DOI: 10.11817/j.ysxb.1004.0609.2021-39796

下引连铸Cu-Ag合金拉拔过程中组织与性能演变

朱学峰1,肖 柱1, 2,宋克兴3,盛晓菲1,戴 杰1,蒋洪赟4,周少强5

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

3. 河南科技大学 材料科学与工程学院,洛阳 471023;

4. 浙江天宁合金材料有限公司,金华 321002;

5. 深圳市中金岭南有色金属股份有限公司,深圳 518040)

摘 要:采用下引连铸工艺制备了d 11 mm Cu-4%Ag合金棒坯,棒坯具有高轴向取向柱状晶组织,表面质量良好,断后伸长率达到35.0%,可直接进行拉拔加工成d 0.04 mm微细丝,无中间退火的累积冷变形量达99.998%。拉拔过程中,在一般变形阶段,棒材变形机制为位错滑移,形成了较多的位错胞,晶内发生微区晶体转动,随应变量增大,剪切变形程度加剧,晶内形成了较多的切变带;在大变形阶段,通过各种动态回复机制如纳米孪晶、位错墙的亚晶化,层状界面,实现大塑性变形。随着变形量的增加,棒材的抗拉强度和硬度分别由铸态的245 MPa和63.4 HV增加至变形量99.7%时的655 MPa和187 HV,而导电率由90.3% IACS则降低至82.2% IACS。上述下引连铸-连续拉拔加工方式制备Cu-Ag合金微细丝材具有短流程、高效率的优势,提供了新的思路。

关键词:Cu-Ag合金;下引连铸;定向凝固;拉拔;力学性能

文章编号:1004-0609(2021)-05-1176-12 中图分类号:TG27 文献标志码:A

引文格式:朱学峰, 肖 柱, 宋克兴, 等. 下引连铸Cu-Ag合金拉拔过程中组织与性能演变[J]. 中国有色金属学报, 2021, 31(5): 1176-1187. DOI: 10.11817/j.ysxb.1004.0609.2021-39796

ZHU Xue-feng, XIAO Zhu, SONG Ke-xing, et al. Microstructure and properties evolution of Cu-Ag alloy prepared by downward continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(5): 1176-1187. DOI: 10.11817/j.ysxb.1004.0609.2021-39796

强脉冲磁场是研究核聚变及中子散射等物理学基本问题的必要实验条件,高强磁场的发展已经受到导体材料综合性能的限制[1]。SAKAI等[2]研究出比Cu-Nb合金性能更优异的Cu-Ag合金,其性能指标为导电率80% IACS、强度1 GPa。随后日本金属材料研究所[3]开发出由铜基体和很多超细银纤维组成的微观复合材料,其性能指标为导电率75%IACS~83%IACS、室温拉伸强度0.7~1.1 GPa。Cu-Ag合金具有高强度、高电导率的综合性能,是很有前景的强磁场绕线材料、集成电路引线框架及未来高速列车用接触线材。

Ag相较于其他合金元素对铜合金的导电率影响较小,且能很好地提高基体强度[4]。前期研究[5]表明,对于不同Ag含量(质量分数)的Cu-Ag合金,其组织形态存在差异,致使强度和导电率也有所不同。若以Ag作为合金元素,在铸态条件下Ag应以共晶组织或次生相形态存在于Cu枝晶基体中。当w(Ag)≤6% 时,合金中只有单一富Cu固溶体(α相)存在。随着Ag含量增加,合金中树枝晶Cu基体的枝晶臂间出现连续网状共晶体,此时共晶区域的体积分数不断增大,初生α相体积分数逐渐减小,次生相的增多引起的第二相强化及界面强化使得强度迅速增大,但次生Ag相与Cu基体之间的界面对电子的散射作用的增加促使导电率迅速下降,而且也同时增加了成本。

当w(Ag)≥30%,由于Cu基体被越来越多的共晶体分离开,显微将表现出更明显的树枝状形态,导电率和强度的变化都基本保持不变。因此研究w(Ag)≤6%的Cu-Ag合金非常有意义。

目前通用的制备铜银合金丝材、线材的生产流程较为繁杂[6]。普通熔铸法制备的等轴晶铜银合金在拉拔过程中需要进行一系列的中间退火,以消除其在冷变形中积累的残余应力[7-8],这一生产流程需耗费较多的物力及财力。与传统熔铸法相比,定向凝固制备的合金能有效消除横向晶界,得到连续柱状晶组织,在棒线坯纵向上获得较高的电导率及加工性能[9-11],可省略加工过程中的中间退火环节,从而降低了能耗,并缩短了制备过程。现在提出一种短流程、高效率、低能耗的制备方法,该方法通过下引连铸得到Cu-Ag合金柱状晶棒坯,这种棒坯具有平行于凝固方向的高强 “软”取向[12],不需经过中间退火,通过连续冷拉拔得铜银微细丝材。

“软”取向[12],不需经过中间退火,通过连续冷拉拔得铜银微细丝材。

本研究通过下引定向凝固技术制备Cu-4%Ag合金棒坯。在不经过热处理的条件下,直接将铸态Cu-Ag合金棒坯连续在室温下拉拔多道次,最终期望制备出直径为d 50 μm的Cu-Ag合金丝材。并研究拉拔过程中组织与性能的演变。

