Effect of rolling and heat treatment on microstructure and

properties of Ti-26 sheet

ZHAO Bin(赵彬), YANG Ying-li(杨英丽), GUO Di-zi(郭荻子),

SU Hang-biao(苏航标), YIN Jing-ou(殷京瓯)

Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China

Received 15 July 2007; accepted 10 September 2007

Abstract: The effect of heat treatment and rolling process on the properties and microstructures of Ti-26 (Ti-15V-3Al-3Cr-3Sn-Forming) sheet was studied. The results show that the best rolling temperature for Ti-26 alloy is in the temperature range from 900 ℃ to 950℃. Under this condition, the resistance of deformation and yield ratio are low and the alloy has better hot work ability. The alloy will achieve better mechanical properties and completely recrystallized b microstructure when the deformation ratio is not less than 60% and the solution temperature is 30 ℃ above the phase transformation temperature. The best heat treatment conditions are recommended as: 790℃, 30 min, AC or WQ followed by 510 ℃, 10 h, AC. Under this heat treatment condition the strength of the Ti-26 alloy is 1 230 MPa and the elongation is 15%.

Key words: Ti-26 titanium alloys; sheet material; heat treatment; rolling processing

1 Introduction

The research on near-β titanium alloy has been a very important subject in the development of titanium alloy for its good heat-treatment strengthening effect, perfect creep resistance and good workability. Recently near-β titanium has been widely used to military affairs, business spaceflight, medicine and so on[1-3]. Ti-26 alloy (Ti-15V-3Al-3Cr-3Sn-1Nb-Forming) is a kind of high-strength beta titanium alloy developed by Northwest Institute for Nonferrous Metal Research with strength of 1 250 MPa for bolts materials to substitute TB3. It is also widely used in pieces of the spacecraft structure and missiles with complex structures such as fuel tank parts. The composition of Ti-26 is similar to that of Ti-15-3 alloy which was developed by USA in ingredients. Because of the addition of neutral alloying elements such as Zr and Sn, Ti-26 alloy avoids the brittle failure which was caused by eutectoid reaction[4-6] used at high temperature. Furthermore, Ti-26 alloy has been used to sheet material and tubular product for its better cold formability, performance, fatigue-resistance and welding capacity. In order to make a profound study and expand the application of beta-titanium, the further research on the effect of heat treatment and processing on microstructure and mechanical properties of Ti-26 sheet are carried out, which will offer proper process technology for Ti-26 sheet material. But also, the research results in this paper will also offer theoretical instruction to other processing of neat-β titanium.

2 Experimental

Ti26 alloy ingot with diameter of 50 mm was fabricated by vacuum consumable arc furnace melting for two times. Plate with thickness of 4 mm was fabricated by hot rolling above the phase transformation temperature after the ingot was originally forged at 1 150 ℃. Then plates were subjected to different deformations (20%-80%) of cold rolling after sand blasting and pickling. The experimental samples with the thickness from 1.6 to 2.5 mm were used for heat treatment test.

Heating, solution treatment, and aging for slab were conducted in a 500 kW resistance furnace. The specimens were subjected to hot and cold rolling by four 550 mm reversible rolling mills with the multi-rolling. Specimens used for different heat treatment and microstructure observation and mechanical properties testing were cut from the plate in vertical and horizontalrolling direction. The tensile testing at room temperature was conducted by Instron Tensile-1185. The preparation of tensile specimens met the requirements of ASTN E8. The width for work part was 12.5 mm, the standard distance for tensile testing was 50 mm long. The observation of microstructure was conducted by optical microscopy.

3 Results and discussion

3.1 Effect of rolling temperature

Ti-26 alloy has better hot work ability for its b microstructure. A suitable initial forging temperature is the critical of ensuring better performance and mechanical properties of Ti-26 alloy for its higher deformation resistance compared to TC4 alloy.

