of Route C sheets during the deep drawing. So it can be concluded that anisotropy of mechanical behavior can be improved by changing the rolling route.

Table 1 Anisotropy parameters of Route A, Route B and Route C samples

3.3 Deep drawing behavior

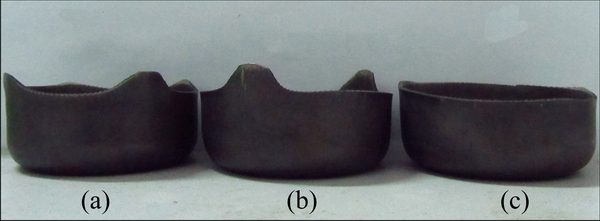

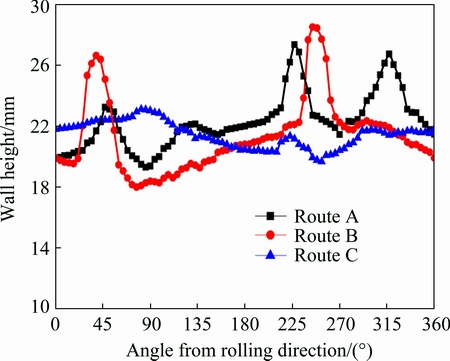

The deep-drawn cups of sheets rolled by three different routes are shown in Fig. 7. It can be seen that deep-drawn cups of Route A and Route B rolled sheets exhibit obvious earing, which is related to the value of Δr [23]. Compared with Route A and Route B samples, the earing of Route C samples is negligible. Figure 8 shows the wall height change of the cup from 0° to 360°, the curve indicates that the earring appeared at angle of 45° to the RD. The appearance of earring is due to rolled sheets with different directional fiber textures, which made the flow of the metal during deep drawing process not consistent at different directions. The earring height is related with the planar anisotropic coefficient Δr. The Δr-values of different rolling routes calculated using the above equations are -0.43, -0.41 and 0.08, respectively. The larger the Δr-value, the higher the earring height. The absolute Δr values of Route A and Route B rolled samples are much larger than that of Route C rolled samples, so the deep-drawn cups produced by Route A and Route B rolled samples show obvious earing and Route C rolled sheet produces a cup with nearly uniform height after deep drawing.

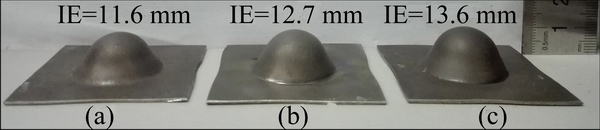

Figure 9 shows the Erichsen values (IE) of the annealed sheets rolled by different Routes. The IE are 11.6, 12.7 and 13.6 mm for Route A, Route B and Route C, respectively. The result shows that rolling direction influences the stretch formability and the CR is the most effective in improving the stretch formability of CP-Ti sheets, compared to the other two routes, which may be attributed to the weakened texture intensity.

Fig. 7 Deep-drawn cups of rolled CP-Ti sheets produced by Route A (a), Route B (b) and Route C (c)

Fig. 8 Earring profiles for deep-drawing process of CP-Ti produced by Route A (a), Route B (b) and Route C (c)

Fig. 9 Erichsen values (IE) of annealed sheets rolled by Route A (a), Route B (b) and Route C (c)

4 Conclusions

1) Compared with unidirectional rolling (Route A and Route B), cross rolling (Route C) can weaken texture intensity effectively.

2) The UR samples exhibit obvious planar anisotropy behavior in both strength and elongation, but the CR samples show isotropic properties in tension along different loading directions. Therefore, it can be concluded that mechanical anisotropy can be improved by changing rolling route.

3) The deep-drawn cups of UR samples show obvious earing; however, the drawn cups of CR samples are with nearly uniform height after deep drawing, which correspond to the value of planar anisotropy Δr. Accordingly, it can be reached that cross rolling can avoid occurrence of earing.