1 实验

1.1 棒坯制备

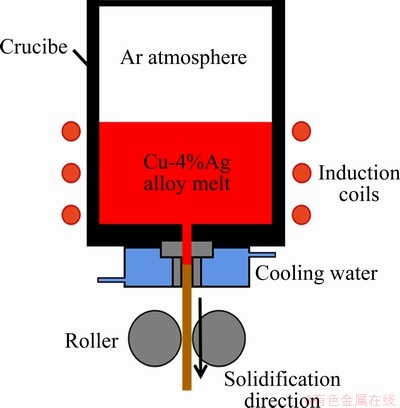

在Cu加入少量的Ag,能有效提高铜合金综合性能,Ag相较于其他合金元素对铜合金的导电率影响较小。本文控制Cu-Ag合金棒坯Ag含量(质量分数)为4%,采用下引连铸工艺制备了d 11 mm的Cu-4%Ag合金棒坯,其化学成分(质量分数)为:Ag,3.96%;Cu,96.04%。参考下引连铸工艺的前期研究结果[13],本文采用的连铸制备参数如下:合金熔体温度为1180 ℃,拉停比为2:1,结晶器冷却水流量为300 L/h,连铸速度为18 mm/min。图1所示为下引连铸装置的示意图。

图1 下引连铸装置的示意图

Fig. 1 Schematic diagram of directional solidification device

1.2 线材的拉拔加工

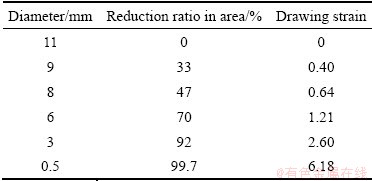

采用拉拔方式对下引连铸制备的Cu-4%Ag合金棒坯直接进行加工,将棒坯由d 11 mm冷拔至d 0.04 mm。拉拔过程中不进行中间退火。线材拉拔变形量用拉拔前后横断面积变化率(断面收缩率 )及拉拔应变

)及拉拔应变 表示,根据双递减法指定拉拔参数,并选取几个典型拉拔应变的样品进行显微组织观察,如表1所示。

表示,根据双递减法指定拉拔参数,并选取几个典型拉拔应变的样品进行显微组织观察,如表1所示。

表1 选取测试的拉拔试样

Table 1 Selected as-drawn samples for testing

1.3 线材的拉拔加工

为了分析连铸线材拉拔过程显微组织变化规律,本文从连铸棒坯和拉拔棒、线材上切取中心纵截面试样,经粗磨、细磨、机械抛光后,采用30 g FeCl3+50 mL HCL +40 mL H2O 混合溶液进行腐蚀,在莱卡EC3型光学金相显微镜下观察试样中心纵截面的金相组织;采用ZEISS EVO-18 Special Edition型扫描电子显微镜对不同变形量棒、线材试样拉伸断口形貌进行分析;采用振动抛光,在配备电子背散射衍射(EBSD)探头的SUPRA55型扫描电镜上分析不同变形量棒、线材试样纵截面上的显微组织。沿棒、线材纵截面切取0.5 mm的薄片,将其粗磨、细磨至30~50 μm,采用MTP-1A型磁力驱动双喷电解减薄器制备透射电镜(TEM)试样,电解双喷液为硝酸甲醇溶液(体积比1:2),实验温度-30 ℃,电流45 mA。采用G20场发射透射电镜分析不同变形量试样的显微组织。

参照 GB/T 228—2010《金属材料室温拉伸试验方法》制备拉伸试样。采用MTS万能材料试验机分析连铸棒坯和不同变形量拉拔试样的力学性能,拉伸应变速率约为1×10-3 s-1。每组拉伸试样共3个,测试结果取其平均值。采用HXD-1000T型维氏显微硬度计测试不同变形量拉拔试样的显微硬度,载荷大小为9.8 N,加载时间为15 s,每组试样测试5个点,测试结果取其平均值。采用双臂电桥装置在20 ℃下测量电导率。

2 结果与分析

2.1 棒坯的组织与力学性能

2.1.1 棒坯组织

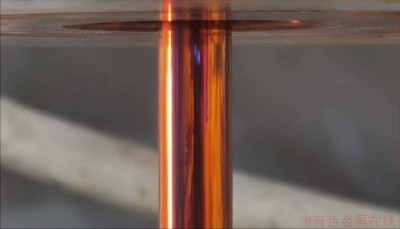

采用下引连铸制备了d 11 mm的Cu-4%Ag合金棒坯,其表面形貌如图2所示,棒坯纵截面显微组织如图3所示,凝固方向用SD白色箭头所示。

图2 下引连铸Cu-4%Ag合金棒坯表面形貌

Fig. 2 Surface morphology of as-cast Cu-4%Ag alloy bar

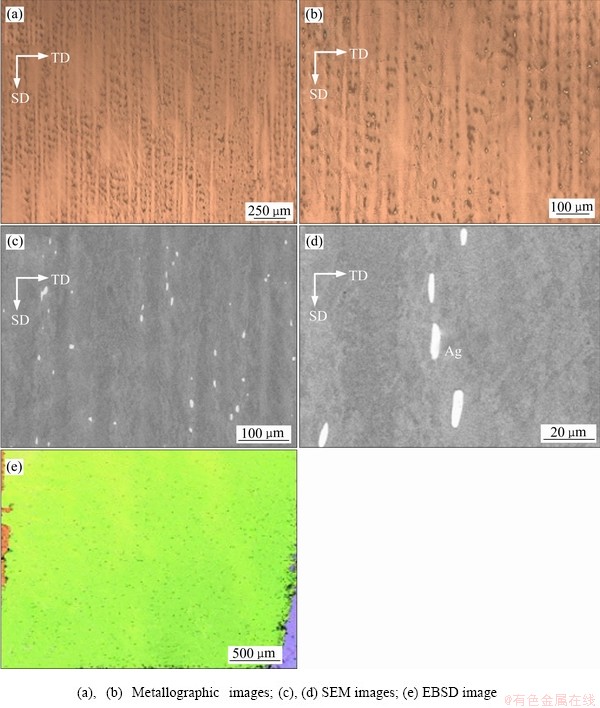

图3 Cu-4%Ag合金棒坯显微组织

Fig. 3 Microstructures of as-cast Cu-4%Ag alloy bar

Cu-4%Ag合金棒坯表面光滑,具有粗大沿轴向生长的柱状晶,柱状晶内有着平行排布的树枝晶结构,横向晶界极少,柱状晶晶界平直,如图3(a)、(b)、(e)所示。EDS分析显示,图3(c)、(d)中白色粒子为Ag粒子,可以看出Ag相较为均匀地分布在柱状晶枝晶间隙。