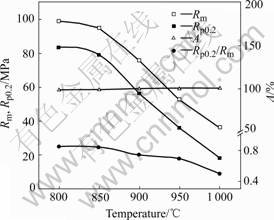

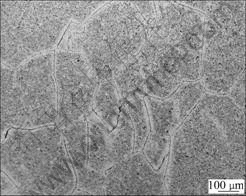

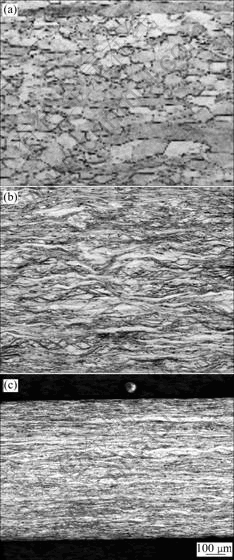

The mechanical properties of Ti-26 alloy at high temperature are shown in Fig.1. It can be found that the strength significantly decreases with increasing the testing temperature. When the testing temperature is increased to 900 ℃ the ultimate tensile strength is 76 MPa. Compared to 95 MPa at 850 ℃, there is about 20% decrease. When the testing temperature is 950 ℃, the ultimate tensile strength is only 50% of the ones at 800 ℃. At the same time, the elongation of the alloy shows little change. It is well known that the more difference value between yield limit and ultimate tensile strength (namely with low yield ratio), the better the properties of unstable deformation resistance for titanium alloy[8]. The yield ratio of Ti-26 alloy rapidly decreases during the temperature range of 850 ℃ to 950 ℃. The Rp0.2/Rm is 0.74 when the temperature is 900 ℃. The yield ratio continues to decrease when the temperature is beyond 900 ℃. Because the excessive high temperature will lead to a series of problems such as course grains, and serious surface oxidation. The rolling temperature of Ti-26 alloy is chosen at 900 ℃. Fig.2 shows the microstructure of Ti-26 sheet after hot rolling treatment.

Fig.1 High temperature mechanical properties of Ti-26 alloy

Fig.2 Microstructure of Ti-26 sheet after hot rolling treatment

3.2 Effect of cold deformation on microstructures and mechanical properties of Ti-26

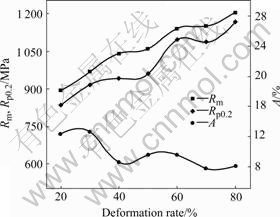

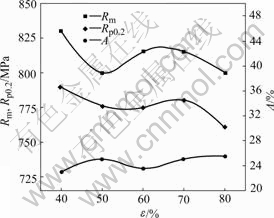

The microstructure of Ti-26 sheet is full-β phase after solid solution treatment, which hold more slip system and can support large cold deformation without cracking. The δ4 mm hot plate at different processing rates after solution treatment is tested, and the mechanical properties of the alloy sheet are shown in Fig.3. From Fig.3, it can be seen that there is obvious effect of the deformation rate on the mechanical properties of sheet material. The tensile strength is increasing with increasing deformation rate. During the early stages of deformation process, there is linear relationship between tensile strength and deformation rate. When the deformation rate is in the range of 50% to 70%, the effect of deformation rate on tensile strength weakens. At the same time, the elongation of Ti-26 sheet is decreasing with the increasing deformation rate. But the elongation still keep to a certain degree (about 6%) with the biggest deformation rate (80%), which can meet the demands of general processing and indicates good cold deformability of Ti-26 alloy. Compared with the microstructures of the alloy after various cold deformations as shown in Fig.4, it can be seen that the grains are lengthened along the direction of deformation. When the deformation rate is beyond 60%, the grains obviously lengthen and in some domain there are many fine grains because of broken original grains[9], which indicates the microstructure of Ti-26 alloy can be refined when the deformation is beyond 60%.