4) The CR samples show higher Erichsen values compared with UR samples, which indicates that CR can effectively improve stretch formability.

References

[1] KIM W J, YOO S J, LEE J B. Microstructure and mechanical properties of pure Ti processed by high-ratio differential speed rolling at room temperature [J]. Scripta Materialia, 2010, 62: 451-454.

[2] ROODPOSHTI P S, FARAHBAKHSH N, SARKAR A, MURTY K L. Microstructural approach to equal channel angular processing of commercially pure titanium—A review [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1353-1366.

[3] ZHANG Xu-hu, TANG Bin, ZHANG Xia-lu, KOU Hong-chao, LI Jin-shan, ZHOU Lian. Microstructure and texture of commercially pure titanium in cold deep drawing [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 496-502.

[4] XU Chun, ZHU Wen-feng. Comparison of microstructures and mechanical properties between forging and rolling processes for commercially pure titanium [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1939-1946.

[5] LI Kai, YANG Ping. Interaction among deformation, recrystallization and phase transformation of TA2 pure titanium during hot compression [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1863-1870.

[6] YIN Yan-fei, XU Wei, SUN Qiao-yan, XIAO Lin, SUN Jun. Deformation and fracture behavior of commercially pure titanium with gradient nano-to-micron-grained surface layer [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 738-747.

[7] HAMA T, NAGAO H, KOBUKI A, FUJIMOTO H, TAKUDA H. Work-hardening and twinning behaviors in a commercially pure titanium sheet under various loading paths [J]. Materials Science and Engineering A, 2015, 620: 390-398.

[8] ZHU Z S, LIU R Y, YAN M G, CAO C X, GU J L, CHEN N P. Texture control and the anisotropy of mechanical properties in titanium sheet [J]. Journal of Materials Science, 1997, 32: 5163-5167.

[9] BRIDIER F, VILLECHAISE P, MENDEZ J. Analysis of the different slip systems activated by tension in a alpha/beta titanium alloy in relation with local crystallographic orientation [J]. Acta Materialia, 2005, 53: 555-567.

[10] QIN Hong, JONAS J. Variant selection during secondary and tertiary twinning in pure titanium [J]. Acta Materialia, 2014, 75: 198-211.

[11] QIN Hong, JONAS J, YU Hong-bing, BRODUSCH N, GAUVIN R, ZHANG Xi-yan. Initiation and accommodation of primary twins in high-purity titanium [J]. Acta Materialia, 2014, 71: 293-305.

[12] SALEM A, KALIDINDI S, DOHERTY R. Strain hardening of titanium: Role of deformation twinning [J]. Acta Materialia, 2003, 51: 4225-4237.

[13] SALEM A A, KALIDINDI S R, SEMIATIN S L. Strain hardening due to deformation twinning in α-titanium: Constitutive relations and crystal-plasticity modeling [J]. Acta Materialia, 2005, 53: 3495-3502.

[14] ISHIKI M, KUWABARA T, HAYASHIDA Y. Measurement and analysis of differential work hardening behavior of pure titanium sheet using spline function [J]. International Journal of Material Forming, 2011, 4: 193-204.

[15] NIXON M, CAZACU O, LEBENSOHN R. Anisotropic response of high-purity α-titanium: Experimental characterization and constitutive modeling [J]. International Journal of Plasticity, 2010, 26: 516-532.

[16] HUANG Xin-sheng, SUZUKI K, CHINO Y. Improvement of stretch formability of pure titanium sheet by differential speed rolling [J]. Scripta Materialia, 2010, 63: 473-476.

[17] MURASAWA G, MORIMOTO T, YONEYAMA S. Nucleation and growth behavior of twin region around yield point of polycrystalline pure Ti [J]. Experimental Mechanics, 2011, 52: 503-512.