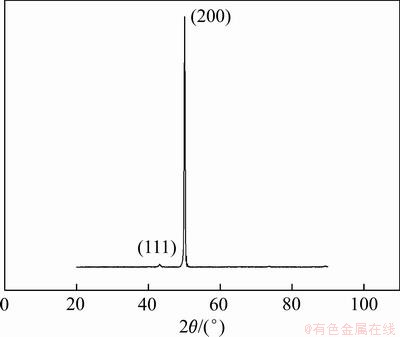

为进一步观察晶粒取向,对其进行XRD测定,结果如图4所示。从图4可以看出,棒坯主要含 取向晶粒,

取向晶粒, 取向晶粒极少。这归因于Cu-4%Ag合金为面心立方金属,其

取向晶粒极少。这归因于Cu-4%Ag合金为面心立方金属,其 取向晶粒生长速度最快,

取向晶粒生长速度最快, 取向次之,

取向次之, 取向最慢。因此,在高轴向温度梯度下,

取向最慢。因此,在高轴向温度梯度下, 取向晶粒会逐步占据优势,最终生成只含

取向晶粒会逐步占据优势,最终生成只含 取向的晶粒[14]。

取向的晶粒[14]。

图4 Cu-4%Ag合金棒坯的XRD谱

Fig. 4 XRD pattern of as-cast Cu-4%Ag alloy bar

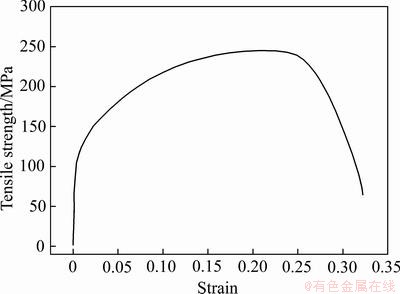

2.1.2 棒坯力学性能

对棒坯的力学性能与进行室温拉伸测试,图5所示为棒坯室温拉伸工程应力-工程应变曲线。从图5可以看出,Cu-4%Ag棒坯组织流变应力低,伸长率高,抗拉强度为245.4 MPa,屈服强度为79.8 MPa,断后伸长率可达到35.0%。表明棒坯在轴向塑性指标比较优异,有利于后续冷加工成形。

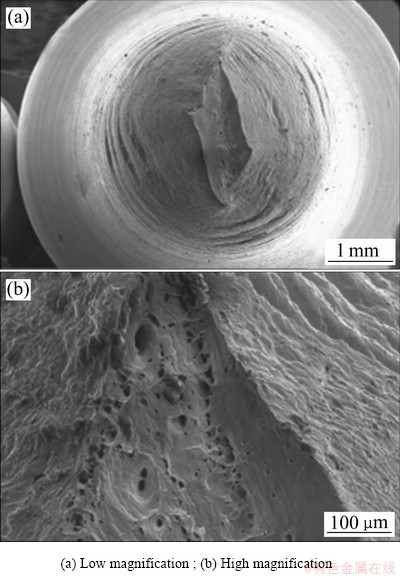

采用扫描电子显微镜(SEM)对棒坯拉伸断口形貌进行观察,如图6所示。从图6可以看出,断口上存在明显的大而深的韧窝,韧窝尺寸可达到50 μm。此外从宏观断口形貌上看,断口剪切唇区占了很大的比例,而放射区几乎不存在。由此可以得出,下引连铸Cu-4%Ag合金棒坯的塑性、韧性良好,在轴向有着优良的加工性能。

图5 Cu-4%Ag合金棒坯室温拉伸应力-应变曲线

Fig. 5 Tensile stress-strain curve of as-cast Cu-4%Ag alloy bar at room temperature

图6 Cu-4%Ag合金棒坯拉伸断口形貌

Fig. 6 Tensile fracture morphologies of as-cast Cu-4%Ag bar

综合上述实验结果可知,采用下引连铸制备的d 11 mm Cu-4%Ag合金棒坯具有良好的表面质量和高轴向取向柱状晶组织,轴向力学性能均匀性较好,断后伸长率达到35.0%,无需表面处理及中间退火,可直接进行后续拉拔加工。

2.2 Cu-4%Ag棒坯拉拔加过程中的组织与性能

2.2.1 表面形貌

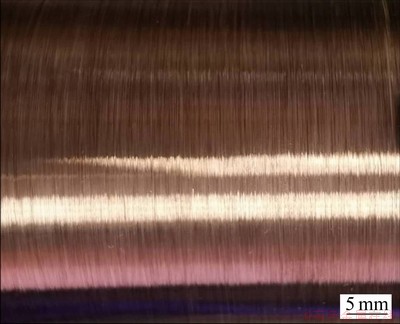

在拉拔机上对下引连铸制备的d 11 mm的合金棒坯进行冷拉拔,不经过中间退火,可连续拉拔加工至d 0.04 mm的Cu-4%Ag合金丝材,无中间退火的累计冷变形量达99.998%。图7所示为d 0.04 mm Cu-4%Ag合金丝材的表面形貌。从图7中可以看出,大变形加工后丝材表面光亮,无裂纹等明显的缺陷,下引连铸Cu-4%Ag合金棒坯具有优良的拉拔加工性能。