Fig.3 Mechanical properties of alloy after various cold deformation treatments

Fig.4 Microstructures of alloy after various cold deformations: (a) ε=20%; (b) ε=60%; (c) ε=80%

3.3 Effect of heat treatment on microstructures and mechanical properties of Ti-26

3.3.1 Effect of solution treatment on microstructures and mechanical properties of Ti-26

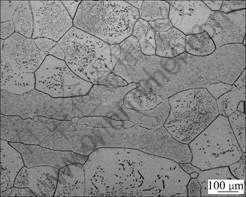

Full-β grains can be obtained by solution treatment. But also, during the solution process the recrystallization process can be completed and fine β grains can be gained, which leads to the best cold deformability and perfect mechanical properties after aging treatment. In this experiment, the solution temperature of Ti-26 alloy was chosen as above 30 ℃ of the phase transformation temperature. The mechanical properties after solution treatment at 790 ℃ for 30 min with various deformations are shown in Fig.5. It can be seen that the effect of deformation rate on tensile strength is little after solution treatment for the alloy, and the elongation even keeps unchanged. Fig.6 shows the microstructure of the alloy with the deformation of 60% after solution treatment at 790 ℃ for 30 min and air cooling, which indicates the recrystallization process has completed after solution treatment at 790 ℃.

Fig.5 Mechanical properties after solution treatment at 790 ℃ for 30 min with various deformations

Fig.6 Microstructure of alloy with deformation of 60% after solution treatment at 790 ℃ for 30 min and air cooling

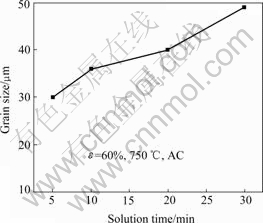

The relationship between the grain size and solution time at 790 ℃ is shown in Fig.7. It can be found that nearly linear relationship exists between the size of grains and the time of solution treatment. Thus under the condition of completed recrystallization, for the best mechanical properties to different sheet materials, the shorter solution time is required.

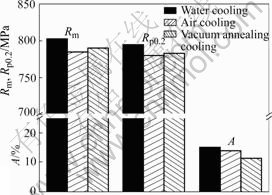

The cooling method of solution treatment produces obvious effect on the mechanical properties of titanium alloy. In this experiment three cooling methods, i.e. water quenching, air cooling with argon protecting and vacuum annealing cooling in furnace were carried out. The effect of three cooling methods on the tensile properties of the alloy is shown in Fig.8. It can be seen that the effect of cooling rate on mechanical properties is little. According to the mechanical properties of Ti-26 sheet material with different cooling methods, water quenching is the best way for the alloy.

3.3.2 Effect of aging temperature and time on mechanical properties of Ti-26 alloy

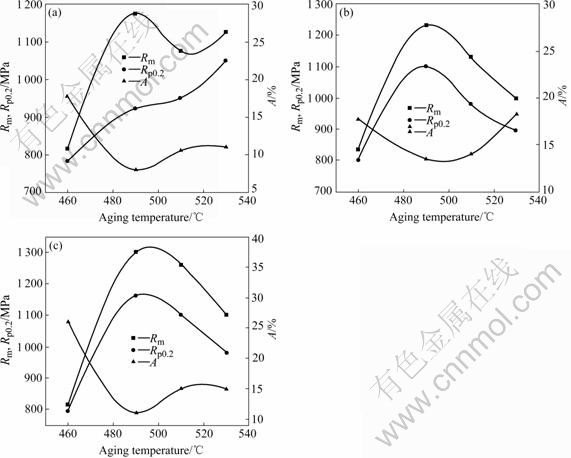

Fig.9 shows the relationship between the mechani- cal properties and aging temperature for the alloy with

Fig.7 Relationship between grain size and solution time

various deformations. From Fig.9 it can be found that aging strength increases with increasing deformation ratio. When the deformation ratio is 60%, Ti-26 sheet achieves better mechanical properties. For various deformation ratios, when the aging temperature is 490 ℃, the tensile strength reaches the maximum and the plasticity is the lowest. When the aging temperature increases, the strength of the alloy decreases and the plasticity increases. And when the aging temperature is 510 ℃, the alloy achieves the best mechanical properties. After aged at 490 ℃, there are much more diffused precipitates which lead to higher tensile strength. When the aging temperature is beyond 490 ℃, net precipitates are eliminated which is formed during aging process at low temperature[10].