[18] ROTH A, LEBYODKIN M A, LEBEDKINA T A, LECOMTE J S, RICHETON T, AMOUZOU K E K. Mechanisms of anisotropy of mechanical properties of α-titanium in tension conditions [J]. Materials Science and Engineering A, 2014, 596: 236-243.

[19] WON J W, PARK C H, HONG S G, LEE C S. Deformation anisotropy and associated mechanisms in rolling textured high purity titanium [J]. Journal of Alloys and Compounds, 2015, 651: 245-254.

[20] WON J W, PARK K, HONG S G, LEE C S. Anisotropic yielding behavior of rolling textured high purity titanium [J]. Materials Science and Engineering A, 2015, 637: 215-221.

[21] SATOH J, GOTOH M, MAEDA Y. Stretch-drawing of titanium sheets [J]. Journal of Materials Processing Technology, 2003, 139: 201-207.

[22] TANG Wei-qin, HUANG Shi-yao, LI Da-yong, PENG Ying-hong. Mechanical anisotropy and deep drawing behaviors of AZ31 magnesium alloy sheets produced by unidirectional and cross rolling [J]. Journal of Materials Processing Technology, 2015, 215: 320-326.

[23] OHWUE T, KOBAYASHI Y. Analysis of earring in circular-shell deep-drawing of bcc and HCP sheet metals [J]. Procedia Engineering, 2014, 81: 887-892.

[24] ZHANG Hua, HUANG Guang-sheng, ROVEN H, WANG Li-fei, PAN Fu-sheng. Influence of different rolling routes on the microstructure evolution and properties of AZ31 magnesium alloy sheets [J]. Materials & Design, 2013, 50: 667-673.

[25] ZHANG Hua, HUANG Guang-sheng, WANG Li-fei, ROVEN H, PAN Fu-sheng. Enhanced mechanical properties of AZ31 magnesium alloy sheets processed by three-directional rolling [J]. Journal of Alloys and Compounds, 2013, 575: 408-413.

[26] XIONG Jiang-ying, CHEN Zhi-yong, YI Liu, HU Shao-hua, CHEN Tao, LIU Chu-ming. Microstructure and mechanical properties of annealed Mg-0.6wt%Zr sheets by unidirectional and cross rolling [J]. Materials Science and Engineering A, 2014, 590: 60-65.

刘定凯1,2,黄光胜1,2,3,龚桂林1,2,王冠刚1,2,潘复生1,2,3

1. 重庆大学 机械传动国家重点实验室 材料科学与工程学院,重庆 400044;

2. 重庆大学 国家镁合金工程技术研究中心,重庆 400044;

3. 重庆科学技术研究院 重庆先进材料研究中心,重庆 401123

摘 要:研究了不同轧制路径对工业纯钛板机械各向异性及成形性的影响。路径A和路径B是分别沿原始轧向和横向的单向轧制,路径C是交叉轧制,即每次轧制之后旋转90°继续轧制。测试了不同轧制路径获得板材的显微织构、力学性能(强度、伸长率)和各向异性。X射线衍射结果表明从路径A到路径C,轧制板材的织构逐渐减弱。与路径A和路径B相比较,路径C轧制的板材的平面各向异性系数更小。拉深实验显示交叉轧制可以有效地避免制耳的产生;杯突实验表明交叉轧制可以提高钛板成型能力。

关键词:工业纯钛;交叉轧制;各向异性;织构;拉深

(Edited by Yun-bin HE)

Foundation item: Project (CDJZR14130009) supported by the Fundamental Research Funds for the Central Universities, China; Project (CSTC2012GGB50003) supported by the Scientific and Technological Program of Chongqing Science and Technology Commission, China; Project (CSCT2014FAZKTJCSF50004) supported by the Demonstrative Project of Chongqing Science and Technology Commission, China

Corresponding author: Guang-sheng HUANG; Tel: +86-23-65112239; Fax: +86-23-65102821; E-mail: gshuang@cqu.edu.cn

DOI: 10.1016/S1003-6326(17)60151-1