图7 0.04 mm Cu-4%Ag合金丝材表面形貌

Fig. 7 Surface morphology of Cu-4%Ag alloy wire of 0.04mm

2.2.2 拉拔组织的演变

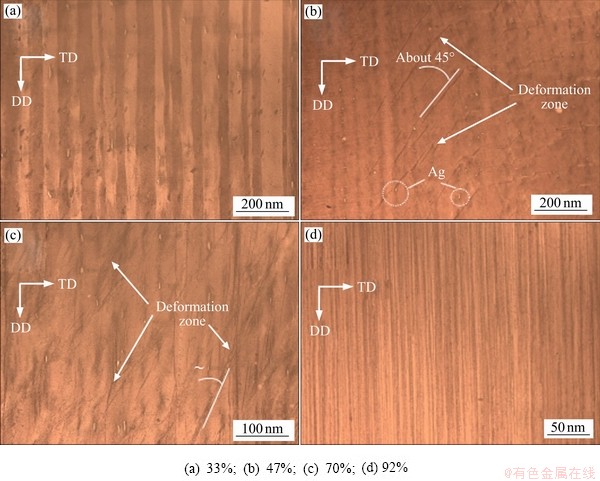

图8所示为不同变形量拉拔线材纵截面的金相组织,图中DD (Drawing direction)白色箭头代表拉拔方向。在室温拉拔强塑性变形下,宏观组织演变主要是粗大柱状晶向纤维晶发展,以及纤维晶细化的过程。当断面收缩率为33%时,柱状晶晶粒分裂破碎,形成若干与拉拔方向平行的柱状条带(见图8(a));随着变形程度加深,当断面收缩率为47%时,棒材表面部分区域出现变形带,变形带与拉拔方向夹角约呈45°(见图8(b));当断面收缩率达到70%,在形变亚结构的影响下,原晶界逐渐模糊,发展出大角度晶界,变形带数量增多,且变形带与拉拔方向夹角变小,大致呈30°(见图8(c));当断面收缩率达到90%以上时,线材呈明显的纤维组织,且纤维组织不断被破碎、细化、拉长,其方向大致与拉拔方向平行(见图8(d))。

图8 不同拉拔断面收缩率的Cu-4%Ag合金线材金相图

Fig. 8 Metallographic diagrams of Cu-4%Ag alloy with different reduction ratio in area

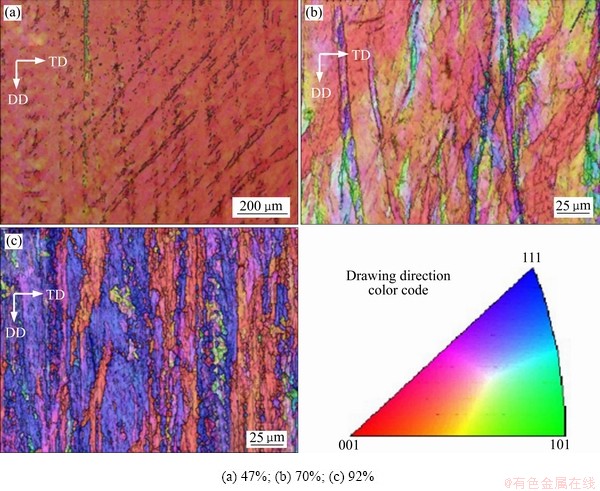

图9 不同拉拔断面收缩率的Cu-4%Ag合金线材EBSD图

Fig. 9 EBSD images of Cu-4%Ag alloy with different reduction ratios in area

为了进一步分析拉拔过程中Cu-4%Ag合金线材组织变化规律,采用电子背散射衍射成像技术(EBSD)对47%、70%、92%不同断面收缩率的试样组织进行微区取向分析,如图9所示。图中黑色粗实线代表大角度晶界(取向差>15°),黑色细实线代表小角度晶界(5°<取向差<15°),拉拔方向如白色箭头所示。当断面收缩率为47%时,此时变形程度较小,组织中主要是 取向,同时由于晶粒内部开动了不同滑移系的位错,在晶内出现了少量分布较均匀的小角度晶界,且出现了与拉拔方向呈约45°的变形带(见图9(a));随着变形量的增大,当变形量达到70%时,由于线材受到拉拔模具径向和周向压应力、轴向拉应力的作用,晶粒发生破碎、细化且局部晶粒转动加剧,尤其在变形带附近晶粒取向发生了明显的变化,表明剪变形带使变形带附近晶粒发生严重扭转,导致这些晶粒取向差异较大,(见图9(b));当断面收缩率达到92%,变形带与拉拔方向夹角进一步减小,原晶界变得模糊,晶界逐渐趋向与拉拔方向平行,呈明显纤维组织特征,晶界变形带晶粒转动加剧,相邻晶粒取向差会逐渐变大,晶粒主要呈

取向,同时由于晶粒内部开动了不同滑移系的位错,在晶内出现了少量分布较均匀的小角度晶界,且出现了与拉拔方向呈约45°的变形带(见图9(a));随着变形量的增大,当变形量达到70%时,由于线材受到拉拔模具径向和周向压应力、轴向拉应力的作用,晶粒发生破碎、细化且局部晶粒转动加剧,尤其在变形带附近晶粒取向发生了明显的变化,表明剪变形带使变形带附近晶粒发生严重扭转,导致这些晶粒取向差异较大,(见图9(b));当断面收缩率达到92%,变形带与拉拔方向夹角进一步减小,原晶界变得模糊,晶界逐渐趋向与拉拔方向平行,呈明显纤维组织特征,晶界变形带晶粒转动加剧,相邻晶粒取向差会逐渐变大,晶粒主要呈 与