Fig.8 Effect of cooling method on tensile properties of alloy

Fig.9 Relationship between mechanical properties and aging temperature for alloy with various deformations: (a) ε=40%; (b) ε=60%; (a) ε=80%

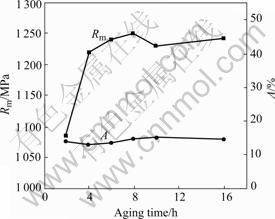

Fig.10 shows the relationship between mechanical properties and aging time at 510 ℃ for the alloy with 60% deformation. It can be found that the alloy achieves the best matched properties for tensile strength and plasticity when the aging time is 10 h. Thus it could be deduced that for Ti-26 sheet the best aging process is aging at 510 ℃ for 10 h followed by air cooling. Under this condition the tensile strength is 1 230 MPa and the elongation is not less than 15%.

Fig.10 Relationship between mechanical properties and aging time under 60% deformation rate

4 Conclusions

1) Ti-26 alloy sheets have lower resistance of deformation, yield ratio and better hot workability under the rolling temperature range from 900 ℃ to 950 ℃.

2) Ti-26 alloy sheet can be largely cold deformed, β grain can be completely broken at 60% deformation rate.

3) Ti-26 alloy will achieve better mechanical properties and completely recrystallized b microstructure when the solution temperature is above 30 ℃ of phase transformation temperature. The best heat treatment conditions are recommended as: 790 ℃, 30 min, AC or WQ followed by 510 ℃, 10 h, AC. Under this heat treatment condition the strength is 1 230 MPa and the elongation is 15%.

References

[1] BANIA P J. Beta titanium alloys in the 90’s [M]. The Minerals, Metals & Materials Society, 1993: 125.

[2] WANG Jian-lin. Developing and aplications of the high-strengh β-titanium alloy [J]. Shonghai Steel & Iron Research, 2001, 2: 25-33. (in Chinese)

[3] ZHANG S Q, MA H T, YANG H Y, LI M Q. Study of anew high strength beta titanium alloy for fasteners [C]// Proceedings of Xi’an International Titanium Conference. Beijing: International Academic Press, 1998: 370-375.

[4] ZHANG Ying-nan, LI Ming-qiang, ZHANG Shu-qi. Effects of hot-processing on microstructure and tensile properties for TB3 alloy [J]. Heat Treatment of Metals, 2000, 9: 14-15. (in Chinese)

[5] ZHANG Shu-qi. Development of high-strength titanium alloys used in fasteners [J]. Titanium Industrial Progress, 1998, 5: 1-3. (in Chinese)

[6] ZHANG Wei, ZHANG Shu-qi. Effect of processing and heat treatment on microstructures and properties of the Ti-26 alloy [J]. Rare Metals Newsletter, 2002, 12(17): 17-18. (in Chinese)

[7] ZHU Jian-wen, ZHAO Yong-qing, QI Yun-lian, WANG Qing-ru. Influences of heat treatment and rolling temperature on Ti-15-3 titanium alloys sheet [J]. Titanium Industry Progress, 2004, 21(4): 42-44. (in Chinese)

[8] LI You-qin. Shape formation of titanium sheet by punching [M]. Beijing: National Defense Industry Press, 1986: 22. (in Chinese)

[9] BOLESUWA E A. Titanium alloy metallography [M]. CHENG Shi-qing, transl. Beijing: National Defence Industry Press,1986: 186. (in Chinese)

[10] LI Guo-chun, XIAO Chun. Study on heat treatment of TB8 titanium alloys sheets [J]. Science and Technology of Chengdu Plane, 2003, 1: 25-28. (in Chinese)

Foundation item: Project(2007CB613807) supported by the National Basic Research Program of China

Corresponding author: ZHAO Bin; Tel: +86-29-86231078; E-mail: zhaobin_51@126.com

(Edited by YUAN Sai-qian)