与 取向,此外,在局部区域出现少量细小晶粒(见图9(c))。

取向,此外,在局部区域出现少量细小晶粒(见图9(c))。

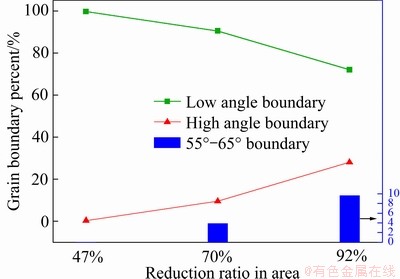

图10所示为不同拉拔断面收缩率的Cu-4%Ag合金晶界统计图。由图10可以看出,在拉拔初期(断面收缩率为47%),柱状晶晶粒沿拉拔方向拉长,在模具径向与周向向压应力与轴向拉应力的作用下,晶粒内部出现较多小角度晶界(2°<取向差<15°),占比为99.95%,此时变形程度低,晶粒取向变化较小,大角度晶界(取向差>15° )极少,占比仅为0.05%;当拉拔变形程度增大(断面收缩率为70%)时,晶粒取向变化增大,大角度晶界数量迅速增加,其占比由断面收缩率70%时的9.5%迅速增加至断面收缩率92%时的28%;小角度晶界占比逐渐降低,其占比由断面收缩率70%时的90.5%迅速降至断面收缩率92%时的72%。此外,当断面收缩率达到70%~92%时,取向角为55°~65° 的晶界(面心立方金属纳米孪晶界)存在一定的分布。

图10 不同拉拔断面收缩率的Cu-4%Ag合金晶界统计图

Fig. 10 Grain boundaries diagram of Cu-4%Ag alloy with different reduction ratios in area

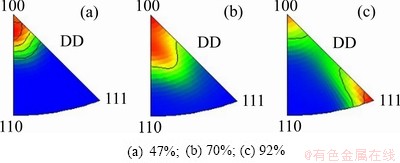

图11所示为不同拉拔断面收缩率的Cu-4%Ag线材反极图(IPF图)。各反极图均在拉拔方向,当断面收缩率较小时,Cu相的晶粒取向集中在 方向,随着拉拔道次增加,断面收缩率增大,晶粒取向变为集中在

方向,随着拉拔道次增加,断面收缩率增大,晶粒取向变为集中在 、

、 方向。

方向。

图11 不同拉拔断面收缩率的Cu-4%Ag合金线材反极图(IPF图)

Fig. 11 Inverse pole diagrams of Cu-4%Ag alloy with different reduction ratios in area (IPF diagram)

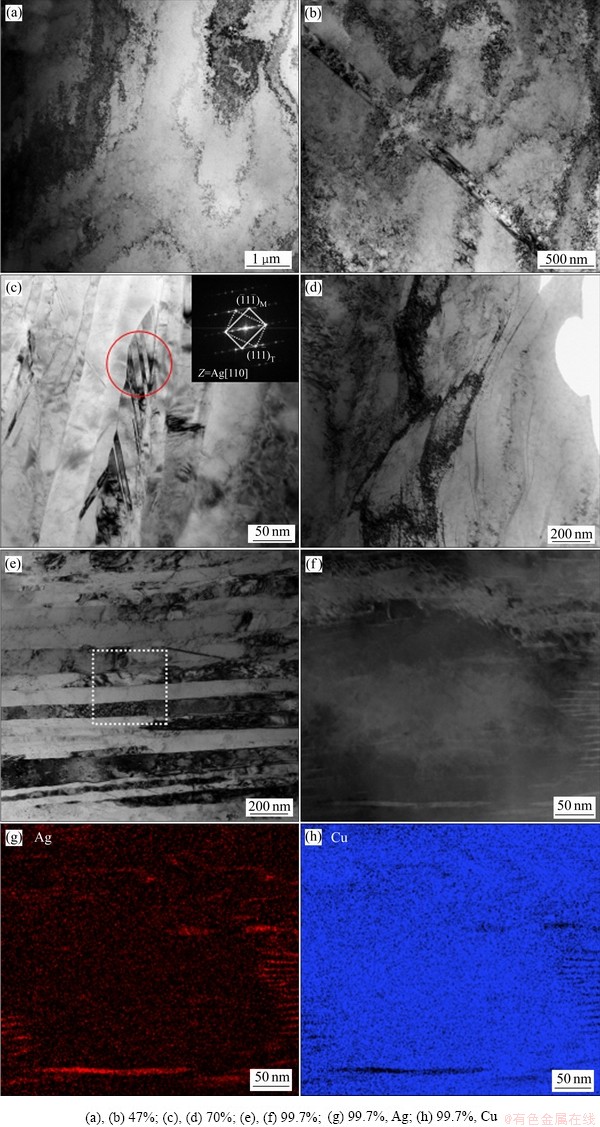

图12所示为不同断面收缩率的Cu-4%Ag合金棒线材组织的TEM像。当变形量为47%时,合金棒材内部产生了大量位错,位错增殖,相互缠结,晶内形成了长条状的位错胞,位错胞壁主要由稠密位错墙组成,胞内位错密度较低,如图12(a)所示。当变形量增大至70%时,位错塞积导致局部区域产生严重的应力集中,有利于增大局部区域的剪切变形,在线材局部区域形成宽度约为200 nm的变形带组织,如图12(b)所示。此外,该阶段还形成了由局部剪切变形和变形带导致的Ag形变纳米孪晶,如图12(c)所示,以及由交滑移产生的亚晶界,如图12(d)所示。当变形量达到为99.7%时,在大塑性变形下,位错界面的形貌由稠密位错墙转为平直的层状结构,大量拉长的平直晶粒构成了纤维组织,如图12(e)所示。此外,图12(f)、(g)、(h)所示分别为HADDF图、Ag和Cu相的Mapping图,可以看到尺寸约为2 nm的拉长的细小纳米Ag纤维分布在层状界面。

2.2.3 拉拔过程中的性能演变

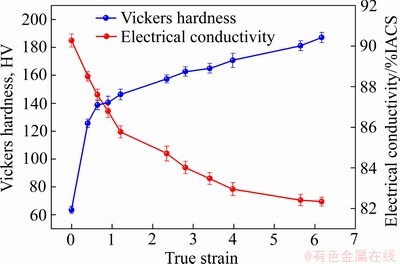

图13所示为拉拔过程中 Cu-4%Ag合金的硬度、电导率随拉拔应变变化的曲线。从图13可以看出,在一般变形阶段,合金的硬度由铸态的63.4 HV增长到断面收缩率为47%时(对应拉拔应变η=6.18)的138.7 HV及断面收缩率为70%时(对应拉拔应变η=6.18)的146.2 HV,呈明显的加工硬化现象。在大变形阶段,合金硬度以低硬化速率缓慢增加,当变形量达到99.7%(对应拉拔应变 η=6.18)时,合金硬度为187.0 HV。与硬度变化趋势相反,在一般变形阶段,合金的导电率随拉拔程度增大显著降低,当断面收缩率为92%(对应拉拔应变η=2.60),合金导电率下降至84.2 %IACS。在大变形阶段,导电率下降趋势变缓,当断面收缩率为99.7%,导电率仍能保持在82.2 %IACS。

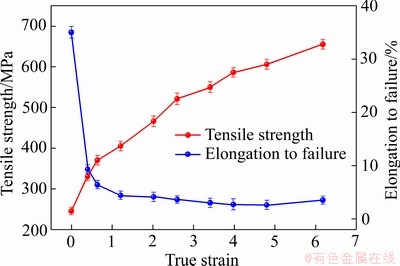

图14所示为拉拔过程中Cu-4%Ag合金抗拉强度、断后伸长率随拉拔应变变化的曲线。从图14可以看出,与硬度变化趋势相近,在一般变形阶段,合金抗拉强度由铸态的 245 MPa 升高到断面收缩率 70% 时的405 MPa ,而断后伸长率由 35.0%急剧下降到 6.1%。在大变形阶段,抗拉强度缓慢增加,断后伸长率几乎保持不变,当变形量为99.7%时,抗拉强度增大到 655 MPa ,而断后伸长率略微降低至约 4.1%。

3 讨论

Cu-4%Ag合金棒坯具有高轴向取向柱状晶组织和较少的横向晶界,柱状晶晶粒取向主要为 (见图4),这是因为立方晶系中不同的取向的生长速度有显著的差异,针对面心立方金属

(见图4),这是因为立方晶系中不同的取向的生长速度有显著的差异,针对面心立方金属 方向最快,

方向最快, 方向次之,

方向次之, 方向最慢[14-15],因此当温度梯度平行于轴向时

方向最慢[14-15],因此当温度梯度平行于轴向时 取向晶粒会占据优势,最终生成几乎只含

取向晶粒会占据优势,最终生成几乎只含 取向的柱状晶组织。

取向的柱状晶组织。

已有的研究发现[16-17],面心立方金属中不同晶体学取向的晶粒滑移模式及其位错组态演变存在显著差异。在不同滑移模式下,各滑移系组合间相互交互作用存在显著差异,导致在同一变形程度下 取向晶粒内的位错密度最低(Ⅱ型组织),而

取向晶粒内的位错密度最低(Ⅱ型组织),而 取向晶粒内的位错密度最高(Ⅲ型组织)。

取向晶粒内的位错密度最高(Ⅲ型组织)。

图12 不同拉拔断面收缩率的Cu-4%Ag合金线材透射图

Fig. 12 TEM images of Cu-4%Ag alloy wire with different reduction ratios in area

图13 拉拔过程中Cu-4%Ag合金的硬度、电导-拉拔应变曲线

Fig. 13 Hardness, electrical conductivity-drawing strain curves of Cu-4%Ag alloy during drawing process

图14 拉拔过程中Cu-4%Ag合金的抗拉强度、断后伸长率-拉拔应变曲线

Fig. 14 Tensile strength, elongation after fracture-drawing strain curves of Cu-4%Ag alloy during drawing process

连铸合金棒坯在变形过程中,位错在晶粒内沿轴向滑移的平均自由程较大、且位错塞积造成的位错密度较低[18],因而具有 软取向的连续柱状晶组织Cu-4%Ag合金棒坯较普通多晶材料具有更

软取向的连续柱状晶组织Cu-4%Ag合金棒坯较普通多晶材料具有更

低的流变应力(245 MPa)、高伸长率(35.0%)及加工硬化率,有利于获得高塑性实现超延展变形。

拉拔过程中性能的变化与组织演变密切相关,拉拔过程中显微组织和微观结构的演变的塑性变形机制,可以分为一般变形阶段[19](变形量:0≤ε≤92%;拉拔应变:0≤η≤2.6)和大变形阶段(变形量:92%≤ε;拉拔应变:2.6≤η)。

在一般变形阶段,合金晶粒内部产生大量弥散分布的位错网结构及粗大的位错胞(见图12(a))对合金室温拉伸变形过程中形成的位错运动具有较大的阻碍作用,随塑性变形程度的加大,变形组织不断演化,形成典型的变形带组织[20],变形带与轴向夹角逐渐减小(见图8(b)、图9(b)、图12(b)),这些变形带界面由高密度位错组成,对位错运动阻碍作用增大,导致合金棒材的硬度和抗拉强度持续增 大[21],同时缺陷的显著增多降低电子平均自由程导致导电率的下降[22](见图12、13)。

在大变形阶段,大量次生界面和剪切变形诱发纳米孪晶的生成(见图12(c)),相对于滑移系众多的中高层错能的Cu合金,Cu-4%Ag合金层错能仅为66.34 mJ/m2[23],孪生所需的临界切应力较小,易于产生纳米孪晶[24],使Cu-Ag合金强度、塑性同步提高。此外,为进一步塑性变形,出现了部分动态回复及再结晶以降低位错密度[25-26](见图12(d)),当位错塞积到一定程度,稠密的位错墙转为层状界面[27](如图12(e)),界面运动、滑移及流变也可以吸收高密度位错,Ag第二相经过大变形形成尺寸细小的纤维相,在作为纤维强化相的同时,对导电率的影响较小[28],导致抗拉强度以低加工硬化速率持续增长,导电率的下降趋于平稳。

根据上述结果和分析可以得出,采用下引连铸制备的Cu-4%Ag合金棒坯具有良好的表面质量,另外,连铸棒坯具有高轴向取向柱状晶组织,周向力学性能均匀性较好,沿轴向延伸变形的断后伸长率达到35.0%,无中间退火的累积冷变形量可达99.998%。基于这些优势,本文提出采用下引连铸工艺制备Cu-4%Ag合金棒坯,直接进行连续冷拉拔的加工工艺,可省略传统生产工艺中的轧制、表面处理、中间退火等工序,具有工艺流程短、能耗低、生产成本低等优点。

4 结论

1) 采用下引连铸制备的d 11 mm Cu-4%Ag合金棒坯具有良好的表面质量和高轴向取向柱状晶组织,断后伸长率达到35.0%,可直接进行拉拔加工,无中间退火的累积冷变形量可达99.998%,表明下引连铸Cu-4%Ag合金棒坯具有优良的拉拔加工性能。

2) 在拉拔过程中,在一般变形阶段,棒材变形机制为位错滑移,形成了较多的位错胞,晶内发生微区晶体转动,随应变量增大,剪切变形程度加剧,晶内形成了较多的切变带;在大变形阶段,通过各种动态回复机制如纳米孪晶、位错墙的亚晶化,层状界面,实现大塑性变形。

3) 在拉拔过程中,在一般变形阶段,当变形量为47%时,在位错大量增殖抗拉强度和硬度由铸态的245 MPa和63.4 HV分别升高到370 MPa和138.7 HV,电导率由铸态的90.3%IACS降到变形量92%的84.2% IACS;在大变形阶段,抗拉强度以较低加工硬化速率持续增长,导电率的下降趋于平稳,当变形量为99.87%,抗拉强度和硬度达到655 MPa和187.0 HV,导电率保持在82.2% IACS。

REFERENCES

[1] 姜业欣, 娄花芬, 解浩峰, 等. 先进铜合金材料发展现状与展望[J]. 中国工程科学, 2020, 22(5): 84-92.

JIANG Ye-xin, LUO Hua-fen, XIE Hao-feng, et al. Development status and prospects of advanced copper alloy[J]. Engineering Science, 2020, 22(5): 84-92.

[2] SAKAI Y, INOUE K, MAEDA H. New high-strength, high-conductivity Cu-Ag alloy sheets[J]. Acta Metallurgica Et Materialia, 1995, 43(4): 1517-1522.

[3] 黄金昌. 高强度和高导电的铜银合金丝材和片材及其应用[J]. 稀有金属快报, 1997(5): 1-2.

HUANG Jin-chang. High-strength and high-conductivity Cu-Ag alloy wire and sheet and applications[J]. Rare Metals Letters, 1997(5): 1-2.

[4] ZUO Xiao-wei, GUO Rui, ZHAO Cong-cong, et al. Microstructure and properties of Cu-6wt%Ag composite thermomechanical-processed after directionally solidifying with magnetic field[J]. Journal of Alloys and Compounds, 2016, 676: 46-53.

[5] HE J, JI V, MENG L. Effects of strain and annealing on the intensity and distribution of crystal texture in Cu-12wt.% Ag[J]. Materials Science and Engineering A, 2007, 478(1/2): 305-313.

[6] HU Jin-lin, ZHANG Jin-dong, MENG Liang. Morphology evolution of two-phase Cu-Ag alloys under different conditions[J]. Journal of Zhejiang University (Science A), 2009, 10(3): 458-463.

[7] ASTA M, BECKERMANN C, KARMA A, et al. Solidification microstructures and solid-state parallels: Recent developments, future directions[J]. Acta Materialia, 2009, 57(4): 941-971.

[8] EFTNK B P, MARA N A, KINGSTEDT O T, et al. Deformation response of cube-on-cube and non-coherent twin interfaces in AgCu eutectic under dynamic plastic compression[J]. Materials Science and Engineering A, 2018, 712: 313-324.

[9] TAKAAKI H, KIYOSHI M, AKIRA M, et al. Development of high strength-high conductivity Cu-6wt%Ag alloy for high field magnet[J]. MRS Advances, 2016, 1(17): 1137-1148.

[10] 沈 月, 付作鑫, 张国全, 等. 高强高导铜银合金的研究现状及发展趋势[J]. 材料导报, 2012, 26(13): 109-113.

SHEN Yue, FU Zuo-xin, ZHANG Guo-quan, et al. Researching prospect and developing tendency on high-strength and high-conductivity copper-silver alloys[J]. Materials Reports, 2012, 26(13): 109-113.

[11] ZHANG Hong-tao, JIANG Yan-bin, XIE Jian-xin, et al. Precipitation behavior, microstructure and properties of aged Cu-1.7wt%Be alloy[J]. Journal of Alloys and Compounds, 2019, 773: 1121-1130.

[12] 王英民, 毛大立. 形变纤维增强高强度高电导率的Cu-Ag合金[J]. 稀有金属材料与工程, 2001, 30(4): 295-298.

WANG Ying-min, MAO Da-li. Deformed fiber strengthened high-strength and high-conductivity alloy[J]. Rare Metal Materials and Engineering, 2001, 30(4): 295-298.

[13] JIANG Yan-bin, XU Jun, LIU Xin-hua, et al. Effects of Fe content on the microstructure and properties of CuNi10FeMn1 alloy tubes fabricated by HCCM horizontal continuous casting[J]. International Journal of Minerals, Metallurgy, and Materials, 2016, 23(4): 449-457.

[14] ZHAO Hui-min, FU Hua-dong, XIE Ming, et al. Effect of Ag content and drawing strain on microstructure and properties of directionally solidified Cu-Ag alloy[J]. Vacuum, 2018, 154: 238-251.

[15] JIA N, RAABE D, ZHAO X. Texture and microstructure evolution during non-crystallographic shear banding in a plane strain compressed Cu-Ag metal matrix composite[J]. Acta Materialia, 2014, 76: 238-251.

[16] HUANG X. Grain orientation effect on microstructure in tensile strained copper[J]. Scripta Materialia, 1998, 38(11): 1697-1703.

[17] HANSEN N, HUANG X. Microstructure and flow stress of polycrystals and single crystals[J]. Acta Materialia, 1998, 46(5): 1827-1836.

[18] 谢建新, 王 宇, 黄海友. 连续柱状晶组织铜及铜合金的超延展变形行为与塑性提高机制[J]. 中国有色金属学报, 2011, 21(10): 2324-2336.

XIE Jian-xin, WANG Yu, HUANG Hai-you. Extreme plastic extensibility and ductility improvement mechanisms of continuous columnar-grained copper and copper alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2324-2336.

[19] 吴 恒, 张 鸿, 吕佳峰, 等. 连续柱状晶组织纯铜室温超延展变形机理[J]. 中国有色金属学报, 2017, 27(12): 2426-2433.

WU Heng, ZHANG Hong, Lü Jia-feng, et al. Extreme plastic extensibility mechanism of continuous columnar- grained copper at ambient temperature[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2426-2433.

[20] WANG Ren-ke, ZHANG Hui, TANG Lin, et al. Adiabatic shear deformation behaviors of cold-rolled copper under different impact loading directions[J]. Materials Science and Engineering A, 2019, 754(29): 330-338.

[21] PAUL H, DRIVER J H, MAURICE C, et al. Shear band microtexure formation in twinned face centred cubic single crystals[J]. Materials Science and Engineering A, 2003, 359(1): 178-191.

[22] WULFF F, BREACH C D, DITTMER K. Crystallographic texure of drawn gold bonding wires using electron backscattered diffraction(EBSD)[J]. Journal of Materials Science Letters, 2003, 22(19): 1373-1376.

[23] CAI T, LI K Q, ZHANG Z J, et al. Predicting the variation of stacking fault energy for binary Cu alloys by first-principles calculations[J]. Journal of Materials Science & Technology, 2020, 53: 61-65.

[24] 李 祎, 张祥凯, 何克坚, 等. 层错能对铜合金室温变形及退火过程中晶粒细化的影响[J]. 中国有色金属学报, 2016, 26(1): 66-76.

LI Yi, ZHANG Xiang-kai, HE Ke-jian, et al. Effect of stack fault energy on grain refinement of Cu alloy during room temperature deformation and subsequent annealing[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 66-76.

[25] SAKAI T, BELYAKOV A, KAIBYSHEV R, et al. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation condition[J]. Progress in Materials Science, 2014, 60: 130-207.

[26] LIU J B, MENG L, ZENG Y W. Microstructure evolution and properties of Cu-Ag microcomposites with different Ag content[J]. Materials Science and Engineering A, 2006, 435: 237-244.

[27] HANAZAKI K, SHIGEIRI N, TSUJI N. Change in microstructure and mechanical properties during deep wire drawing of copper[J]. Materials Science and Engineering A, 2010, 527(21): 5699-5707.

[28] 何钦生, 邹兴政, 李 方, 等. Cu-Ag合金原位纤维复合材料研究现状[J]. 材料导报, 2018, 32(15): 2684–2692, 2700.

HE Qin-sheng, ZOU Xing-zheng, LI Fang, et al. Research status of Cu-Ag alloy in-situ filamentary composites[J]. Materials Review, 2018, 32(15): 2684–2692, 2700.

Microstructure and properties evolution of Cu-Ag alloy prepared by downward continuous casting

ZHU Xue-feng1, XIAO Zhu1, 2, SONG Ke-xing3, SHENG Xiao-fei1, DAI Jie1, JIANG Hong-yun4, ZHOU Shao-qiang5

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

3. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023

4. Zhejiang Tianning Alloy Material Co., Ltd., Jinhua 321002, China;

5. Shenzhen Zhongjin Lingnan Nonfemet Co., Ltd., Shenzhen 518040, China)

Abstract: A d 40 μm Cu-4%Ag alloy wire with high strength and high electrical conductivity was prepared by continuously directional solidification and cold drawing. The evolutions of microstructure and properties were investigated by means of optical microscope observation, electron microscopes observation, hardness test, tensile test, and electrical conductivity measurement. The results show that the continuous columnar grain structure uniformly distributes along the solidification direction in the as-cast alloy. The drawing process is divided into different stages, corresponding to the main deformation mechanism of the dislocation slip and twinning, the microcrystalline rotation, the dynamic recovery, the evolution of layered interface, and partial dynamic recrystallization. After the deformation with the area reduction ratio of 99.7%, the tensile strength, hardness and electrical conductivity of the alloys are 655 MPa, 187 HV and 82.2%IACS, respectively.

Key words: Cu-Ag alloy; downward continuous casting; directional solidification; drawing; mechanical properties

Foundation item: Projects(51974375, U1637210) supported by the National Natural Science Foundation of China; Project(JSGG20170824162647398) supported by the Technology Research Program, Shenzhen, China

Received date: 2020-07-10; Accepted date: 2020-11-06

Corresponding author: XIAO Zhu; Tel: +86-13187054506; E-mail: xiaozhumse@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51974375,U1637210);深圳市科技计划资助项目(JSGG20170824162647398)

收稿日期:2020-07-10;修订日期:2020-11-06

通信作者:肖 柱,教授,博士;电话:13974910804;E-mail:xiaozhumse@163.com